Zirconia as a Key Player in Sustainable Tech Development

Zirconia Tech Evolution

Zirconia has undergone a remarkable evolution in its technological applications, transforming from a niche material to a key player in sustainable technology development. The journey of zirconia began in the early 20th century when it was primarily used in refractory applications due to its high melting point and excellent thermal properties. However, the discovery of its unique phase transformation toughening mechanism in the 1970s marked a significant turning point in its technological trajectory.

In the 1980s and 1990s, zirconia found its way into the field of advanced ceramics, particularly in structural and biomedical applications. The development of yttria-stabilized zirconia (YSZ) opened up new possibilities in areas such as solid oxide fuel cells and thermal barrier coatings. This period saw intensive research into improving the material's properties, leading to enhanced strength, toughness, and stability.

The early 2000s witnessed a surge in zirconia's application in the dental industry. Its biocompatibility, aesthetics, and mechanical properties made it an ideal material for dental implants and prosthetics. Concurrently, advancements in manufacturing techniques, such as computer-aided design and manufacturing (CAD/CAM), revolutionized the production of zirconia-based components, enabling more complex and precise structures.

As environmental concerns gained prominence in the 2010s, zirconia's role in sustainable technologies became increasingly significant. Its application in catalytic converters for reducing vehicle emissions expanded, while its use in water purification systems grew due to its chemical stability and ion exchange properties. The material also found new applications in energy storage and conversion technologies, contributing to the development of more efficient and environmentally friendly energy solutions.

Recent years have seen a focus on nanotechnology and composite materials involving zirconia. Researchers are exploring zirconia nanoparticles and nanocomposites for applications ranging from advanced coatings to drug delivery systems. The integration of zirconia with other materials, such as graphene and carbon nanotubes, is opening up new frontiers in material science and sustainable technology development.

Looking ahead, the evolution of zirconia technology is expected to continue its trajectory towards more sustainable and efficient applications. Emerging areas of research include its potential use in quantum computing, advanced sensors, and next-generation energy storage systems. As global efforts to combat climate change intensify, zirconia's unique properties position it as a crucial material in the development of green technologies and circular economy solutions.

Sustainable Market Demand

The market demand for zirconia in sustainable technology development has been steadily increasing, driven by its unique properties and versatile applications. As industries worldwide shift towards more environmentally friendly practices, zirconia has emerged as a key material in various sustainable technologies.

In the energy sector, zirconia plays a crucial role in the development of solid oxide fuel cells (SOFCs), which offer high efficiency and low emissions for power generation. The global SOFC market is projected to grow significantly in the coming years, with zirconia-based electrolytes being a critical component. This growth is fueled by the increasing demand for clean energy solutions and the push for decarbonization in both developed and developing economies.

The automotive industry is another major driver of zirconia demand in sustainable technologies. As vehicle manufacturers strive to meet stringent emissions standards and improve fuel efficiency, zirconia-based oxygen sensors have become essential components in modern engine management systems. These sensors help optimize combustion processes, reducing harmful emissions and improving overall vehicle performance. With the global automotive market continuing to expand and the rise of electric vehicles, the demand for advanced sensor technologies incorporating zirconia is expected to grow substantially.

In the field of water treatment and purification, zirconia-based membranes and adsorbents are gaining traction due to their superior chemical stability and separation efficiency. As water scarcity becomes a pressing global issue, the demand for advanced water treatment technologies is on the rise. Zirconia-based materials offer promising solutions for removing contaminants and improving water quality, driving their adoption in both industrial and municipal water treatment applications.

The aerospace industry is also contributing to the sustainable market demand for zirconia. Its high-temperature resistance and low thermal conductivity make it an ideal material for thermal barrier coatings in aircraft engines. These coatings improve engine efficiency and reduce fuel consumption, aligning with the industry's goals of reducing carbon emissions and enhancing sustainability in air travel.

Furthermore, the growing focus on circular economy principles has led to increased interest in zirconia's potential for recycling and reuse. Its durability and chemical stability make it an attractive option for developing long-lasting, recyclable products across various industries. This aligns with the broader market trend towards sustainable materials and manufacturing processes.

As governments worldwide implement stricter environmental regulations and sustainability targets, the demand for zirconia in green technologies is expected to accelerate. This trend is further supported by increasing consumer awareness and preference for eco-friendly products and solutions. The versatility of zirconia in addressing multiple sustainability challenges positions it as a key material in the transition towards a more sustainable future across diverse industries and applications.

Zirconia Challenges

Despite its promising applications in sustainable technology, zirconia faces several significant challenges that hinder its widespread adoption and full potential realization. One of the primary obstacles is the high energy requirement for zirconia production, which currently relies heavily on fossil fuels. This energy-intensive process not only increases production costs but also contradicts the material's sustainable image, creating a paradox in its environmental benefits.

The scarcity and uneven global distribution of zirconium resources pose another critical challenge. With limited natural deposits concentrated in a few regions, supply chain vulnerabilities and potential geopolitical tensions could impact the long-term availability and pricing stability of zirconia-based technologies. This scarcity also raises concerns about the material's scalability for mass production in various sustainable applications.

Zirconia's inherent brittleness and low fracture toughness present significant engineering challenges, particularly in applications requiring high mechanical stress or thermal cycling. While efforts to improve these properties through composite materials and advanced manufacturing techniques show promise, they often come at the cost of increased complexity and production expenses, potentially limiting zirconia's competitiveness against alternative materials.

The development of efficient and cost-effective recycling processes for zirconia-based products remains a substantial hurdle. The material's high melting point and chemical stability, while advantageous in many applications, make it challenging to recycle or reprocess at the end of its lifecycle. This limitation could potentially undermine zirconia's role in circular economy models and sustainable product design.

Furthermore, the lack of standardization in zirconia production and application methodologies across different industries poses challenges for quality control and regulatory compliance. This inconsistency can lead to variability in performance and reliability, potentially slowing down the adoption of zirconia-based solutions in critical sustainable technologies.

Lastly, there is a significant knowledge gap in understanding the long-term environmental impacts of zirconia nanoparticles and their potential toxicity. As the use of zirconia in nanoscale applications grows, concerns about its bioaccumulation and effects on ecosystems need to be thoroughly addressed to ensure its sustainable use aligns with environmental safety standards.

Current Zirconia Apps

01 Zirconia synthesis and processing

Various methods for synthesizing and processing zirconia materials, including techniques for controlling particle size, crystalline structure, and purity. This encompasses sol-gel processes, hydrothermal synthesis, and other advanced manufacturing techniques to produce zirconia powders or bulk materials with specific properties.- Zirconia synthesis and processing: Various methods for synthesizing and processing zirconia materials, including techniques for controlling particle size, crystalline structure, and purity. This encompasses sol-gel methods, hydrothermal synthesis, and other advanced processing techniques to produce zirconia with specific properties for different applications.

- Zirconia-based ceramics and composites: Development of zirconia-based ceramic materials and composites with enhanced mechanical, thermal, and chemical properties. This includes the creation of zirconia-toughened ceramics, zirconia-alumina composites, and other multi-component systems for applications in various industries such as aerospace, automotive, and medical devices.

- Dental and biomedical applications of zirconia: Utilization of zirconia in dental and biomedical applications, including dental implants, crowns, bridges, and orthopedic implants. This focuses on the biocompatibility, aesthetics, and mechanical strength of zirconia-based materials for medical use, as well as techniques for fabrication and surface modification to improve integration with biological tissues.

- Zirconia in fuel cells and energy applications: Application of zirconia materials in solid oxide fuel cells (SOFCs) and other energy-related technologies. This includes the development of yttria-stabilized zirconia (YSZ) electrolytes, zirconia-based electrodes, and other components for high-temperature fuel cells and energy conversion devices.

- Zirconia coatings and thin films: Methods for depositing zirconia coatings and thin films on various substrates for protective, optical, and functional applications. This encompasses techniques such as physical vapor deposition, chemical vapor deposition, and sol-gel coating processes to create zirconia layers with specific properties for use in optics, electronics, and corrosion protection.

02 Zirconia-based composites and coatings

Development of composite materials and coatings incorporating zirconia for enhanced mechanical, thermal, or chemical properties. This includes zirconia-reinforced ceramics, metal-zirconia composites, and protective coatings for various industrial applications, such as thermal barrier coatings in aerospace or wear-resistant coatings in manufacturing.Expand Specific Solutions03 Dental and biomedical applications of zirconia

Utilization of zirconia in dental and biomedical fields, particularly for prosthetics, implants, and other medical devices. This covers the development of zirconia-based materials with improved biocompatibility, mechanical strength, and aesthetic properties for dental crowns, bridges, and orthopedic implants.Expand Specific Solutions04 Zirconia in catalysis and fuel cells

Applications of zirconia as a catalyst support or active component in catalytic processes and fuel cell technologies. This includes the development of zirconia-based materials with high surface area, specific pore structures, or doped compositions to enhance catalytic activity or ionic conductivity for energy conversion and chemical processing.Expand Specific Solutions05 Stabilization and phase control of zirconia

Methods and additives for stabilizing specific crystalline phases of zirconia, particularly the tetragonal and cubic phases, at room temperature. This involves the use of dopants, such as yttria, ceria, or magnesia, to control the phase transformation behavior and enhance the mechanical and thermal properties of zirconia-based materials for various applications.Expand Specific Solutions

Key Zirconia Players

The research on zirconia as a key player in sustainable tech development is in a growth phase, with increasing market size and technological advancements. The global zirconia market is expanding due to its versatile applications in various industries. Technologically, zirconia is reaching maturity in some sectors while still evolving in others. Companies like Kyocera Corp., Saint-Gobain Ceramics & Plastics, Inc., and CoorsTek, Inc. are leading in zirconia applications for ceramics and advanced materials. Bloom Energy Corp. is utilizing zirconia in sustainable energy solutions, while DENSO Corp. and LG Electronics, Inc. are exploring its potential in electronics and automotive sectors. Academic institutions such as Harbin Institute of Technology and Nanjing University are contributing to fundamental research, pushing the boundaries of zirconia's capabilities in sustainable technologies.

Kyocera Corp.

Saint-Gobain Ceramics & Plastics, Inc.

Zirconia Innovations

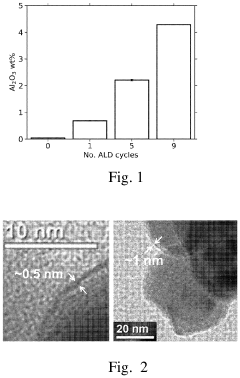

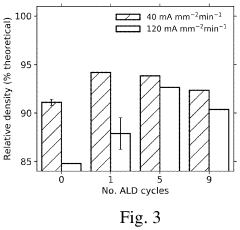

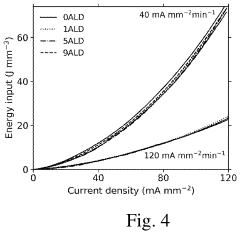

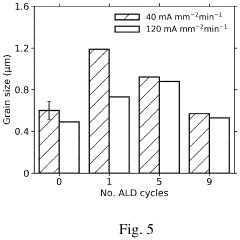

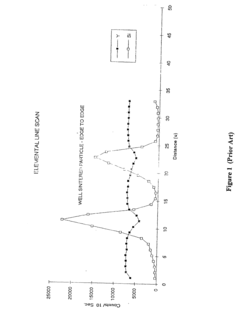

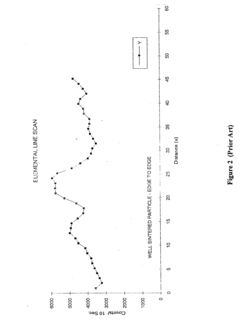

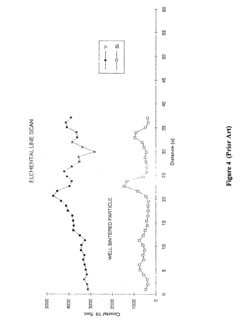

- The use of atomic layer deposition (ALD) to homogeneously disperse a secondary phase, such as Al2O3, on the surface of ceramic particles before flash sintering, ensuring a well-dispersed and amorphous secondary phase throughout the ceramic green body, thereby controlling densification behavior and microstructural homogeneity.

- The production of chemically and morphologically uniform stabilized zirconia powders in the form of substantially spheroidal hollow spheres, achieved through electrofusion with stabilizing oxides like yttria, followed by plasma fusion to create particles with less than 2% monoclinic zirconia and sizes under 200 micrometers, ensuring high tetragonal crystal phase stability.

Environmental Impact

Zirconia's role in sustainable technology development is closely tied to its environmental impact, which spans various aspects of its lifecycle and applications. The production of zirconia involves mining zircon sand, which can lead to habitat disruption and soil erosion if not managed responsibly. However, modern mining practices are increasingly adopting sustainable methods to minimize these impacts, including land rehabilitation and water conservation techniques.

In terms of energy consumption, the process of converting zircon to zirconia is energy-intensive, primarily due to the high temperatures required for calcination. This energy demand contributes to carbon emissions, particularly if fossil fuels are the primary energy source. Nevertheless, the industry is making strides in improving energy efficiency and exploring renewable energy options to reduce its carbon footprint.

One of the most significant environmental benefits of zirconia lies in its durability and longevity. When used in applications such as ceramic coatings, dental implants, and industrial components, zirconia's exceptional wear resistance and chemical stability lead to products with extended lifespans. This longevity reduces the need for frequent replacements, thereby conserving resources and minimizing waste generation over time.

Zirconia's role in clean energy technologies further enhances its environmental credentials. Its use in solid oxide fuel cells and as a catalyst in hydrogen production contributes to the development of cleaner energy alternatives. These applications have the potential to reduce reliance on fossil fuels and decrease overall greenhouse gas emissions.

In the realm of water treatment, zirconia-based materials show promise in removing contaminants more efficiently than traditional methods. This could lead to improved water quality and reduced chemical usage in treatment processes, positively impacting aquatic ecosystems and human health.

However, the end-of-life management of zirconia products presents challenges. While zirconia itself is not toxic, its disposal or recycling can be complex due to its high melting point and chemical stability. Research into effective recycling methods for zirconia-containing products is ongoing, aiming to close the loop in its lifecycle and further enhance its sustainability profile.

As the demand for sustainable materials grows, the zirconia industry is increasingly focusing on developing eco-friendly production methods and exploring new applications that leverage its unique properties to address environmental challenges. This ongoing research and development are crucial in positioning zirconia as a key player in the transition towards more sustainable technological solutions.

Zirconia Supply Chain

The zirconia supply chain plays a crucial role in the sustainable development of various industries, particularly in advanced ceramics, electronics, and renewable energy technologies. The supply chain begins with the extraction of zircon sand, primarily found in Australia, South Africa, and China. These countries dominate the global zircon production, with Australia accounting for nearly 50% of the world's supply.

Once extracted, zircon undergoes processing to produce zirconium oxychloride, which is then further refined into zirconia. This process involves multiple stages, including chlorination, purification, and calcination. The production of high-purity zirconia requires sophisticated technology and stringent quality control measures, making it a specialized industry with relatively few major players.

The zirconia supply chain faces several challenges, including the concentration of raw material sources in a few countries, which can lead to supply vulnerabilities. Additionally, the energy-intensive nature of zirconia production raises concerns about its environmental impact, prompting research into more sustainable processing methods.

In recent years, there has been a growing emphasis on developing a circular economy for zirconia. This involves recycling and reusing zirconia-based products, particularly in industries such as dental prosthetics and fuel cells. Such initiatives aim to reduce reliance on primary raw materials and minimize waste.

The demand for zirconia is driven by its unique properties, including high strength, thermal stability, and chemical inertness. These characteristics make it invaluable in applications ranging from solid oxide fuel cells to advanced ceramics used in extreme environments. As industries continue to seek materials that can withstand harsh conditions while maintaining performance, the zirconia supply chain is expected to evolve to meet these growing demands.

Innovations in the supply chain are focusing on improving efficiency and sustainability. This includes the development of more energy-efficient processing techniques, the exploration of alternative zirconium sources, and the implementation of advanced recycling technologies. These efforts are crucial for ensuring a stable and environmentally responsible supply of zirconia for future sustainable technologies.