Zirconia's Role in Next-Generation Aerospace Materials

Zirconia Aerospace Evolution

Zirconia has played a pivotal role in the evolution of aerospace materials, marking significant milestones in the industry's pursuit of lighter, stronger, and more heat-resistant components. The journey of zirconia in aerospace applications began in the mid-20th century, with its initial use primarily focused on thermal barrier coatings for jet engine components.

As aerospace technology advanced, so did the applications of zirconia. In the 1970s and 1980s, researchers began exploring zirconia's potential as a structural ceramic, recognizing its exceptional mechanical properties and thermal stability. This period saw the development of partially stabilized zirconia (PSZ) and tetragonal zirconia polycrystals (TZP), which offered improved toughness and strength compared to traditional ceramics.

The 1990s marked a significant leap in zirconia's aerospace applications with the introduction of yttria-stabilized zirconia (YSZ) coatings for turbine blades. This innovation dramatically increased the operating temperatures of jet engines, leading to improved fuel efficiency and performance. Concurrently, zirconia-based composites started gaining traction, combining the material's inherent properties with those of other advanced materials.

Entering the 21st century, nanotechnology opened new frontiers for zirconia in aerospace. Nanostructured zirconia coatings and composites emerged, offering unprecedented combinations of strength, toughness, and thermal resistance. These advancements enabled the development of more efficient and durable aerospace components, from engine parts to thermal protection systems for spacecraft.

Recent years have seen a focus on integrating zirconia into additive manufacturing processes for aerospace applications. This trend has allowed for the creation of complex, lightweight structures that were previously impossible to manufacture, pushing the boundaries of aircraft and spacecraft design.

Looking ahead, the role of zirconia in next-generation aerospace materials is set to expand further. Research is ongoing into ultra-high temperature zirconia composites for hypersonic vehicle applications, as well as smart zirconia-based materials that can adapt to changing environmental conditions. The material's potential in advanced propulsion systems and space exploration technologies continues to drive innovation in the field.

Throughout its evolution in aerospace applications, zirconia has consistently demonstrated its versatility and potential for enhancing performance, efficiency, and durability. As aerospace technology continues to advance, zirconia remains at the forefront of materials science, promising to play a crucial role in shaping the future of flight and space exploration.

Aerospace Market Demand

The aerospace market is experiencing a significant surge in demand for advanced materials that can withstand extreme conditions while offering superior performance. Zirconia, with its exceptional properties, is poised to play a crucial role in meeting these evolving needs. The global aerospace market is projected to grow substantially over the next decade, driven by increasing air travel, space exploration initiatives, and defense spending.

Commercial aviation remains a key driver of aerospace market demand. Airlines are seeking more fuel-efficient aircraft to reduce operational costs and meet stringent environmental regulations. This has led to a growing interest in lightweight materials that can improve fuel efficiency without compromising structural integrity. Zirconia-based composites and coatings offer potential solutions by providing high strength-to-weight ratios and excellent thermal resistance.

The space exploration sector is another area where zirconia's unique properties are highly valued. As space agencies and private companies push the boundaries of space travel and satellite technology, there is an increasing need for materials that can withstand the harsh conditions of space. Zirconia's thermal stability and resistance to radiation make it an attractive option for spacecraft components and thermal protection systems.

Defense aerospace applications also contribute significantly to the market demand for advanced materials. Military aircraft and missiles require materials that can perform under extreme conditions, including high temperatures and corrosive environments. Zirconia's ability to maintain its mechanical properties at elevated temperatures makes it a promising candidate for various defense aerospace applications.

The emerging urban air mobility market, including electric vertical takeoff and landing (eVTOL) vehicles, is creating new opportunities for innovative materials. As these vehicles require a delicate balance of lightweight construction and durability, zirconia-based materials could play a role in addressing these challenges.

Additive manufacturing techniques are gaining traction in the aerospace industry, enabling the production of complex geometries and reducing material waste. Zirconia's compatibility with advanced manufacturing processes positions it well to meet the industry's evolving production needs.

Environmental concerns and sustainability goals are also shaping market demand. The aerospace industry is under pressure to reduce its carbon footprint, leading to increased interest in materials that can contribute to more efficient and environmentally friendly aircraft designs. Zirconia's potential to enhance engine efficiency and reduce emissions aligns well with these sustainability objectives.

As the aerospace market continues to evolve, the demand for materials that can meet increasingly stringent performance requirements while offering cost-effectiveness and sustainability will only grow. Zirconia's unique combination of properties positions it as a key material in addressing these market needs and driving innovation in next-generation aerospace applications.

Zirconia Tech Challenges

Zirconia, a versatile ceramic material, faces several significant challenges in its application to next-generation aerospace materials. One of the primary obstacles is its inherent brittleness, which limits its use in high-stress environments typical of aerospace applications. This brittleness can lead to catastrophic failure under sudden impacts or extreme loading conditions, necessitating the development of toughening mechanisms or composite structures to mitigate this risk.

Another major challenge lies in the thermal properties of zirconia. While it exhibits excellent thermal insulation characteristics, its thermal expansion coefficient is relatively high compared to other aerospace materials. This mismatch in thermal expansion can lead to stress buildup and potential failure in multi-material systems, particularly during rapid temperature changes experienced in aerospace environments.

The manufacturing processes for zirconia-based aerospace components also present significant hurdles. Achieving consistent, high-density parts with complex geometries remains a challenge, especially when considering the need for large-scale production. Advanced manufacturing techniques such as additive manufacturing show promise but require further refinement to meet the stringent quality and reliability standards of the aerospace industry.

Zirconia's phase transformation behavior, while beneficial for some applications, can be problematic in others. The material undergoes a phase change from tetragonal to monoclinic structure under certain conditions, which is accompanied by a volume change. This transformation can induce internal stresses and potentially lead to microcracking, affecting the long-term durability and reliability of zirconia-based components in aerospace applications.

The integration of zirconia with other materials in composite structures presents another set of challenges. Ensuring strong, durable interfaces between zirconia and other materials, such as metals or polymers, is crucial for developing high-performance aerospace composites. This requires innovative bonding techniques and careful consideration of the chemical and physical interactions at material interfaces.

Lastly, the long-term stability and aging behavior of zirconia in aerospace environments remain areas of concern. Exposure to extreme temperatures, radiation, and corrosive environments can potentially degrade zirconia's properties over time. Understanding and mitigating these aging effects is essential for ensuring the longevity and reliability of zirconia-based aerospace components throughout their operational lifetime.

Current Zirconia Solutions

01 Zirconia synthesis and processing methods

Various methods for synthesizing and processing zirconia are explored, including sol-gel techniques, hydrothermal processes, and chemical vapor deposition. These methods aim to control the crystalline structure, particle size, and purity of zirconia for different applications.- Zirconia synthesis and processing methods: Various methods for synthesizing and processing zirconia are described, including techniques for controlling particle size, crystalline structure, and purity. These methods can involve different precursors, reaction conditions, and post-processing steps to achieve desired properties for specific applications.

- Zirconia-based composites and coatings: Development of zirconia-based composites and coatings for enhanced mechanical, thermal, and chemical properties. These materials can be used in various applications, including aerospace, automotive, and industrial sectors, offering improved durability and performance compared to pure zirconia.

- Dental and biomedical applications of zirconia: Utilization of zirconia in dental and biomedical applications, such as dental implants, crowns, and orthopedic implants. The material's biocompatibility, strength, and aesthetic properties make it suitable for these applications, with ongoing research focusing on improving its performance and integration with biological tissues.

- Zirconia in fuel cells and energy applications: Application of zirconia in solid oxide fuel cells and other energy-related technologies. The material's unique properties, such as high ionic conductivity at elevated temperatures, make it valuable for these applications. Research focuses on optimizing zirconia-based electrolytes and electrodes for improved efficiency and durability.

- Stabilization and phase transformation of zirconia: Methods for stabilizing zirconia in its various crystalline phases and controlling phase transformations. This includes the use of dopants and specific processing techniques to achieve desired crystal structures and properties for different applications, such as improving the material's mechanical strength and thermal stability.

02 Zirconia-based dental materials

Zirconia is widely used in dental applications due to its biocompatibility and mechanical properties. Innovations in this field include improved zirconia-based ceramics for dental implants, crowns, and bridges, as well as techniques for coloring and shaping zirconia dental prosthetics.Expand Specific Solutions03 Zirconia in advanced ceramics and composites

Zirconia is incorporated into advanced ceramic materials and composites to enhance their mechanical, thermal, and electrical properties. These materials find applications in aerospace, automotive, and industrial sectors, offering improved durability and performance.Expand Specific Solutions04 Stabilized zirconia for high-temperature applications

Research focuses on developing stabilized zirconia materials that maintain their properties at high temperatures. These materials are crucial for applications such as thermal barrier coatings, solid oxide fuel cells, and high-temperature sensors.Expand Specific Solutions05 Zirconia nanoparticles and their applications

Zirconia nanoparticles are being developed for various applications, including catalysis, optics, and biomedicine. Research in this area focuses on controlling nanoparticle size, shape, and surface properties to optimize their performance in specific applications.Expand Specific Solutions

Aerospace Material Players

The aerospace materials market, particularly in relation to zirconia's role, is in a growth phase characterized by increasing demand for high-performance materials. The global aerospace materials market is projected to expand significantly, driven by the need for lightweight, durable, and heat-resistant components. Zirconia's unique properties make it a promising candidate for next-generation aerospace applications. Companies like 3M Innovative Properties Co., United Technologies Corp., and Saint-Gobain Ceramics & Plastics, Inc. are at the forefront of developing zirconia-based solutions for aerospace. The technology is maturing rapidly, with ongoing research at institutions such as Harbin Institute of Technology and Central South University pushing the boundaries of zirconia's capabilities in extreme aerospace environments.

BASF SE

United Technologies Corp.

Key Zirconia Innovations

- Zirconia-based particles with 0.02 to 20 mole percent lanthanide element oxide and 0 to 15 mole percent yttrium oxide are synthesized using a hydrothermal treatment method, resulting in crystalline particles with an average primary size of no greater than 100 nanometers, which are then used in sols, composites, and sintered bodies to enhance mechanical properties and refractive index.

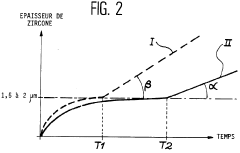

- Adding metallic elements like cerium or magnesium to stabilize the quadratic phase of zirconia, preventing its transformation into cubic or monoclinic forms, thereby maintaining low corrosion kinetics and mechanical integrity, with cerium being preferably added up to 6% by weight to ensure solubility and low thermal neutron capture.

Zirconia Safety Standards

The development and implementation of safety standards for zirconia in aerospace applications are crucial to ensure the material's reliable performance and the overall safety of aircraft and spacecraft. These standards encompass various aspects, including material composition, manufacturing processes, quality control, and performance testing.

One of the primary safety considerations for zirconia in aerospace materials is its thermal stability. Standards have been established to define acceptable temperature ranges for different zirconia-based composites, ensuring they maintain their structural integrity under extreme conditions. These standards typically include thermal cycling tests to simulate the rapid temperature changes experienced during flight.

Mechanical property requirements form another critical component of zirconia safety standards. These include specifications for tensile strength, compressive strength, fracture toughness, and fatigue resistance. The standards outline testing procedures to verify that zirconia-based components meet or exceed the minimum requirements for their intended applications.

Chemical resistance is also addressed in zirconia safety standards for aerospace materials. Guidelines are in place to ensure that zirconia-based components can withstand exposure to various chemicals, including fuels, lubricants, and cleaning agents commonly used in aerospace environments. Corrosion resistance tests are typically mandated to evaluate long-term durability.

Quality control measures are an integral part of zirconia safety standards. These include specifications for raw material purity, manufacturing process controls, and non-destructive testing methods. X-ray diffraction analysis and electron microscopy are often required to verify the material's microstructure and phase composition.

Specific standards have been developed for zirconia's use in critical aerospace components, such as thermal barrier coatings for turbine blades. These standards define acceptable thickness ranges, adhesion strength, and thermal cycling performance. They also outline inspection procedures to detect potential defects or delamination.

Environmental considerations are increasingly incorporated into zirconia safety standards for aerospace applications. This includes guidelines for the safe disposal of zirconia-containing components at the end of their lifecycle and requirements for using environmentally friendly manufacturing processes.

Certification processes play a vital role in ensuring compliance with zirconia safety standards. Aerospace manufacturers must demonstrate that their zirconia-based components meet all applicable standards through rigorous testing and documentation. This often involves third-party verification and periodic audits to maintain certification.

As aerospace technology continues to advance, zirconia safety standards are regularly reviewed and updated. Industry bodies, such as the Aerospace Materials Specifications (AMS) committee, work closely with researchers and manufacturers to incorporate new findings and address emerging challenges in the use of zirconia for next-generation aerospace materials.

Environmental Impact

The environmental impact of zirconia in next-generation aerospace materials is a critical consideration as the industry moves towards more sustainable practices. Zirconia, while offering exceptional properties for aerospace applications, presents both challenges and opportunities in terms of its environmental footprint.

One of the primary environmental concerns associated with zirconia production is the energy-intensive manufacturing process. The extraction and refinement of zirconium dioxide require high temperatures and significant energy inputs, contributing to greenhouse gas emissions. However, ongoing research aims to develop more energy-efficient production methods, such as advanced sintering techniques and novel catalytic processes, which could substantially reduce the carbon footprint of zirconia manufacturing.

The durability and longevity of zirconia-based aerospace components offer a positive environmental aspect. The material's exceptional wear resistance and thermal stability contribute to extended service life for aircraft parts, reducing the frequency of replacements and, consequently, the overall material consumption and waste generation in the aerospace industry. This longevity aligns with sustainability goals by minimizing the need for frequent part production and disposal.

Recycling and end-of-life management of zirconia-containing aerospace materials present both challenges and opportunities. While zirconia itself is not easily recyclable in its pure form, ongoing research explores methods for recovering and repurposing zirconia from composite materials. Advanced separation techniques and chemical processes are being developed to extract zirconia from end-of-life aerospace components, potentially creating a circular economy for this valuable material.

The use of zirconia in aerospace applications can indirectly contribute to environmental benefits through improved fuel efficiency. Zirconia's low thermal conductivity and high-temperature stability make it an excellent material for thermal barrier coatings in jet engines. These coatings allow engines to operate at higher temperatures, increasing overall efficiency and reducing fuel consumption. The resulting decrease in emissions per flight contributes to the aerospace industry's efforts to reduce its environmental impact.

However, the potential release of zirconia nanoparticles during the lifecycle of aerospace components raises environmental and health concerns. While zirconia is generally considered biologically inert, the long-term effects of nanoparticle exposure on ecosystems and human health are not fully understood. Ongoing research focuses on assessing the potential risks and developing mitigation strategies to ensure the safe use of zirconia-based materials throughout their lifecycle.

As the aerospace industry continues to prioritize sustainability, the role of zirconia in next-generation materials will likely evolve. Future developments may focus on bio-inspired zirconia composites, utilizing naturally occurring structures to enhance material properties while minimizing environmental impact. Additionally, the integration of zirconia into additive manufacturing processes for aerospace components could lead to more efficient material use and reduced waste generation during production.