Zirconia's Future in Smart Device Applications

Zirconia in Smart Devices: Background and Objectives

Zirconia, a versatile ceramic material, has been gaining significant attention in the smart device industry due to its unique properties and potential applications. The evolution of zirconia in smart devices can be traced back to its initial use in traditional ceramics and industrial applications. As technology advanced, researchers and engineers began exploring zirconia's potential in electronic components and structural materials for smart devices.

The primary objective of incorporating zirconia into smart devices is to enhance their durability, performance, and aesthetic appeal. Zirconia's exceptional mechanical strength, thermal stability, and electrical insulation properties make it an ideal candidate for various components in smartphones, wearables, and other smart devices. Additionally, its biocompatibility opens up possibilities for medical and health-related smart devices.

The technological trend in smart devices is moving towards miniaturization, increased functionality, and improved durability. Zirconia aligns well with these trends, offering solutions to challenges such as heat dissipation, structural integrity, and scratch resistance. As smart devices become more integral to our daily lives, the demand for materials that can withstand frequent use and harsh environments continues to grow.

One of the key drivers for zirconia's adoption in smart devices is its potential to replace traditional materials like glass and metal. Zirconia ceramics can be engineered to have similar or superior properties to these materials while offering additional benefits such as improved thermal management and reduced electromagnetic interference. This makes zirconia an attractive option for device manufacturers looking to innovate and differentiate their products in a competitive market.

The development of zirconia applications in smart devices has seen significant progress in recent years. Researchers have been exploring various forms of zirconia, including thin films, nanoparticles, and composite materials, to tailor its properties for specific device components. These advancements have led to improvements in areas such as display technology, battery performance, and overall device durability.

Looking ahead, the future of zirconia in smart devices appears promising. As manufacturing techniques improve and new applications are discovered, we can expect to see more widespread adoption of zirconia in various smart device components. The ongoing research into zirconia's properties and potential applications suggests that this material will play a crucial role in shaping the next generation of smart devices, contributing to enhanced user experiences and device longevity.

Market Demand Analysis for Zirconia-Based Smart Components

The market demand for zirconia-based smart components is experiencing significant growth, driven by the increasing adoption of smart devices across various industries. As consumer electronics, wearables, and IoT devices become more prevalent, manufacturers are seeking advanced materials that can enhance the performance, durability, and functionality of their products. Zirconia, with its unique properties, is emerging as a promising material for smart device applications.

In the consumer electronics sector, there is a growing demand for scratch-resistant and durable screens, casings, and other external components. Zirconia's exceptional hardness and wear resistance make it an attractive option for smartphone and tablet manufacturers looking to improve the longevity and aesthetics of their devices. The market for zirconia-based protective coatings and components in this sector is expected to expand rapidly in the coming years.

Wearable technology, including smartwatches and fitness trackers, represents another significant market opportunity for zirconia-based components. These devices require materials that are not only durable but also biocompatible and aesthetically pleasing. Zirconia's ability to meet these criteria positions it as a preferred material for wearable device casings, sensors, and display covers.

The automotive industry is also driving demand for zirconia-based smart components. As vehicles become increasingly connected and autonomous, there is a growing need for robust, high-performance materials in sensors, displays, and other electronic components. Zirconia's thermal stability and electrical properties make it suitable for use in harsh automotive environments, contributing to the material's rising demand in this sector.

In the medical device industry, zirconia is gaining traction for its biocompatibility and potential applications in smart implants and diagnostic devices. The material's inertness and ability to be integrated with electronic components make it valuable for developing next-generation medical technologies, such as smart prosthetics and implantable sensors.

The aerospace and defense sectors are exploring zirconia-based components for advanced sensing and communication systems. The material's high strength-to-weight ratio and resistance to extreme conditions make it suitable for use in aircraft components and military equipment, where reliability and performance are critical.

As smart home technologies continue to evolve, there is an emerging market for zirconia-based components in household appliances and IoT devices. From smart thermostats to advanced kitchen appliances, manufacturers are looking to incorporate durable, aesthetically pleasing materials that can withstand frequent use and environmental factors.

While the market demand for zirconia-based smart components is promising, challenges such as high production costs and limited manufacturing capabilities need to be addressed to fully capitalize on the material's potential. As research and development efforts continue to improve production techniques and expand applications, the market for zirconia in smart devices is expected to grow substantially, offering significant opportunities for manufacturers and technology companies alike.

Current Challenges in Zirconia Integration for Smart Devices

The integration of zirconia into smart devices presents several significant challenges that researchers and manufacturers are currently grappling with. One of the primary obstacles is the material's inherent brittleness, which can lead to cracking or shattering under stress. This characteristic poses a considerable risk in devices that may be subjected to impacts or drops, potentially compromising the structural integrity of the product.

Another challenge lies in the manufacturing process of zirconia components for smart devices. The high melting point of zirconia necessitates specialized equipment and techniques for shaping and processing, which can increase production costs and complexity. Additionally, achieving the precise dimensions and tolerances required for intricate smart device components with zirconia can be more difficult compared to traditional materials like plastics or metals.

The electrical properties of zirconia also present a hurdle in its integration into smart devices. While zirconia is an excellent electrical insulator, this property can be both an advantage and a disadvantage. In applications where electrical conductivity is required, such as in touchscreens or antennas, additional engineering solutions must be developed to overcome zirconia's insulating nature.

Thermal management is another area of concern when incorporating zirconia into smart devices. The material's low thermal conductivity can lead to heat accumulation in certain components, potentially affecting the performance and longevity of electronic elements within the device. Engineers must devise innovative cooling solutions or thermal management strategies to mitigate this issue.

Furthermore, the bonding of zirconia to other materials used in smart devices poses a significant challenge. Creating strong, durable bonds between zirconia and metals, plastics, or other ceramics is crucial for ensuring the structural integrity and longevity of the device. Developing effective bonding techniques that can withstand the rigors of daily use and environmental factors remains an active area of research.

Lastly, the cost factor associated with zirconia integration cannot be overlooked. While the material offers superior properties in many aspects, its higher cost compared to traditional materials used in smart devices may limit its widespread adoption. Manufacturers must balance the benefits of zirconia against the increased production expenses, potentially restricting its use to high-end or specialized devices where the added value justifies the cost.

Addressing these challenges requires a multidisciplinary approach, combining materials science, engineering, and manufacturing expertise. As research progresses, innovative solutions are emerging to overcome these hurdles, paving the way for broader integration of zirconia in future smart device applications.

Existing Zirconia Applications in Smart Devices

01 Zirconia synthesis and processing methods

Various methods for synthesizing and processing zirconia are explored, including sol-gel techniques, hydrothermal processes, and chemical vapor deposition. These methods aim to control the particle size, crystalline structure, and purity of zirconia for different applications.- Zirconia synthesis and processing methods: Various techniques for synthesizing and processing zirconia materials, including sol-gel methods, hydrothermal synthesis, and sintering processes. These methods aim to control the crystal structure, particle size, and properties of zirconia for different applications.

- Zirconia-based dental materials: Development of zirconia-based materials for dental applications, such as crowns, bridges, and implants. These materials offer high strength, biocompatibility, and aesthetic properties suitable for dental restorations.

- Zirconia in catalysis and fuel cells: Utilization of zirconia as a catalyst support or component in catalytic systems and solid oxide fuel cells. Zirconia's thermal stability and oxygen ion conductivity make it valuable for these applications.

- Zirconia-based composites and coatings: Development of composite materials and coatings incorporating zirconia to enhance mechanical, thermal, and wear-resistant properties. These materials find applications in aerospace, automotive, and industrial sectors.

- Zirconia in electronic and optical applications: Utilization of zirconia in electronic components, optical devices, and sensors. Zirconia's dielectric properties, high refractive index, and chemical stability make it suitable for various high-tech applications.

02 Zirconia-based dental materials

Zirconia is widely used in dental applications due to its biocompatibility and mechanical properties. Innovations in this field include improved zirconia-based ceramics for dental implants, crowns, and bridges, as well as techniques for coloring and shaping zirconia dental prosthetics.Expand Specific Solutions03 Zirconia in advanced ceramics and composites

Zirconia is incorporated into advanced ceramic materials and composites to enhance their mechanical, thermal, and electrical properties. Applications include high-performance structural ceramics, thermal barrier coatings, and solid oxide fuel cells.Expand Specific Solutions04 Stabilized zirconia and phase transformation

Research focuses on stabilizing zirconia in its various crystalline phases, particularly the tetragonal and cubic forms. Stabilization techniques, such as doping with other oxides, are explored to control phase transformation and improve material properties for specific applications.Expand Specific Solutions05 Zirconia nanoparticles and thin films

Development of zirconia nanoparticles and thin films for various applications, including optical coatings, sensors, and catalysts. Research focuses on controlling particle size, shape, and surface properties to enhance performance in specific applications.Expand Specific Solutions

Key Players in Zirconia-Smart Device Industry

The market for zirconia in smart device applications is in a growth phase, with increasing demand driven by the material's unique properties. The global market size is expanding, fueled by the rising adoption of smart devices across various sectors. Technologically, zirconia applications are advancing rapidly, with companies like Kyocera Corp., Tosoh Corp., and Saint-Gobain Ceramics & Plastics, Inc. leading innovation. These firms are developing advanced zirconia-based components for smart devices, focusing on improving durability, thermal management, and miniaturization. Emerging players such as Huawei Technologies Co., Ltd. and LG Electronics, Inc. are also contributing to the technological maturity by integrating zirconia into cutting-edge smart device designs, indicating a competitive and dynamic landscape with significant potential for future growth and innovation.

Kyocera Corp.

Tosoh Corp.

Innovative Zirconia Properties for Smart Device Enhancement

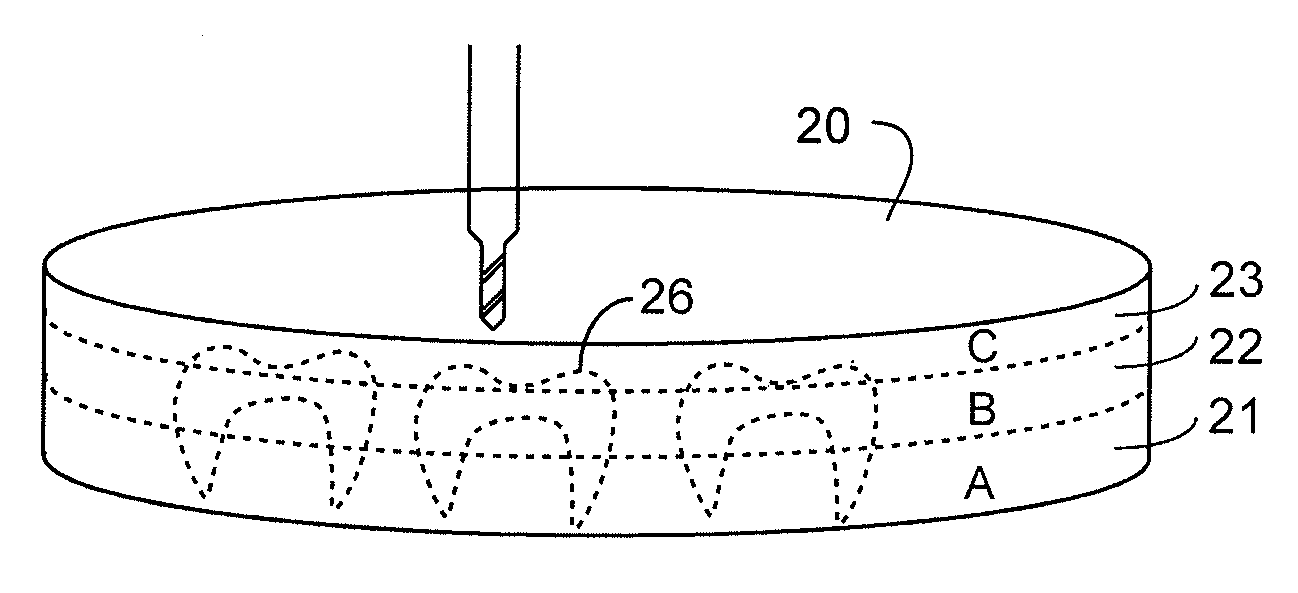

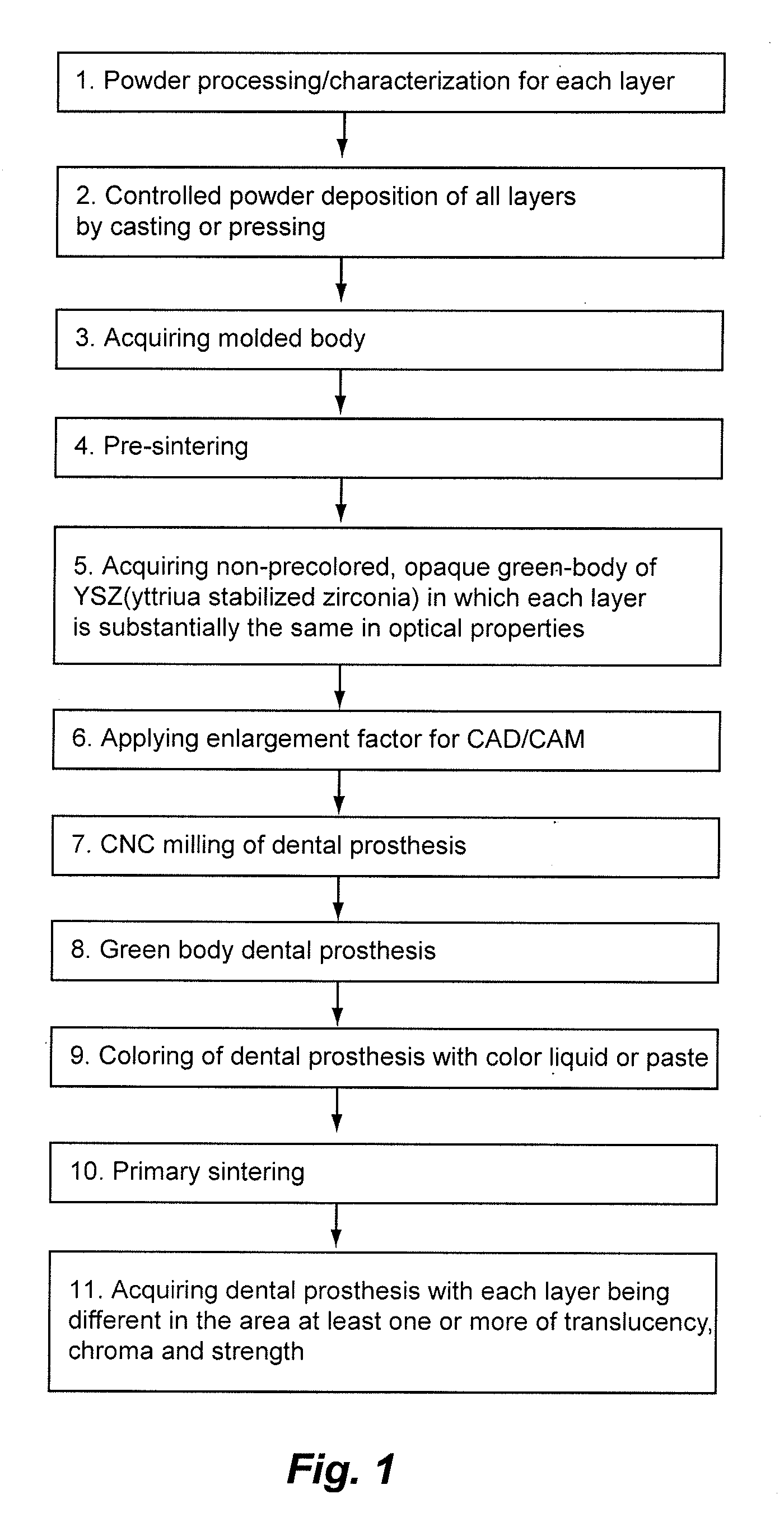

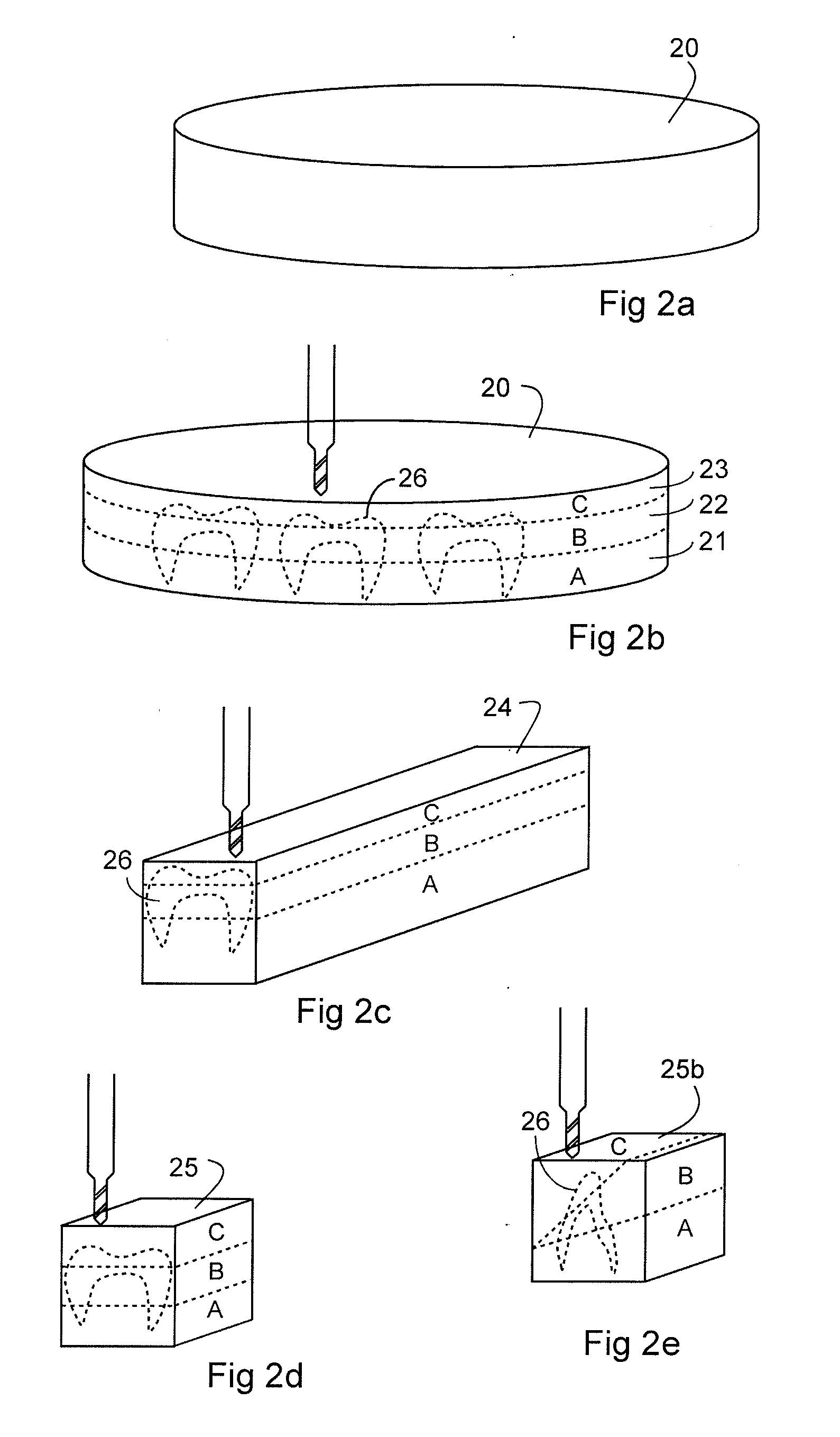

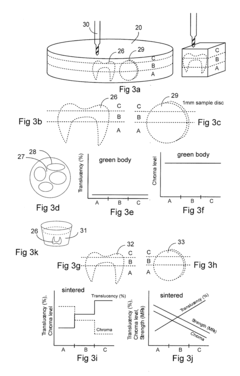

- A green body zirconia dental blank with multiple layers of different chemical compositions, specifically varying amounts of yttria, is developed to achieve consistent optical characteristics before sintering, allowing for milling, coloring, and sintering to produce dental prostheses with varying optical properties, including translucency and chroma, mimicking natural tooth characteristics.

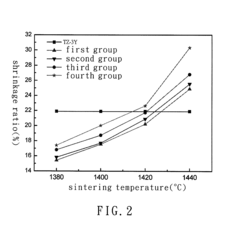

- A method involving wet mixing of silicon-containing zirconia powder with sodium carbonate and tetraethoxysilane, followed by calcination at reduced temperatures (900-1200°C) and subsequent sintering at 1415-1450°C to produce a silicon-containing zirconia calcined and sintered body with increased compactness and structural strength.

Environmental Impact of Zirconia in Electronics

The environmental impact of zirconia in electronics is a crucial consideration as smart devices become increasingly prevalent. Zirconia, a ceramic material known for its durability and thermal properties, has both positive and negative implications for the environment throughout its lifecycle in electronic applications.

From a production standpoint, zirconia mining and processing can lead to habitat disruption and energy-intensive manufacturing processes. However, its longevity in electronic components can potentially reduce the frequency of device replacements, thereby decreasing electronic waste over time. This durability factor is particularly significant in the context of sustainable product design and circular economy principles.

In terms of device performance, zirconia's excellent thermal properties contribute to improved heat dissipation in electronic components. This enhanced thermal management can lead to increased energy efficiency and potentially longer device lifespans, indirectly reducing the environmental footprint associated with frequent device replacements and energy consumption.

The use of zirconia in smart devices may also impact recycling and end-of-life management. While ceramic materials like zirconia are generally inert and non-toxic, their integration into complex electronic assemblies can complicate recycling processes. This challenge necessitates the development of advanced recycling technologies and design-for-disassembly strategies to ensure effective material recovery and minimize environmental impact at the end of a device's life cycle.

Furthermore, the potential for zirconia to replace certain rare earth elements or toxic materials in electronic components could have positive environmental implications. By reducing reliance on materials with more severe environmental impacts, zirconia could contribute to greener electronics manufacturing practices.

As smart devices continue to evolve, the role of zirconia in miniaturization and performance enhancement may lead to devices with smaller form factors and potentially reduced material usage. This trend could result in a decrease in overall resource consumption and associated environmental impacts in the production phase.

However, it is essential to consider the potential for increased device functionality enabled by zirconia to drive higher energy consumption during use. This aspect underscores the need for holistic lifecycle assessments to fully understand the net environmental impact of zirconia in smart device applications.

Zirconia Supply Chain Analysis for Smart Device Manufacturing

The zirconia supply chain for smart device manufacturing is a complex network involving multiple stages and stakeholders. Raw zirconia is primarily sourced from mineral deposits, with Australia, South Africa, and the United States being major producers. The extraction process involves mining, beneficiation, and chemical processing to obtain zirconium oxide.

Once extracted, the raw material undergoes further refinement to meet the stringent quality requirements of smart device applications. This process typically involves advanced purification techniques and precise control of particle size and crystal structure. Key players in this stage include specialty chemical companies and advanced materials manufacturers.

The refined zirconia is then supplied to component manufacturers who specialize in producing specific parts for smart devices. These components may include ceramic casings, protective layers for displays, or internal structural elements. The manufacturing process often involves advanced ceramic forming techniques such as injection molding or precision machining.

Smart device manufacturers represent the next link in the supply chain. They integrate zirconia components into their products, leveraging the material's unique properties to enhance device performance and durability. Major smartphone and wearable device manufacturers are increasingly incorporating zirconia into their designs.

The supply chain also includes various supporting industries, such as equipment suppliers for mining and processing, logistics providers for material transportation, and quality control services to ensure compliance with industry standards.

Challenges in the zirconia supply chain for smart devices include potential supply disruptions due to geopolitical factors, fluctuations in raw material prices, and the need for continuous innovation to meet evolving device specifications. Additionally, environmental concerns related to mining and processing operations are driving efforts towards more sustainable practices throughout the supply chain.

To address these challenges, industry players are exploring strategies such as diversifying supply sources, investing in recycling technologies, and developing alternative materials. Vertical integration is also becoming more common, with some larger manufacturers acquiring or partnering with upstream suppliers to ensure a stable supply of high-quality zirconia.

As smart device technologies continue to advance, the zirconia supply chain is expected to evolve, with increasing emphasis on sustainability, efficiency, and the ability to meet more demanding material specifications. This evolution will likely involve closer collaboration between suppliers, manufacturers, and research institutions to drive innovation and optimize the entire supply chain process.