How to fabricate LLZO pouch cells for benchmarking

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LLZO Solid Electrolyte Background and Objectives

Lithium lanthanum zirconium oxide (LLZO) has emerged as one of the most promising solid-state electrolyte materials for next-generation lithium batteries. The development of LLZO can be traced back to 2007 when Murugan et al. first reported its high ionic conductivity of 10^-4 S/cm at room temperature. Since then, LLZO has attracted significant attention due to its exceptional properties including high ionic conductivity, excellent chemical stability against lithium metal, and wide electrochemical stability window.

The evolution of LLZO technology has been marked by several key advancements. Initially, researchers focused on understanding the crystal structure and ionic transport mechanisms. The discovery that cubic phase LLZO exhibits significantly higher conductivity than tetragonal phase led to extensive research on stabilizing the cubic structure through doping strategies. Elements such as Al, Ga, and Ta have been successfully employed to stabilize the cubic phase at room temperature, enhancing ionic conductivity to levels approaching 10^-3 S/cm.

Recent technological trends in LLZO research have shifted toward addressing processing challenges and interface issues. Innovations in synthesis methods have evolved from traditional solid-state reactions to sol-gel processes, co-precipitation methods, and flame spray pyrolysis, enabling better control over particle size, morphology, and purity. These advancements have gradually improved the sinterability of LLZO and reduced grain boundary resistance.

The primary technical objective in LLZO pouch cell fabrication is to develop a scalable, reproducible manufacturing process that maintains the material's intrinsic properties while enabling practical energy density and cycling performance. This includes achieving thin electrolyte layers (<100 μm) with minimal defects, establishing stable interfaces between the electrolyte and electrodes, and ensuring uniform pressure distribution within the pouch cell architecture.

Additional objectives include optimizing the cell assembly process to minimize moisture exposure, as LLZO is highly sensitive to humidity, and developing effective strategies to reduce interfacial resistance between LLZO and electrodes. The ultimate goal is to create benchmark LLZO pouch cells that can demonstrate the material's full potential in terms of safety, cycle life, and performance under practical operating conditions.

The benchmarking of LLZO pouch cells serves as a critical step in bridging fundamental materials research with practical battery applications. By establishing standardized fabrication protocols and performance metrics, researchers can systematically evaluate various LLZO compositions, architectures, and interface engineering strategies, accelerating the development pathway toward commercial solid-state batteries with superior safety and energy density compared to conventional liquid electrolyte systems.

The evolution of LLZO technology has been marked by several key advancements. Initially, researchers focused on understanding the crystal structure and ionic transport mechanisms. The discovery that cubic phase LLZO exhibits significantly higher conductivity than tetragonal phase led to extensive research on stabilizing the cubic structure through doping strategies. Elements such as Al, Ga, and Ta have been successfully employed to stabilize the cubic phase at room temperature, enhancing ionic conductivity to levels approaching 10^-3 S/cm.

Recent technological trends in LLZO research have shifted toward addressing processing challenges and interface issues. Innovations in synthesis methods have evolved from traditional solid-state reactions to sol-gel processes, co-precipitation methods, and flame spray pyrolysis, enabling better control over particle size, morphology, and purity. These advancements have gradually improved the sinterability of LLZO and reduced grain boundary resistance.

The primary technical objective in LLZO pouch cell fabrication is to develop a scalable, reproducible manufacturing process that maintains the material's intrinsic properties while enabling practical energy density and cycling performance. This includes achieving thin electrolyte layers (<100 μm) with minimal defects, establishing stable interfaces between the electrolyte and electrodes, and ensuring uniform pressure distribution within the pouch cell architecture.

Additional objectives include optimizing the cell assembly process to minimize moisture exposure, as LLZO is highly sensitive to humidity, and developing effective strategies to reduce interfacial resistance between LLZO and electrodes. The ultimate goal is to create benchmark LLZO pouch cells that can demonstrate the material's full potential in terms of safety, cycle life, and performance under practical operating conditions.

The benchmarking of LLZO pouch cells serves as a critical step in bridging fundamental materials research with practical battery applications. By establishing standardized fabrication protocols and performance metrics, researchers can systematically evaluate various LLZO compositions, architectures, and interface engineering strategies, accelerating the development pathway toward commercial solid-state batteries with superior safety and energy density compared to conventional liquid electrolyte systems.

Market Analysis for Solid-State Battery Technologies

The solid-state battery market is experiencing unprecedented growth, driven by increasing demand for safer, higher energy density power solutions across multiple industries. Current market valuations place the global solid-state battery sector at approximately $500 million in 2023, with projections indicating potential expansion to $8-10 billion by 2030, representing a compound annual growth rate exceeding 30%. This remarkable growth trajectory is primarily fueled by automotive applications, which are expected to constitute over 60% of the total market share by 2028.

LLZO (Li7La3Zr2O12) garnet-based solid electrolytes represent a significant segment within this market, valued for their high ionic conductivity and stability against lithium metal anodes. The market for LLZO-specific technologies is currently estimated at $85 million, with specialized pouch cell configurations gaining particular attention for benchmarking and validation purposes.

Demand analysis reveals three primary market segments actively pursuing LLZO pouch cell technologies: electric vehicle manufacturers seeking higher energy density and safety improvements; consumer electronics companies exploring next-generation battery solutions; and grid storage developers requiring enhanced safety profiles for large-scale installations. Among these, automotive applications demonstrate the strongest growth potential, with major manufacturers including Toyota, BMW, and Volkswagen investing substantially in solid-state technology development programs.

Regional market distribution shows Asia-Pacific leading with approximately 45% market share, particularly driven by Japan and South Korea's advanced battery manufacturing infrastructure. North America follows at 30%, with significant research activities concentrated in universities and national laboratories, while Europe accounts for 20% with strong governmental support for sustainable energy technologies.

Key market drivers include increasingly stringent safety regulations for lithium-ion batteries, consumer demand for longer-lasting portable electronics, and automotive industry pressure to extend electric vehicle ranges. The benchmarking of LLZO pouch cells specifically addresses critical market needs for standardized performance metrics, enabling more accurate comparison between competing solid-state technologies and accelerating commercialization timelines.

Market barriers include high manufacturing costs, with current LLZO-based cells costing 4-5 times more than conventional lithium-ion equivalents, scalability challenges in maintaining consistent electrolyte properties at production volumes, and integration difficulties with existing battery manufacturing infrastructure. Despite these challenges, market analysts predict LLZO pouch cell technologies will reach cost parity with advanced lithium-ion batteries by 2028-2030, potentially triggering widespread commercial adoption.

LLZO (Li7La3Zr2O12) garnet-based solid electrolytes represent a significant segment within this market, valued for their high ionic conductivity and stability against lithium metal anodes. The market for LLZO-specific technologies is currently estimated at $85 million, with specialized pouch cell configurations gaining particular attention for benchmarking and validation purposes.

Demand analysis reveals three primary market segments actively pursuing LLZO pouch cell technologies: electric vehicle manufacturers seeking higher energy density and safety improvements; consumer electronics companies exploring next-generation battery solutions; and grid storage developers requiring enhanced safety profiles for large-scale installations. Among these, automotive applications demonstrate the strongest growth potential, with major manufacturers including Toyota, BMW, and Volkswagen investing substantially in solid-state technology development programs.

Regional market distribution shows Asia-Pacific leading with approximately 45% market share, particularly driven by Japan and South Korea's advanced battery manufacturing infrastructure. North America follows at 30%, with significant research activities concentrated in universities and national laboratories, while Europe accounts for 20% with strong governmental support for sustainable energy technologies.

Key market drivers include increasingly stringent safety regulations for lithium-ion batteries, consumer demand for longer-lasting portable electronics, and automotive industry pressure to extend electric vehicle ranges. The benchmarking of LLZO pouch cells specifically addresses critical market needs for standardized performance metrics, enabling more accurate comparison between competing solid-state technologies and accelerating commercialization timelines.

Market barriers include high manufacturing costs, with current LLZO-based cells costing 4-5 times more than conventional lithium-ion equivalents, scalability challenges in maintaining consistent electrolyte properties at production volumes, and integration difficulties with existing battery manufacturing infrastructure. Despite these challenges, market analysts predict LLZO pouch cell technologies will reach cost parity with advanced lithium-ion batteries by 2028-2030, potentially triggering widespread commercial adoption.

Current Challenges in LLZO Pouch Cell Fabrication

Despite significant advancements in LLZO solid electrolyte development, fabricating benchmark-quality LLZO pouch cells remains challenging due to several critical technical barriers. The interface between LLZO and lithium metal electrodes presents a fundamental obstacle, as achieving stable, low-impedance contact is difficult. Surface contamination from atmospheric exposure, particularly carbonate formation, significantly increases interfacial resistance and compromises cell performance. Even with pristine surfaces, the rigid ceramic nature of LLZO creates mechanical contact issues that prevent intimate electrode-electrolyte interfaces.

Processing limitations further complicate fabrication efforts. LLZO requires high-temperature sintering (>1000°C) to achieve adequate ionic conductivity, making it incompatible with conventional pouch cell assembly techniques designed for liquid electrolytes. The brittleness of LLZO electrolytes presents handling challenges during cell assembly, with thin sheets prone to fracture under minimal stress. These mechanical properties necessitate specialized handling protocols that are difficult to standardize for benchmarking purposes.

Scale-up issues represent another significant hurdle. While laboratory-scale LLZO pellets can be produced with relatively consistent properties, fabricating larger-area sheets with uniform thickness, density, and conductivity remains problematic. Variations in material properties across the electrolyte surface lead to inconsistent performance metrics, undermining the reliability of benchmarking efforts. The lack of standardized fabrication protocols further exacerbates reproducibility issues between different research groups.

Current sealing technologies present additional complications. Traditional heat-sealing methods used for conventional pouch cells are often incompatible with the rigid LLZO components. The hermetic sealing required to exclude moisture and contaminants is difficult to achieve while maintaining the structural integrity of the ceramic electrolyte. This challenge is compounded by the need for specialized current collectors that can maintain good contact with both the solid electrolyte and active materials.

Testing standardization represents a final major challenge. The performance metrics relevant to LLZO cells differ significantly from those of conventional liquid-electrolyte cells. Parameters such as interfacial impedance evolution, mechanical stability during cycling, and tolerance to environmental factors require specialized testing protocols that are not yet widely standardized. This lack of standardization makes meaningful comparison between different LLZO pouch cell designs difficult, hindering progress toward optimized configurations.

Processing limitations further complicate fabrication efforts. LLZO requires high-temperature sintering (>1000°C) to achieve adequate ionic conductivity, making it incompatible with conventional pouch cell assembly techniques designed for liquid electrolytes. The brittleness of LLZO electrolytes presents handling challenges during cell assembly, with thin sheets prone to fracture under minimal stress. These mechanical properties necessitate specialized handling protocols that are difficult to standardize for benchmarking purposes.

Scale-up issues represent another significant hurdle. While laboratory-scale LLZO pellets can be produced with relatively consistent properties, fabricating larger-area sheets with uniform thickness, density, and conductivity remains problematic. Variations in material properties across the electrolyte surface lead to inconsistent performance metrics, undermining the reliability of benchmarking efforts. The lack of standardized fabrication protocols further exacerbates reproducibility issues between different research groups.

Current sealing technologies present additional complications. Traditional heat-sealing methods used for conventional pouch cells are often incompatible with the rigid LLZO components. The hermetic sealing required to exclude moisture and contaminants is difficult to achieve while maintaining the structural integrity of the ceramic electrolyte. This challenge is compounded by the need for specialized current collectors that can maintain good contact with both the solid electrolyte and active materials.

Testing standardization represents a final major challenge. The performance metrics relevant to LLZO cells differ significantly from those of conventional liquid-electrolyte cells. Parameters such as interfacial impedance evolution, mechanical stability during cycling, and tolerance to environmental factors require specialized testing protocols that are not yet widely standardized. This lack of standardization makes meaningful comparison between different LLZO pouch cell designs difficult, hindering progress toward optimized configurations.

Established LLZO Pouch Cell Fabrication Methods

01 LLZO solid electrolyte synthesis methods

Various synthesis methods are employed to produce LLZO (Li7La3Zr2O12) solid electrolytes for pouch cells. These include sol-gel processing, solid-state reaction methods, and solution-based approaches. The synthesis parameters such as temperature, time, and precursor materials significantly affect the crystallinity, density, and ionic conductivity of the resulting LLZO. Advanced techniques like spray pyrolysis and combustion synthesis are also utilized to achieve high-quality LLZO with controlled grain size and minimal impurities.- LLZO solid electrolyte synthesis methods: Various methods for synthesizing LLZO (Li7La3Zr2O12) solid electrolytes for pouch cells, including sol-gel processing, solid-state reaction methods, and solution-based approaches. These synthesis techniques focus on controlling the crystal structure, grain size, and ionic conductivity of LLZO to optimize its performance as a solid electrolyte in battery applications. Different dopants and processing parameters can be adjusted to enhance the cubic phase stability and lithium-ion conductivity.

- Pouch cell assembly with LLZO electrolytes: Techniques for assembling pouch cells incorporating LLZO solid electrolytes, including electrode-electrolyte interface engineering, stacking methods, and sealing processes. These methods address challenges such as achieving good contact between electrodes and the solid electrolyte, minimizing interfacial resistance, and ensuring proper sealing to prevent moisture ingress. The assembly processes often involve specialized equipment for precise alignment and controlled pressure application during cell construction.

- Interface engineering for LLZO-based cells: Methods for improving the interfaces between LLZO solid electrolytes and electrodes in pouch cells, including surface modification techniques, buffer layer integration, and interfacial coating approaches. These engineering solutions aim to reduce interfacial resistance, enhance mechanical adhesion, and prevent unwanted chemical reactions at the interfaces. Various coating materials and deposition techniques are employed to create stable interfaces that facilitate efficient ion transport while maintaining mechanical integrity during cycling.

- Composite electrolyte systems with LLZO: Development of composite electrolyte systems incorporating LLZO particles or structures combined with polymers or other materials for improved mechanical properties and processing capabilities in pouch cells. These composite approaches aim to combine the high ionic conductivity of LLZO with the flexibility and processability of polymers or other matrix materials. The resulting composite electrolytes can be fabricated into thin films suitable for pouch cell configurations while maintaining adequate ionic conductivity and mechanical strength.

- Scalable manufacturing processes for LLZO pouch cells: Industrial-scale manufacturing techniques for LLZO-based pouch cells, including roll-to-roll processing, large-batch synthesis methods, and automated assembly approaches. These scalable processes focus on cost reduction, quality control, and high-throughput production of LLZO electrolytes and their integration into pouch cell formats. Innovations in this area include specialized equipment design, process optimization, and quality control methods to ensure consistent performance of mass-produced LLZO pouch cells.

02 Pouch cell assembly with LLZO electrolytes

The assembly of pouch cells incorporating LLZO solid electrolytes involves specialized techniques to ensure proper interfacial contact between the electrolyte and electrodes. This includes surface treatment of LLZO to improve wettability, application of pressure during assembly, and the use of interlayers to reduce interfacial resistance. The pouch cell configuration typically involves stacking or winding of electrode-electrolyte assemblies followed by sealing in a flexible pouch material under controlled atmosphere conditions to prevent moisture contamination.Expand Specific Solutions03 LLZO-polymer composite electrolytes for flexible pouch cells

LLZO-polymer composite electrolytes combine the high ionic conductivity of LLZO with the flexibility and processability of polymers, making them ideal for pouch cell applications. Fabrication methods include dispersion of LLZO particles in polymer matrices, in-situ polymerization around LLZO structures, and creation of vertically aligned LLZO structures within polymer films. These composites address challenges such as brittleness of pure LLZO while maintaining good electrochemical performance and enabling the production of flexible, thin-format pouch cells.Expand Specific Solutions04 Interface engineering for LLZO-based pouch cells

Interface engineering is crucial for optimizing LLZO-based pouch cells. Techniques include coating electrode surfaces with buffer layers, modifying LLZO surfaces with lithium-conductive materials, and creating gradient structures to reduce interfacial resistance. Atomic layer deposition, pulsed laser deposition, and solution-based coating methods are employed to create these engineered interfaces. These approaches address challenges related to chemical and mechanical stability at the electrode-electrolyte interfaces, which are critical for long-term cycling performance of LLZO pouch cells.Expand Specific Solutions05 Scalable manufacturing processes for LLZO pouch cells

Scalable manufacturing processes for LLZO pouch cells focus on techniques suitable for mass production. These include tape casting of LLZO sheets, roll-to-roll processing of composite electrolytes, and automated assembly systems for cell stacking. Advanced sintering methods like spark plasma sintering and microwave sintering are employed to reduce processing time and energy consumption. Quality control measures such as in-line monitoring of thickness uniformity, defect detection, and electrochemical testing are integrated into the manufacturing workflow to ensure consistent performance of the produced cells.Expand Specific Solutions

Leading Organizations in LLZO Development

The LLZO pouch cell fabrication market is in an early growth phase, characterized by increasing research activity but limited commercial deployment. The market size remains relatively modest, primarily driven by research institutions and battery manufacturers exploring solid-state battery technologies. Technologically, LLZO pouch cells are still in the development stage, with academic institutions like Zhejiang University, Tsinghua University, and Xi'an Jiaotong University leading fundamental research, while companies such as LG Energy Solution, SK Innovation, and Hefei Guoxuan High-Tech Power Energy are advancing industrial applications. The technology maturity varies significantly across players, with major battery manufacturers demonstrating more integrated approaches to scaling production, while research institutions focus on addressing core challenges in electrolyte synthesis, interface engineering, and cell assembly techniques.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced fabrication techniques for LLZO (Li7La3Zr2O12) solid-state electrolyte pouch cells, focusing on scalable manufacturing processes. Their approach involves tape-casting methods to create thin LLZO ceramic sheets (10-30μm) that maintain mechanical integrity while allowing for flexibility in pouch cell configurations. The company employs hot-pressing techniques at controlled temperatures (1000-1200°C) to achieve high relative density (>95%) LLZO layers with optimized Li-ion conductivity (>0.5 mS/cm at room temperature). LG's proprietary interface engineering addresses the critical electrode-electrolyte contact issues by using specialized coatings and pressure-application methods during cell assembly to minimize interfacial resistance. Their benchmarking protocol includes standardized cycling tests at various C-rates, temperature performance evaluations (-20°C to 60°C), and long-term stability assessments exceeding 1000 cycles.

Strengths: Industry-leading manufacturing scale capabilities, established quality control systems, and integration with existing battery production lines. Their approach enables relatively high throughput compared to academic settings. Weaknesses: Higher production costs compared to conventional liquid electrolyte cells, and challenges in achieving uniform LLZO-electrode interfaces across large-format cells.

Xi'an Jiaotong University

Technical Solution: Xi'an Jiaotong University has developed a comprehensive approach to LLZO pouch cell fabrication for benchmarking purposes. Their methodology begins with a modified solid-state reaction synthesis of LLZO powder with Ta-doping (0.5-0.6 mol%) to stabilize the cubic phase and enhance ionic conductivity. The university employs a unique dry-pressing technique followed by isostatic pressing at 200-300 MPa to create dense LLZO pellets, which are then precision-machined to desired thicknesses (100-500μm). Their sintering protocol involves a two-step process with an initial hold at 800°C followed by high-temperature sintering at 1180°C in oxygen atmosphere with sacrificial powder to minimize lithium loss. Xi'an Jiaotong's researchers have pioneered an innovative interface treatment using thin lithium-containing interlayers (Li3N or Li2S-P2S5) applied through pulsed laser deposition to improve contact with electrodes. Their pouch cell assembly process incorporates specialized fixtures to maintain uniform pressure distribution across the cell stack during sealing and cycling. For benchmarking, they've established standardized protocols including impedance measurements at various temperatures (-20°C to 80°C), critical current density determination, and long-term cycling tests under different pressure conditions.

Strengths: Excellent control over LLZO density and microstructure through their specialized pressing techniques, resulting in high mechanical strength and consistent ionic conductivity. Comprehensive benchmarking methodology that evaluates multiple performance metrics under varied conditions. Weaknesses: Time-intensive fabrication process with multiple manual steps that could introduce variability. Limited demonstration of thin (<100μm) LLZO membranes suitable for high-energy-density applications.

Critical Patents and Research on LLZO Processing

A method of synthesis of lithium lanthanum zirconium oxide (LLZO) and doped LLZO, solid-state electrolytes for li-ion battery

PatentPendingIN202411040069A

Innovation

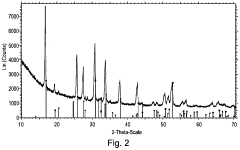

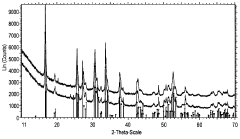

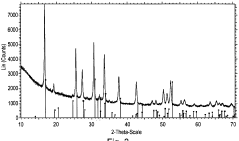

- A modified sol-gel method is employed at low temperatures (400 to 600 °C) for synthesizing phase pure LLZO and doped LLZO, involving the homogenous mixing of metal ions to form a network structure, with intermittent addition of lithium salt and subsequent heat treatment, which results in ionic conductivity of 10^-4 S/cm.

Process for the production of powdered lithium lanthanum zirconium oxide

PatentInactiveDE102013114768A1

Innovation

- A grinding process for LLZO that includes the addition of organic solvents like isopropanol and lithium, aluminum, tantalum, or niobium salts to stabilize the cubic phase, minimizing secondary phase precipitation and lattice constant changes.

Benchmarking Standards and Testing Protocols

To establish reliable benchmarking for LLZO pouch cells, standardized testing protocols are essential for ensuring reproducibility and comparability across different research groups and manufacturing processes. The development of these standards requires consideration of multiple parameters specific to solid-state battery technology, particularly those using LLZO (Li7La3Zr2O12) as the solid electrolyte.

Current benchmarking standards for LLZO pouch cells should include electrochemical performance metrics such as capacity retention, rate capability, and cycling stability. These metrics must be measured under controlled temperature conditions, typically ranging from room temperature to elevated temperatures (25-80°C), to evaluate the thermal stability advantages of solid-state systems. Coulombic efficiency measurements are particularly critical for solid-state cells to identify any side reactions occurring at the electrode-electrolyte interfaces.

Mechanical testing protocols represent another crucial aspect of LLZO pouch cell benchmarking. Unlike liquid electrolyte systems, solid-state batteries require evaluation of interfacial contact maintenance during cycling. Standardized protocols should include measurements of stack pressure effects on performance and mechanical integrity tests after extended cycling. The development of specialized equipment to maintain consistent pressure during testing is an emerging area of focus.

Safety testing protocols for LLZO pouch cells differ significantly from conventional lithium-ion batteries. Standard tests should include nail penetration, thermal runaway resistance, and short-circuit behavior. The unique safety advantages of solid electrolytes must be quantified through comparative testing against conventional systems under identical conditions to provide meaningful benchmarks.

Accelerated aging protocols are essential for predicting long-term performance. These should include calendar aging at various states of charge and temperatures, as well as cycle aging under different depth-of-discharge conditions. For LLZO systems specifically, protocols must address the potential for lithium dendrite formation through the ceramic electrolyte under various current densities and temperature conditions.

Standardization efforts should also include cell preparation protocols to minimize variability between research groups. This includes specifications for electrode composition, LLZO thickness uniformity, interface treatment procedures, and assembly environment requirements. The establishment of reference materials and control samples would significantly enhance the reliability of comparative studies across the research community.

Current benchmarking standards for LLZO pouch cells should include electrochemical performance metrics such as capacity retention, rate capability, and cycling stability. These metrics must be measured under controlled temperature conditions, typically ranging from room temperature to elevated temperatures (25-80°C), to evaluate the thermal stability advantages of solid-state systems. Coulombic efficiency measurements are particularly critical for solid-state cells to identify any side reactions occurring at the electrode-electrolyte interfaces.

Mechanical testing protocols represent another crucial aspect of LLZO pouch cell benchmarking. Unlike liquid electrolyte systems, solid-state batteries require evaluation of interfacial contact maintenance during cycling. Standardized protocols should include measurements of stack pressure effects on performance and mechanical integrity tests after extended cycling. The development of specialized equipment to maintain consistent pressure during testing is an emerging area of focus.

Safety testing protocols for LLZO pouch cells differ significantly from conventional lithium-ion batteries. Standard tests should include nail penetration, thermal runaway resistance, and short-circuit behavior. The unique safety advantages of solid electrolytes must be quantified through comparative testing against conventional systems under identical conditions to provide meaningful benchmarks.

Accelerated aging protocols are essential for predicting long-term performance. These should include calendar aging at various states of charge and temperatures, as well as cycle aging under different depth-of-discharge conditions. For LLZO systems specifically, protocols must address the potential for lithium dendrite formation through the ceramic electrolyte under various current densities and temperature conditions.

Standardization efforts should also include cell preparation protocols to minimize variability between research groups. This includes specifications for electrode composition, LLZO thickness uniformity, interface treatment procedures, and assembly environment requirements. The establishment of reference materials and control samples would significantly enhance the reliability of comparative studies across the research community.

Scale-up Considerations for Commercial Production

Transitioning LLZO pouch cell fabrication from laboratory scale to commercial production presents significant challenges that must be addressed systematically. The current laboratory-scale production methods typically yield small quantities of cells with manual assembly processes, which are not economically viable for mass production. Commercial scale-up requires automation of critical manufacturing steps, including LLZO synthesis, electrode preparation, cell assembly, and electrolyte filling processes.

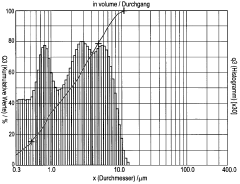

Material consistency becomes paramount at larger scales, necessitating robust quality control protocols for LLZO powder synthesis and processing. Variations in particle size distribution, density, and ionic conductivity must be minimized to ensure consistent cell performance across production batches. Implementing statistical process control methods and in-line quality monitoring systems will be essential for maintaining tight manufacturing tolerances.

Equipment design for high-volume production presents another critical consideration. Custom machinery for handling thin ceramic components must be developed, as conventional battery manufacturing equipment is not optimized for solid-state components. Specialized tooling for precise alignment of LLZO layers and controlled pressure application during lamination processes will be required to minimize interfacial resistance issues that commonly plague solid-state batteries.

Energy consumption during high-temperature sintering processes represents a significant cost factor in scaled production. Development of lower-temperature processing methods or more energy-efficient sintering technologies could substantially reduce manufacturing costs. Alternative approaches such as cold sintering or field-assisted sintering techniques (FAST) show promise for reducing energy requirements while maintaining LLZO performance characteristics.

Yield optimization becomes increasingly important at commercial scale, where material costs significantly impact economic viability. Current laboratory fabrication methods often accept relatively high rejection rates, but commercial production will require defect rates below 100 parts per million. This necessitates development of non-destructive testing methods capable of identifying defects in ceramic electrolytes before final cell assembly.

Supply chain considerations must also be addressed, particularly regarding lithium and zirconium raw materials. Securing stable, cost-effective sources of high-purity precursors will be essential for maintaining consistent product quality and managing production costs. Strategic partnerships with material suppliers may be necessary to ensure adequate supply as production volumes increase.

Material consistency becomes paramount at larger scales, necessitating robust quality control protocols for LLZO powder synthesis and processing. Variations in particle size distribution, density, and ionic conductivity must be minimized to ensure consistent cell performance across production batches. Implementing statistical process control methods and in-line quality monitoring systems will be essential for maintaining tight manufacturing tolerances.

Equipment design for high-volume production presents another critical consideration. Custom machinery for handling thin ceramic components must be developed, as conventional battery manufacturing equipment is not optimized for solid-state components. Specialized tooling for precise alignment of LLZO layers and controlled pressure application during lamination processes will be required to minimize interfacial resistance issues that commonly plague solid-state batteries.

Energy consumption during high-temperature sintering processes represents a significant cost factor in scaled production. Development of lower-temperature processing methods or more energy-efficient sintering technologies could substantially reduce manufacturing costs. Alternative approaches such as cold sintering or field-assisted sintering techniques (FAST) show promise for reducing energy requirements while maintaining LLZO performance characteristics.

Yield optimization becomes increasingly important at commercial scale, where material costs significantly impact economic viability. Current laboratory fabrication methods often accept relatively high rejection rates, but commercial production will require defect rates below 100 parts per million. This necessitates development of non-destructive testing methods capable of identifying defects in ceramic electrolytes before final cell assembly.

Supply chain considerations must also be addressed, particularly regarding lithium and zirconium raw materials. Securing stable, cost-effective sources of high-purity precursors will be essential for maintaining consistent product quality and managing production costs. Strategic partnerships with material suppliers may be necessary to ensure adequate supply as production volumes increase.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!