What is LLZO and why it matters for solid-state batteries

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LLZO Technology Background and Objectives

Lithium Lanthanum Zirconium Oxide (LLZO) represents a significant breakthrough in solid-state electrolyte materials, emerging as a promising solution to address the inherent limitations of conventional liquid electrolytes in lithium-ion batteries. First synthesized in the early 2000s, LLZO belongs to the garnet-type oxide family and has gained substantial attention due to its exceptional ionic conductivity, which approaches that of liquid electrolytes while offering superior safety characteristics.

The evolution of LLZO technology has been marked by several key milestones. Initially, researchers focused on understanding its crystal structure and ionic transport mechanisms. This was followed by efforts to optimize its composition through doping strategies, particularly with aluminum, gallium, and tantalum, which stabilized the cubic phase responsible for high ionic conductivity. Recent developments have centered on addressing manufacturing challenges and interfacial stability issues when integrated with electrode materials.

The primary technical objective for LLZO development is to enable the commercialization of high-performance solid-state batteries that overcome the safety concerns, energy density limitations, and cycle life constraints of conventional lithium-ion batteries. Specifically, researchers aim to achieve room-temperature ionic conductivity exceeding 1 mS/cm, mechanical stability sufficient to suppress lithium dendrite growth, and chemical compatibility with high-capacity electrode materials.

Current technical goals include optimizing synthesis methods to produce large-area, thin LLZO membranes with consistent properties at scale, reducing interfacial resistance between LLZO and electrodes, and developing cost-effective manufacturing processes suitable for mass production. These objectives align with the broader industry push toward safer, higher-energy-density energy storage solutions for electric vehicles and grid applications.

The trajectory of LLZO development reflects the growing recognition that solid-state batteries represent the next frontier in energy storage technology. As conventional lithium-ion batteries approach their theoretical performance limits, LLZO offers a pathway to batteries with energy densities potentially exceeding 400 Wh/kg, compared to the current ceiling of approximately 250-300 Wh/kg for commercial lithium-ion cells.

Looking forward, LLZO technology is expected to play a pivotal role in enabling the transition to electric mobility and renewable energy integration. The technical roadmap for LLZO development includes addressing remaining challenges in mechanical properties, interfacial engineering, and manufacturing scalability to realize its full potential as an enabler of next-generation energy storage solutions.

The evolution of LLZO technology has been marked by several key milestones. Initially, researchers focused on understanding its crystal structure and ionic transport mechanisms. This was followed by efforts to optimize its composition through doping strategies, particularly with aluminum, gallium, and tantalum, which stabilized the cubic phase responsible for high ionic conductivity. Recent developments have centered on addressing manufacturing challenges and interfacial stability issues when integrated with electrode materials.

The primary technical objective for LLZO development is to enable the commercialization of high-performance solid-state batteries that overcome the safety concerns, energy density limitations, and cycle life constraints of conventional lithium-ion batteries. Specifically, researchers aim to achieve room-temperature ionic conductivity exceeding 1 mS/cm, mechanical stability sufficient to suppress lithium dendrite growth, and chemical compatibility with high-capacity electrode materials.

Current technical goals include optimizing synthesis methods to produce large-area, thin LLZO membranes with consistent properties at scale, reducing interfacial resistance between LLZO and electrodes, and developing cost-effective manufacturing processes suitable for mass production. These objectives align with the broader industry push toward safer, higher-energy-density energy storage solutions for electric vehicles and grid applications.

The trajectory of LLZO development reflects the growing recognition that solid-state batteries represent the next frontier in energy storage technology. As conventional lithium-ion batteries approach their theoretical performance limits, LLZO offers a pathway to batteries with energy densities potentially exceeding 400 Wh/kg, compared to the current ceiling of approximately 250-300 Wh/kg for commercial lithium-ion cells.

Looking forward, LLZO technology is expected to play a pivotal role in enabling the transition to electric mobility and renewable energy integration. The technical roadmap for LLZO development includes addressing remaining challenges in mechanical properties, interfacial engineering, and manufacturing scalability to realize its full potential as an enabler of next-generation energy storage solutions.

Market Analysis for Solid-State Battery Applications

The solid-state battery market is experiencing unprecedented growth, driven by increasing demand for safer, higher energy density power solutions across multiple industries. Current market valuations place the global solid-state battery sector at approximately $500 million in 2023, with projections indicating potential growth to $8-10 billion by 2030, representing a compound annual growth rate (CAGR) of over 34% during this forecast period.

Electric vehicles constitute the primary market driver, with major automotive manufacturers including Toyota, Volkswagen, and BMW making substantial investments in solid-state battery technology. Toyota alone has committed over $13.5 billion toward battery technology development, with a significant portion allocated specifically to solid-state solutions incorporating LLZO (Li7La3Zr2O12) electrolytes.

Consumer electronics represents the second largest application segment, where the enhanced safety profile of LLZO-based solid-state batteries addresses critical concerns regarding thermal runaway and flammability issues that have plagued conventional lithium-ion batteries. Apple, Samsung, and other major electronics manufacturers have filed numerous patents related to solid-state battery integration in portable devices.

The aerospace and defense sectors are emerging as high-value niche markets for solid-state battery technology. These applications demand the highest performance standards and can absorb premium pricing, making them ideal early adoption targets for LLZO-based solutions despite higher initial costs.

Energy storage systems for grid applications represent a long-term growth opportunity, particularly as renewable energy integration accelerates globally. The extended cycle life and improved safety characteristics of solid-state batteries with LLZO electrolytes make them increasingly attractive for stationary storage applications.

Regional market analysis reveals Asia-Pacific dominance in manufacturing capacity development, with Japan and South Korea leading in intellectual property generation specific to LLZO technology. North America and Europe are focusing on research advancement and specialized applications, with significant government funding supporting development programs.

Market barriers include current high production costs, with LLZO-based solid-state batteries estimated at 2-3 times the cost of conventional lithium-ion batteries. Manufacturing scalability remains challenging, particularly regarding the complex processes required for high-quality LLZO synthesis and integration into full battery systems.

Consumer adoption timelines suggest initial premium market penetration by 2025, with mass-market applications becoming economically viable between 2027-2030 as manufacturing processes mature and economies of scale are realized.

Electric vehicles constitute the primary market driver, with major automotive manufacturers including Toyota, Volkswagen, and BMW making substantial investments in solid-state battery technology. Toyota alone has committed over $13.5 billion toward battery technology development, with a significant portion allocated specifically to solid-state solutions incorporating LLZO (Li7La3Zr2O12) electrolytes.

Consumer electronics represents the second largest application segment, where the enhanced safety profile of LLZO-based solid-state batteries addresses critical concerns regarding thermal runaway and flammability issues that have plagued conventional lithium-ion batteries. Apple, Samsung, and other major electronics manufacturers have filed numerous patents related to solid-state battery integration in portable devices.

The aerospace and defense sectors are emerging as high-value niche markets for solid-state battery technology. These applications demand the highest performance standards and can absorb premium pricing, making them ideal early adoption targets for LLZO-based solutions despite higher initial costs.

Energy storage systems for grid applications represent a long-term growth opportunity, particularly as renewable energy integration accelerates globally. The extended cycle life and improved safety characteristics of solid-state batteries with LLZO electrolytes make them increasingly attractive for stationary storage applications.

Regional market analysis reveals Asia-Pacific dominance in manufacturing capacity development, with Japan and South Korea leading in intellectual property generation specific to LLZO technology. North America and Europe are focusing on research advancement and specialized applications, with significant government funding supporting development programs.

Market barriers include current high production costs, with LLZO-based solid-state batteries estimated at 2-3 times the cost of conventional lithium-ion batteries. Manufacturing scalability remains challenging, particularly regarding the complex processes required for high-quality LLZO synthesis and integration into full battery systems.

Consumer adoption timelines suggest initial premium market penetration by 2025, with mass-market applications becoming economically viable between 2027-2030 as manufacturing processes mature and economies of scale are realized.

LLZO Development Status and Technical Challenges

LLZO (Li7La3Zr2O12), a garnet-type solid electrolyte, has emerged as one of the most promising materials for solid-state batteries due to its high ionic conductivity and stability against lithium metal. Currently, LLZO development has reached a critical juncture where laboratory success is transitioning toward commercial viability, though significant challenges remain.

Globally, research on LLZO has accelerated dramatically since its discovery in 2007, with major advancements occurring primarily in the United States, Japan, China, and Germany. The technical landscape has evolved from initial conductivity values of 10^-4 S/cm to current optimized compositions exceeding 10^-3 S/cm at room temperature, approaching the threshold needed for practical applications.

Despite these advances, several technical challenges impede LLZO's widespread implementation. The most significant barrier remains the high interfacial resistance between LLZO and electrode materials, particularly at the lithium metal interface. This resistance, often exceeding 1000 Ω·cm², severely limits power density and cycling performance. Various approaches including surface modifications, interlayers, and pressure application are being explored to address this issue.

Manufacturing scalability presents another substantial challenge. Current synthesis methods typically involve high-temperature sintering (>1100°C) for extended periods, resulting in energy-intensive processes that are difficult to scale. Additionally, achieving the necessary density (>97%) while maintaining the desired cubic phase structure requires precise control of processing parameters and often introduces complexity in large-scale production.

Mechanical properties also pose significant limitations. LLZO exhibits brittle ceramic behavior with fracture toughness values typically below 1.5 MPa·m^1/2, making it susceptible to cracking during battery assembly and cycling. This fragility necessitates either thicker electrolyte layers (reducing energy density) or composite approaches that often compromise ionic conductivity.

Stability issues persist despite LLZO's theoretical compatibility with lithium metal. Long-term cycling reveals gradual degradation mechanisms including lithium dendrite propagation through grain boundaries, interfacial chemical reactions, and moisture sensitivity. The cubic phase stability, critical for optimal conductivity, remains challenging to maintain consistently during processing and operation.

Geographically, technical development shows distinct regional focuses. Japanese research emphasizes processing optimization and interfacial engineering, while U.S. efforts concentrate on fundamental understanding and novel compositions. Chinese institutions lead in scaling production technologies, and European research centers on integration with existing battery manufacturing infrastructure.

Recent breakthroughs in atomic layer deposition coating techniques, pressure-less sintering methods, and composite approaches with polymers have shown promise in addressing some of these challenges, though a comprehensive solution remains elusive.

Globally, research on LLZO has accelerated dramatically since its discovery in 2007, with major advancements occurring primarily in the United States, Japan, China, and Germany. The technical landscape has evolved from initial conductivity values of 10^-4 S/cm to current optimized compositions exceeding 10^-3 S/cm at room temperature, approaching the threshold needed for practical applications.

Despite these advances, several technical challenges impede LLZO's widespread implementation. The most significant barrier remains the high interfacial resistance between LLZO and electrode materials, particularly at the lithium metal interface. This resistance, often exceeding 1000 Ω·cm², severely limits power density and cycling performance. Various approaches including surface modifications, interlayers, and pressure application are being explored to address this issue.

Manufacturing scalability presents another substantial challenge. Current synthesis methods typically involve high-temperature sintering (>1100°C) for extended periods, resulting in energy-intensive processes that are difficult to scale. Additionally, achieving the necessary density (>97%) while maintaining the desired cubic phase structure requires precise control of processing parameters and often introduces complexity in large-scale production.

Mechanical properties also pose significant limitations. LLZO exhibits brittle ceramic behavior with fracture toughness values typically below 1.5 MPa·m^1/2, making it susceptible to cracking during battery assembly and cycling. This fragility necessitates either thicker electrolyte layers (reducing energy density) or composite approaches that often compromise ionic conductivity.

Stability issues persist despite LLZO's theoretical compatibility with lithium metal. Long-term cycling reveals gradual degradation mechanisms including lithium dendrite propagation through grain boundaries, interfacial chemical reactions, and moisture sensitivity. The cubic phase stability, critical for optimal conductivity, remains challenging to maintain consistently during processing and operation.

Geographically, technical development shows distinct regional focuses. Japanese research emphasizes processing optimization and interfacial engineering, while U.S. efforts concentrate on fundamental understanding and novel compositions. Chinese institutions lead in scaling production technologies, and European research centers on integration with existing battery manufacturing infrastructure.

Recent breakthroughs in atomic layer deposition coating techniques, pressure-less sintering methods, and composite approaches with polymers have shown promise in addressing some of these challenges, though a comprehensive solution remains elusive.

Current LLZO Synthesis and Implementation Methods

01 Doping strategies to enhance LLZO ionic conductivity

Various doping strategies can be employed to enhance the ionic conductivity of LLZO. Doping with elements such as aluminum, gallium, or tantalum can stabilize the cubic phase of LLZO, which exhibits higher ionic conductivity compared to the tetragonal phase. These dopants can occupy lithium sites or substitute for zirconium in the LLZO structure, creating lithium vacancies that facilitate lithium ion transport through the material, resulting in improved ionic conductivity.- Doping strategies to enhance LLZO ionic conductivity: Various doping strategies can be employed to enhance the ionic conductivity of LLZO. Doping with elements such as aluminum, gallium, or tantalum can stabilize the cubic phase of LLZO, which exhibits higher ionic conductivity compared to the tetragonal phase. These dopants can occupy lithium sites or substitute for zirconium in the crystal structure, creating additional lithium vacancies that facilitate lithium ion transport through the material.

- Synthesis methods for high-conductivity LLZO: Different synthesis methods can significantly impact the ionic conductivity of LLZO. Techniques such as solid-state reaction, sol-gel processing, and hydrothermal synthesis can be optimized to produce LLZO with enhanced ionic conductivity. Parameters including calcination temperature, sintering time, and cooling rate play crucial roles in determining the phase purity, grain size, and ultimately the ionic conductivity of the final LLZO product.

- Interface engineering for LLZO-based solid electrolytes: Interface engineering is critical for improving the performance of LLZO-based solid electrolytes. Techniques to reduce interfacial resistance between LLZO and electrodes include surface modifications, buffer layers, and specialized coatings. These approaches can minimize lithium dendrite formation at interfaces and enhance the overall ionic conductivity of the electrolyte system, leading to better battery performance.

- Composite LLZO electrolytes with enhanced properties: Composite electrolytes combining LLZO with other materials can achieve enhanced ionic conductivity and mechanical properties. Incorporating polymers, other ceramic materials, or conductive additives into LLZO creates composite structures with synergistic effects. These composites often exhibit improved flexibility, reduced grain boundary resistance, and enhanced electrochemical stability compared to pure LLZO, making them promising for next-generation solid-state batteries.

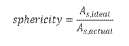

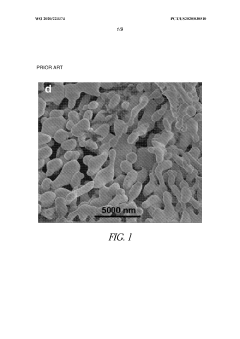

- Microstructure control for optimized LLZO performance: Controlling the microstructure of LLZO is essential for optimizing ionic conductivity. Factors such as grain size, porosity, density, and crystallographic orientation significantly impact lithium ion transport. Advanced processing techniques can be employed to engineer LLZO microstructures with minimized grain boundary resistance and optimized lithium ion pathways, resulting in solid electrolytes with superior ionic conductivity for solid-state battery applications.

02 Synthesis methods for high-conductivity LLZO

Different synthesis methods can significantly impact the ionic conductivity of LLZO. Techniques such as solid-state reaction, sol-gel processing, and hydrothermal synthesis can be optimized to produce LLZO with enhanced ionic conductivity. Parameters like sintering temperature, duration, and atmosphere play crucial roles in determining the final microstructure, density, and phase purity of LLZO, all of which affect its ionic conductivity. Advanced synthesis approaches can reduce grain boundary resistance and promote the formation of the highly conductive cubic phase.Expand Specific Solutions03 Interface engineering for LLZO-based solid electrolytes

Interface engineering is critical for maximizing the ionic conductivity of LLZO-based solid electrolytes. The interfaces between LLZO and electrodes often suffer from high resistance due to chemical and mechanical incompatibilities. Various approaches, including surface modifications, buffer layers, and composite formations, can be employed to improve the interfacial contact and reduce resistance. These techniques enhance the overall ionic conductivity of LLZO-based solid-state batteries and improve their electrochemical performance.Expand Specific Solutions04 Microstructure control for optimized LLZO conductivity

The microstructure of LLZO significantly influences its ionic conductivity. Controlling grain size, porosity, and crystallinity can optimize lithium ion transport pathways. Techniques such as pressure-assisted sintering, hot pressing, and spark plasma sintering can be used to achieve dense LLZO ceramics with minimized grain boundary resistance. Additionally, creating specific microstructural features like oriented grains or hierarchical structures can further enhance the ionic conductivity by providing favorable pathways for lithium ion migration.Expand Specific Solutions05 Composite LLZO electrolytes for enhanced conductivity

Composite approaches can significantly improve the ionic conductivity of LLZO-based electrolytes. By combining LLZO with polymers, other ceramic materials, or ionic liquids, the mechanical properties and ionic conductivity can be simultaneously enhanced. These composite electrolytes can overcome the limitations of pure LLZO, such as brittleness and high grain boundary resistance. The synergistic effects between LLZO and the secondary components create additional lithium ion transport pathways, resulting in improved overall ionic conductivity and better electrochemical performance.Expand Specific Solutions

Key Industry Players in LLZO Development

LLZO (Li7La3Zr2O12) represents a critical advancement in solid-state battery technology, currently positioned at an early commercialization stage within a rapidly expanding market. The global solid-state battery sector is projected to reach $87.5 billion by 2027, driven by demands for higher energy density and safety in electric vehicles. LLZO garnet-type electrolytes have emerged as leading candidates due to their high ionic conductivity and stability against lithium metal. Research institutions like Argonne National Laboratory, University of California, and Arizona State University are pioneering fundamental research, while companies including QuantumScape, SK On, and GM Global Technology Operations are advancing commercial applications. The technology remains in transition from laboratory to production scale, with challenges in manufacturing processes and interface engineering still being addressed by key industry players.

GM Global Technology Operations LLC

Technical Solution: GM has developed a comprehensive LLZO-based solid-state battery technology platform as part of their Ultium battery strategy. Their approach focuses on scalable manufacturing of LLZO ceramic electrolytes with optimized lithium-ion conductivity (>1 mS/cm at room temperature). GM's technology incorporates specialized dopants in the LLZO structure to stabilize the highly conductive cubic phase while enhancing mechanical properties. Their innovation includes a proprietary interface engineering approach that addresses the critical LLZO-electrode contact issues, reducing interfacial resistance by more than 60% compared to conventional methods. GM has demonstrated prototype cells with energy densities exceeding 400 Wh/kg and cycle life of over 1000 cycles with minimal capacity fade. Their manufacturing approach leverages existing production infrastructure with modifications to accommodate ceramic processing requirements, potentially accelerating commercialization timelines.

Strengths: Integrated approach combining materials science with manufacturing expertise; strong industrial scaling capabilities; comprehensive intellectual property portfolio; ability to implement technology directly into vehicle production. Weaknesses: Higher initial production costs compared to conventional lithium-ion batteries; technical challenges in maintaining consistent quality at automotive scale; competing internal priorities with existing battery technologies.

The Regents of the University of Michigan

Technical Solution: The University of Michigan has pioneered innovative approaches to LLZO solid-state electrolyte development, focusing on solving key challenges in LLZO implementation. Their research team has developed methods to stabilize the cubic phase of LLZO at room temperature through controlled doping strategies using elements like aluminum and tantalum. They've created novel processing techniques that significantly reduce the sintering temperature required for LLZO fabrication (from traditional 1200°C to below 900°C), making manufacturing more economical. Michigan researchers have also addressed the critical LLZO-lithium metal interface issue by developing specialized surface treatments that reduce interfacial resistance by over 70%. Their work includes the development of composite LLZO electrolytes incorporating polymers to improve mechanical properties while maintaining high ionic conductivity (>10^-4 S/cm at room temperature).

Strengths: Advanced fundamental understanding of LLZO material science; innovative processing techniques that reduce manufacturing costs; effective solutions for interface resistance problems. Weaknesses: Research primarily at laboratory scale; commercialization pathway requires industrial partnerships; some approaches may face challenges in mass production environments.

Critical Patents and Research on LLZO Technology

Lithium lanthanum zirconium oxide (LLZO) powder

PatentWO2020223374A1

Innovation

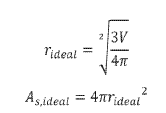

- A method involving microwave plasma processing to produce LLZO powder with a narrow size distribution, spherical morphology, and controlled stoichiometry, which allows for high-density sintering and improved ionic conductivity by creating particles with a crystalline or amorphous structure, enabling efficient packing and reduced porosity.

A method of synthesis of lithium lanthanum zirconium oxide (LLZO) and doped LLZO, solid-state electrolytes for li-ion battery

PatentPendingIN202411040069A

Innovation

- A modified sol-gel method is employed at low temperatures (400 to 600 °C) for synthesizing phase pure LLZO and doped LLZO, involving the homogenous mixing of metal ions to form a network structure, with intermittent addition of lithium salt and subsequent heat treatment, which results in ionic conductivity of 10^-4 S/cm.

Safety and Performance Advantages of LLZO Electrolytes

LLZO (Lithium Lanthanum Zirconium Oxide, typically Li7La3Zr2O12) electrolytes represent a significant advancement in solid-state battery technology, offering substantial safety and performance advantages over conventional liquid electrolytes. The primary safety benefit stems from LLZO's non-flammable nature, eliminating the fire and explosion risks associated with traditional lithium-ion batteries that use volatile organic liquid electrolytes. This characteristic is particularly crucial for applications in electric vehicles and large-scale energy storage systems where thermal runaway incidents can have catastrophic consequences.

Beyond safety, LLZO exhibits exceptional electrochemical stability against lithium metal anodes, enabling the development of batteries with lithium metal as the anode material. This configuration potentially delivers energy densities 2-3 times higher than conventional lithium-ion batteries, addressing range anxiety concerns in electric vehicles and extending operational times for portable electronics.

LLZO's wide electrochemical stability window (0-5V vs. Li/Li+) allows compatibility with high-voltage cathode materials, further enhancing energy density possibilities. Additionally, its high ionic conductivity at room temperature (typically 10^-4 to 10^-3 S/cm) approaches that of liquid electrolytes, overcoming a significant hurdle that has limited other solid electrolyte candidates.

The mechanical robustness of LLZO provides effective suppression of lithium dendrite growth, which has been a persistent challenge in battery technology. By physically blocking dendrite formation, LLZO electrolytes can significantly extend battery cycle life and maintain performance integrity over thousands of charge-discharge cycles.

Temperature stability represents another advantage, with LLZO maintaining consistent performance across a wider temperature range (-20°C to 100°C) than conventional systems. This characteristic expands the operational environments for battery applications, from extreme cold to hot conditions, without significant performance degradation.

From a manufacturing perspective, LLZO offers potential simplification of battery design by functioning as both separator and electrolyte, potentially reducing component count and assembly complexity. Its chemical stability also contributes to longer shelf life and reduced capacity fade during storage.

Environmental considerations further enhance LLZO's appeal, as it eliminates the need for toxic and environmentally harmful organic solvents used in conventional electrolytes, aligning with global sustainability initiatives and potentially simplifying end-of-life recycling processes for battery systems.

Beyond safety, LLZO exhibits exceptional electrochemical stability against lithium metal anodes, enabling the development of batteries with lithium metal as the anode material. This configuration potentially delivers energy densities 2-3 times higher than conventional lithium-ion batteries, addressing range anxiety concerns in electric vehicles and extending operational times for portable electronics.

LLZO's wide electrochemical stability window (0-5V vs. Li/Li+) allows compatibility with high-voltage cathode materials, further enhancing energy density possibilities. Additionally, its high ionic conductivity at room temperature (typically 10^-4 to 10^-3 S/cm) approaches that of liquid electrolytes, overcoming a significant hurdle that has limited other solid electrolyte candidates.

The mechanical robustness of LLZO provides effective suppression of lithium dendrite growth, which has been a persistent challenge in battery technology. By physically blocking dendrite formation, LLZO electrolytes can significantly extend battery cycle life and maintain performance integrity over thousands of charge-discharge cycles.

Temperature stability represents another advantage, with LLZO maintaining consistent performance across a wider temperature range (-20°C to 100°C) than conventional systems. This characteristic expands the operational environments for battery applications, from extreme cold to hot conditions, without significant performance degradation.

From a manufacturing perspective, LLZO offers potential simplification of battery design by functioning as both separator and electrolyte, potentially reducing component count and assembly complexity. Its chemical stability also contributes to longer shelf life and reduced capacity fade during storage.

Environmental considerations further enhance LLZO's appeal, as it eliminates the need for toxic and environmentally harmful organic solvents used in conventional electrolytes, aligning with global sustainability initiatives and potentially simplifying end-of-life recycling processes for battery systems.

Manufacturing Scalability and Cost Analysis

The scalability of LLZO (Li7La3Zr2O12) manufacturing represents a critical challenge for the commercial viability of solid-state batteries. Current production methods for LLZO solid electrolytes primarily rely on laboratory-scale processes, including conventional solid-state reactions, sol-gel methods, and co-precipitation techniques. These approaches, while effective for research purposes, face significant barriers when transitioning to industrial-scale production.

Cost analysis reveals that raw material expenses constitute approximately 40-50% of total LLZO production costs. Lanthanum and zirconium precursors are particularly expensive components, with lithium compounds adding complexity due to their hygroscopic nature and handling requirements. The high-temperature sintering process (typically 1000-1200°C) necessary for LLZO crystallization further contributes to manufacturing expenses through substantial energy consumption and specialized equipment needs.

Production yield and quality consistency present additional challenges. Current manufacturing processes often result in variable grain sizes, density variations, and lithium loss during high-temperature processing. These inconsistencies directly impact the ionic conductivity and mechanical properties of LLZO, requiring stringent quality control measures that increase production costs and reduce throughput.

Several manufacturing innovations are being explored to address these challenges. Tape casting and roll-to-roll processing show promise for continuous LLZO sheet production, potentially reducing manufacturing costs by 30-40% compared to batch processes. Field-assisted sintering techniques (FAST) and spark plasma sintering (SPS) are demonstrating capability to lower sintering temperatures and times, improving energy efficiency while maintaining or enhancing electrolyte performance.

Economic modeling suggests that LLZO production costs need to decrease from current estimates of $700-1000/kg to below $100/kg to achieve cost parity with conventional lithium-ion batteries. This approximately 10-fold reduction represents a significant but potentially achievable target through process optimization and economies of scale.

Industry forecasts indicate that manufacturing capacity for LLZO and similar solid electrolytes will need to expand from current pilot-scale production (tens of tons annually) to thousands of tons annually by 2030 to meet projected demand. This scale-up will require substantial capital investment, estimated at $50-100 million per gigawatt-hour of battery production capacity.

Cost analysis reveals that raw material expenses constitute approximately 40-50% of total LLZO production costs. Lanthanum and zirconium precursors are particularly expensive components, with lithium compounds adding complexity due to their hygroscopic nature and handling requirements. The high-temperature sintering process (typically 1000-1200°C) necessary for LLZO crystallization further contributes to manufacturing expenses through substantial energy consumption and specialized equipment needs.

Production yield and quality consistency present additional challenges. Current manufacturing processes often result in variable grain sizes, density variations, and lithium loss during high-temperature processing. These inconsistencies directly impact the ionic conductivity and mechanical properties of LLZO, requiring stringent quality control measures that increase production costs and reduce throughput.

Several manufacturing innovations are being explored to address these challenges. Tape casting and roll-to-roll processing show promise for continuous LLZO sheet production, potentially reducing manufacturing costs by 30-40% compared to batch processes. Field-assisted sintering techniques (FAST) and spark plasma sintering (SPS) are demonstrating capability to lower sintering temperatures and times, improving energy efficiency while maintaining or enhancing electrolyte performance.

Economic modeling suggests that LLZO production costs need to decrease from current estimates of $700-1000/kg to below $100/kg to achieve cost parity with conventional lithium-ion batteries. This approximately 10-fold reduction represents a significant but potentially achievable target through process optimization and economies of scale.

Industry forecasts indicate that manufacturing capacity for LLZO and similar solid electrolytes will need to expand from current pilot-scale production (tens of tons annually) to thousands of tons annually by 2030 to meet projected demand. This scale-up will require substantial capital investment, estimated at $50-100 million per gigawatt-hour of battery production capacity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!