How to Minimize Thermal Expansion in Zirconia?

Zirconia Thermal Expansion Background and Objectives

Zirconia, a versatile ceramic material, has gained significant attention in various industries due to its exceptional properties. However, its thermal expansion characteristics pose challenges in many applications. The evolution of zirconia technology has been driven by the need to enhance its thermal stability and minimize expansion under high-temperature conditions.

The primary objective in addressing zirconia's thermal expansion is to maintain dimensional stability across a wide range of temperatures. This is crucial for applications in aerospace, automotive, and energy sectors where components are subjected to extreme thermal cycling. Researchers and engineers have been working tirelessly to develop innovative solutions that can mitigate the effects of thermal expansion without compromising zirconia's other desirable properties.

Historically, the development of zirconia has progressed through several key stages. Initially, pure zirconia was limited in its applications due to its phase transformation and associated volume changes. The discovery of stabilized zirconia marked a significant milestone, as it allowed for the material to maintain its cubic structure at room temperature. This breakthrough opened up new possibilities for zirconia in high-temperature applications.

The current technological landscape focuses on advanced compositional and microstructural modifications to further reduce thermal expansion. Researchers are exploring various approaches, including the incorporation of dopants, creation of composite structures, and manipulation of grain boundaries. These efforts aim to achieve a delicate balance between thermal stability and other critical properties such as strength and toughness.

Looking ahead, the trajectory of zirconia thermal expansion research is expected to follow several promising paths. One area of interest is the development of functionally graded materials that can provide localized control over thermal expansion. Another avenue involves the use of nanotechnology to engineer zirconia at the atomic level, potentially leading to unprecedented control over its thermal behavior.

The quest to minimize thermal expansion in zirconia is not just a scientific pursuit but also an economic imperative. Industries relying on high-performance ceramics are constantly seeking materials that can withstand more extreme conditions while maintaining dimensional accuracy. As such, advancements in this field have the potential to drive innovation across multiple sectors, from energy production to advanced manufacturing.

In conclusion, the background and objectives of minimizing thermal expansion in zirconia reflect a complex interplay of scientific discovery, technological innovation, and industrial demand. The ongoing efforts in this field are poised to unlock new possibilities for zirconia applications, potentially revolutionizing high-temperature material solutions across various industries.

Market Demand for Low Thermal Expansion Zirconia

The market demand for low thermal expansion zirconia has been steadily increasing across various industries due to its unique properties and versatile applications. This material's ability to maintain dimensional stability under extreme temperature conditions makes it highly sought after in sectors where precision and reliability are paramount.

In the aerospace industry, low thermal expansion zirconia is gaining traction for use in high-temperature components of jet engines and thermal barrier coatings. The material's resistance to thermal shock and excellent thermal insulation properties contribute to improved engine efficiency and longevity. As the aerospace sector continues to push the boundaries of performance and fuel efficiency, the demand for advanced materials like low thermal expansion zirconia is expected to grow significantly.

The electronics industry represents another major market for this specialized zirconia. With the ongoing miniaturization of electronic devices and the increasing power densities in semiconductors, thermal management has become a critical challenge. Low thermal expansion zirconia is being incorporated into substrates and packaging materials to mitigate thermal stress and improve the reliability of electronic components.

In the energy sector, particularly in nuclear power plants and high-temperature fuel cells, low thermal expansion zirconia finds applications in critical components that must withstand extreme temperatures and corrosive environments. The material's stability and resistance to thermal cycling make it an ideal choice for these demanding applications, driving demand in this sector.

The medical industry is also showing increased interest in low thermal expansion zirconia, especially in dental and orthopedic implants. The material's biocompatibility, combined with its mechanical strength and dimensional stability, makes it an excellent choice for long-lasting and reliable implants. As the global population ages and the demand for medical implants rises, this sector is expected to contribute significantly to the overall market growth for low thermal expansion zirconia.

The automotive industry is another key driver of demand, particularly in the development of more efficient and durable engine components. Low thermal expansion zirconia is being used in exhaust gas sensors, fuel injector components, and thermal barrier coatings for engine parts, contributing to improved fuel efficiency and reduced emissions.

As industries continue to push the limits of material performance in high-temperature applications, the market for low thermal expansion zirconia is projected to expand. This growth is further supported by ongoing research and development efforts to enhance the material's properties and manufacturing processes, potentially opening up new applications and markets in the future.

Current Challenges in Zirconia Thermal Expansion Control

Zirconia's thermal expansion control presents significant challenges in various applications, particularly in high-temperature environments. The primary issue stems from zirconia's inherent thermal expansion coefficient, which is relatively high compared to other ceramic materials. This property leads to dimensional instability and potential structural failures when subjected to thermal cycling or rapid temperature changes.

One of the main challenges is maintaining the structural integrity of zirconia components during thermal cycling. As temperature fluctuates, the material expands and contracts, causing internal stresses that can lead to microcracking and eventual failure. This is particularly problematic in applications such as thermal barrier coatings for gas turbines, where the material must withstand extreme temperature gradients and frequent thermal cycling.

Another significant challenge is the mismatch in thermal expansion coefficients between zirconia and other materials in composite structures. This mismatch can result in delamination, spalling, or cracking at interfaces, compromising the overall performance and longevity of the composite system. For instance, in dental applications, the difference in thermal expansion between zirconia crowns and natural tooth structure can lead to micro-gaps and potential failure of dental restorations.

The phase transformation of zirconia at elevated temperatures also poses a challenge in controlling thermal expansion. Zirconia undergoes a tetragonal to monoclinic phase transformation, which is accompanied by a volume change. This transformation can induce additional stresses and further complicate the thermal expansion behavior of the material.

Achieving uniform thermal expansion across complex zirconia components is another hurdle. Variations in thickness or geometry can lead to differential expansion, resulting in localized stresses and potential failure points. This is particularly challenging in the production of large or intricately shaped zirconia parts for industrial applications.

The development of effective dopants or composite systems to mitigate zirconia's thermal expansion remains an ongoing challenge. While various approaches have been explored, such as the addition of rare earth oxides or the creation of zirconia-based composites, finding solutions that effectively reduce thermal expansion without compromising other desirable properties of zirconia is complex.

Lastly, the accurate measurement and prediction of thermal expansion behavior in zirconia under various conditions present technical difficulties. The development of reliable models and testing methodologies to characterize thermal expansion across a wide range of temperatures and in different environments is crucial for advancing control strategies.

Existing Strategies for Minimizing Zirconia Thermal Expansion

01 Thermal expansion control in zirconia materials

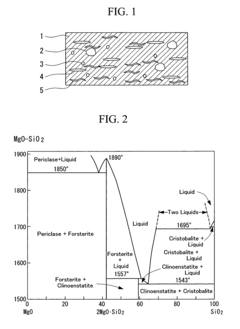

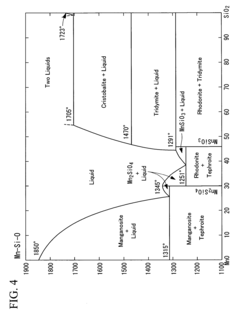

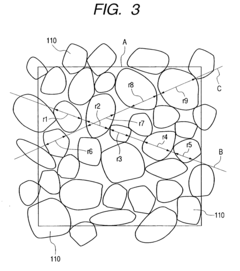

Various methods are employed to control the thermal expansion of zirconia materials, including doping with other elements, creating composite structures, and manipulating the crystal structure. These techniques aim to improve the material's thermal stability and performance in high-temperature applications.- Thermal expansion control in zirconia-based materials: Various methods are employed to control the thermal expansion of zirconia-based materials, including the addition of stabilizers, dopants, or other compounds. These additives can modify the crystal structure and phase transitions of zirconia, resulting in improved thermal expansion properties for specific applications.

- Zirconia composites for thermal management: Zirconia is often combined with other materials to create composites with tailored thermal expansion characteristics. These composites can be designed to match the thermal expansion of other components in high-temperature applications, reducing thermal stresses and improving overall system performance.

- Measurement and characterization of zirconia thermal expansion: Accurate measurement and characterization of zirconia's thermal expansion properties are crucial for material selection and design. Various techniques and instruments are used to determine the thermal expansion coefficient of zirconia materials under different conditions and temperature ranges.

- Applications utilizing zirconia's thermal expansion properties: Zirconia's unique thermal expansion characteristics are exploited in various applications, including thermal barrier coatings, solid oxide fuel cells, and high-temperature sensors. The material's ability to withstand thermal cycling and maintain structural integrity at elevated temperatures makes it valuable in these fields.

- Nanostructured zirconia for improved thermal properties: Nanostructured zirconia materials are being developed to enhance thermal expansion control and other properties. These materials often exhibit different thermal behavior compared to their bulk counterparts, offering new possibilities for tailoring thermal expansion characteristics in advanced applications.

02 Zirconia-based thermal barrier coatings

Zirconia is widely used in thermal barrier coatings due to its low thermal conductivity and high melting point. The thermal expansion properties of zirconia-based coatings are crucial for their performance and durability in extreme temperature environments, such as in gas turbine engines.Expand Specific Solutions03 Zirconia in dental and medical applications

The thermal expansion characteristics of zirconia are important in dental and medical applications, particularly in the fabrication of prosthetics and implants. Controlling the thermal expansion helps ensure proper fit and longevity of zirconia-based medical devices.Expand Specific Solutions04 Measurement and characterization of zirconia thermal expansion

Various techniques and instruments are used to measure and characterize the thermal expansion of zirconia materials. These methods are essential for understanding the behavior of zirconia under different temperature conditions and optimizing its properties for specific applications.Expand Specific Solutions05 Zirconia in high-temperature sensors and electronics

The thermal expansion properties of zirconia are utilized in the development of high-temperature sensors and electronic components. Understanding and controlling the thermal expansion of zirconia is crucial for ensuring the reliability and accuracy of these devices in extreme temperature environments.Expand Specific Solutions

Key Players in Advanced Ceramics Industry

The thermal expansion minimization of zirconia is a critical challenge in an industry that is transitioning from research to commercial applications. The market for zirconia-based products is expanding, driven by demand in sectors like aerospace, automotive, and dental implants. Companies such as DENSO Corp., Mitsubishi Heavy Industries, and Safran Aircraft Engines are actively developing solutions, indicating a growing market size. The technology is approaching maturity, with firms like Kyocera Corp., NGK Insulators, and VITA Zahnfabrik H. Rauter GmbH & Co. KG leading in patent filings. However, the presence of diverse players from materials science, electronics, and energy sectors suggests ongoing innovation and potential for further advancements in thermal expansion control techniques.

BASF Corp.

Daiichi Kigenso Kagaku Kogyo Co., Ltd.

Innovative Approaches in Zirconia Microstructure Engineering

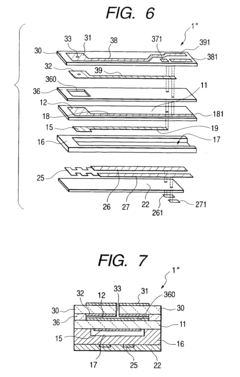

- Development of novel thermal barrier coating materials with orthorhombic or monoclinic structures derived from perovskite, tetragonal layer structures, or specific oxide compositions like LaTaO4, which exhibit higher melting points, lower thermal conductivity, and greater thermal expansion coefficients, reducing phase transitions and stress between the coating and substrate.

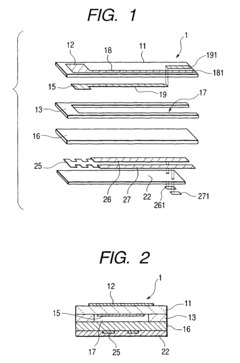

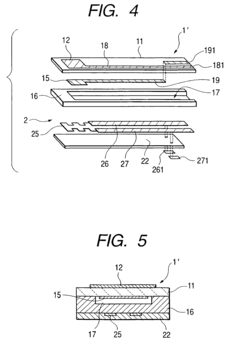

- A multilayered air-fuel ratio sensing element with a partially stabilized zirconia solid electrolytic body containing 5-7 mol% yttria and an alumina substrate, optimized to have specific relative densities and grain sizes, minimizing thermal expansion differences and maintaining a stable M/C ratio to prevent cracking.

Environmental Impact of Zirconia Production and Use

The production and use of zirconia have significant environmental implications that warrant careful consideration. The extraction of zirconium from its primary ore, zircon, involves energy-intensive processes such as chlorination and reduction, which contribute to greenhouse gas emissions. Mining operations for zircon can lead to habitat disruption and soil erosion, particularly in sensitive ecosystems. Furthermore, the refining process generates waste materials that require proper disposal to prevent soil and water contamination.

In the manufacturing of zirconia products, high-temperature sintering processes consume substantial amounts of energy, primarily from fossil fuel sources, leading to increased carbon footprint. The production of stabilized zirconia, which is crucial for minimizing thermal expansion, often involves the use of rare earth elements like yttrium. The mining and processing of these elements can have severe environmental consequences, including the generation of toxic and radioactive waste.

The use of zirconia in various applications, while beneficial for its durability and thermal properties, presents both positive and negative environmental impacts. On the positive side, zirconia's longevity in applications such as dental implants and industrial components reduces the need for frequent replacements, thereby conserving resources in the long term. Additionally, its use in thermal barrier coatings for gas turbines improves energy efficiency, potentially offsetting some of the environmental costs associated with its production.

However, the disposal of zirconia-containing products at the end of their lifecycle poses challenges. While zirconia itself is not toxic, the composite materials it is often used in can be difficult to recycle or dispose of safely. This is particularly true for electronic components and medical devices, where zirconia may be combined with other materials that require special handling.

The increasing demand for zirconia in advanced technologies, such as solid oxide fuel cells and oxygen sensors, underscores the need for sustainable production methods. Research into more environmentally friendly extraction and manufacturing processes is ongoing, with a focus on reducing energy consumption and minimizing waste generation. Efforts to develop recycling techniques for zirconia-containing products are also crucial for mitigating the long-term environmental impact of this material.

In addressing the challenge of minimizing thermal expansion in zirconia, it is essential to consider the environmental trade-offs. While stabilized zirconia offers improved thermal properties, the environmental cost of producing and using stabilizing agents must be weighed against the benefits. Future research should focus on developing eco-friendly stabilization methods and exploring alternative materials that can provide similar thermal performance with reduced environmental impact.

Zirconia Applications in Extreme Temperature Environments

Zirconia has emerged as a critical material in extreme temperature environments due to its exceptional thermal and mechanical properties. Its high melting point, low thermal conductivity, and excellent chemical stability make it ideal for applications where materials are subjected to intense heat and corrosive conditions. In aerospace, zirconia is utilized in thermal barrier coatings for jet engine components, protecting underlying metal structures from extreme temperatures and extending their operational lifespan.

The nuclear industry also benefits from zirconia's unique properties. It is employed in fuel rod cladding and reactor vessel linings, where its resistance to radiation damage and chemical corrosion is crucial. These applications require materials that can withstand temperatures exceeding 1000°C while maintaining structural integrity and minimizing thermal expansion.

In the field of industrial furnaces and kilns, zirconia plays a vital role as a refractory material. Its low thermal conductivity and high thermal shock resistance make it an excellent choice for lining high-temperature furnaces used in metal processing, glass manufacturing, and ceramic production. Zirconia's ability to withstand rapid temperature changes without cracking or spalling ensures prolonged equipment life and improved energy efficiency.

The automotive industry has also found applications for zirconia in extreme temperature environments. Oxygen sensors in exhaust systems utilize zirconia's unique ionic conductivity at high temperatures to measure and control air-fuel ratios, improving engine performance and reducing emissions. Additionally, zirconia-based ceramic brake rotors are being developed for high-performance vehicles, offering superior heat dissipation and wear resistance compared to traditional metal rotors.

In the field of space exploration, zirconia's thermal properties are leveraged in heat shields for spacecraft re-entry. Its ability to withstand the extreme temperatures generated during atmospheric re-entry while providing thermal insulation is crucial for protecting sensitive equipment and ensuring mission success. Furthermore, zirconia-based materials are being investigated for use in advanced propulsion systems, where they can withstand the high temperatures and corrosive environments associated with rocket engines.

As industries continue to push the boundaries of material performance in extreme conditions, zirconia's role in these applications is likely to expand. Ongoing research focuses on enhancing its thermal stability, reducing thermal expansion, and improving its overall performance in high-temperature environments. These advancements will enable the development of more efficient and durable systems capable of operating under increasingly demanding conditions.