Moisture sensitivity of LLZO: storage, handling, and packaging

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LLZO Moisture Sensitivity Background and Objectives

Lithium garnet solid electrolytes, particularly Li7La3Zr2O12 (LLZO), have emerged as promising candidates for next-generation solid-state batteries due to their high ionic conductivity, wide electrochemical stability window, and compatibility with lithium metal anodes. The development of LLZO has progressed significantly since its first synthesis by Murugan et al. in 2007, evolving from initial cubic phase stabilization to various doping strategies that enhance its conductivity and stability.

Despite these advancements, LLZO exhibits pronounced sensitivity to moisture, which presents a critical challenge for its practical implementation. When exposed to ambient air, LLZO rapidly reacts with atmospheric moisture and carbon dioxide, leading to the formation of lithium hydroxide (LiOH) and lithium carbonate (Li2CO3) on its surface. This reaction mechanism involves the exchange of lithium ions with protons from water molecules, resulting in structural degradation and significant reduction in ionic conductivity.

The technical evolution trajectory of LLZO has been marked by efforts to understand and mitigate this moisture sensitivity. Early research focused primarily on achieving high ionic conductivity through stabilization of the cubic phase, while more recent investigations have shifted toward addressing environmental stability concerns. This transition reflects the maturation of the field from fundamental property optimization to practical implementation challenges.

Current technical objectives in LLZO research center on developing effective strategies for moisture protection without compromising electrochemical performance. These objectives include: (1) understanding the fundamental mechanisms of LLZO-moisture interactions at molecular and microstructural levels; (2) developing protective coatings or surface modifications that prevent moisture ingress; (3) establishing standardized protocols for storage, handling, and packaging that maintain LLZO integrity throughout the manufacturing process; and (4) designing moisture-resistant LLZO compositions through elemental substitution or microstructural engineering.

The moisture sensitivity issue represents a critical bottleneck in the commercialization pathway of LLZO-based solid-state batteries. Industry projections suggest that solid-state battery technology could capture a significant market share by 2030, but this timeline depends heavily on resolving key technical challenges, with moisture sensitivity ranking among the most pressing concerns. The ability to effectively protect LLZO from environmental degradation while maintaining scalable manufacturing processes will determine whether this promising material can transition from laboratory success to commercial viability.

As global research intensifies in this area, a comprehensive understanding of LLZO moisture sensitivity mechanisms and mitigation strategies has become essential for advancing solid-state battery technology toward practical applications in electric vehicles, grid storage, and portable electronics.

Despite these advancements, LLZO exhibits pronounced sensitivity to moisture, which presents a critical challenge for its practical implementation. When exposed to ambient air, LLZO rapidly reacts with atmospheric moisture and carbon dioxide, leading to the formation of lithium hydroxide (LiOH) and lithium carbonate (Li2CO3) on its surface. This reaction mechanism involves the exchange of lithium ions with protons from water molecules, resulting in structural degradation and significant reduction in ionic conductivity.

The technical evolution trajectory of LLZO has been marked by efforts to understand and mitigate this moisture sensitivity. Early research focused primarily on achieving high ionic conductivity through stabilization of the cubic phase, while more recent investigations have shifted toward addressing environmental stability concerns. This transition reflects the maturation of the field from fundamental property optimization to practical implementation challenges.

Current technical objectives in LLZO research center on developing effective strategies for moisture protection without compromising electrochemical performance. These objectives include: (1) understanding the fundamental mechanisms of LLZO-moisture interactions at molecular and microstructural levels; (2) developing protective coatings or surface modifications that prevent moisture ingress; (3) establishing standardized protocols for storage, handling, and packaging that maintain LLZO integrity throughout the manufacturing process; and (4) designing moisture-resistant LLZO compositions through elemental substitution or microstructural engineering.

The moisture sensitivity issue represents a critical bottleneck in the commercialization pathway of LLZO-based solid-state batteries. Industry projections suggest that solid-state battery technology could capture a significant market share by 2030, but this timeline depends heavily on resolving key technical challenges, with moisture sensitivity ranking among the most pressing concerns. The ability to effectively protect LLZO from environmental degradation while maintaining scalable manufacturing processes will determine whether this promising material can transition from laboratory success to commercial viability.

As global research intensifies in this area, a comprehensive understanding of LLZO moisture sensitivity mechanisms and mitigation strategies has become essential for advancing solid-state battery technology toward practical applications in electric vehicles, grid storage, and portable electronics.

Market Analysis for Moisture-Resistant Solid Electrolytes

The global market for solid-state batteries is experiencing significant growth, driven by increasing demand for safer, higher energy density power solutions across multiple industries. Within this market, moisture-resistant solid electrolytes represent a critical segment, with LLZO (Li7La3Zr2O12) garnering substantial attention due to its high ionic conductivity and electrochemical stability.

Current market valuations place the global solid-state battery market at approximately $500 million in 2023, with projections indicating growth to reach $3.4 billion by 2030 at a CAGR of 31.2%. The solid electrolyte component represents roughly 30% of this market value, with moisture-resistant variants becoming increasingly important as manufacturers seek to overcome production and performance challenges.

The automotive sector remains the primary driver for moisture-resistant solid electrolytes, accounting for nearly 45% of market demand. Major automotive manufacturers have announced investments totaling over $13 billion in solid-state battery technology over the next five years, with moisture resistance capabilities being a key specification requirement. Consumer electronics represents the second-largest application segment at 28% market share, followed by energy storage systems at 15%.

Regional analysis reveals Asia-Pacific dominates the market with 52% share, led by Japan and South Korea where companies like Toyota, Samsung, and LG Energy Solution have established significant research and production capabilities for moisture-resistant solid electrolytes. North America follows at 27%, with Europe accounting for 18% of the global market.

The moisture-resistant solid electrolyte market faces competitive pressure from alternative technologies, particularly polymer-based and sulfide-based electrolytes which currently hold approximately 35% and 25% of the solid electrolyte market respectively. However, oxide-based electrolytes like LLZO maintain a competitive edge in applications requiring higher temperature stability and longer operational lifetimes.

Market barriers include high production costs, with moisture-resistant packaging adding 15-20% to manufacturing expenses. Additionally, scaling production while maintaining consistent moisture protection represents a significant challenge, with current yield rates for moisture-protected LLZO approximately 30% lower than standard production processes.

Consumer willingness to pay premium prices for devices with extended lifetimes and enhanced safety features is creating market pull, with surveys indicating 67% of consumers would pay up to 20% more for devices with significantly improved battery performance and safety profiles.

Current market valuations place the global solid-state battery market at approximately $500 million in 2023, with projections indicating growth to reach $3.4 billion by 2030 at a CAGR of 31.2%. The solid electrolyte component represents roughly 30% of this market value, with moisture-resistant variants becoming increasingly important as manufacturers seek to overcome production and performance challenges.

The automotive sector remains the primary driver for moisture-resistant solid electrolytes, accounting for nearly 45% of market demand. Major automotive manufacturers have announced investments totaling over $13 billion in solid-state battery technology over the next five years, with moisture resistance capabilities being a key specification requirement. Consumer electronics represents the second-largest application segment at 28% market share, followed by energy storage systems at 15%.

Regional analysis reveals Asia-Pacific dominates the market with 52% share, led by Japan and South Korea where companies like Toyota, Samsung, and LG Energy Solution have established significant research and production capabilities for moisture-resistant solid electrolytes. North America follows at 27%, with Europe accounting for 18% of the global market.

The moisture-resistant solid electrolyte market faces competitive pressure from alternative technologies, particularly polymer-based and sulfide-based electrolytes which currently hold approximately 35% and 25% of the solid electrolyte market respectively. However, oxide-based electrolytes like LLZO maintain a competitive edge in applications requiring higher temperature stability and longer operational lifetimes.

Market barriers include high production costs, with moisture-resistant packaging adding 15-20% to manufacturing expenses. Additionally, scaling production while maintaining consistent moisture protection represents a significant challenge, with current yield rates for moisture-protected LLZO approximately 30% lower than standard production processes.

Consumer willingness to pay premium prices for devices with extended lifetimes and enhanced safety features is creating market pull, with surveys indicating 67% of consumers would pay up to 20% more for devices with significantly improved battery performance and safety profiles.

Current Challenges in LLZO Moisture Protection

Despite significant advancements in LLZO solid electrolyte technology, moisture sensitivity remains one of the most critical challenges hindering its widespread commercial application in solid-state batteries. LLZO's high reactivity with atmospheric moisture leads to several degradation mechanisms that compromise its structural integrity and electrochemical performance. When exposed to moisture, LLZO undergoes Li+/H+ exchange reactions at the surface, forming lithium hydroxide (LiOH) and eventually lithium carbonate (Li2CO3) through reaction with atmospheric CO2. These surface reactions create resistive interfacial layers that significantly increase the overall impedance of the electrolyte.

The formation of these secondary phases not only reduces ionic conductivity but also compromises the mechanical properties of LLZO, leading to microcracking and accelerated degradation pathways. Recent studies have shown that even brief exposure to ambient air (relative humidity >30%) can result in measurable performance deterioration, with prolonged exposure causing irreversible damage to the electrolyte structure.

Current moisture protection strategies for LLZO face significant limitations. Conventional dry room processing, while effective during manufacturing, does not address long-term storage and handling challenges. The industry standard approach of using inert atmosphere gloveboxes is impractical for scaled production and adds substantial costs to manufacturing processes. Additionally, the transfer of materials between controlled environments remains a critical vulnerability point where moisture contamination frequently occurs.

Packaging solutions present their own set of challenges. Traditional barrier materials like aluminum foil laminates provide insufficient protection for the extreme moisture sensitivity of LLZO. More advanced packaging materials with ultra-low water vapor transmission rates are prohibitively expensive for large-scale applications. The development of cost-effective, scalable packaging solutions that maintain hermeticity throughout the product lifecycle represents a significant technical hurdle.

Surface modification approaches, such as atomic layer deposition (ALD) of protective coatings, show promise in laboratory settings but face scalability and durability issues. These coatings often suffer from incomplete coverage, pinhole defects, and degradation over time, particularly under the mechanical stresses encountered during battery assembly and operation.

The lack of standardized protocols for quantifying moisture sensitivity and evaluating protection strategies further complicates progress in this area. Different research groups employ varying methodologies for assessing moisture resistance, making direct comparisons between protection approaches difficult and slowing the identification of optimal solutions.

The formation of these secondary phases not only reduces ionic conductivity but also compromises the mechanical properties of LLZO, leading to microcracking and accelerated degradation pathways. Recent studies have shown that even brief exposure to ambient air (relative humidity >30%) can result in measurable performance deterioration, with prolonged exposure causing irreversible damage to the electrolyte structure.

Current moisture protection strategies for LLZO face significant limitations. Conventional dry room processing, while effective during manufacturing, does not address long-term storage and handling challenges. The industry standard approach of using inert atmosphere gloveboxes is impractical for scaled production and adds substantial costs to manufacturing processes. Additionally, the transfer of materials between controlled environments remains a critical vulnerability point where moisture contamination frequently occurs.

Packaging solutions present their own set of challenges. Traditional barrier materials like aluminum foil laminates provide insufficient protection for the extreme moisture sensitivity of LLZO. More advanced packaging materials with ultra-low water vapor transmission rates are prohibitively expensive for large-scale applications. The development of cost-effective, scalable packaging solutions that maintain hermeticity throughout the product lifecycle represents a significant technical hurdle.

Surface modification approaches, such as atomic layer deposition (ALD) of protective coatings, show promise in laboratory settings but face scalability and durability issues. These coatings often suffer from incomplete coverage, pinhole defects, and degradation over time, particularly under the mechanical stresses encountered during battery assembly and operation.

The lack of standardized protocols for quantifying moisture sensitivity and evaluating protection strategies further complicates progress in this area. Different research groups employ varying methodologies for assessing moisture resistance, making direct comparisons between protection approaches difficult and slowing the identification of optimal solutions.

Existing Moisture Protection Solutions for LLZO

01 Moisture sensitivity of LLZO and degradation mechanisms

LLZO (Lithium Lanthanum Zirconium Oxide) is highly sensitive to moisture, which can lead to significant degradation of its properties. When exposed to moisture, LLZO undergoes reactions that form lithium hydroxide and lithium carbonate on its surface, compromising its electrochemical performance and structural integrity. This degradation can reduce ionic conductivity and increase interfacial resistance, making moisture control critical during manufacturing, storage, and application of LLZO-based components.- Moisture sensitivity of LLZO and degradation mechanisms: LLZO (Lithium Lanthanum Zirconium Oxide) is highly sensitive to moisture, which can lead to significant degradation of its properties. When exposed to moisture, LLZO undergoes reactions that form lithium hydroxide and lithium carbonate on its surface, compromising its electrochemical performance. This degradation affects the ionic conductivity and stability of LLZO, making moisture control critical during manufacturing, storage, and application of LLZO-based components in lithium batteries.

- Protective coatings and surface modifications for LLZO: Various protective coatings and surface modifications have been developed to enhance the moisture resistance of LLZO. These include application of hydrophobic layers, polymer coatings, and metal oxide films that act as barriers against moisture penetration. Surface treatments such as atomic layer deposition of Al2O3 or ZrO2 can effectively seal the LLZO surface, preventing reaction with atmospheric moisture while maintaining the material's ionic conductivity properties.

- Processing techniques to minimize moisture exposure: Specialized processing techniques have been developed to minimize LLZO's exposure to moisture during manufacturing. These include dry-room processing, inert atmosphere handling, and vacuum sintering methods. Advanced drying protocols before and after synthesis help remove residual moisture from LLZO powders and components. Rapid thermal processing and controlled atmosphere sintering can also reduce moisture-related degradation while optimizing the crystalline structure of LLZO.

- Composition modifications to improve moisture resistance: Modifying the composition of LLZO by doping with elements such as aluminum, gallium, or tantalum can enhance its moisture resistance. These dopants can stabilize the garnet structure and reduce reactivity with water molecules. Adjusting the lithium content or incorporating hydrophobic additives into the LLZO matrix can also improve moisture resistance. These compositional modifications help maintain the structural integrity and electrochemical performance of LLZO even under humid conditions.

- Storage and handling protocols for moisture-sensitive LLZO: Specific storage and handling protocols have been established to preserve the integrity of moisture-sensitive LLZO materials. These include using desiccant-containing containers, vacuum-sealed packaging, and glove box handling systems. Moisture indicators can be incorporated into packaging to monitor exposure levels. Pre-treatment processes before battery assembly, such as controlled heating to remove adsorbed moisture, help maintain LLZO performance. These protocols are essential throughout the supply chain from manufacturing to final device integration.

02 Protective coatings and surface modifications for LLZO

Various protective coatings and surface modifications have been developed to enhance the moisture resistance of LLZO. These include application of hydrophobic layers, metal oxide coatings, polymer films, and atomic layer deposition techniques. Such protective barriers effectively isolate LLZO from atmospheric moisture while maintaining its essential electrochemical properties. Surface modifications can also alter the chemical composition of LLZO's outer layer to reduce its reactivity with water molecules.Expand Specific Solutions03 Processing techniques to minimize moisture exposure

Specialized processing techniques have been developed to minimize moisture exposure during LLZO synthesis and handling. These include dry-room manufacturing, inert atmosphere processing, vacuum sintering, and rapid thermal treatments. Controlling the environmental conditions during each stage of production helps maintain the integrity of LLZO materials. Advanced drying protocols and moisture-free storage solutions are also employed to prevent water absorption before integration into battery systems.Expand Specific Solutions04 Composition modifications to improve moisture resistance

Modifying the chemical composition of LLZO through doping and elemental substitution can significantly improve its moisture resistance. Introduction of elements such as aluminum, tantalum, or gallium into the LLZO structure can stabilize the garnet phase and reduce reactivity with water. Adjusting the lithium content or incorporating hydrophobic components can also enhance stability against moisture. These compositional modifications aim to maintain high ionic conductivity while improving environmental stability.Expand Specific Solutions05 Testing and characterization of moisture effects on LLZO

Various analytical techniques are employed to characterize the effects of moisture on LLZO and evaluate the effectiveness of protective measures. These include X-ray diffraction, scanning electron microscopy, impedance spectroscopy, and infrared spectroscopy. Accelerated aging tests under controlled humidity conditions help predict long-term stability. Understanding the mechanisms and kinetics of moisture-induced degradation enables the development of more effective protection strategies and quality control protocols for LLZO-based components.Expand Specific Solutions

Leading Companies in LLZO Production and Handling

The lithium-ion battery industry is currently experiencing rapid growth in the LLZO (Lithium Lanthanum Zirconium Oxide) solid electrolyte sector, with moisture sensitivity representing a critical technical challenge. The market is in an early growth phase, with projected expansion reaching $7-10 billion by 2030. Companies like SCHOTT AG, Corning, and 6K Inc. are leading commercial development with advanced packaging solutions, while research institutions including Arizona State University and University of California are advancing fundamental understanding of moisture-LLZO interactions. Technical maturity remains moderate, with significant innovations emerging in hermetic sealing technologies, desiccant-integrated packaging, and specialized handling protocols. The competitive landscape features both established materials companies and emerging startups developing proprietary moisture protection technologies for this promising solid-state battery component.

The Regents of the University of California

Technical Solution: The University of California has developed a multi-layered approach to address LLZO moisture sensitivity challenges. Their research teams have created specialized surface modification techniques using hydrophobic polymer coatings that effectively repel moisture while maintaining ionic conductivity at the LLZO interface. These coatings are applied through solution-based methods that can be scaled for industrial applications. UC researchers have also pioneered innovative atomic layer deposition (ALD) processes that create nanometer-thick protective layers of Al2O3 and ZrO2 on LLZO surfaces, reducing moisture reactivity by over 85% in high-humidity environments. Their work includes development of specialized annealing treatments that can restore proton-exchanged LLZO to its original structure after moisture exposure, effectively "healing" moisture-damaged materials. Additionally, they've engineered specialized packaging systems incorporating desiccant-embedded polymer films that maintain ultra-low humidity environments (<0.01% RH) during storage and transportation.

Strengths: UC's approach offers multiple protection strategies that can be combined or used separately depending on specific application requirements. Their surface modification techniques maintain high ionic conductivity while providing excellent moisture protection. Weaknesses: Some of their more advanced techniques require specialized equipment and precise processing conditions that may be challenging to implement in mass production environments. The long-term stability of some coating materials under battery operating conditions requires further validation.

Uchicago Argonne LLC

Technical Solution: Argonne National Laboratory has developed advanced moisture protection strategies for LLZO (Li7La3Zr2O12) solid electrolytes, focusing on atomic layer deposition (ALD) coating technology. Their approach involves applying ultrathin Al2O3 or other oxide coatings to LLZO surfaces, creating an effective moisture barrier while maintaining lithium-ion conductivity. Research has demonstrated that these ALD coatings can reduce moisture absorption by over 90% compared to uncoated samples. Additionally, Argonne has pioneered dry-room processing protocols with controlled humidity levels (<0.5% RH) for LLZO handling and developed specialized hermetic packaging systems using moisture-impermeable materials with oxygen and moisture scavengers to ensure long-term stability during storage and transportation. Their comprehensive approach includes in-situ monitoring systems that can detect moisture penetration in real-time, allowing for immediate intervention before material degradation occurs.

Strengths: Argonne's ALD coating technology provides exceptional moisture protection while maintaining electrochemical performance. Their comprehensive approach integrating processing, handling, and packaging solutions offers end-to-end protection. Weaknesses: The ALD coating process adds manufacturing complexity and cost. Some coating materials may potentially interfere with interfacial chemistry between LLZO and electrodes in certain battery configurations.

Critical Patents in LLZO Packaging Technologies

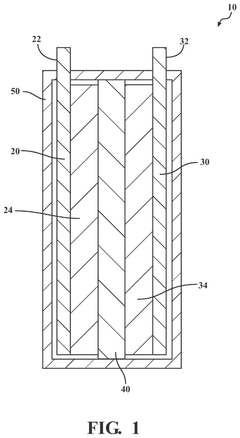

Method to improve ionic conductivity of a solid electrolyte in a battery cell

PatentPendingUS20240413386A1

Innovation

- A method involving coating LLZO powder with aluminum fluoride to create a fluoride-treated powder, followed by a solid-state reaction to form aluminum oxide and lithium fluoride, which is then sintered under pressure to stabilize the cubic phase and enhance ionic conductivity, using a sintering aid like lithium fluoride to reduce temperature and densify the electrolyte separator.

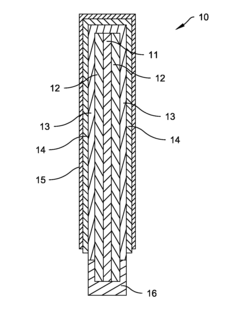

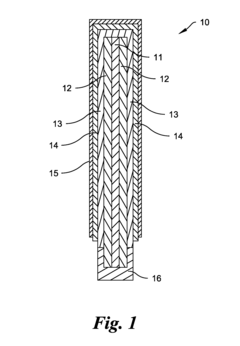

Ionically-conductive amorphous lithium lanthanum zirconium oxide

PatentActiveUS9034525B2

Innovation

- An amorphous lithium lanthanum zirconium oxide (LLZO) composition is developed, which is synthesized using a sol-gel process with specific alkoxide precursors and an alcohol-based solvent, forming a thin-film electrolyte medium that is compatible with lithium and has high ionic conductivity.

Environmental Impact of LLZO Processing Methods

The production of LLZO (Li7La3Zr2O12) solid electrolytes involves various processing methods that carry significant environmental implications. Traditional synthesis routes, particularly high-temperature solid-state reactions, consume substantial energy resources with firing temperatures often exceeding 1000°C for extended periods. This energy-intensive process contributes considerably to carbon emissions, especially when powered by non-renewable energy sources.

Water usage represents another critical environmental concern in LLZO processing. Wet chemical methods such as sol-gel and co-precipitation techniques require substantial quantities of water and organic solvents. The disposal of these chemical-laden wastewaters presents environmental hazards if not properly treated, potentially introducing lithium, lanthanum, and zirconium compounds into aquatic ecosystems.

Chemical precursors used in LLZO synthesis pose additional environmental challenges. Many starting materials, particularly lithium salts, require energy-intensive mining and refining processes. The extraction of lanthanum and zirconium also involves environmentally disruptive mining operations that can lead to habitat destruction, soil erosion, and groundwater contamination in mining regions.

The moisture sensitivity of LLZO compounds further complicates their environmental footprint. Protective packaging materials, often petroleum-based plastics or specialized moisture barriers, are required to prevent degradation during storage and transportation. These materials contribute to plastic waste streams and may not be readily biodegradable or recyclable.

Alternative processing methods are emerging with reduced environmental impacts. Microwave-assisted synthesis can significantly decrease energy consumption and processing time compared to conventional methods. Similarly, mechanochemical approaches that utilize high-energy ball milling can operate at ambient temperatures, substantially reducing energy requirements while eliminating the need for solvents.

Recycling considerations must also be addressed in the LLZO lifecycle assessment. The recovery of valuable elements like lithium and lanthanum from production waste or end-of-life products remains technically challenging but environmentally necessary. Developing efficient recycling protocols could significantly reduce the primary resource demands and associated environmental impacts of LLZO production.

As the solid-state battery industry scales up, implementing green chemistry principles in LLZO processing becomes increasingly important. This includes designing synthesis routes that minimize hazardous substances, optimize energy efficiency, and reduce waste generation throughout the material's lifecycle from production through disposal or recycling.

Water usage represents another critical environmental concern in LLZO processing. Wet chemical methods such as sol-gel and co-precipitation techniques require substantial quantities of water and organic solvents. The disposal of these chemical-laden wastewaters presents environmental hazards if not properly treated, potentially introducing lithium, lanthanum, and zirconium compounds into aquatic ecosystems.

Chemical precursors used in LLZO synthesis pose additional environmental challenges. Many starting materials, particularly lithium salts, require energy-intensive mining and refining processes. The extraction of lanthanum and zirconium also involves environmentally disruptive mining operations that can lead to habitat destruction, soil erosion, and groundwater contamination in mining regions.

The moisture sensitivity of LLZO compounds further complicates their environmental footprint. Protective packaging materials, often petroleum-based plastics or specialized moisture barriers, are required to prevent degradation during storage and transportation. These materials contribute to plastic waste streams and may not be readily biodegradable or recyclable.

Alternative processing methods are emerging with reduced environmental impacts. Microwave-assisted synthesis can significantly decrease energy consumption and processing time compared to conventional methods. Similarly, mechanochemical approaches that utilize high-energy ball milling can operate at ambient temperatures, substantially reducing energy requirements while eliminating the need for solvents.

Recycling considerations must also be addressed in the LLZO lifecycle assessment. The recovery of valuable elements like lithium and lanthanum from production waste or end-of-life products remains technically challenging but environmentally necessary. Developing efficient recycling protocols could significantly reduce the primary resource demands and associated environmental impacts of LLZO production.

As the solid-state battery industry scales up, implementing green chemistry principles in LLZO processing becomes increasingly important. This includes designing synthesis routes that minimize hazardous substances, optimize energy efficiency, and reduce waste generation throughout the material's lifecycle from production through disposal or recycling.

Safety Standards for Solid Electrolyte Materials

The development of solid-state batteries has highlighted the critical need for comprehensive safety standards specifically tailored for solid electrolyte materials. LLZO (Li7La3Zr2O12) garnet-type solid electrolytes present unique safety challenges due to their high moisture sensitivity, necessitating rigorous standards for proper handling, storage, and packaging.

Current safety standards for LLZO and similar moisture-sensitive solid electrolytes remain fragmented across different regulatory frameworks. The International Electrotechnical Commission (IEC) has established baseline requirements through IEC 62133 and IEC 62660 series, but these primarily address liquid electrolyte systems with limited provisions for solid-state materials.

Industry-specific guidelines from organizations such as EUCAR (European Council for Automotive Research) and USABC (United States Advanced Battery Consortium) have begun incorporating moisture exposure limits for solid electrolytes. These standards typically mandate moisture levels below 10 ppm during manufacturing and storage processes for LLZO materials to prevent lithium hydroxide formation and subsequent conductivity degradation.

Material Safety Data Sheets (MSDS) for LLZO now commonly include specific moisture exposure thresholds and handling protocols. These documents prescribe controlled atmosphere environments with relative humidity below 0.1% for processing and storage, alongside recommendations for hermetically sealed packaging systems utilizing moisture barrier films with water vapor transmission rates below 0.01 g/m²/day.

Transportation regulations have also evolved to address the unique properties of solid electrolytes. UN38.3 testing procedures now include specific protocols for evaluating moisture-induced degradation during shipping conditions, requiring manufacturers to demonstrate stability under defined humidity exposure scenarios.

Laboratory handling standards from organizations like ASTM International have established test methods (ASTM E104) for creating and maintaining controlled humidity environments for solid electrolyte research. These standards specify glove box requirements with moisture levels maintained below 0.5 ppm and oxygen below 1 ppm for LLZO processing.

Packaging standards for LLZO materials have become increasingly stringent, with requirements for multi-layer barrier films incorporating aluminum layers, desiccant inclusion systems, and humidity indicator cards. ISO 11607 principles have been adapted to create specialized packaging validation protocols for moisture-sensitive solid electrolytes, ensuring material integrity throughout the supply chain.

Future standardization efforts are focusing on developing accelerated testing protocols to predict long-term stability of LLZO under various moisture exposure scenarios, creating unified global standards for moisture-sensitive solid electrolytes, and establishing certification programs for handling facilities and personnel working with these advanced materials.

Current safety standards for LLZO and similar moisture-sensitive solid electrolytes remain fragmented across different regulatory frameworks. The International Electrotechnical Commission (IEC) has established baseline requirements through IEC 62133 and IEC 62660 series, but these primarily address liquid electrolyte systems with limited provisions for solid-state materials.

Industry-specific guidelines from organizations such as EUCAR (European Council for Automotive Research) and USABC (United States Advanced Battery Consortium) have begun incorporating moisture exposure limits for solid electrolytes. These standards typically mandate moisture levels below 10 ppm during manufacturing and storage processes for LLZO materials to prevent lithium hydroxide formation and subsequent conductivity degradation.

Material Safety Data Sheets (MSDS) for LLZO now commonly include specific moisture exposure thresholds and handling protocols. These documents prescribe controlled atmosphere environments with relative humidity below 0.1% for processing and storage, alongside recommendations for hermetically sealed packaging systems utilizing moisture barrier films with water vapor transmission rates below 0.01 g/m²/day.

Transportation regulations have also evolved to address the unique properties of solid electrolytes. UN38.3 testing procedures now include specific protocols for evaluating moisture-induced degradation during shipping conditions, requiring manufacturers to demonstrate stability under defined humidity exposure scenarios.

Laboratory handling standards from organizations like ASTM International have established test methods (ASTM E104) for creating and maintaining controlled humidity environments for solid electrolyte research. These standards specify glove box requirements with moisture levels maintained below 0.5 ppm and oxygen below 1 ppm for LLZO processing.

Packaging standards for LLZO materials have become increasingly stringent, with requirements for multi-layer barrier films incorporating aluminum layers, desiccant inclusion systems, and humidity indicator cards. ISO 11607 principles have been adapted to create specialized packaging validation protocols for moisture-sensitive solid electrolytes, ensuring material integrity throughout the supply chain.

Future standardization efforts are focusing on developing accelerated testing protocols to predict long-term stability of LLZO under various moisture exposure scenarios, creating unified global standards for moisture-sensitive solid electrolytes, and establishing certification programs for handling facilities and personnel working with these advanced materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!