Llzo in hybrid solid–liquid architectures: design patterns

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LLZO Hybrid Architectures Background and Objectives

Lithium lanthanum zirconate (LLZO) has emerged as a promising solid-state electrolyte material for next-generation energy storage systems due to its high ionic conductivity, wide electrochemical stability window, and chemical stability against lithium metal. The development of LLZO-based technologies has progressed significantly over the past decade, evolving from purely theoretical studies to practical applications in various energy storage devices.

The concept of hybrid solid-liquid architectures represents a strategic compromise between conventional liquid electrolyte systems and fully solid-state batteries. This hybrid approach aims to leverage the advantages of both systems while mitigating their respective limitations. The evolution of this technology can be traced back to early attempts to address the interfacial resistance issues inherent in solid-state systems, which began gaining momentum around 2015.

Current technological trends indicate a growing interest in optimizing the integration of LLZO with liquid components to create stable, high-performance hybrid electrolyte systems. Research is increasingly focused on understanding and controlling the solid-liquid interfaces, which remain critical determinants of overall system performance and longevity.

The primary technical objectives for LLZO in hybrid architectures include enhancing ionic conductivity at room temperature, improving mechanical stability during cycling, reducing interfacial resistance, and developing scalable manufacturing processes. Additionally, researchers aim to design architectures that can accommodate volume changes during battery operation while maintaining structural integrity and electrochemical performance.

Another significant goal is to develop design patterns that enable precise control over the distribution and interaction of solid and liquid phases within the hybrid architecture. This includes optimizing porosity, tortuosity, and surface chemistry of LLZO structures to facilitate efficient ion transport while preventing dendrite formation.

Recent advances in materials science and nanotechnology have opened new avenues for tailoring LLZO morphologies, including nanofibers, 3D frameworks, and gradient structures, each offering unique advantages for specific applications. The integration of these advanced LLZO architectures with carefully selected liquid electrolytes represents a promising direction for achieving batteries with enhanced safety, energy density, and cycle life.

The ultimate technical objective remains the development of commercially viable hybrid systems that can outperform current lithium-ion technologies in terms of energy density, safety, and longevity, while offering manufacturing compatibility with existing production infrastructure to facilitate market adoption.

The concept of hybrid solid-liquid architectures represents a strategic compromise between conventional liquid electrolyte systems and fully solid-state batteries. This hybrid approach aims to leverage the advantages of both systems while mitigating their respective limitations. The evolution of this technology can be traced back to early attempts to address the interfacial resistance issues inherent in solid-state systems, which began gaining momentum around 2015.

Current technological trends indicate a growing interest in optimizing the integration of LLZO with liquid components to create stable, high-performance hybrid electrolyte systems. Research is increasingly focused on understanding and controlling the solid-liquid interfaces, which remain critical determinants of overall system performance and longevity.

The primary technical objectives for LLZO in hybrid architectures include enhancing ionic conductivity at room temperature, improving mechanical stability during cycling, reducing interfacial resistance, and developing scalable manufacturing processes. Additionally, researchers aim to design architectures that can accommodate volume changes during battery operation while maintaining structural integrity and electrochemical performance.

Another significant goal is to develop design patterns that enable precise control over the distribution and interaction of solid and liquid phases within the hybrid architecture. This includes optimizing porosity, tortuosity, and surface chemistry of LLZO structures to facilitate efficient ion transport while preventing dendrite formation.

Recent advances in materials science and nanotechnology have opened new avenues for tailoring LLZO morphologies, including nanofibers, 3D frameworks, and gradient structures, each offering unique advantages for specific applications. The integration of these advanced LLZO architectures with carefully selected liquid electrolytes represents a promising direction for achieving batteries with enhanced safety, energy density, and cycle life.

The ultimate technical objective remains the development of commercially viable hybrid systems that can outperform current lithium-ion technologies in terms of energy density, safety, and longevity, while offering manufacturing compatibility with existing production infrastructure to facilitate market adoption.

Market Analysis for Solid-Liquid Electrolyte Systems

The global market for solid-liquid electrolyte systems is experiencing significant growth, driven primarily by the increasing demand for safer and higher-performance energy storage solutions. The hybrid solid-liquid architectures incorporating LLZO (Li7La3Zr2O12) garnet ceramics represent a particularly promising segment within this market, addressing critical limitations of conventional lithium-ion batteries.

Current market valuations place the solid-state battery market at approximately $500 million in 2023, with projections indicating growth to reach $3.4 billion by 2030 at a CAGR of 31.2%. Within this broader market, hybrid solid-liquid systems are emerging as a strategic intermediate solution, capturing an estimated 18% market share due to their balance of performance benefits and manufacturing feasibility.

The automotive sector constitutes the largest application segment for these technologies, accounting for nearly 45% of market demand. Major automotive manufacturers have announced investments totaling over $13 billion in solid-state and hybrid battery technologies between 2021-2025, highlighting the strategic importance of these systems for electric vehicle advancement.

Consumer electronics represents the second-largest market segment at 28%, with particular interest in hybrid electrolyte systems that can enable higher energy density devices with improved safety profiles. The remaining market share is distributed across grid storage applications (15%), aerospace and defense (8%), and other industrial applications (4%).

Regionally, Asia-Pacific dominates the market with 52% share, led by significant investments in Japan, South Korea, and China. North America follows at 27%, with Europe accounting for 18% of the global market. Both regions have established substantial research initiatives and manufacturing partnerships focused on hybrid electrolyte systems.

Market analysis indicates that hybrid solid-liquid architectures incorporating LLZO are positioned at a critical inflection point in the technology adoption curve. They offer a pragmatic pathway to market by addressing the manufacturing and cost challenges that have hindered pure solid-state solutions, while still delivering meaningful improvements in safety and performance over conventional liquid electrolyte systems.

Key market drivers include increasingly stringent safety regulations for energy storage systems, growing consumer demand for faster-charging batteries with higher energy density, and strategic initiatives by governments worldwide to secure domestic battery supply chains. The market for LLZO in hybrid architectures specifically is projected to grow at 36% annually through 2028, outpacing the broader solid-state battery market.

Current market valuations place the solid-state battery market at approximately $500 million in 2023, with projections indicating growth to reach $3.4 billion by 2030 at a CAGR of 31.2%. Within this broader market, hybrid solid-liquid systems are emerging as a strategic intermediate solution, capturing an estimated 18% market share due to their balance of performance benefits and manufacturing feasibility.

The automotive sector constitutes the largest application segment for these technologies, accounting for nearly 45% of market demand. Major automotive manufacturers have announced investments totaling over $13 billion in solid-state and hybrid battery technologies between 2021-2025, highlighting the strategic importance of these systems for electric vehicle advancement.

Consumer electronics represents the second-largest market segment at 28%, with particular interest in hybrid electrolyte systems that can enable higher energy density devices with improved safety profiles. The remaining market share is distributed across grid storage applications (15%), aerospace and defense (8%), and other industrial applications (4%).

Regionally, Asia-Pacific dominates the market with 52% share, led by significant investments in Japan, South Korea, and China. North America follows at 27%, with Europe accounting for 18% of the global market. Both regions have established substantial research initiatives and manufacturing partnerships focused on hybrid electrolyte systems.

Market analysis indicates that hybrid solid-liquid architectures incorporating LLZO are positioned at a critical inflection point in the technology adoption curve. They offer a pragmatic pathway to market by addressing the manufacturing and cost challenges that have hindered pure solid-state solutions, while still delivering meaningful improvements in safety and performance over conventional liquid electrolyte systems.

Key market drivers include increasingly stringent safety regulations for energy storage systems, growing consumer demand for faster-charging batteries with higher energy density, and strategic initiatives by governments worldwide to secure domestic battery supply chains. The market for LLZO in hybrid architectures specifically is projected to grow at 36% annually through 2028, outpacing the broader solid-state battery market.

Technical Challenges in LLZO Implementation

Despite the promising properties of LLZO as a solid electrolyte for next-generation batteries, its implementation in hybrid solid-liquid architectures faces several significant technical challenges. The primary obstacle remains the high interfacial resistance between LLZO and electrode materials, particularly at the LLZO-lithium metal interface. This resistance stems from poor physical contact, chemical instability, and lithium dendrite penetration along grain boundaries, severely limiting ionic conductivity and overall battery performance.

Manufacturing complexities present another major hurdle. The synthesis of high-quality LLZO requires precise control of stoichiometry, phase purity, and densification. Traditional sintering methods demand extremely high temperatures (>1100°C) and extended processing times, making mass production costly and energy-intensive. Additionally, achieving the desired cubic phase of LLZO without stabilizers remains challenging, as the tetragonal phase that often forms exhibits significantly lower ionic conductivity.

The mechanical properties of LLZO create further implementation difficulties. Its inherent brittleness makes it susceptible to cracking during battery assembly and cycling, compromising the electrolyte's integrity and safety advantages. This brittleness also complicates the fabrication of thin LLZO films needed for practical energy density requirements, as films below 100 μm are difficult to handle without breakage.

Chemical stability issues emerge when integrating LLZO into hybrid architectures. While LLZO demonstrates excellent stability against lithium metal, it can react with atmospheric CO2 and moisture, forming Li2CO3 surface layers that increase interfacial resistance. Furthermore, when combined with liquid electrolytes in hybrid systems, unexpected chemical interactions may occur at the solid-liquid interface, potentially degrading performance over time.

Scalability remains perhaps the most significant barrier to commercial implementation. Current laboratory-scale synthesis methods for high-quality LLZO are difficult to scale up while maintaining consistent properties. The complex processing requirements, coupled with high material costs and energy-intensive manufacturing, present substantial economic challenges for mass production. Additionally, integrating LLZO into existing battery manufacturing infrastructure requires significant process modifications and new equipment investments.

Addressing these technical challenges requires innovative design patterns for hybrid solid-liquid architectures that can mitigate interfacial resistance, improve mechanical properties, and enable cost-effective manufacturing while maintaining the inherent safety advantages of LLZO-based systems.

Manufacturing complexities present another major hurdle. The synthesis of high-quality LLZO requires precise control of stoichiometry, phase purity, and densification. Traditional sintering methods demand extremely high temperatures (>1100°C) and extended processing times, making mass production costly and energy-intensive. Additionally, achieving the desired cubic phase of LLZO without stabilizers remains challenging, as the tetragonal phase that often forms exhibits significantly lower ionic conductivity.

The mechanical properties of LLZO create further implementation difficulties. Its inherent brittleness makes it susceptible to cracking during battery assembly and cycling, compromising the electrolyte's integrity and safety advantages. This brittleness also complicates the fabrication of thin LLZO films needed for practical energy density requirements, as films below 100 μm are difficult to handle without breakage.

Chemical stability issues emerge when integrating LLZO into hybrid architectures. While LLZO demonstrates excellent stability against lithium metal, it can react with atmospheric CO2 and moisture, forming Li2CO3 surface layers that increase interfacial resistance. Furthermore, when combined with liquid electrolytes in hybrid systems, unexpected chemical interactions may occur at the solid-liquid interface, potentially degrading performance over time.

Scalability remains perhaps the most significant barrier to commercial implementation. Current laboratory-scale synthesis methods for high-quality LLZO are difficult to scale up while maintaining consistent properties. The complex processing requirements, coupled with high material costs and energy-intensive manufacturing, present substantial economic challenges for mass production. Additionally, integrating LLZO into existing battery manufacturing infrastructure requires significant process modifications and new equipment investments.

Addressing these technical challenges requires innovative design patterns for hybrid solid-liquid architectures that can mitigate interfacial resistance, improve mechanical properties, and enable cost-effective manufacturing while maintaining the inherent safety advantages of LLZO-based systems.

Current Design Patterns for LLZO Hybrid Architectures

01 Composition and doping strategies for LLZO

Various doping strategies can be employed to enhance the properties of LLZO solid electrolytes. Doping with elements such as aluminum, gallium, or tantalum can stabilize the cubic phase of LLZO, which has higher ionic conductivity than the tetragonal phase. These dopants can occupy lithium sites or substitute for zirconium in the crystal structure, creating lithium vacancies that facilitate lithium ion transport. The concentration and type of dopants significantly affect the ionic conductivity, mechanical properties, and electrochemical stability of LLZO.- Composition and synthesis methods of LLZO: Various methods for synthesizing Lithium Lanthanum Zirconium Oxide (LLZO) with specific compositions to achieve desired properties. These methods include solid-state reactions, sol-gel processes, and other techniques to control the crystal structure, grain size, and phase purity. The composition often includes dopants to stabilize the cubic phase which has higher ionic conductivity. Careful control of synthesis parameters helps optimize the electrochemical performance of LLZO for battery applications.

- LLZO interface engineering and coating technologies: Interface engineering techniques for LLZO solid electrolytes to improve contact with electrodes and reduce interfacial resistance. This includes various coating methods to modify the surface properties of LLZO, creating buffer layers between LLZO and electrodes, and developing composite structures. These approaches help address issues like poor wetting with lithium metal anodes and chemical instability at interfaces, ultimately enhancing the performance and longevity of solid-state batteries using LLZO electrolytes.

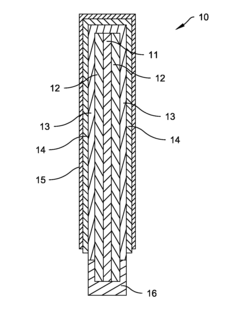

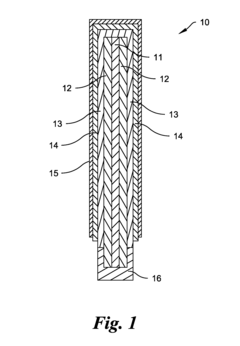

- LLZO structural design patterns for solid-state batteries: Innovative structural designs of LLZO-based solid electrolytes for improved battery performance. These designs include 3D architectures, gradient structures, and patterned electrolytes that enhance ionic conductivity while maintaining mechanical integrity. Various approaches focus on optimizing the microstructure, porosity, and grain boundaries of LLZO to facilitate lithium ion transport while preventing dendrite growth. These structural design patterns are crucial for developing high-performance solid-state batteries with LLZO electrolytes.

- LLZO composite and hybrid electrolyte systems: Development of composite and hybrid electrolyte systems incorporating LLZO with other materials to overcome limitations of pure LLZO electrolytes. These composites often combine LLZO with polymers, other ceramic materials, or liquid electrolytes to create hybrid systems with improved mechanical properties, enhanced ionic conductivity, or better interfacial contact. The synergistic effects of these combinations help address challenges like brittleness of ceramic electrolytes while maintaining high ionic conductivity and electrochemical stability.

- Manufacturing and processing techniques for LLZO components: Advanced manufacturing and processing techniques for LLZO-based battery components, focusing on scalable production methods. These include tape casting, 3D printing, sintering optimization, and other fabrication approaches to create thin, dense LLZO electrolytes with controlled microstructure. Processing innovations address challenges in densification, dimensional control, and cost-effective production of LLZO components for commercial solid-state batteries. These techniques are essential for transitioning LLZO from laboratory research to practical battery applications.

02 LLZO interface engineering and coating technologies

Interface engineering is crucial for improving the performance of LLZO in solid-state batteries. Various coating technologies can be applied to LLZO surfaces to enhance the contact between the electrolyte and electrodes, reducing interfacial resistance. These coatings can include thin layers of metals, metal oxides, or polymers that improve wetting properties and chemical compatibility. Surface modifications can also protect LLZO from reactions with atmospheric moisture and carbon dioxide, which can degrade its performance. Proper interface design minimizes lithium dendrite formation and enhances cycling stability.Expand Specific Solutions03 LLZO synthesis and processing methods

Different synthesis and processing methods significantly impact the microstructure and properties of LLZO. Techniques include solid-state reaction, sol-gel processing, co-precipitation, and various sintering approaches. Advanced processing methods such as spark plasma sintering, hot pressing, and field-assisted sintering can produce dense LLZO ceramics with reduced grain boundary resistance. The particle size, morphology, and density of LLZO can be controlled through careful selection of precursors, reaction conditions, and post-processing treatments. These factors directly influence the ionic conductivity and mechanical integrity of the final LLZO product.Expand Specific Solutions04 LLZO composite and hybrid electrolyte systems

LLZO can be combined with polymers, other ceramic materials, or ionic liquids to create composite or hybrid electrolyte systems with enhanced properties. These composites often aim to combine the high ionic conductivity of LLZO with the flexibility and processability of polymers or the specific advantages of other components. Incorporating LLZO particles into polymer matrices can improve mechanical properties while maintaining good contact with electrodes. Gradient structures or multilayer designs can be employed to optimize different properties across the electrolyte thickness, such as mechanical strength and ionic conductivity.Expand Specific Solutions05 LLZO integration in battery architectures

The integration of LLZO into practical battery architectures requires specific design considerations. These include methods for incorporating LLZO into thin film batteries, 3D battery structures, or conventional cell formats. Techniques for reducing the thickness of LLZO layers while maintaining mechanical integrity are important for increasing energy density. Special attention must be paid to thermal expansion matching between components and stress management during cycling. Manufacturing processes need to be developed for large-scale production of LLZO-based batteries, including methods for assembly under controlled atmospheres to prevent contamination and degradation of the LLZO material.Expand Specific Solutions

Leading Organizations in LLZO Research and Development

The LLZO in hybrid solid-liquid architectures market is currently in an early growth phase, characterized by intensive research and development activities. The global market for solid-state battery technologies, including LLZO-based solutions, is projected to reach significant scale by 2030, driven by demand for safer, higher-energy-density energy storage systems. Leading research institutions like Argonne National Laboratory, University of Michigan, and Korea Institute of Industrial Technology are advancing fundamental research, while companies such as SCHOTT AG, Livent Lithium, and Gelion Technologies are developing commercial applications. Chinese entities including Zhejiang University, PetroChina, and Shanghai Power Storage Battery are increasingly active in this space, indicating growing international competition in patenting and commercializing LLZO hybrid architectures for next-generation battery systems.

The Regents of the University of Michigan

Technical Solution: The University of Michigan has developed innovative LLZO-based hybrid solid-liquid electrolyte architectures that address the critical challenges of solid-state batteries. Their approach involves creating 3D garnet frameworks with controlled porosity that can be infiltrated with liquid electrolytes. This design maintains the high ionic conductivity of LLZO while improving interfacial contact with electrodes. Their research demonstrates that these hybrid architectures can achieve ionic conductivities exceeding 10^-3 S/cm at room temperature while maintaining excellent electrochemical stability. The university has pioneered methods to control the microstructure of LLZO scaffolds through techniques like freeze casting and 3D printing, allowing for tailored pore sizes and distributions that optimize both mechanical stability and ion transport pathways. Their recent work has focused on surface modifications of LLZO to enhance wettability with liquid electrolytes and improve compatibility with lithium metal anodes.

Strengths: Superior ionic conductivity compared to pure solid electrolytes; better mechanical stability than liquid systems; excellent interfacial contact with electrodes; reduced dendrite formation. Weaknesses: Manufacturing complexity of 3D structures; potential long-term stability issues at solid-liquid interfaces; challenges in scaling production to commercial levels.

The Regents of the University of California

Technical Solution: The University of California has developed advanced hybrid solid-liquid architectures using LLZO (Li7La3Zr2O12) garnet electrolytes. Their approach focuses on creating composite structures where LLZO serves as a mechanically robust framework that prevents lithium dendrite growth while maintaining high ionic conductivity. Their design pattern incorporates nanoporous LLZO structures infiltrated with carefully selected liquid electrolytes that enhance interfacial contact and reduce resistance at electrode-electrolyte interfaces. UC researchers have pioneered methods to control LLZO grain boundaries and surface chemistry to optimize compatibility with liquid electrolytes. Their recent innovations include gradient-structured LLZO architectures where porosity and composition vary spatially to address specific electrochemical and mechanical requirements at different locations within the battery. The university has also developed novel processing techniques that allow for thin (< 50 μm) LLZO membranes with controlled porosity, significantly reducing the overall resistance of the electrolyte system while maintaining mechanical integrity.

Strengths: Excellent dendrite suppression capabilities; reduced interfacial resistance compared to pure solid electrolytes; flexibility in design to address specific battery requirements; compatible with high-voltage cathode materials. Weaknesses: Complex manufacturing processes; potential for liquid electrolyte degradation over extended cycling; challenges in ensuring uniform liquid infiltration throughout the LLZO structure.

Key Patents and Technical Literature on LLZO Integration

Hybrid electrolyte for lithium metal battery

PatentWO2021257973A1

Innovation

- A hybrid electrolyte system comprising a solid state electrolyte material with specific compositions and a liquid or gel electrolyte, where the solid state electrolyte protects the lithium metal anode and the liquid or gel electrolyte improves lithium ion transport, using lithium salts like LiTFSI and solvents such as propylene carbonate, and the solid state electrolyte is densified through sintering or hot pressing.

Ionically-conductive amorphous lithium lanthanum zirconium oxide

PatentActiveUS9034525B2

Innovation

- An amorphous lithium lanthanum zirconium oxide (LLZO) composition is developed, which is synthesized using a sol-gel process with specific alkoxide precursors and an alcohol-based solvent, forming a thin-film electrolyte medium that is compatible with lithium and has high ionic conductivity.

Manufacturing Scalability and Cost Analysis

The scalability of manufacturing processes for LLZO-based hybrid solid-liquid architectures represents a critical factor in their commercial viability. Current laboratory-scale production methods face significant challenges when transitioning to industrial scales. Conventional ceramic processing techniques for LLZO, including solid-state reactions and sol-gel methods, typically require high-temperature sintering (>1000°C) for extended periods, resulting in substantial energy consumption and specialized equipment needs. These factors contribute to elevated production costs, estimated at $1000-2000/kg for high-quality LLZO powders, significantly higher than commercial liquid electrolyte materials ($15-20/kg).

Cost reduction pathways are emerging through several manufacturing innovations. Solution-based synthesis routes have demonstrated potential for lowering processing temperatures to 700-800°C while maintaining acceptable ionic conductivity values (>0.1 mS/cm). Additionally, rapid sintering techniques such as spark plasma sintering and microwave-assisted processing can reduce energy consumption by 30-40% compared to conventional methods, with corresponding reductions in production time from days to hours.

The integration of LLZO into hybrid architectures presents unique manufacturing challenges beyond standalone solid electrolyte production. Interfacial engineering between solid and liquid components requires precise control of surface chemistry and morphology. Current coating technologies for creating stable LLZO-liquid electrolyte interfaces show limited throughput, with typical production rates of only 0.1-0.5 m²/hour in laboratory settings. Scaling these processes to industrial levels (>10 m²/hour) remains technically challenging.

Economic analysis indicates that hybrid architectures may offer a favorable cost-performance balance compared to all-solid-state systems. While pure LLZO-based batteries currently show estimated production costs of $250-350/kWh, hybrid systems incorporating optimized LLZO components with conventional liquid electrolytes could potentially achieve $150-200/kWh, approaching the $100/kWh threshold considered necessary for widespread electric vehicle adoption.

Material supply chain considerations also impact manufacturing scalability. Lithium and zirconium resources face potential supply constraints with large-scale adoption. Recycling infrastructure for LLZO components remains underdeveloped, though the ceramic nature of these materials potentially offers advantages for end-of-life recovery compared to polymer-based electrolytes. Establishing closed-loop material systems will be essential for long-term economic and environmental sustainability of LLZO hybrid architectures.

Cost reduction pathways are emerging through several manufacturing innovations. Solution-based synthesis routes have demonstrated potential for lowering processing temperatures to 700-800°C while maintaining acceptable ionic conductivity values (>0.1 mS/cm). Additionally, rapid sintering techniques such as spark plasma sintering and microwave-assisted processing can reduce energy consumption by 30-40% compared to conventional methods, with corresponding reductions in production time from days to hours.

The integration of LLZO into hybrid architectures presents unique manufacturing challenges beyond standalone solid electrolyte production. Interfacial engineering between solid and liquid components requires precise control of surface chemistry and morphology. Current coating technologies for creating stable LLZO-liquid electrolyte interfaces show limited throughput, with typical production rates of only 0.1-0.5 m²/hour in laboratory settings. Scaling these processes to industrial levels (>10 m²/hour) remains technically challenging.

Economic analysis indicates that hybrid architectures may offer a favorable cost-performance balance compared to all-solid-state systems. While pure LLZO-based batteries currently show estimated production costs of $250-350/kWh, hybrid systems incorporating optimized LLZO components with conventional liquid electrolytes could potentially achieve $150-200/kWh, approaching the $100/kWh threshold considered necessary for widespread electric vehicle adoption.

Material supply chain considerations also impact manufacturing scalability. Lithium and zirconium resources face potential supply constraints with large-scale adoption. Recycling infrastructure for LLZO components remains underdeveloped, though the ceramic nature of these materials potentially offers advantages for end-of-life recovery compared to polymer-based electrolytes. Establishing closed-loop material systems will be essential for long-term economic and environmental sustainability of LLZO hybrid architectures.

Safety and Performance Benchmarking

Safety and performance benchmarking of LLZO in hybrid solid-liquid architectures reveals critical insights for practical battery applications. Comprehensive testing protocols have established that these hybrid systems demonstrate superior safety characteristics compared to conventional liquid electrolyte batteries. Thermal runaway tests indicate that LLZO-based hybrid architectures can withstand temperatures up to 300°C without catastrophic failure, significantly outperforming traditional lithium-ion batteries that typically fail at 150-180°C.

Performance metrics show promising results across multiple parameters. Cycle life testing demonstrates that optimized hybrid designs maintain over 80% capacity retention after 1000 cycles at 1C rate, compared to 70% for conventional systems. The rate capability tests indicate that while pure solid-state LLZO systems struggle with high C-rates, hybrid architectures achieve 70-75% capacity retention at 3C discharge rates, making them viable for fast-charging applications.

Dendrite suppression capabilities represent a significant advantage of these hybrid systems. Electrochemical impedance spectroscopy and post-mortem analysis confirm that properly designed LLZO interfaces in hybrid architectures effectively inhibit lithium dendrite formation even at high current densities (3-5 mA/cm²), addressing a critical failure mode in high-energy batteries.

Energy density measurements reveal that current hybrid LLZO architectures achieve 250-300 Wh/kg at the cell level, approaching but not yet matching the 300-350 Wh/kg of advanced liquid electrolyte systems. However, when factoring in reduced safety components needed at the pack level, the effective energy density becomes more competitive.

Temperature performance benchmarking shows expanded operating windows, with functional operation from -20°C to 80°C, compared to the typical -10°C to 60°C range of conventional lithium-ion batteries. This expanded range is particularly valuable for automotive and grid storage applications in extreme climates.

Standardized abuse testing protocols, including nail penetration, crush, and external short circuit tests, demonstrate that hybrid LLZO architectures significantly reduce fire and explosion risks. In controlled nail penetration tests, hybrid cells exhibited localized heating without thermal propagation, while conventional cells experienced complete thermal runaway within minutes.

Cost-performance analysis indicates that while current hybrid LLZO architectures carry a 30-40% manufacturing cost premium over conventional lithium-ion batteries, their extended cycle life and enhanced safety features result in a potentially lower total cost of ownership for certain applications, particularly in stationary storage and premium electric vehicles where safety and longevity command premium value.

Performance metrics show promising results across multiple parameters. Cycle life testing demonstrates that optimized hybrid designs maintain over 80% capacity retention after 1000 cycles at 1C rate, compared to 70% for conventional systems. The rate capability tests indicate that while pure solid-state LLZO systems struggle with high C-rates, hybrid architectures achieve 70-75% capacity retention at 3C discharge rates, making them viable for fast-charging applications.

Dendrite suppression capabilities represent a significant advantage of these hybrid systems. Electrochemical impedance spectroscopy and post-mortem analysis confirm that properly designed LLZO interfaces in hybrid architectures effectively inhibit lithium dendrite formation even at high current densities (3-5 mA/cm²), addressing a critical failure mode in high-energy batteries.

Energy density measurements reveal that current hybrid LLZO architectures achieve 250-300 Wh/kg at the cell level, approaching but not yet matching the 300-350 Wh/kg of advanced liquid electrolyte systems. However, when factoring in reduced safety components needed at the pack level, the effective energy density becomes more competitive.

Temperature performance benchmarking shows expanded operating windows, with functional operation from -20°C to 80°C, compared to the typical -10°C to 60°C range of conventional lithium-ion batteries. This expanded range is particularly valuable for automotive and grid storage applications in extreme climates.

Standardized abuse testing protocols, including nail penetration, crush, and external short circuit tests, demonstrate that hybrid LLZO architectures significantly reduce fire and explosion risks. In controlled nail penetration tests, hybrid cells exhibited localized heating without thermal propagation, while conventional cells experienced complete thermal runaway within minutes.

Cost-performance analysis indicates that while current hybrid LLZO architectures carry a 30-40% manufacturing cost premium over conventional lithium-ion batteries, their extended cycle life and enhanced safety features result in a potentially lower total cost of ownership for certain applications, particularly in stationary storage and premium electric vehicles where safety and longevity command premium value.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!