Tape casting LLZO electrolytes: slurry formulation best practices

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LLZO Electrolyte Development Background and Objectives

The development of solid-state lithium-ion batteries has gained significant momentum in recent years due to their potential to overcome safety and performance limitations of conventional liquid electrolyte batteries. Among various solid electrolyte materials, Li7La3Zr2O12 (LLZO) garnet-type ceramics have emerged as one of the most promising candidates due to their high ionic conductivity, wide electrochemical stability window, and chemical stability against lithium metal.

The evolution of LLZO electrolyte technology can be traced back to 2007 when Murugan et al. first reported cubic LLZO with an ionic conductivity of 10^-4 S/cm at room temperature. Since then, significant research efforts have focused on improving its properties through doping strategies, processing techniques, and interface engineering. The technological trajectory has moved from powder synthesis optimization to advanced manufacturing methods that enable thin film production.

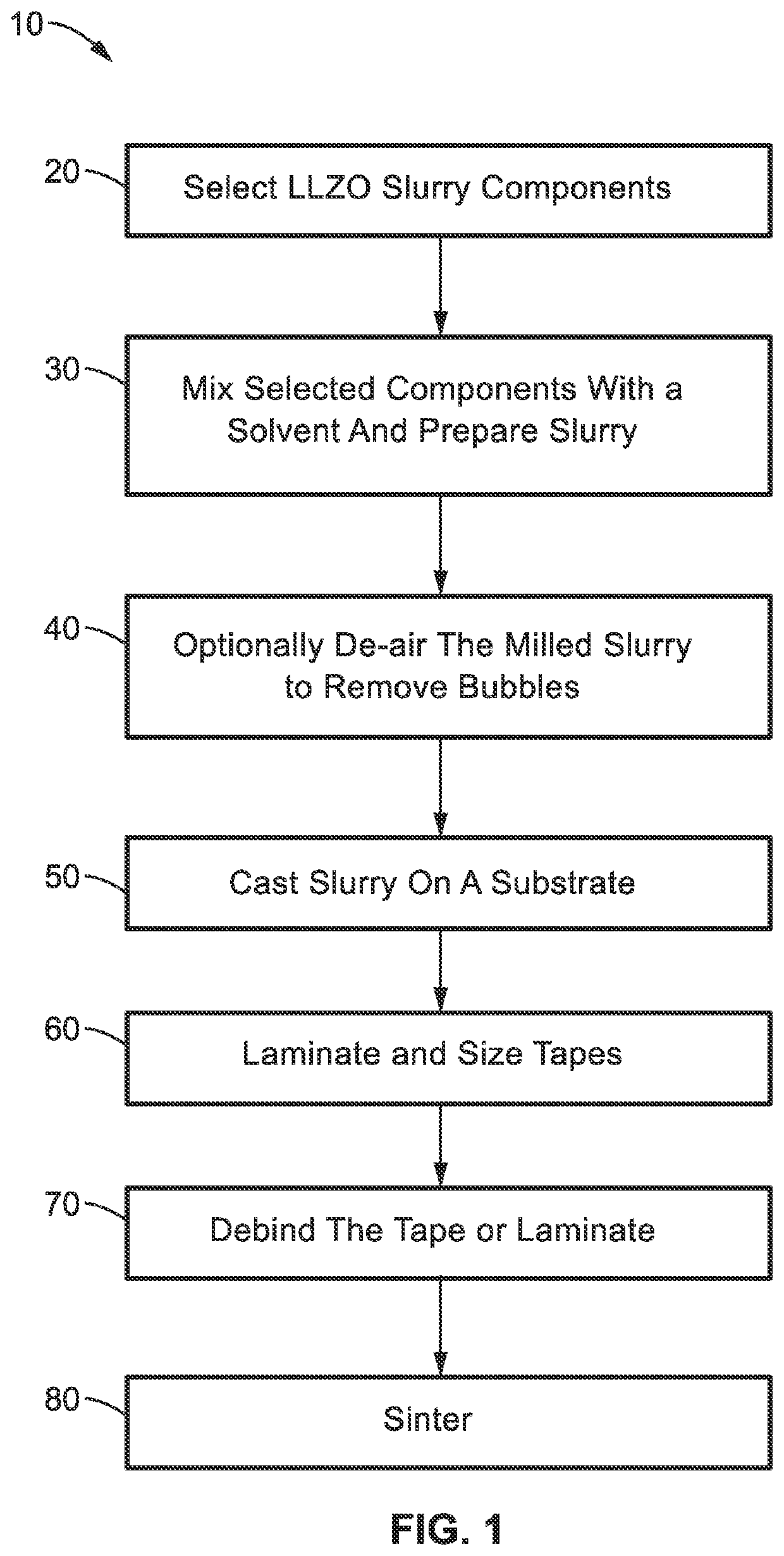

Tape casting has become a critical processing technique for LLZO electrolytes as it allows for the fabrication of thin, large-area ceramic sheets with controlled thickness and microstructure. This technique offers scalability advantages crucial for industrial production of solid-state batteries. However, the success of tape casting heavily depends on slurry formulation, which remains a significant technical challenge in the field.

The primary objective of LLZO electrolyte development through tape casting is to achieve thin (20-50 μm) electrolyte layers with high ionic conductivity (>10^-3 S/cm at room temperature), excellent mechanical properties, and minimal interfacial resistance. These properties are essential for enabling high-energy-density solid-state batteries with fast charging capabilities and long cycle life.

Current research goals focus on optimizing slurry formulations to control the microstructure of tape-cast LLZO sheets, minimize sintering temperatures while maintaining high relative density (>95%), and develop scalable manufacturing processes compatible with existing battery production infrastructure. Additionally, there is significant interest in understanding the relationship between slurry composition, green tape properties, and final electrolyte performance.

The technological landscape is rapidly evolving, with recent breakthroughs in sintering aids, dispersants, and binder systems specifically tailored for LLZO materials. These advances aim to address persistent challenges such as Li volatility during high-temperature sintering, grain boundary resistance, and mechanical integrity of thin ceramic sheets.

As the field progresses, establishing best practices for LLZO slurry formulation represents a critical step toward commercial viability of solid-state batteries, potentially enabling the next generation of safe, high-energy-density energy storage solutions for electric vehicles, portable electronics, and grid applications.

The evolution of LLZO electrolyte technology can be traced back to 2007 when Murugan et al. first reported cubic LLZO with an ionic conductivity of 10^-4 S/cm at room temperature. Since then, significant research efforts have focused on improving its properties through doping strategies, processing techniques, and interface engineering. The technological trajectory has moved from powder synthesis optimization to advanced manufacturing methods that enable thin film production.

Tape casting has become a critical processing technique for LLZO electrolytes as it allows for the fabrication of thin, large-area ceramic sheets with controlled thickness and microstructure. This technique offers scalability advantages crucial for industrial production of solid-state batteries. However, the success of tape casting heavily depends on slurry formulation, which remains a significant technical challenge in the field.

The primary objective of LLZO electrolyte development through tape casting is to achieve thin (20-50 μm) electrolyte layers with high ionic conductivity (>10^-3 S/cm at room temperature), excellent mechanical properties, and minimal interfacial resistance. These properties are essential for enabling high-energy-density solid-state batteries with fast charging capabilities and long cycle life.

Current research goals focus on optimizing slurry formulations to control the microstructure of tape-cast LLZO sheets, minimize sintering temperatures while maintaining high relative density (>95%), and develop scalable manufacturing processes compatible with existing battery production infrastructure. Additionally, there is significant interest in understanding the relationship between slurry composition, green tape properties, and final electrolyte performance.

The technological landscape is rapidly evolving, with recent breakthroughs in sintering aids, dispersants, and binder systems specifically tailored for LLZO materials. These advances aim to address persistent challenges such as Li volatility during high-temperature sintering, grain boundary resistance, and mechanical integrity of thin ceramic sheets.

As the field progresses, establishing best practices for LLZO slurry formulation represents a critical step toward commercial viability of solid-state batteries, potentially enabling the next generation of safe, high-energy-density energy storage solutions for electric vehicles, portable electronics, and grid applications.

Market Analysis for Solid-State Battery Electrolytes

The solid-state battery electrolyte market is experiencing unprecedented growth, driven by the increasing demand for safer, higher energy density batteries across multiple industries. The global market for solid-state battery electrolytes was valued at approximately $500 million in 2022 and is projected to reach $3.4 billion by 2030, representing a compound annual growth rate (CAGR) of 27.3% during the forecast period.

LLZO (Li7La3Zr2O12) garnet-type electrolytes have emerged as one of the most promising ceramic electrolyte materials due to their high ionic conductivity, excellent stability against lithium metal, and wide electrochemical window. The market segment specifically for LLZO electrolytes is expected to grow at a CAGR of 31.2% through 2030, outpacing the overall solid-state electrolyte market.

The automotive sector represents the largest application market for solid-state electrolytes, accounting for approximately 65% of the total demand. Major automotive manufacturers including Toyota, BMW, and Volkswagen have announced significant investments in solid-state battery technology, with commercialization targets between 2025 and 2028. This automotive push is creating substantial pull for advanced manufacturing techniques like tape casting of LLZO electrolytes.

Consumer electronics constitutes the second-largest market segment at 22%, with manufacturers seeking higher energy density and safer battery solutions for smartphones, laptops, and wearable devices. The remaining 13% is distributed across energy storage systems, medical devices, and aerospace applications.

Regionally, Asia Pacific dominates the market with 48% share, led by Japan, South Korea, and China, where substantial R&D investments and government support have accelerated development. North America follows with 27% market share, while Europe accounts for 21%. Both regions have established strong research ecosystems and manufacturing capabilities for advanced ceramic processing.

The market landscape is characterized by a mix of established materials companies, battery manufacturers, and specialized startups. Key players focusing on LLZO electrolyte development include Ionic Materials, Solid Power, QuantumScape, and Samsung SDI. These companies are actively developing scalable manufacturing processes, with tape casting emerging as a preferred method for thin-film LLZO electrolyte production due to its cost-effectiveness and scalability.

Market analysts identify several key drivers for LLZO electrolytes: increasing safety concerns with conventional lithium-ion batteries, growing demand for higher energy density power sources, and supportive government regulations promoting electric vehicle adoption. However, challenges remain in scaling production processes and reducing manufacturing costs to achieve price parity with conventional liquid electrolyte systems.

LLZO (Li7La3Zr2O12) garnet-type electrolytes have emerged as one of the most promising ceramic electrolyte materials due to their high ionic conductivity, excellent stability against lithium metal, and wide electrochemical window. The market segment specifically for LLZO electrolytes is expected to grow at a CAGR of 31.2% through 2030, outpacing the overall solid-state electrolyte market.

The automotive sector represents the largest application market for solid-state electrolytes, accounting for approximately 65% of the total demand. Major automotive manufacturers including Toyota, BMW, and Volkswagen have announced significant investments in solid-state battery technology, with commercialization targets between 2025 and 2028. This automotive push is creating substantial pull for advanced manufacturing techniques like tape casting of LLZO electrolytes.

Consumer electronics constitutes the second-largest market segment at 22%, with manufacturers seeking higher energy density and safer battery solutions for smartphones, laptops, and wearable devices. The remaining 13% is distributed across energy storage systems, medical devices, and aerospace applications.

Regionally, Asia Pacific dominates the market with 48% share, led by Japan, South Korea, and China, where substantial R&D investments and government support have accelerated development. North America follows with 27% market share, while Europe accounts for 21%. Both regions have established strong research ecosystems and manufacturing capabilities for advanced ceramic processing.

The market landscape is characterized by a mix of established materials companies, battery manufacturers, and specialized startups. Key players focusing on LLZO electrolyte development include Ionic Materials, Solid Power, QuantumScape, and Samsung SDI. These companies are actively developing scalable manufacturing processes, with tape casting emerging as a preferred method for thin-film LLZO electrolyte production due to its cost-effectiveness and scalability.

Market analysts identify several key drivers for LLZO electrolytes: increasing safety concerns with conventional lithium-ion batteries, growing demand for higher energy density power sources, and supportive government regulations promoting electric vehicle adoption. However, challenges remain in scaling production processes and reducing manufacturing costs to achieve price parity with conventional liquid electrolyte systems.

Current Challenges in LLZO Tape Casting Technology

Despite significant advancements in LLZO solid electrolyte technology, tape casting processes for LLZO face several persistent challenges that impede commercial-scale production and optimal performance. The primary challenge lies in slurry formulation stability, where LLZO particles tend to agglomerate and settle rapidly due to their high density (approximately 5.2 g/cm³). This sedimentation creates non-uniform green tapes with inconsistent thickness and density gradients, ultimately compromising the electrochemical performance of the final electrolyte.

Rheological control presents another significant hurdle, as LLZO slurries often exhibit non-Newtonian behavior that varies considerably with solid loading, binder selection, and processing conditions. Achieving the ideal viscosity profile that balances good flow during casting while preventing particle sedimentation remains difficult to standardize across different LLZO powder characteristics.

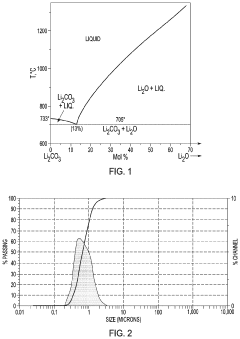

The high surface reactivity of LLZO with atmospheric moisture and CO₂ introduces contamination issues during slurry preparation. Even brief exposure can lead to Li₂CO₃ and LiOH formation on particle surfaces, degrading ionic conductivity and creating interfacial resistance. This necessitates stringent environmental controls during processing that are difficult to maintain in large-scale production environments.

Binder-LLZO interactions pose additional complications, as conventional organic binders used in tape casting may react with LLZO surfaces or leave carbonaceous residues after thermal processing. These residues can create insulating barriers between LLZO particles, reducing overall ionic conductivity. Finding binder systems that provide adequate green strength while minimizing detrimental interactions remains challenging.

Thickness control and uniformity issues persist in current tape casting methods. Producing LLZO tapes below 50 μm while maintaining mechanical integrity has proven particularly difficult, yet thin electrolytes are essential for minimizing overall battery resistance. Edge effects and thickness variations across cast tapes lead to inconsistent performance in final devices.

Scalability constraints further complicate commercial implementation, as laboratory-scale formulations often fail to translate directly to industrial production. Differences in mixing energies, drying kinetics, and equipment configurations between lab and industrial settings require significant reformulation efforts, increasing development costs and time-to-market.

Defect formation during drying and sintering represents another major challenge, with cracks, pinholes, and warping commonly observed in LLZO tapes. These defects create potential short-circuit pathways in assembled batteries and compromise mechanical integrity, significantly reducing manufacturing yield rates.

Rheological control presents another significant hurdle, as LLZO slurries often exhibit non-Newtonian behavior that varies considerably with solid loading, binder selection, and processing conditions. Achieving the ideal viscosity profile that balances good flow during casting while preventing particle sedimentation remains difficult to standardize across different LLZO powder characteristics.

The high surface reactivity of LLZO with atmospheric moisture and CO₂ introduces contamination issues during slurry preparation. Even brief exposure can lead to Li₂CO₃ and LiOH formation on particle surfaces, degrading ionic conductivity and creating interfacial resistance. This necessitates stringent environmental controls during processing that are difficult to maintain in large-scale production environments.

Binder-LLZO interactions pose additional complications, as conventional organic binders used in tape casting may react with LLZO surfaces or leave carbonaceous residues after thermal processing. These residues can create insulating barriers between LLZO particles, reducing overall ionic conductivity. Finding binder systems that provide adequate green strength while minimizing detrimental interactions remains challenging.

Thickness control and uniformity issues persist in current tape casting methods. Producing LLZO tapes below 50 μm while maintaining mechanical integrity has proven particularly difficult, yet thin electrolytes are essential for minimizing overall battery resistance. Edge effects and thickness variations across cast tapes lead to inconsistent performance in final devices.

Scalability constraints further complicate commercial implementation, as laboratory-scale formulations often fail to translate directly to industrial production. Differences in mixing energies, drying kinetics, and equipment configurations between lab and industrial settings require significant reformulation efforts, increasing development costs and time-to-market.

Defect formation during drying and sintering represents another major challenge, with cracks, pinholes, and warping commonly observed in LLZO tapes. These defects create potential short-circuit pathways in assembled batteries and compromise mechanical integrity, significantly reducing manufacturing yield rates.

State-of-the-Art Slurry Formulation Methodologies

01 LLZO solid electrolyte composition and preparation

LLZO (Lithium Lanthanum Zirconium Oxide) solid electrolytes can be prepared with specific compositions to enhance ionic conductivity and stability. These compositions typically involve doping with elements such as aluminum, tantalum, or gallium to stabilize the cubic phase structure. The preparation methods include solid-state reactions, sol-gel processes, and co-precipitation techniques to achieve high-purity LLZO powders suitable for slurry formulation.- LLZO solid electrolyte composition and preparation: LLZO (Lithium Lanthanum Zirconium Oxide) solid electrolytes can be prepared with specific compositions to enhance ionic conductivity and stability. These compositions typically include lithium, lanthanum, zirconium, and oxygen in specific ratios, often with dopants such as aluminum, tantalum, or gallium to stabilize the cubic phase. The preparation methods include solid-state reactions, sol-gel processes, and co-precipitation techniques to achieve the desired crystal structure and properties for solid-state battery applications.

- Slurry formulation components for LLZO-based electrolytes: The slurry formulation for LLZO-based electrolytes typically consists of LLZO powder, binders, solvents, and additives. Common binders include PVDF (polyvinylidene fluoride), NBR (nitrile butadiene rubber), or SBR (styrene-butadiene rubber). Solvents such as NMP (N-methyl-2-pyrrolidone), water, or alcohol are used to disperse the components. Additives like plasticizers and dispersants are incorporated to improve the rheological properties and stability of the slurry, ensuring uniform coating and optimal performance in the final electrolyte layer.

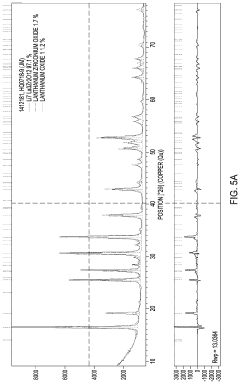

- Processing techniques for LLZO electrolyte slurries: Various processing techniques are employed for LLZO electrolyte slurries to achieve optimal performance. These include ball milling or planetary milling to reduce particle size and ensure homogeneous distribution, ultrasonic dispersion to break agglomerates, and controlled drying conditions to prevent cracking and ensure uniform thickness. The slurry viscosity is carefully controlled through formulation adjustments to enable various coating methods such as tape casting, screen printing, or doctor blade techniques, resulting in uniform electrolyte layers with desired mechanical properties.

- Interface engineering for LLZO-based electrolyte systems: Interface engineering is crucial for LLZO-based electrolyte systems to ensure good contact between the electrolyte and electrodes. This involves surface modifications of LLZO particles, incorporation of interface layers, or addition of specific additives to the slurry. Techniques such as coating LLZO particles with lithium-ion conductive materials, adding lithium salts to improve wettability, or introducing buffer layers can significantly reduce interfacial resistance. These approaches enhance the electrochemical performance and stability of the solid-state batteries by improving the lithium-ion transport across interfaces.

- Composite LLZO electrolyte formulations: Composite LLZO electrolyte formulations combine LLZO with other materials to enhance performance characteristics. These composites may include polymer matrices (such as PEO, PMMA, or PVdF-HFP) to improve flexibility and processability, secondary ceramic fillers (like Al2O3, SiO2, or other lithium-ion conductors) to enhance mechanical properties or ionic conductivity, or carbon-based materials to improve electrical contact. The composite approach allows for tailoring the electrolyte properties to specific applications, balancing ionic conductivity, mechanical strength, and processability for optimal battery performance.

02 Slurry binder systems for LLZO electrolytes

Various binder systems are used in LLZO slurry formulations to provide mechanical strength and adhesion properties. Common binders include PVDF (polyvinylidene fluoride), NBR (nitrile butadiene rubber), SBR (styrene-butadiene rubber), and water-soluble polymers like CMC (carboxymethyl cellulose). The selection of appropriate binders affects the rheological properties of the slurry, the distribution of LLZO particles, and ultimately the performance of the solid electrolyte layer.Expand Specific Solutions03 Solvent selection and dispersion techniques

The choice of solvents plays a crucial role in LLZO slurry formulation, affecting dispersion quality and coating properties. Common solvents include NMP (N-methyl-2-pyrrolidone), acetone, ethanol, and water-based systems. Advanced dispersion techniques such as ball milling, ultrasonication, and high-shear mixing are employed to break agglomerates and achieve uniform particle distribution in the slurry, which is essential for forming homogeneous electrolyte layers.Expand Specific Solutions04 Additives for enhanced slurry performance

Various additives are incorporated into LLZO slurry formulations to enhance performance characteristics. These include dispersants to prevent particle agglomeration, plasticizers to improve flexibility, conductive additives to enhance ionic conductivity, and sintering aids to lower densification temperature. The careful selection and optimization of these additives can significantly improve the electrochemical properties and mechanical integrity of the resulting LLZO electrolyte layers.Expand Specific Solutions05 Coating and processing methods for LLZO slurries

LLZO slurries can be processed using various coating techniques such as tape casting, doctor blade coating, screen printing, and spray coating to form thin electrolyte layers. Post-coating treatments including drying protocols, calendering, and sintering processes are critical for achieving desired microstructure, density, and ionic conductivity. The optimization of these processing parameters significantly affects the final performance of LLZO solid electrolytes in battery applications.Expand Specific Solutions

Leading Organizations in LLZO Electrolyte Manufacturing

The tape casting LLZO electrolytes market is in an early growth phase, characterized by intensive R&D activities across academic institutions and industry players. The market size remains relatively modest but is expanding rapidly due to increasing demand for solid-state batteries in electric vehicles and energy storage applications. From a technological maturity perspective, the field is transitioning from laboratory research to commercial implementation. Leading academic institutions like MIT, University of California, and Arizona State University are pioneering fundamental research, while industrial players including Toyota, LG Chem, and Hyundai are focusing on scalable manufacturing processes. Corning and Resonac are leveraging their materials expertise to advance slurry formulation techniques, while automotive companies such as GM and Honda are investing in the technology to secure future battery supply chains.

Massachusetts Institute of Technology

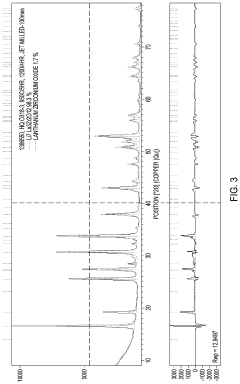

Technical Solution: MIT has developed advanced tape casting techniques for LLZO solid electrolytes focusing on optimized slurry formulations. Their approach involves precise control of solvent systems (typically combining toluene and ethanol) with carefully selected binder ratios (PVB/PEG) to achieve optimal rheological properties. MIT researchers have established that maintaining a solid loading of 40-50 vol% LLZO powder with particle sizes below 10μm significantly improves green tape quality[1]. Their slurry formulation incorporates dispersants (fish oil or phosphate esters) at 1-3 wt% to prevent agglomeration, while plasticizers are added at a ratio of 2:1 to binder content to enhance flexibility. MIT's process includes a two-stage mixing protocol: initial powder dispersion followed by binder addition, with de-airing under vacuum to eliminate bubbles before casting at controlled doctor blade heights (100-200μm) and drying rates[3].

Strengths: Superior control over microstructure and density with demonstrated high ionic conductivity (>10^-4 S/cm); excellent reproducibility and scalability potential for industrial applications. Weaknesses: Requires precise environmental control during casting and drying; higher complexity in slurry preparation compared to conventional methods; potential challenges in achieving uniform thickness below 50μm.

The Regents of the University of California

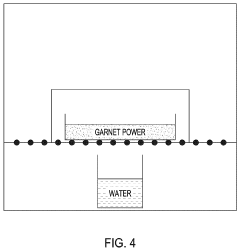

Technical Solution: The University of California has developed a sophisticated tape casting methodology for LLZO electrolytes with emphasis on controlling interfacial properties. Their slurry formulation utilizes a mixed solvent system of ethanol and xylene (40:60) with polyvinyl butyral (PVB) as the primary binder at 4-6 wt% relative to ceramic content. UC researchers have established that incorporating a small amount (0.5-1.5 wt%) of aluminum oxide as a sintering aid significantly improves densification while stabilizing the cubic phase of LLZO[9]. Their process employs a specialized dispersant system based on phosphate esters (1-2 wt%) combined with careful pH control to achieve optimal dispersion of LLZO particles. The UC approach includes a distinctive ball milling protocol with zirconia media for 36-48 hours to achieve uniform particle size distribution (d90 < 5μm) and eliminate agglomerates. Their casting process incorporates precise control of doctor blade gap (150-250μm) and casting speed (10-20 cm/min) to achieve green tapes with uniform thickness. UC's sintering protocol includes a specialized atmosphere control system that maintains lithium stoichiometry while achieving >94% theoretical density, resulting in ionic conductivities consistently above 4×10^-4 S/cm at room temperature[10].

Strengths: Excellent control over interfacial properties with demonstrated low resistance at electrode interfaces; superior phase stability during sintering; good mechanical properties with minimal defects. Weaknesses: Complex processing requiring specialized equipment; higher sensitivity to raw material variations; more challenging quality control for large-area production.

Critical Patents and Literature on LLZO Tape Casting

Binder systems and methods for tape casting lithium garnet electrolytes

PatentActiveUS20220093960A1

Innovation

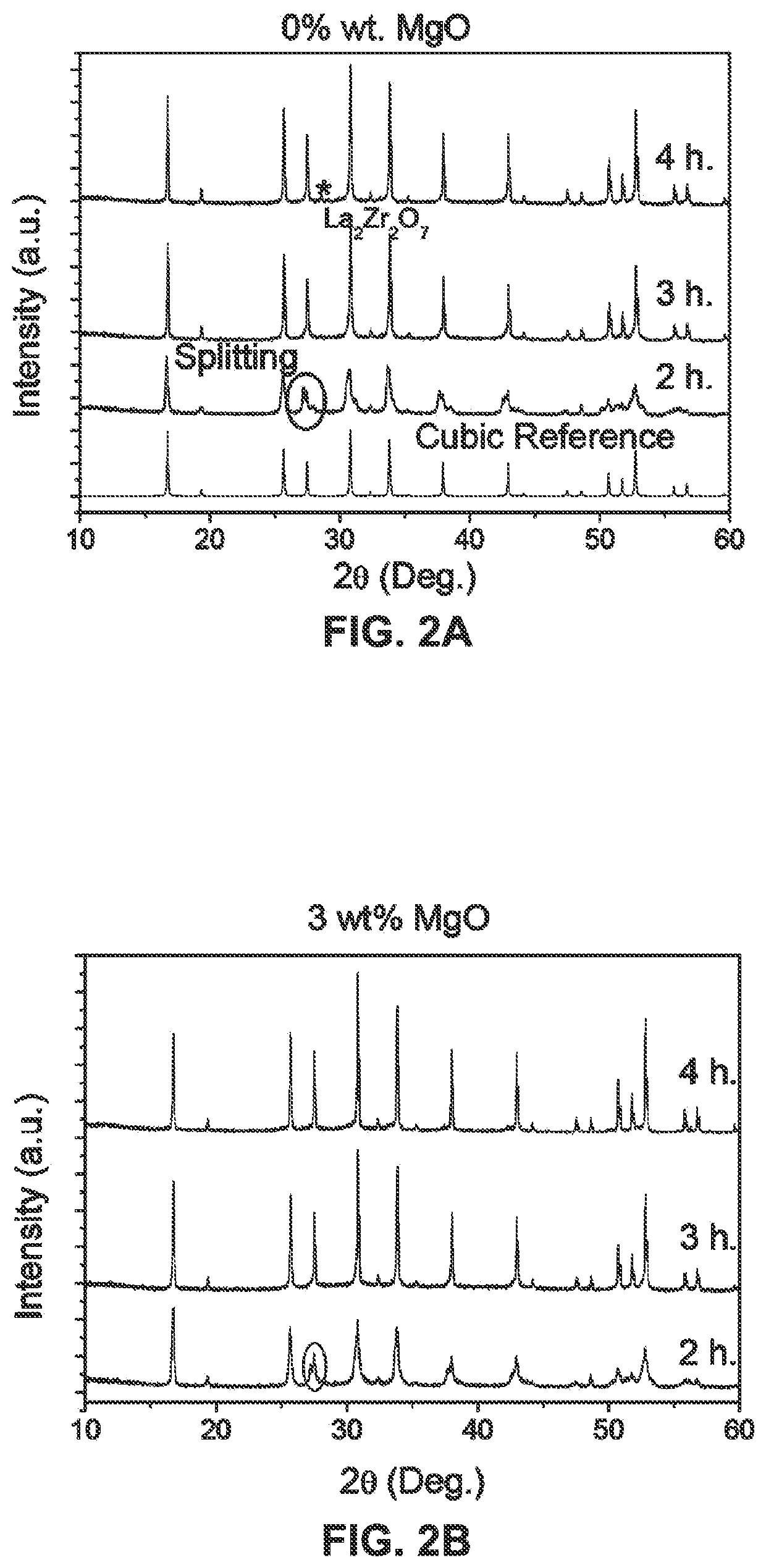

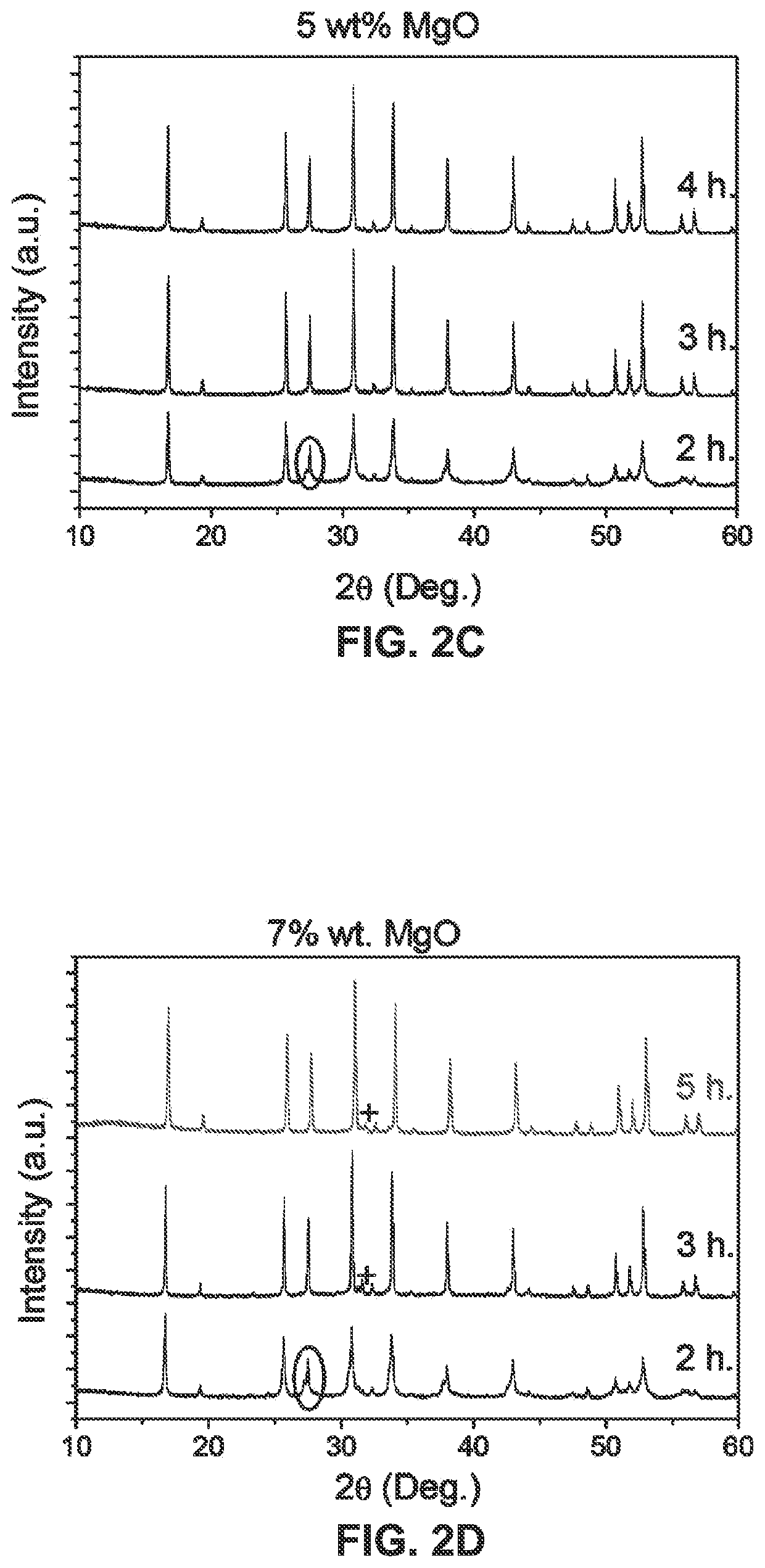

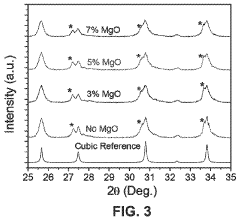

- Optimized tape casting systems using a two-step slurry mixing process with specific binder and solvent systems, including the use of MgO as a sintering additive, and careful optimization of sintering protocols to produce high-density, high-conductivity Al-LLZO sheets without the need for mother-powder covering or externally applied pressure.

Passivated LLZO particles and tape casting of LLZO films

PatentActiveUS12002924B2

Innovation

- A passivated LLZO particle with a core-shell structure, where the core is optionally doped and surrounded by a shell of H-LLZO, H3O+-LLZO, and/or Li2CO3, is developed, along with a tape casting method using a slip composition with excess lithium sources like Li2CO3, LiOH, and LiCl, allowing for stable processing in air and reducing the need for inert atmospheres.

Scale-up Considerations for Industrial Production

Scaling up tape casting processes for LLZO electrolyte production from laboratory to industrial scale requires careful consideration of multiple factors to maintain quality, consistency, and economic viability. The transition demands significant adjustments in equipment, process parameters, and quality control systems.

Industrial-scale tape casting operations necessitate larger casting machines with automated features for continuous production. These systems typically include automated slurry feeding mechanisms, precision doctor blade assemblies, and temperature-controlled drying chambers. Investment in specialized equipment capable of handling wider casting widths (typically 30-100 cm compared to laboratory scales of 5-15 cm) becomes essential for commercial viability.

Process parameters require substantial recalibration during scale-up. Casting speed must be optimized to balance throughput with quality, typically ranging from 0.5-2 m/min depending on slurry rheology. Drying conditions need precise control across larger areas to prevent defects like cracking or warping. The drying profile must be carefully engineered with gradual temperature ramping to accommodate the increased tape dimensions.

Slurry preparation presents unique challenges at industrial scale. Batch sizes increase from laboratory quantities (100-500 mL) to industrial volumes (10-100 L), necessitating powerful mixing equipment capable of maintaining homogeneity. Mixing times and protocols require adjustment to ensure consistent dispersion of LLZO particles throughout larger volumes. Degassing procedures become more complex and time-intensive for larger batches.

Quality control systems must evolve to accommodate continuous production. In-line monitoring technologies for thickness, density, and defect detection become critical. Statistical process control methods should be implemented to track key parameters and detect deviations early. Sampling protocols must be developed to ensure representative testing across production runs.

Economic considerations significantly impact scale-up decisions. Material efficiency becomes paramount, with recovery and recycling systems for solvents and expensive LLZO materials offering substantial cost benefits. Energy consumption optimization, particularly in drying and sintering stages, directly affects production costs. Labor requirements shift from manual laboratory processes to automated systems requiring specialized operator training.

Environmental and safety considerations intensify with scale-up. Larger quantities of potentially flammable solvents necessitate enhanced ventilation systems and safety protocols. Waste management strategies must be developed for production-scale operations, with particular attention to recycling opportunities and proper disposal of chemical waste.

Industrial-scale tape casting operations necessitate larger casting machines with automated features for continuous production. These systems typically include automated slurry feeding mechanisms, precision doctor blade assemblies, and temperature-controlled drying chambers. Investment in specialized equipment capable of handling wider casting widths (typically 30-100 cm compared to laboratory scales of 5-15 cm) becomes essential for commercial viability.

Process parameters require substantial recalibration during scale-up. Casting speed must be optimized to balance throughput with quality, typically ranging from 0.5-2 m/min depending on slurry rheology. Drying conditions need precise control across larger areas to prevent defects like cracking or warping. The drying profile must be carefully engineered with gradual temperature ramping to accommodate the increased tape dimensions.

Slurry preparation presents unique challenges at industrial scale. Batch sizes increase from laboratory quantities (100-500 mL) to industrial volumes (10-100 L), necessitating powerful mixing equipment capable of maintaining homogeneity. Mixing times and protocols require adjustment to ensure consistent dispersion of LLZO particles throughout larger volumes. Degassing procedures become more complex and time-intensive for larger batches.

Quality control systems must evolve to accommodate continuous production. In-line monitoring technologies for thickness, density, and defect detection become critical. Statistical process control methods should be implemented to track key parameters and detect deviations early. Sampling protocols must be developed to ensure representative testing across production runs.

Economic considerations significantly impact scale-up decisions. Material efficiency becomes paramount, with recovery and recycling systems for solvents and expensive LLZO materials offering substantial cost benefits. Energy consumption optimization, particularly in drying and sintering stages, directly affects production costs. Labor requirements shift from manual laboratory processes to automated systems requiring specialized operator training.

Environmental and safety considerations intensify with scale-up. Larger quantities of potentially flammable solvents necessitate enhanced ventilation systems and safety protocols. Waste management strategies must be developed for production-scale operations, with particular attention to recycling opportunities and proper disposal of chemical waste.

Environmental Impact and Sustainability Assessment

The environmental footprint of tape casting LLZO electrolytes represents a critical consideration in the broader context of sustainable solid-state battery development. The manufacturing process involves multiple components including ceramic powders, organic binders, plasticizers, and solvents that each carry distinct environmental implications. Particularly concerning are the volatile organic compounds (VOCs) released during the drying and sintering stages, which contribute to air pollution and potential health hazards for workers in production facilities.

Water-based slurry systems have emerged as promising alternatives to traditional solvent-based formulations, significantly reducing VOC emissions. However, these aqueous systems present challenges in achieving optimal rheological properties and homogeneous dispersion of LLZO particles, necessitating careful formulation adjustments and potentially longer processing times that may increase energy consumption.

Energy intensity represents another substantial environmental concern, particularly during the high-temperature sintering process required for LLZO densification, typically conducted at temperatures exceeding 1100°C for extended periods. This energy demand translates directly to carbon emissions when powered by non-renewable energy sources. Recent research has explored microwave-assisted sintering and spark plasma sintering techniques that can reduce energy requirements by up to 40% while simultaneously shortening processing times.

Material efficiency in tape casting operations presents both challenges and opportunities for sustainability improvement. Current processes typically generate 15-25% material waste through edge trimming and defective sheets. Closed-loop recycling systems for ceramic material recovery from production waste have demonstrated potential to reclaim up to 80% of discarded LLZO powder, though the separation of organic components remains technically challenging.

Life cycle assessment (LCA) studies comparing tape-cast LLZO electrolytes with conventional liquid electrolytes indicate potential long-term environmental benefits despite higher manufacturing impacts. The extended cycle life and enhanced safety of solid-state batteries containing LLZO electrolytes contribute to reduced lifetime environmental impact through longer service periods and elimination of toxic liquid electrolytes.

Industry adoption of green chemistry principles in slurry formulation has accelerated, with particular focus on replacing toxic solvents like N-methyl-2-pyrrolidone (NMP) with more environmentally benign alternatives such as ethanol and water. Similarly, bio-derived binders are increasingly substituting petroleum-based polymers, though challenges in performance parity remain to be fully addressed through ongoing research and development efforts.

Water-based slurry systems have emerged as promising alternatives to traditional solvent-based formulations, significantly reducing VOC emissions. However, these aqueous systems present challenges in achieving optimal rheological properties and homogeneous dispersion of LLZO particles, necessitating careful formulation adjustments and potentially longer processing times that may increase energy consumption.

Energy intensity represents another substantial environmental concern, particularly during the high-temperature sintering process required for LLZO densification, typically conducted at temperatures exceeding 1100°C for extended periods. This energy demand translates directly to carbon emissions when powered by non-renewable energy sources. Recent research has explored microwave-assisted sintering and spark plasma sintering techniques that can reduce energy requirements by up to 40% while simultaneously shortening processing times.

Material efficiency in tape casting operations presents both challenges and opportunities for sustainability improvement. Current processes typically generate 15-25% material waste through edge trimming and defective sheets. Closed-loop recycling systems for ceramic material recovery from production waste have demonstrated potential to reclaim up to 80% of discarded LLZO powder, though the separation of organic components remains technically challenging.

Life cycle assessment (LCA) studies comparing tape-cast LLZO electrolytes with conventional liquid electrolytes indicate potential long-term environmental benefits despite higher manufacturing impacts. The extended cycle life and enhanced safety of solid-state batteries containing LLZO electrolytes contribute to reduced lifetime environmental impact through longer service periods and elimination of toxic liquid electrolytes.

Industry adoption of green chemistry principles in slurry formulation has accelerated, with particular focus on replacing toxic solvents like N-methyl-2-pyrrolidone (NMP) with more environmentally benign alternatives such as ethanol and water. Similarly, bio-derived binders are increasingly substituting petroleum-based polymers, though challenges in performance parity remain to be fully addressed through ongoing research and development efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!