How to Harness Fluoroantimonic Acid’s Full Potential?

JUN 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fluoroantimonic Acid Overview and Research Objectives

Fluoroantimonic acid, a superacid composed of a mixture of hydrogen fluoride (HF) and antimony pentafluoride (SbF5), stands as one of the strongest known acids in existence. Its exceptional acidity, surpassing that of pure sulfuric acid by orders of magnitude, has captivated researchers and industry professionals alike. The acid's unique properties stem from its ability to protonate even extremely weak bases, making it a powerful tool in various chemical processes.

The development of fluoroantimonic acid can be traced back to the mid-20th century, with significant advancements in understanding its structure and behavior occurring in recent decades. As research progressed, the potential applications of this superacid have expanded, spanning across multiple industries and scientific disciplines. From catalysis in petrochemical processes to the synthesis of novel materials, fluoroantimonic acid has demonstrated remarkable versatility.

Despite its immense potential, harnessing the full capabilities of fluoroantimonic acid remains a challenge due to its extreme reactivity and corrosive nature. Current research objectives focus on overcoming these limitations while maximizing the acid's utility in various applications. Key areas of investigation include developing safer handling methods, exploring new reaction pathways, and identifying novel applications in materials science and organic synthesis.

One of the primary goals in fluoroantimonic acid research is to enhance its stability and controllability in industrial settings. This involves the development of specialized containment materials and handling protocols that can withstand the acid's corrosive properties while maintaining its reactivity. Additionally, researchers are exploring ways to modulate the acid's strength, potentially creating a range of superacids with tailored properties for specific applications.

Another significant research objective is to expand the acid's role in catalysis. Fluoroantimonic acid's ability to activate inert compounds makes it an attractive candidate for various catalytic processes, particularly in the petrochemical industry. Ongoing studies aim to optimize its catalytic efficiency while minimizing unwanted side reactions and environmental impact.

In the field of materials science, researchers are investigating the use of fluoroantimonic acid in the synthesis of novel compounds and materials with unique properties. This includes the development of new polymers, advanced ceramics, and nanomaterials that could revolutionize industries such as electronics, aerospace, and energy storage.

Furthermore, the potential of fluoroantimonic acid in organic synthesis is being extensively explored. Its ability to facilitate challenging transformations and generate reactive intermediates opens up new possibilities for the creation of complex organic molecules, potentially impacting pharmaceutical development and fine chemical production.

As research progresses, a key objective is to balance the acid's extraordinary reactivity with practical considerations such as safety, scalability, and environmental impact. This holistic approach aims to unlock fluoroantimonic acid's full potential while addressing the challenges associated with its use, paving the way for groundbreaking advancements across multiple scientific and industrial domains.

The development of fluoroantimonic acid can be traced back to the mid-20th century, with significant advancements in understanding its structure and behavior occurring in recent decades. As research progressed, the potential applications of this superacid have expanded, spanning across multiple industries and scientific disciplines. From catalysis in petrochemical processes to the synthesis of novel materials, fluoroantimonic acid has demonstrated remarkable versatility.

Despite its immense potential, harnessing the full capabilities of fluoroantimonic acid remains a challenge due to its extreme reactivity and corrosive nature. Current research objectives focus on overcoming these limitations while maximizing the acid's utility in various applications. Key areas of investigation include developing safer handling methods, exploring new reaction pathways, and identifying novel applications in materials science and organic synthesis.

One of the primary goals in fluoroantimonic acid research is to enhance its stability and controllability in industrial settings. This involves the development of specialized containment materials and handling protocols that can withstand the acid's corrosive properties while maintaining its reactivity. Additionally, researchers are exploring ways to modulate the acid's strength, potentially creating a range of superacids with tailored properties for specific applications.

Another significant research objective is to expand the acid's role in catalysis. Fluoroantimonic acid's ability to activate inert compounds makes it an attractive candidate for various catalytic processes, particularly in the petrochemical industry. Ongoing studies aim to optimize its catalytic efficiency while minimizing unwanted side reactions and environmental impact.

In the field of materials science, researchers are investigating the use of fluoroantimonic acid in the synthesis of novel compounds and materials with unique properties. This includes the development of new polymers, advanced ceramics, and nanomaterials that could revolutionize industries such as electronics, aerospace, and energy storage.

Furthermore, the potential of fluoroantimonic acid in organic synthesis is being extensively explored. Its ability to facilitate challenging transformations and generate reactive intermediates opens up new possibilities for the creation of complex organic molecules, potentially impacting pharmaceutical development and fine chemical production.

As research progresses, a key objective is to balance the acid's extraordinary reactivity with practical considerations such as safety, scalability, and environmental impact. This holistic approach aims to unlock fluoroantimonic acid's full potential while addressing the challenges associated with its use, paving the way for groundbreaking advancements across multiple scientific and industrial domains.

Industrial Applications and Market Demand Analysis

Fluoroantimonic acid, known as the world's strongest superacid, has garnered significant attention in various industrial sectors due to its exceptional chemical properties. The market demand for this powerful compound is driven by its potential applications in catalysis, materials processing, and energy production.

In the petrochemical industry, fluoroantimonic acid shows promise as a highly efficient catalyst for hydrocarbon cracking and isomerization processes. Its ability to protonate even weak bases makes it invaluable in the production of high-octane gasoline and other refined petroleum products. The global demand for cleaner and more efficient fuels continues to grow, creating a substantial market opportunity for fluoroantimonic acid-based catalysts.

The semiconductor industry represents another key market for fluoroantimonic acid. Its extreme acidity makes it useful in etching and cleaning silicon wafers, potentially improving the efficiency and precision of microchip manufacturing processes. As the demand for smaller, more powerful electronic devices increases, the semiconductor industry's need for advanced processing chemicals like fluoroantimonic acid is expected to rise.

In materials science, fluoroantimonic acid's ability to dissolve normally inert substances opens up new possibilities for materials processing and synthesis. This property could revolutionize the production of advanced ceramics, specialty polymers, and novel composite materials. The growing demand for high-performance materials in aerospace, automotive, and renewable energy sectors could drive significant market growth for fluoroantimonic acid in this area.

The energy sector presents another promising application for fluoroantimonic acid. Its potential use in next-generation battery technologies, particularly in the development of more efficient and longer-lasting lithium-ion batteries, could address the increasing demand for improved energy storage solutions. As the world transitions towards renewable energy sources and electric vehicles, the market for advanced battery technologies is projected to expand rapidly.

However, the widespread adoption of fluoroantimonic acid faces challenges due to its extreme corrosiveness and reactivity. Stringent safety regulations and the need for specialized handling equipment may limit its use in certain industries. Additionally, the high production costs associated with fluoroantimonic acid could impact its market penetration, particularly in price-sensitive applications.

Despite these challenges, the unique properties of fluoroantimonic acid continue to attract research and development efforts across multiple industries. As new applications are discovered and existing processes are optimized, the market demand for this superacid is expected to grow. The key to harnessing its full potential lies in developing safer handling methods, reducing production costs, and identifying novel applications that can fully leverage its extraordinary chemical properties.

In the petrochemical industry, fluoroantimonic acid shows promise as a highly efficient catalyst for hydrocarbon cracking and isomerization processes. Its ability to protonate even weak bases makes it invaluable in the production of high-octane gasoline and other refined petroleum products. The global demand for cleaner and more efficient fuels continues to grow, creating a substantial market opportunity for fluoroantimonic acid-based catalysts.

The semiconductor industry represents another key market for fluoroantimonic acid. Its extreme acidity makes it useful in etching and cleaning silicon wafers, potentially improving the efficiency and precision of microchip manufacturing processes. As the demand for smaller, more powerful electronic devices increases, the semiconductor industry's need for advanced processing chemicals like fluoroantimonic acid is expected to rise.

In materials science, fluoroantimonic acid's ability to dissolve normally inert substances opens up new possibilities for materials processing and synthesis. This property could revolutionize the production of advanced ceramics, specialty polymers, and novel composite materials. The growing demand for high-performance materials in aerospace, automotive, and renewable energy sectors could drive significant market growth for fluoroantimonic acid in this area.

The energy sector presents another promising application for fluoroantimonic acid. Its potential use in next-generation battery technologies, particularly in the development of more efficient and longer-lasting lithium-ion batteries, could address the increasing demand for improved energy storage solutions. As the world transitions towards renewable energy sources and electric vehicles, the market for advanced battery technologies is projected to expand rapidly.

However, the widespread adoption of fluoroantimonic acid faces challenges due to its extreme corrosiveness and reactivity. Stringent safety regulations and the need for specialized handling equipment may limit its use in certain industries. Additionally, the high production costs associated with fluoroantimonic acid could impact its market penetration, particularly in price-sensitive applications.

Despite these challenges, the unique properties of fluoroantimonic acid continue to attract research and development efforts across multiple industries. As new applications are discovered and existing processes are optimized, the market demand for this superacid is expected to grow. The key to harnessing its full potential lies in developing safer handling methods, reducing production costs, and identifying novel applications that can fully leverage its extraordinary chemical properties.

Current Challenges in Fluoroantimonic Acid Utilization

Fluoroantimonic acid, known as the world's strongest superacid, presents significant challenges in its utilization due to its extreme reactivity and corrosive nature. One of the primary obstacles is the acid's incompatibility with most conventional materials, including glass and many metals. This severely limits the options for containment and handling, necessitating the use of specialized materials such as polytetrafluoroethylene (PTFE) or certain fluoropolymers.

The high reactivity of fluoroantimonic acid also poses safety concerns for researchers and industrial workers. Exposure risks are substantial, requiring stringent safety protocols and specialized personal protective equipment. The acid's ability to protonate almost any substance it comes into contact with makes it exceptionally dangerous to handle, limiting its practical applications in many fields.

Another significant challenge lies in controlling the acid's reactivity for specific applications. While its extreme acidity can be beneficial in certain chemical processes, harnessing this power for precise and controlled reactions remains difficult. The acid's tendency to react violently with water and many organic compounds further complicates its use in synthetic chemistry and industrial processes.

The environmental impact of fluoroantimonic acid is also a major concern. Its production, use, and disposal require careful management to prevent ecological damage. The acid's potential to generate toxic fumes and its ability to decompose many materials make it a significant environmental hazard if not properly contained and handled.

From a practical standpoint, the cost and complexity of working with fluoroantimonic acid present economic challenges. The specialized equipment, safety measures, and expertise required for its handling and use significantly increase operational costs. This economic factor limits its widespread adoption in industrial applications, despite its potential benefits in certain chemical processes.

The lack of comprehensive research on the long-term effects of fluoroantimonic acid exposure, both on human health and the environment, presents another challenge. This knowledge gap hinders the development of more advanced safety protocols and limits our understanding of the acid's full range of potential applications and risks.

Lastly, the regulatory landscape surrounding the use of such potent substances adds another layer of complexity. Stringent regulations and permitting requirements for the production, transport, and use of fluoroantimonic acid create logistical challenges for researchers and industries looking to explore its potential applications.

The high reactivity of fluoroantimonic acid also poses safety concerns for researchers and industrial workers. Exposure risks are substantial, requiring stringent safety protocols and specialized personal protective equipment. The acid's ability to protonate almost any substance it comes into contact with makes it exceptionally dangerous to handle, limiting its practical applications in many fields.

Another significant challenge lies in controlling the acid's reactivity for specific applications. While its extreme acidity can be beneficial in certain chemical processes, harnessing this power for precise and controlled reactions remains difficult. The acid's tendency to react violently with water and many organic compounds further complicates its use in synthetic chemistry and industrial processes.

The environmental impact of fluoroantimonic acid is also a major concern. Its production, use, and disposal require careful management to prevent ecological damage. The acid's potential to generate toxic fumes and its ability to decompose many materials make it a significant environmental hazard if not properly contained and handled.

From a practical standpoint, the cost and complexity of working with fluoroantimonic acid present economic challenges. The specialized equipment, safety measures, and expertise required for its handling and use significantly increase operational costs. This economic factor limits its widespread adoption in industrial applications, despite its potential benefits in certain chemical processes.

The lack of comprehensive research on the long-term effects of fluoroantimonic acid exposure, both on human health and the environment, presents another challenge. This knowledge gap hinders the development of more advanced safety protocols and limits our understanding of the acid's full range of potential applications and risks.

Lastly, the regulatory landscape surrounding the use of such potent substances adds another layer of complexity. Stringent regulations and permitting requirements for the production, transport, and use of fluoroantimonic acid create logistical challenges for researchers and industries looking to explore its potential applications.

Existing Handling and Application Methodologies

01 Synthesis and preparation methods

Various methods for synthesizing and preparing fluoroantimonic acid are described. These methods may involve the reaction of hydrogen fluoride with antimony pentafluoride or other precursors under specific conditions. The synthesis process often requires careful control of temperature, pressure, and reactant ratios to achieve the desired product.- Synthesis and production methods: Various methods for synthesizing and producing fluoroantimonic acid are described. These methods may involve different precursors, reaction conditions, and purification techniques to obtain the desired product. The processes aim to optimize yield, purity, and efficiency in the production of this superacid.

- Applications in catalysis: Fluoroantimonic acid is utilized as a powerful catalyst in various chemical reactions. Its strong acidic properties make it effective for promoting reactions such as isomerization, alkylation, and polymerization. The use of this superacid as a catalyst can lead to improved reaction rates and yields in certain industrial processes.

- Material treatment and modification: Fluoroantimonic acid is employed in the treatment and modification of various materials. This includes surface treatments, etching processes, and the alteration of material properties. The superacid's strong protonating ability can be used to modify surfaces or create specific chemical structures in materials.

- Safety and handling considerations: Due to its highly corrosive and reactive nature, special safety measures and handling procedures are necessary when working with fluoroantimonic acid. This includes the use of specialized containment materials, personal protective equipment, and specific storage conditions to prevent accidents and ensure safe usage in laboratory and industrial settings.

- Analytical and characterization techniques: Various analytical and characterization techniques are employed to study the properties and behavior of fluoroantimonic acid. These may include spectroscopic methods, electrochemical analyses, and other advanced instrumental techniques to determine its structure, purity, and reactivity in different chemical environments.

02 Applications in catalysis and chemical reactions

Fluoroantimonic acid is utilized as a powerful catalyst in various chemical reactions due to its extremely high acidity. It can catalyze alkylation, isomerization, and polymerization reactions. The acid's catalytic properties are exploited in the production of high-octane gasoline components and other industrial processes.Expand Specific Solutions03 Use in materials science and surface treatments

Fluoroantimonic acid finds applications in materials science, particularly in surface treatments and modifications. It can be used to etch or modify surfaces of various materials, including metals and semiconductors. The acid's strong protonating ability allows for unique surface chemistry and the creation of specialized coatings or films.Expand Specific Solutions04 Safety and handling considerations

Due to its extreme corrosiveness and reactivity, special safety measures and handling procedures are required when working with fluoroantimonic acid. This includes the use of specialized containment materials, personal protective equipment, and strict protocols for storage and disposal. Proper training and safety precautions are essential for handling this superacid.Expand Specific Solutions05 Analytical and characterization techniques

Various analytical and characterization techniques are employed to study fluoroantimonic acid and its properties. These may include spectroscopic methods, electrochemical analysis, and computational modeling. Such techniques help in understanding the acid's structure, reactivity, and behavior in different chemical environments.Expand Specific Solutions

Key Players in Superacid Research and Production

The competitive landscape for harnessing fluoroantimonic acid's full potential is in its early development stage, with limited market size due to its highly specialized applications. The technology's maturity is still evolving, with research institutions like Central South University, Kunming University of Science & Technology, and Beijing Normal University leading academic efforts. Industry players such as Merck Sharp & Dohme Corp., DAIKIN INDUSTRIES Ltd., and Nissan Chemical Corp. are exploring commercial applications. The field is characterized by a mix of academic and industrial research, with potential for significant breakthroughs in chemical synthesis, catalysis, and materials science. As the technology advances, collaborations between universities and corporations are likely to drive innovation and market expansion.

Merck Sharp & Dohme Corp.

Technical Solution: Merck Sharp & Dohme Corp. has developed a proprietary process for the safe handling and application of fluoroantimonic acid in pharmaceutical synthesis. Their approach involves using specialized containment systems made of fluoropolymer materials resistant to the acid's corrosive nature. The company has also implemented advanced safety protocols and remote handling techniques to minimize human exposure. Additionally, they have explored the use of fluoroantimonic acid as a catalyst in the synthesis of complex organic compounds, potentially leading to more efficient drug manufacturing processes.

Strengths: Advanced safety measures and specialized equipment for handling. Potential for more efficient drug synthesis. Weaknesses: High costs associated with safety measures and specialized equipment. Limited applications outside of pharmaceutical industry.

DAIKIN INDUSTRIES Ltd.

Technical Solution: DAIKIN INDUSTRIES Ltd. has developed innovative applications for fluoroantimonic acid in the production of high-performance fluoropolymers. Their approach involves using the acid as a super-catalyst in polymerization reactions, allowing for the creation of fluoropolymers with unique properties. The company has also invested in advanced containment and neutralization systems to manage the acid safely. Furthermore, DAIKIN has explored the use of fluoroantimonic acid in surface treatment processes for metals, potentially enhancing corrosion resistance in extreme environments.

Strengths: Expertise in fluorine chemistry and fluoropolymer production. Potential for creating novel materials with unique properties. Weaknesses: High production costs and environmental concerns associated with fluorine-based chemicals.

Breakthrough Innovations in Fluoroantimonic Acid Research

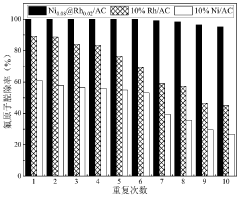

Method for efficiently reducing and defluorinating perfluorinated compound under synergistic catalysis of double metals

PatentActiveCN111003787A

Innovation

- A bimetallic synergistic catalyst using supported Rh and Ni as active components, combined with hydrogen and a strong alkaline proton absorber, performs the reductive defluorination reaction of perfluorinated compounds under heterogeneous catalytic conditions, using hydrogen and alkali metal hydroxidation As a catalyst, the reaction conditions are controlled at 0.1~1.0MPa, 30~80℃, and the catalytic treatment is carried out in a mixed solvent of alcohol and water.

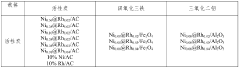

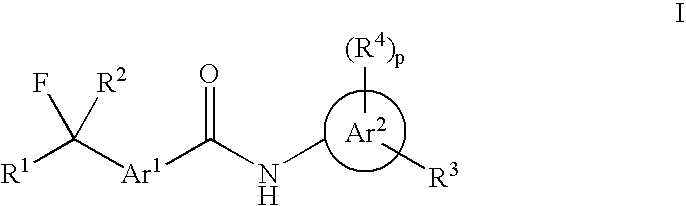

Fluorinated Arylamide Derivatives

PatentInactiveUS20090012075A1

Innovation

- Development of novel fluoroalkylarylamide derivatives that act as potent histone deacetylase inhibitors, capable of inducing terminal differentiation and apoptosis in neoplastic cells, and suitable for treating various diseases including cancer, autoimmune, and neurodegenerative conditions.

Safety Protocols and Environmental Considerations

Harnessing the full potential of fluoroantimonic acid requires stringent safety protocols and careful environmental considerations due to its extreme corrosiveness and reactivity. Proper handling and storage are paramount to prevent accidents and environmental contamination. All personnel working with this superacid must undergo specialized training and wear appropriate personal protective equipment, including chemical-resistant suits, gloves, and respiratory protection.

Containment systems for fluoroantimonic acid must be constructed from materials resistant to its corrosive effects, such as PTFE (Teflon) or certain fluoropolymers. Double containment systems and fail-safe mechanisms should be implemented to prevent leaks or spills. Regular inspections and maintenance of storage and handling equipment are essential to ensure integrity and prevent potential releases.

Emergency response plans must be in place, including spill containment procedures, neutralization protocols, and evacuation strategies. Specialized fire suppression systems are necessary, as water-based methods can exacerbate the acid's reactivity. On-site neutralization agents, such as sodium bicarbonate or calcium carbonate, should be readily available in case of accidental release.

Environmental considerations for fluoroantimonic acid usage extend beyond immediate workplace safety. Proper disposal methods must be established to prevent contamination of soil and water resources. Neutralization and dilution processes should be carefully controlled and monitored before any discharge. Air quality monitoring systems should be implemented to detect and mitigate potential vapor releases.

Long-term environmental impact assessments are crucial when considering large-scale applications of fluoroantimonic acid. This includes evaluating potential effects on local ecosystems, groundwater, and air quality. Developing closed-loop systems that minimize waste generation and maximize recycling of the acid can help reduce environmental risks and improve sustainability.

Regulatory compliance is a critical aspect of fluoroantimonic acid management. Facilities must adhere to strict guidelines set by environmental protection agencies and occupational safety organizations. This includes proper documentation of handling procedures, regular reporting of usage and disposal, and participation in audits to ensure compliance with safety and environmental standards.

Research into safer alternatives or methods to reduce the quantity of fluoroantimonic acid required in processes should be ongoing. This may involve exploring catalytic systems that can achieve similar results with less hazardous materials or developing novel reaction pathways that minimize the need for such extreme acidity.

Containment systems for fluoroantimonic acid must be constructed from materials resistant to its corrosive effects, such as PTFE (Teflon) or certain fluoropolymers. Double containment systems and fail-safe mechanisms should be implemented to prevent leaks or spills. Regular inspections and maintenance of storage and handling equipment are essential to ensure integrity and prevent potential releases.

Emergency response plans must be in place, including spill containment procedures, neutralization protocols, and evacuation strategies. Specialized fire suppression systems are necessary, as water-based methods can exacerbate the acid's reactivity. On-site neutralization agents, such as sodium bicarbonate or calcium carbonate, should be readily available in case of accidental release.

Environmental considerations for fluoroantimonic acid usage extend beyond immediate workplace safety. Proper disposal methods must be established to prevent contamination of soil and water resources. Neutralization and dilution processes should be carefully controlled and monitored before any discharge. Air quality monitoring systems should be implemented to detect and mitigate potential vapor releases.

Long-term environmental impact assessments are crucial when considering large-scale applications of fluoroantimonic acid. This includes evaluating potential effects on local ecosystems, groundwater, and air quality. Developing closed-loop systems that minimize waste generation and maximize recycling of the acid can help reduce environmental risks and improve sustainability.

Regulatory compliance is a critical aspect of fluoroantimonic acid management. Facilities must adhere to strict guidelines set by environmental protection agencies and occupational safety organizations. This includes proper documentation of handling procedures, regular reporting of usage and disposal, and participation in audits to ensure compliance with safety and environmental standards.

Research into safer alternatives or methods to reduce the quantity of fluoroantimonic acid required in processes should be ongoing. This may involve exploring catalytic systems that can achieve similar results with less hazardous materials or developing novel reaction pathways that minimize the need for such extreme acidity.

Economic Feasibility of Large-Scale Production

The economic feasibility of large-scale production of fluoroantimonic acid is a critical factor in harnessing its full potential. This superacid, known for its extreme corrosiveness and reactivity, presents significant challenges in terms of production, storage, and handling. However, its unique properties also offer substantial opportunities in various industrial applications.

The primary cost drivers for large-scale production include specialized equipment, safety measures, and raw materials. Fluoroantimonic acid requires highly resistant materials such as Teflon or fluorinated polymers for containment, significantly increasing infrastructure costs. Additionally, the need for stringent safety protocols and specialized training for personnel adds to the operational expenses.

Raw material costs are another crucial factor. The acid is typically produced by combining hydrogen fluoride and antimony pentafluoride, both of which are expensive and require careful handling. The availability and price fluctuations of these precursors can significantly impact the overall production costs.

Despite these challenges, economies of scale could potentially reduce per-unit costs in large-scale production. Optimizing production processes, improving yield, and developing more efficient catalysts could lead to cost reductions over time. Furthermore, advancements in materials science may result in more cost-effective containment solutions, further improving economic viability.

The market demand for fluoroantimonic acid and its derivatives plays a crucial role in determining economic feasibility. While current applications are limited due to its extreme properties, emerging technologies in fields such as petrochemicals, pharmaceuticals, and advanced materials could expand its market potential. For instance, its use as a super-catalyst in certain chemical reactions could lead to more efficient industrial processes, potentially justifying the high production costs.

Regulatory considerations also impact economic feasibility. Strict environmental and safety regulations may increase compliance costs but could also drive innovation in production and handling techniques. Companies investing in safer, more environmentally friendly production methods may gain a competitive edge in the long term.

In conclusion, while the economic feasibility of large-scale fluoroantimonic acid production faces significant challenges, technological advancements and expanding applications could improve its viability. A comprehensive cost-benefit analysis, considering both current limitations and future potential, is essential for companies considering investment in this area.

The primary cost drivers for large-scale production include specialized equipment, safety measures, and raw materials. Fluoroantimonic acid requires highly resistant materials such as Teflon or fluorinated polymers for containment, significantly increasing infrastructure costs. Additionally, the need for stringent safety protocols and specialized training for personnel adds to the operational expenses.

Raw material costs are another crucial factor. The acid is typically produced by combining hydrogen fluoride and antimony pentafluoride, both of which are expensive and require careful handling. The availability and price fluctuations of these precursors can significantly impact the overall production costs.

Despite these challenges, economies of scale could potentially reduce per-unit costs in large-scale production. Optimizing production processes, improving yield, and developing more efficient catalysts could lead to cost reductions over time. Furthermore, advancements in materials science may result in more cost-effective containment solutions, further improving economic viability.

The market demand for fluoroantimonic acid and its derivatives plays a crucial role in determining economic feasibility. While current applications are limited due to its extreme properties, emerging technologies in fields such as petrochemicals, pharmaceuticals, and advanced materials could expand its market potential. For instance, its use as a super-catalyst in certain chemical reactions could lead to more efficient industrial processes, potentially justifying the high production costs.

Regulatory considerations also impact economic feasibility. Strict environmental and safety regulations may increase compliance costs but could also drive innovation in production and handling techniques. Companies investing in safer, more environmentally friendly production methods may gain a competitive edge in the long term.

In conclusion, while the economic feasibility of large-scale fluoroantimonic acid production faces significant challenges, technological advancements and expanding applications could improve its viability. A comprehensive cost-benefit analysis, considering both current limitations and future potential, is essential for companies considering investment in this area.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!