Reliability tests for LLZO cells: thermal abuse and shorting

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LLZO Solid Electrolyte Background and Testing Objectives

Lithium garnet-type solid electrolytes, particularly Li7La3Zr2O12 (LLZO), have emerged as promising candidates for next-generation solid-state batteries due to their high ionic conductivity, wide electrochemical stability window, and chemical stability against lithium metal. The development of LLZO began in 2007 when Murugan et al. first reported its potential as a solid electrolyte, marking a significant milestone in solid-state battery technology. Since then, research has intensified to optimize its properties and address various challenges associated with its implementation in practical battery systems.

The evolution of LLZO technology has followed several key trends, including compositional modifications through doping strategies to stabilize the highly conductive cubic phase, development of various synthesis methods to control microstructure and grain boundaries, and interface engineering to improve contact with electrodes. These advancements have progressively enhanced the ionic conductivity from initial values of 10^-4 S/cm to current achievements approaching 10^-3 S/cm at room temperature.

Despite these improvements, reliability concerns remain a critical barrier to commercial adoption of LLZO-based solid-state batteries. Thermal abuse and internal shorting represent two fundamental challenges that must be addressed to ensure safe and long-lasting battery performance. Thermal abuse testing evaluates how LLZO cells respond to extreme temperature conditions, which is crucial for understanding safety margins and failure mechanisms. Internal shorting tests assess the electrolyte's ability to prevent dendrite formation and propagation, which can lead to catastrophic battery failure.

The primary objective of reliability testing for LLZO cells is to establish standardized protocols that can accurately predict long-term performance and safety under various operating conditions. These tests aim to quantify the thermal stability limits of LLZO electrolytes, evaluate their mechanical integrity during thermal cycling, and assess their resistance to lithium dendrite penetration under different current densities and pressure conditions.

Additionally, testing objectives include understanding the correlation between material properties (such as grain size, relative density, and dopant concentration) and reliability metrics. This knowledge is essential for optimizing LLZO compositions and microstructures to enhance overall battery performance and safety. The development of accelerated testing methodologies is also crucial to efficiently evaluate the lifetime reliability of LLZO cells without requiring years of real-time testing.

Ultimately, these reliability tests seek to bridge the gap between laboratory demonstrations and commercial viability by providing comprehensive data on failure modes, safety margins, and performance limitations. The results will guide further material development efforts and inform the design of robust battery systems that can meet the demanding requirements of applications ranging from electric vehicles to grid-scale energy storage.

The evolution of LLZO technology has followed several key trends, including compositional modifications through doping strategies to stabilize the highly conductive cubic phase, development of various synthesis methods to control microstructure and grain boundaries, and interface engineering to improve contact with electrodes. These advancements have progressively enhanced the ionic conductivity from initial values of 10^-4 S/cm to current achievements approaching 10^-3 S/cm at room temperature.

Despite these improvements, reliability concerns remain a critical barrier to commercial adoption of LLZO-based solid-state batteries. Thermal abuse and internal shorting represent two fundamental challenges that must be addressed to ensure safe and long-lasting battery performance. Thermal abuse testing evaluates how LLZO cells respond to extreme temperature conditions, which is crucial for understanding safety margins and failure mechanisms. Internal shorting tests assess the electrolyte's ability to prevent dendrite formation and propagation, which can lead to catastrophic battery failure.

The primary objective of reliability testing for LLZO cells is to establish standardized protocols that can accurately predict long-term performance and safety under various operating conditions. These tests aim to quantify the thermal stability limits of LLZO electrolytes, evaluate their mechanical integrity during thermal cycling, and assess their resistance to lithium dendrite penetration under different current densities and pressure conditions.

Additionally, testing objectives include understanding the correlation between material properties (such as grain size, relative density, and dopant concentration) and reliability metrics. This knowledge is essential for optimizing LLZO compositions and microstructures to enhance overall battery performance and safety. The development of accelerated testing methodologies is also crucial to efficiently evaluate the lifetime reliability of LLZO cells without requiring years of real-time testing.

Ultimately, these reliability tests seek to bridge the gap between laboratory demonstrations and commercial viability by providing comprehensive data on failure modes, safety margins, and performance limitations. The results will guide further material development efforts and inform the design of robust battery systems that can meet the demanding requirements of applications ranging from electric vehicles to grid-scale energy storage.

Market Analysis for LLZO-based Solid-State Batteries

The global market for solid-state batteries, particularly those utilizing LLZO (Lithium Lanthanum Zirconate) as a solid electrolyte, is experiencing significant growth driven by increasing demand for safer and higher energy density energy storage solutions. Current market projections indicate that the solid-state battery market could reach $8 billion by 2026, with a compound annual growth rate exceeding 34% between 2021 and 2026.

LLZO-based solid-state batteries are positioned to capture a substantial portion of this market due to their superior thermal stability and potential for preventing thermal runaway incidents that plague conventional lithium-ion batteries. The automotive sector represents the largest potential market for LLZO technology, with major manufacturers including Toyota, BMW, and Volkswagen investing heavily in solid-state battery development programs.

Consumer electronics manufacturers are also showing increased interest in LLZO technology, driven by demands for devices with longer battery life, faster charging capabilities, and enhanced safety profiles. This segment is expected to be an early adopter of solid-state battery technology, serving as a proving ground before wider automotive implementation.

Market research indicates that reliability concerns, particularly regarding thermal abuse resistance and short-circuit prevention, remain key barriers to widespread commercial adoption. End-users across sectors consistently rank safety and reliability as top priorities when considering next-generation battery technologies, creating a clear market pull for solutions that address these specific challenges.

Regional analysis shows Asia-Pacific leading the market development, with Japan and South Korea hosting the most advanced research and manufacturing capabilities for LLZO-based batteries. China is rapidly expanding its presence in this space through substantial government investment in solid-state battery technology as part of its strategic industrial policies.

North American and European markets are characterized by strong research activities and strategic partnerships between automotive manufacturers and battery technology developers. These regions are particularly focused on establishing domestic supply chains for critical battery materials and technologies.

Market surveys reveal that consumers are willing to pay a premium of 15-20% for devices featuring solid-state batteries with proven safety advantages. This price tolerance creates a viable entry point for LLZO technology despite its currently higher manufacturing costs compared to conventional lithium-ion batteries.

The energy storage system (ESS) sector represents an emerging opportunity for LLZO-based batteries, particularly in applications where safety concerns are paramount, such as residential storage systems and grid-scale installations in densely populated areas.

LLZO-based solid-state batteries are positioned to capture a substantial portion of this market due to their superior thermal stability and potential for preventing thermal runaway incidents that plague conventional lithium-ion batteries. The automotive sector represents the largest potential market for LLZO technology, with major manufacturers including Toyota, BMW, and Volkswagen investing heavily in solid-state battery development programs.

Consumer electronics manufacturers are also showing increased interest in LLZO technology, driven by demands for devices with longer battery life, faster charging capabilities, and enhanced safety profiles. This segment is expected to be an early adopter of solid-state battery technology, serving as a proving ground before wider automotive implementation.

Market research indicates that reliability concerns, particularly regarding thermal abuse resistance and short-circuit prevention, remain key barriers to widespread commercial adoption. End-users across sectors consistently rank safety and reliability as top priorities when considering next-generation battery technologies, creating a clear market pull for solutions that address these specific challenges.

Regional analysis shows Asia-Pacific leading the market development, with Japan and South Korea hosting the most advanced research and manufacturing capabilities for LLZO-based batteries. China is rapidly expanding its presence in this space through substantial government investment in solid-state battery technology as part of its strategic industrial policies.

North American and European markets are characterized by strong research activities and strategic partnerships between automotive manufacturers and battery technology developers. These regions are particularly focused on establishing domestic supply chains for critical battery materials and technologies.

Market surveys reveal that consumers are willing to pay a premium of 15-20% for devices featuring solid-state batteries with proven safety advantages. This price tolerance creates a viable entry point for LLZO technology despite its currently higher manufacturing costs compared to conventional lithium-ion batteries.

The energy storage system (ESS) sector represents an emerging opportunity for LLZO-based batteries, particularly in applications where safety concerns are paramount, such as residential storage systems and grid-scale installations in densely populated areas.

Current Challenges in LLZO Cell Reliability Testing

Despite significant advancements in LLZO solid-state electrolyte technology, reliability testing for LLZO cells faces numerous challenges that impede their commercial viability. The current testing protocols for thermal abuse and shorting scenarios remain inadequate and inconsistent across the industry, creating barriers to standardization and mass production.

One primary challenge is the lack of standardized testing methodologies specifically designed for solid-state batteries. Most existing protocols were developed for conventional lithium-ion batteries with liquid electrolytes, which exhibit fundamentally different failure mechanisms. This misalignment results in either overly conservative or dangerously inadequate safety assessments for LLZO cells.

The complex interfacial behavior between LLZO and electrode materials presents another significant testing challenge. During thermal abuse testing, the dynamic changes at these interfaces are difficult to monitor in real-time, leading to incomplete understanding of failure progression. Current analytical techniques struggle to capture the rapid phase transformations and chemical reactions occurring at elevated temperatures.

Shorting tests for LLZO cells face unique difficulties due to the material's inherent properties. Unlike liquid electrolytes that typically fail catastrophically upon internal short circuit, LLZO may develop micro-cracks that propagate gradually before complete failure. These subtle degradation pathways are challenging to detect with conventional testing equipment, requiring sophisticated in-situ characterization techniques that are not widely available.

Scale-up issues further complicate reliability testing. Laboratory-scale tests often fail to predict behavior in full-sized commercial cells, as thermal gradients, mechanical stresses, and electrochemical phenomena manifest differently at larger dimensions. This scaling discrepancy creates uncertainty in translating test results to real-world performance predictions.

The time-dependent nature of LLZO degradation mechanisms poses additional testing challenges. Accelerated aging protocols that accurately reflect long-term reliability remain underdeveloped, with limited correlation between accelerated tests and actual field performance. This temporal disconnect hampers accurate lifetime predictions for LLZO-based energy storage systems.

Environmental sensitivity during testing represents another obstacle. LLZO's reactivity with atmospheric moisture and carbon dioxide means that testing conditions must be precisely controlled to avoid introducing external variables that could skew results. Many testing facilities lack the specialized equipment needed to maintain such controlled environments throughout extended test cycles.

Finally, there exists a significant gap between academic research testing and industry requirements. While researchers focus on fundamental material properties, manufacturers require practical metrics related to manufacturability, cost, and compliance with regulatory standards. Bridging this divide requires collaborative development of testing frameworks that satisfy both scientific rigor and commercial relevance.

One primary challenge is the lack of standardized testing methodologies specifically designed for solid-state batteries. Most existing protocols were developed for conventional lithium-ion batteries with liquid electrolytes, which exhibit fundamentally different failure mechanisms. This misalignment results in either overly conservative or dangerously inadequate safety assessments for LLZO cells.

The complex interfacial behavior between LLZO and electrode materials presents another significant testing challenge. During thermal abuse testing, the dynamic changes at these interfaces are difficult to monitor in real-time, leading to incomplete understanding of failure progression. Current analytical techniques struggle to capture the rapid phase transformations and chemical reactions occurring at elevated temperatures.

Shorting tests for LLZO cells face unique difficulties due to the material's inherent properties. Unlike liquid electrolytes that typically fail catastrophically upon internal short circuit, LLZO may develop micro-cracks that propagate gradually before complete failure. These subtle degradation pathways are challenging to detect with conventional testing equipment, requiring sophisticated in-situ characterization techniques that are not widely available.

Scale-up issues further complicate reliability testing. Laboratory-scale tests often fail to predict behavior in full-sized commercial cells, as thermal gradients, mechanical stresses, and electrochemical phenomena manifest differently at larger dimensions. This scaling discrepancy creates uncertainty in translating test results to real-world performance predictions.

The time-dependent nature of LLZO degradation mechanisms poses additional testing challenges. Accelerated aging protocols that accurately reflect long-term reliability remain underdeveloped, with limited correlation between accelerated tests and actual field performance. This temporal disconnect hampers accurate lifetime predictions for LLZO-based energy storage systems.

Environmental sensitivity during testing represents another obstacle. LLZO's reactivity with atmospheric moisture and carbon dioxide means that testing conditions must be precisely controlled to avoid introducing external variables that could skew results. Many testing facilities lack the specialized equipment needed to maintain such controlled environments throughout extended test cycles.

Finally, there exists a significant gap between academic research testing and industry requirements. While researchers focus on fundamental material properties, manufacturers require practical metrics related to manufacturability, cost, and compliance with regulatory standards. Bridging this divide requires collaborative development of testing frameworks that satisfy both scientific rigor and commercial relevance.

Established Protocols for LLZO Thermal and Short Circuit Testing

01 LLZO solid electrolyte composition and structure

Li7La3Zr2O12 (LLZO) is a promising solid electrolyte material for all-solid-state lithium batteries due to its high ionic conductivity and stability against lithium metal. The reliability of LLZO cells can be improved by optimizing the composition and structure of the electrolyte. This includes doping with elements like Al, Ga, or Ta to stabilize the cubic phase, controlling grain boundaries, and ensuring proper densification during sintering to minimize porosity and enhance mechanical properties.- LLZO solid electrolyte composition and structure: Lithium lanthanum zirconate (LLZO) solid electrolytes can be optimized through specific compositions and structural modifications to enhance reliability in battery cells. Various dopants and additives can be incorporated to stabilize the cubic phase of LLZO, which exhibits higher ionic conductivity. The grain boundary structure and crystallinity of LLZO also play crucial roles in determining the overall performance and reliability of the electrolyte in solid-state batteries.

- Interface engineering for LLZO-based cells: The interface between LLZO solid electrolytes and electrodes is critical for cell reliability. Engineering approaches to improve these interfaces include surface modifications, buffer layers, and specialized coatings that enhance adhesion and reduce interfacial resistance. These techniques help mitigate issues such as lithium dendrite formation and chemical instability at the interfaces, which are major factors affecting the long-term reliability and cycle life of LLZO-based solid-state batteries.

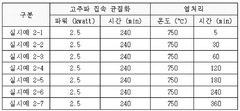

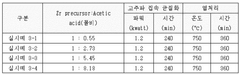

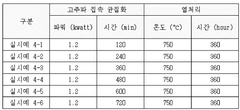

- Manufacturing processes for reliable LLZO cells: Specialized manufacturing techniques are essential for producing reliable LLZO-based cells. These include optimized sintering processes, precise temperature control during fabrication, and advanced assembly methods that minimize contamination and defects. The manufacturing approach significantly impacts the density, uniformity, and mechanical properties of LLZO electrolytes, which directly influence cell reliability and performance under various operating conditions.

- Testing and evaluation methods for LLZO cell reliability: Comprehensive testing protocols are crucial for evaluating the reliability of LLZO-based cells. These include accelerated aging tests, electrochemical impedance spectroscopy, mechanical stress testing, and thermal cycling. Advanced characterization techniques help identify failure mechanisms and degradation pathways in LLZO electrolytes, enabling the development of more reliable solid-state battery systems with improved performance predictions and lifetime estimations.

- Environmental and operational factors affecting LLZO reliability: The reliability of LLZO-based cells is significantly influenced by environmental and operational conditions. Factors such as temperature fluctuations, humidity exposure, mechanical stress, and cycling rates can impact the long-term stability and performance of these cells. Understanding these factors helps in designing more robust LLZO-based battery systems with enhanced reliability under real-world operating conditions and various application scenarios.

02 Interface engineering for LLZO-based batteries

The interface between LLZO solid electrolyte and electrodes is critical for cell reliability. Poor interfacial contact leads to high resistance and lithium dendrite growth. Interface engineering techniques include surface modification of LLZO with thin buffer layers, controlling surface roughness, applying pressure during cell assembly, and introducing interlayers to improve wettability and reduce interfacial resistance. These approaches enhance the electrochemical stability and cycling performance of LLZO-based solid-state batteries.Expand Specific Solutions03 Testing and characterization methods for LLZO reliability

Various testing and characterization methods are employed to evaluate the reliability of LLZO cells. These include electrochemical impedance spectroscopy to monitor interfacial resistance changes, long-term cycling tests to assess capacity retention, temperature-dependent performance tests, mechanical strength measurements, and post-mortem analysis techniques. Advanced imaging methods like SEM and TEM help identify failure mechanisms such as crack formation, dendrite penetration, and interfacial degradation, enabling the development of more reliable LLZO-based batteries.Expand Specific Solutions04 Manufacturing processes for reliable LLZO cells

The manufacturing processes significantly impact the reliability of LLZO cells. Key aspects include powder synthesis methods, sintering conditions, atmosphere control during high-temperature processing, and cell assembly techniques. Advanced manufacturing approaches such as tape casting, 3D printing, and cold sintering can produce LLZO electrolytes with improved homogeneity and reduced defects. Controlling moisture exposure during processing and storage is also crucial as LLZO is sensitive to humidity, which can lead to lithium carbonate formation on the surface and degraded performance.Expand Specific Solutions05 System-level reliability enhancements for LLZO batteries

System-level approaches to enhance LLZO cell reliability include advanced battery management systems that monitor cell parameters and prevent conditions leading to failure, thermal management strategies to maintain optimal operating temperatures, mechanical design considerations to accommodate volume changes during cycling, and protective encapsulation to prevent moisture ingress. Additionally, hybrid electrolyte designs that combine LLZO with polymer or liquid electrolyte components can improve interfacial contact while maintaining the safety benefits of solid-state systems.Expand Specific Solutions

Leading Organizations in LLZO Cell Development

The lithium-lanthanum-zirconium-oxide (LLZO) cell reliability testing market is in its growth phase, with increasing demand driven by the expanding electric vehicle and energy storage sectors. The market is characterized by a mix of established players and emerging specialists focusing on thermal abuse and shorting tests. Leading companies like Samsung Electronics, Samsung SDI, and LG Energy Solution are investing heavily in LLZO technology, while CATL and Huawei are rapidly advancing their capabilities. Academic-industry partnerships with institutions like MIT and Beijing Institute of Technology are accelerating innovation. The technology is approaching commercial maturity, with automotive manufacturers like BMW and battery specialists such as Electrochem Solutions developing standardized testing protocols to address safety concerns that remain critical for widespread adoption.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has engineered a proprietary reliability testing framework for LLZO solid electrolyte cells that focuses on both thermal abuse and shorting scenarios. Their approach combines traditional battery safety tests with LLZO-specific protocols that address the unique failure modes of solid-state systems. For thermal abuse testing, CATL employs gradient heating chambers that can precisely control temperature ramps from -40°C to 800°C while simultaneously monitoring multiple cells. Their shorting test methodology includes both mechanical integrity evaluation (using controlled pressure application) and electrochemical shorting simulation through localized current density manipulation. CATL has developed specialized fixtures that maintain uniform pressure distribution across the solid electrolyte during testing, addressing a key challenge in LLZO cell evaluation. Their testing protocol also incorporates long-duration cycling under thermal stress to evaluate dendrite formation potential through the LLZO layer over extended periods.

Strengths: Extensive manufacturing expertise allows for rapid translation of test results into production improvements; large-scale testing capabilities enable statistical significance in reliability data. Weaknesses: Testing methodology may be optimized for high-volume production rather than fundamental understanding of failure mechanisms; potential gaps in evaluating very long-term degradation modes.

Robert Bosch GmbH

Technical Solution: Bosch has developed a comprehensive reliability testing framework for LLZO-based solid-state batteries that bridges laboratory research and automotive application requirements. Their approach includes accelerated aging protocols that combine thermal cycling (-40°C to 200°C) with mechanical stress application to evaluate LLZO electrolyte integrity under conditions simulating vehicle operation. For thermal abuse testing, Bosch employs custom calorimetry systems that can precisely measure heat generation during controlled heating while simultaneously monitoring cell expansion and gas evolution. Their shorting test methodology incorporates both external short circuit evaluation and internal short simulation using specialized pressure fixtures that can create controlled mechanical deformation of the cell stack. Bosch has also implemented advanced non-destructive testing techniques including ultrasonic scanning and thermography to map defect formation in LLZO layers during reliability testing, providing spatial resolution of degradation processes before catastrophic failure occurs.

Strengths: Testing protocols directly aligned with automotive qualification requirements; strong focus on practical implementation and manufacturability. Weaknesses: May emphasize standardized testing over exploration of novel failure modes; conservative approach could potentially overlook emerging degradation mechanisms specific to new LLZO formulations.

Critical Technical Innovations in LLZO Cell Safety Assessment

Lithium lanthanum zirconium oxide solid electrolyte prepared using high-frequency focused homogenization synthesis method, and preparation method therefor

PatentWO2025075419A1

Innovation

- The development of a lithium lanthanum zirconium oxide (LLZO) solid electrolyte with a cubic normal structure, achieved through homogeneous synthesis in a high-frequency furnace, which enhances ion conductivity and stability while eliminating the risks associated with liquid electrolytes.

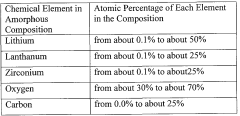

Ionically-conductive amorphous lithium lanthanum zirconium oxide

PatentWO2012018831A1

Innovation

- An amorphous lithium lanthanum zirconium oxide (LLZO) composition is developed as a non-aqueous, non-liquid, ionically-conductive electrolyte medium, synthesized through a sol-gel process using alkoxides in an alcohol-based solvent, which is compatible with lithium and can be manufactured in thin-film configurations, preventing dendritic growth and ensuring safety.

Safety Standards and Certification Requirements

The safety standards and certification requirements for LLZO (Li7La3Zr2O12) solid-state batteries represent a critical framework for ensuring these emerging energy storage technologies can be safely deployed in commercial applications. Current regulatory landscapes for lithium-ion batteries, such as UL 1642, IEC 62133, and UN 38.3, provide baseline requirements but require significant adaptation to address the unique characteristics and failure modes of solid electrolyte systems.

For LLZO cells specifically, thermal abuse testing protocols must be modified to account for the different thermal runaway mechanisms compared to conventional liquid electrolyte systems. While LLZO offers inherent safety advantages through elimination of flammable components, standardized testing must still verify performance under extreme temperature conditions (typically -40°C to 85°C for consumer electronics, and up to 125°C for automotive applications). The current IEC 62660-2 and SAE J2464 standards for abuse testing require adaptation to properly evaluate LLZO's unique thermal stability characteristics.

Short-circuit testing represents another area requiring specialized certification approaches. Unlike liquid electrolyte cells where internal shorts can rapidly propagate, LLZO cells exhibit different failure modes during shorting events. Testing standards must evaluate both external short resistance and internal short propagation mechanisms specific to ceramic electrolytes, including potential crack formation pathways and interfacial degradation processes.

The automotive industry, through standards like ISO 6469 and UNECE R100, imposes particularly stringent requirements that LLZO cells must meet for vehicle integration. These include mechanical integrity tests that must be adapted to account for the brittle nature of ceramic electrolytes under crash conditions. Certification bodies including UL, TÜV, and various national laboratories are currently developing specialized testing protocols for solid-state batteries that address these unique characteristics.

Emerging standards specifically targeting solid-state batteries include the work by IEC Technical Committee 21 on "Secondary cells and batteries," which is developing dedicated safety requirements for solid-state technologies. Additionally, the SAE International Battery Standards Committee is formulating guidelines specifically addressing thermal abuse and shorting scenarios in ceramic electrolyte systems like LLZO.

Manufacturers pursuing LLZO cell commercialization must navigate this evolving regulatory landscape while demonstrating compliance with both established and emerging standards. This requires comprehensive testing regimes that validate performance across multiple abuse scenarios, including thermal cycling, mechanical stress, electrical abuse, and environmental exposure tests tailored to the unique properties of LLZO materials.

For LLZO cells specifically, thermal abuse testing protocols must be modified to account for the different thermal runaway mechanisms compared to conventional liquid electrolyte systems. While LLZO offers inherent safety advantages through elimination of flammable components, standardized testing must still verify performance under extreme temperature conditions (typically -40°C to 85°C for consumer electronics, and up to 125°C for automotive applications). The current IEC 62660-2 and SAE J2464 standards for abuse testing require adaptation to properly evaluate LLZO's unique thermal stability characteristics.

Short-circuit testing represents another area requiring specialized certification approaches. Unlike liquid electrolyte cells where internal shorts can rapidly propagate, LLZO cells exhibit different failure modes during shorting events. Testing standards must evaluate both external short resistance and internal short propagation mechanisms specific to ceramic electrolytes, including potential crack formation pathways and interfacial degradation processes.

The automotive industry, through standards like ISO 6469 and UNECE R100, imposes particularly stringent requirements that LLZO cells must meet for vehicle integration. These include mechanical integrity tests that must be adapted to account for the brittle nature of ceramic electrolytes under crash conditions. Certification bodies including UL, TÜV, and various national laboratories are currently developing specialized testing protocols for solid-state batteries that address these unique characteristics.

Emerging standards specifically targeting solid-state batteries include the work by IEC Technical Committee 21 on "Secondary cells and batteries," which is developing dedicated safety requirements for solid-state technologies. Additionally, the SAE International Battery Standards Committee is formulating guidelines specifically addressing thermal abuse and shorting scenarios in ceramic electrolyte systems like LLZO.

Manufacturers pursuing LLZO cell commercialization must navigate this evolving regulatory landscape while demonstrating compliance with both established and emerging standards. This requires comprehensive testing regimes that validate performance across multiple abuse scenarios, including thermal cycling, mechanical stress, electrical abuse, and environmental exposure tests tailored to the unique properties of LLZO materials.

Failure Mode Analysis and Mitigation Strategies

The comprehensive analysis of LLZO solid-state battery failure modes reveals several critical vulnerabilities. Thermal runaway represents the most severe failure mechanism, typically triggered when cell temperatures exceed 150°C, causing electrolyte decomposition and potential oxygen release from the LLZO structure. This can initiate catastrophic chain reactions, particularly in the presence of lithium metal anodes. Mechanical stress-induced failures constitute another significant concern, as LLZO's brittle ceramic nature makes it susceptible to cracking under physical deformation, thermal cycling, or volume changes during lithium intercalation.

Internal short-circuiting presents a persistent challenge, often resulting from lithium dendrite growth through the LLZO electrolyte. Recent studies indicate that grain boundaries and pre-existing defects serve as preferential pathways for dendrite propagation, with critical current densities typically ranging from 0.5-2 mA/cm² depending on LLZO composition and microstructure. Interface degradation between LLZO and electrodes represents another failure mode, where chemical instability leads to increased impedance and capacity fade over extended cycling.

Mitigation strategies must address these failure modes through multi-faceted approaches. Thermal stability enhancement can be achieved by doping LLZO with elements like Ta, Nb, or Al, which have demonstrated improved thermal tolerance up to 300°C in recent studies. Mechanical reinforcement techniques include incorporating polymer composites or developing gradient structures that distribute stress more effectively across the electrolyte.

Dendrite suppression strategies have shown promising results through microstructure engineering, including controlled grain size distribution and boundary modification. High-density LLZO (>97% theoretical density) with uniform grain structure significantly improves dendrite resistance. Interface stabilization requires specialized coatings and buffer layers, with ALD-deposited Al₂O₃ and Li₃PO₄ interlayers demonstrating effective mitigation of interfacial degradation.

Advanced manufacturing processes, including hot pressing and field-assisted sintering, have emerged as critical enablers for producing LLZO with optimized microstructures that inherently resist multiple failure modes. Implementing redundant safety mechanisms, such as thermal fuses and pressure-release designs, provides additional protection against catastrophic failures. These mitigation strategies must be implemented holistically, as addressing one failure mode in isolation may inadvertently exacerbate others.

Internal short-circuiting presents a persistent challenge, often resulting from lithium dendrite growth through the LLZO electrolyte. Recent studies indicate that grain boundaries and pre-existing defects serve as preferential pathways for dendrite propagation, with critical current densities typically ranging from 0.5-2 mA/cm² depending on LLZO composition and microstructure. Interface degradation between LLZO and electrodes represents another failure mode, where chemical instability leads to increased impedance and capacity fade over extended cycling.

Mitigation strategies must address these failure modes through multi-faceted approaches. Thermal stability enhancement can be achieved by doping LLZO with elements like Ta, Nb, or Al, which have demonstrated improved thermal tolerance up to 300°C in recent studies. Mechanical reinforcement techniques include incorporating polymer composites or developing gradient structures that distribute stress more effectively across the electrolyte.

Dendrite suppression strategies have shown promising results through microstructure engineering, including controlled grain size distribution and boundary modification. High-density LLZO (>97% theoretical density) with uniform grain structure significantly improves dendrite resistance. Interface stabilization requires specialized coatings and buffer layers, with ALD-deposited Al₂O₃ and Li₃PO₄ interlayers demonstrating effective mitigation of interfacial degradation.

Advanced manufacturing processes, including hot pressing and field-assisted sintering, have emerged as critical enablers for producing LLZO with optimized microstructures that inherently resist multiple failure modes. Implementing redundant safety mechanisms, such as thermal fuses and pressure-release designs, provides additional protection against catastrophic failures. These mitigation strategies must be implemented holistically, as addressing one failure mode in isolation may inadvertently exacerbate others.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!