How to Implement Alkyl Compounds in Polymer Engineering?

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Alkyl Compounds in Polymers: Background and Objectives

Alkyl compounds have played a pivotal role in the evolution of polymer engineering, marking significant milestones in the field's development. These organic molecules, characterized by their carbon and hydrogen composition, have been integral to enhancing the properties and performance of polymeric materials since the early 20th century. The journey of implementing alkyl compounds in polymer engineering began with the discovery of their potential to modify polymer structures and has since expanded to encompass a wide range of applications across various industries.

The primary objective of incorporating alkyl compounds into polymers is to tailor the physical, chemical, and mechanical properties of the resulting materials. This customization allows for the creation of polymers with specific characteristics suited to diverse applications, from everyday consumer products to advanced industrial materials. By manipulating the length, branching, and functionality of alkyl groups, researchers and engineers have been able to fine-tune polymer attributes such as flexibility, durability, thermal stability, and chemical resistance.

As the field of polymer engineering has progressed, the implementation of alkyl compounds has evolved from simple modifications to complex, multi-functional enhancements. Early applications focused on improving the processability and durability of polymers, while recent advancements have expanded to include the development of smart materials, self-healing polymers, and environmentally responsive systems. This evolution reflects the growing demand for high-performance materials in sectors such as automotive, aerospace, electronics, and healthcare.

The technological trajectory of alkyl compound implementation in polymers has been shaped by several key factors. Advancements in synthetic chemistry have enabled the creation of increasingly sophisticated alkyl compounds, allowing for more precise control over polymer properties. Concurrently, the development of analytical techniques has improved our understanding of polymer-alkyl interactions at the molecular level, facilitating more targeted and efficient material design.

Looking ahead, the field of alkyl-modified polymers is poised for further innovation. Emerging trends include the exploration of bio-based alkyl compounds to enhance sustainability, the development of stimuli-responsive polymers for smart applications, and the integration of alkyl compounds in nanocomposite materials. These directions align with broader industry goals of creating more sustainable, adaptable, and high-performance polymeric materials.

As we delve deeper into the implementation of alkyl compounds in polymer engineering, it is crucial to consider both the historical context and future potential of this technology. This comprehensive examination will provide valuable insights into the current state of the art, identify key challenges, and illuminate promising avenues for future research and development in this dynamic field.

The primary objective of incorporating alkyl compounds into polymers is to tailor the physical, chemical, and mechanical properties of the resulting materials. This customization allows for the creation of polymers with specific characteristics suited to diverse applications, from everyday consumer products to advanced industrial materials. By manipulating the length, branching, and functionality of alkyl groups, researchers and engineers have been able to fine-tune polymer attributes such as flexibility, durability, thermal stability, and chemical resistance.

As the field of polymer engineering has progressed, the implementation of alkyl compounds has evolved from simple modifications to complex, multi-functional enhancements. Early applications focused on improving the processability and durability of polymers, while recent advancements have expanded to include the development of smart materials, self-healing polymers, and environmentally responsive systems. This evolution reflects the growing demand for high-performance materials in sectors such as automotive, aerospace, electronics, and healthcare.

The technological trajectory of alkyl compound implementation in polymers has been shaped by several key factors. Advancements in synthetic chemistry have enabled the creation of increasingly sophisticated alkyl compounds, allowing for more precise control over polymer properties. Concurrently, the development of analytical techniques has improved our understanding of polymer-alkyl interactions at the molecular level, facilitating more targeted and efficient material design.

Looking ahead, the field of alkyl-modified polymers is poised for further innovation. Emerging trends include the exploration of bio-based alkyl compounds to enhance sustainability, the development of stimuli-responsive polymers for smart applications, and the integration of alkyl compounds in nanocomposite materials. These directions align with broader industry goals of creating more sustainable, adaptable, and high-performance polymeric materials.

As we delve deeper into the implementation of alkyl compounds in polymer engineering, it is crucial to consider both the historical context and future potential of this technology. This comprehensive examination will provide valuable insights into the current state of the art, identify key challenges, and illuminate promising avenues for future research and development in this dynamic field.

Market Analysis for Alkyl-Modified Polymers

The market for alkyl-modified polymers has shown significant growth in recent years, driven by increasing demand across various industries. These modified polymers offer enhanced properties such as improved thermal stability, chemical resistance, and mechanical strength, making them attractive for a wide range of applications.

In the automotive sector, alkyl-modified polymers are gaining traction due to their ability to reduce vehicle weight while maintaining structural integrity. This aligns with the industry's push towards fuel efficiency and emission reduction. The aerospace industry also benefits from these materials, particularly in interior components and non-structural parts where weight savings are crucial.

The packaging industry represents another major market for alkyl-modified polymers. These materials provide excellent barrier properties against moisture and gases, extending the shelf life of food products and reducing waste. As sustainability concerns grow, the biodegradable variants of alkyl-modified polymers are seeing increased adoption in this sector.

In the construction industry, alkyl-modified polymers are used in sealants, adhesives, and coatings due to their durability and weather resistance. The growing trend towards energy-efficient buildings has further boosted demand for these materials in insulation applications.

The electronics industry is another key market, where alkyl-modified polymers find use in circuit boards, connectors, and encapsulants. Their electrical insulation properties and resistance to high temperatures make them ideal for these applications.

Geographically, North America and Europe currently lead the market for alkyl-modified polymers, owing to their well-established manufacturing sectors and stringent environmental regulations. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization and increasing adoption of advanced materials in countries like China and India.

Market analysts project a compound annual growth rate (CAGR) for the global alkyl-modified polymer market in the mid-single digits over the next five years. This growth is attributed to ongoing research and development efforts to expand the application scope of these materials, as well as increasing awareness of their benefits among end-users.

However, the market faces challenges such as the volatility of raw material prices and the need for significant initial investments in production facilities. Additionally, competition from alternative materials and the environmental concerns associated with non-biodegradable polymers could potentially hinder market growth.

In the automotive sector, alkyl-modified polymers are gaining traction due to their ability to reduce vehicle weight while maintaining structural integrity. This aligns with the industry's push towards fuel efficiency and emission reduction. The aerospace industry also benefits from these materials, particularly in interior components and non-structural parts where weight savings are crucial.

The packaging industry represents another major market for alkyl-modified polymers. These materials provide excellent barrier properties against moisture and gases, extending the shelf life of food products and reducing waste. As sustainability concerns grow, the biodegradable variants of alkyl-modified polymers are seeing increased adoption in this sector.

In the construction industry, alkyl-modified polymers are used in sealants, adhesives, and coatings due to their durability and weather resistance. The growing trend towards energy-efficient buildings has further boosted demand for these materials in insulation applications.

The electronics industry is another key market, where alkyl-modified polymers find use in circuit boards, connectors, and encapsulants. Their electrical insulation properties and resistance to high temperatures make them ideal for these applications.

Geographically, North America and Europe currently lead the market for alkyl-modified polymers, owing to their well-established manufacturing sectors and stringent environmental regulations. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization and increasing adoption of advanced materials in countries like China and India.

Market analysts project a compound annual growth rate (CAGR) for the global alkyl-modified polymer market in the mid-single digits over the next five years. This growth is attributed to ongoing research and development efforts to expand the application scope of these materials, as well as increasing awareness of their benefits among end-users.

However, the market faces challenges such as the volatility of raw material prices and the need for significant initial investments in production facilities. Additionally, competition from alternative materials and the environmental concerns associated with non-biodegradable polymers could potentially hinder market growth.

Current Challenges in Alkyl Compound Integration

The integration of alkyl compounds into polymer engineering presents several significant challenges that researchers and industry professionals are currently grappling with. One of the primary obstacles is achieving uniform dispersion of alkyl compounds within the polymer matrix. The inherent incompatibility between hydrophobic alkyl groups and many polymer structures often leads to phase separation, resulting in inconsistent material properties and reduced overall performance.

Another major challenge lies in maintaining the desired mechanical properties of the polymer after alkyl compound incorporation. The introduction of these compounds can significantly alter the polymer's molecular structure, potentially leading to decreased tensile strength, reduced elasticity, or compromised thermal stability. Balancing the benefits of alkyl compound integration with the preservation of essential polymer characteristics remains a complex task.

The long-term stability of alkyl compounds within polymer systems is also a pressing concern. Environmental factors such as temperature fluctuations, UV exposure, and chemical interactions can cause degradation or migration of alkyl compounds over time. This instability not only affects the polymer's performance but may also raise safety and regulatory concerns, particularly in applications involving food contact or medical devices.

Furthermore, the scalability of alkyl compound integration processes poses a significant hurdle for industrial applications. While laboratory-scale experiments may yield promising results, translating these successes to large-scale manufacturing environments often encounters unforeseen complications. Issues such as increased processing times, equipment fouling, and quality control become more pronounced at industrial scales.

The environmental impact of alkyl compound integration is another challenge that cannot be overlooked. As sustainability becomes an increasingly critical factor in materials engineering, there is growing pressure to develop eco-friendly methods for incorporating alkyl compounds. This includes finding renewable sources for these compounds and ensuring that the resulting polymer products are recyclable or biodegradable.

Lastly, the regulatory landscape surrounding alkyl compounds in polymer engineering is complex and evolving. Compliance with various international standards and regulations, particularly in sensitive applications like food packaging or medical devices, requires extensive testing and documentation. Navigating these regulatory requirements while pushing the boundaries of alkyl compound integration adds another layer of complexity to the development process.

Another major challenge lies in maintaining the desired mechanical properties of the polymer after alkyl compound incorporation. The introduction of these compounds can significantly alter the polymer's molecular structure, potentially leading to decreased tensile strength, reduced elasticity, or compromised thermal stability. Balancing the benefits of alkyl compound integration with the preservation of essential polymer characteristics remains a complex task.

The long-term stability of alkyl compounds within polymer systems is also a pressing concern. Environmental factors such as temperature fluctuations, UV exposure, and chemical interactions can cause degradation or migration of alkyl compounds over time. This instability not only affects the polymer's performance but may also raise safety and regulatory concerns, particularly in applications involving food contact or medical devices.

Furthermore, the scalability of alkyl compound integration processes poses a significant hurdle for industrial applications. While laboratory-scale experiments may yield promising results, translating these successes to large-scale manufacturing environments often encounters unforeseen complications. Issues such as increased processing times, equipment fouling, and quality control become more pronounced at industrial scales.

The environmental impact of alkyl compound integration is another challenge that cannot be overlooked. As sustainability becomes an increasingly critical factor in materials engineering, there is growing pressure to develop eco-friendly methods for incorporating alkyl compounds. This includes finding renewable sources for these compounds and ensuring that the resulting polymer products are recyclable or biodegradable.

Lastly, the regulatory landscape surrounding alkyl compounds in polymer engineering is complex and evolving. Compliance with various international standards and regulations, particularly in sensitive applications like food packaging or medical devices, requires extensive testing and documentation. Navigating these regulatory requirements while pushing the boundaries of alkyl compound integration adds another layer of complexity to the development process.

Existing Methods for Alkyl Compound Implementation

01 Synthesis of alkyl compounds

Various methods for synthesizing alkyl compounds are described, including reactions involving alkyl halides, alcohols, and other precursors. These processes often involve catalysts and specific reaction conditions to produce desired alkyl compounds efficiently.- Synthesis of alkyl compounds: Various methods for synthesizing alkyl compounds are described, including reactions involving alkyl halides, alcohols, and other precursors. These processes often involve catalysts and specific reaction conditions to produce desired alkyl derivatives.

- Applications of alkyl compounds in industrial processes: Alkyl compounds find diverse applications in industrial processes, such as in the production of polymers, lubricants, and surfactants. They are also used as intermediates in the synthesis of more complex organic molecules.

- Alkyl compounds in pharmaceutical and cosmetic formulations: Alkyl compounds are utilized in pharmaceutical and cosmetic formulations due to their properties as solvents, emollients, and active ingredients. They can enhance the stability and efficacy of various products.

- Environmental and safety considerations of alkyl compounds: Research focuses on the environmental impact and safety aspects of alkyl compounds, including their biodegradability, toxicity, and potential for bioaccumulation. Efforts are made to develop more environmentally friendly alternatives and improve handling procedures.

- Modification and functionalization of alkyl compounds: Techniques for modifying and functionalizing alkyl compounds are explored to enhance their properties or create new derivatives. This includes processes such as alkylation, oxidation, and the introduction of various functional groups.

02 Applications of alkyl compounds in industrial processes

Alkyl compounds find diverse applications in industrial processes, such as in the production of polymers, lubricants, and surfactants. They are also used as intermediates in the synthesis of various organic compounds and play a role in the petrochemical industry.Expand Specific Solutions03 Alkyl compounds in pharmaceutical and cosmetic formulations

Alkyl compounds are utilized in pharmaceutical and cosmetic formulations due to their properties as solvents, emollients, and active ingredients. They can enhance the stability and efficacy of various products, including drugs and personal care items.Expand Specific Solutions04 Environmental and safety considerations of alkyl compounds

Research focuses on the environmental impact and safety aspects of alkyl compounds, including their biodegradability, toxicity, and potential for bioaccumulation. Studies aim to develop more environmentally friendly alternatives and improve handling and disposal methods.Expand Specific Solutions05 Modification and functionalization of alkyl compounds

Techniques for modifying and functionalizing alkyl compounds are explored to enhance their properties or create new derivatives. This includes processes such as alkylation, halogenation, and the introduction of various functional groups to tailor the compounds for specific applications.Expand Specific Solutions

Key Players in Alkyl-Polymer Engineering

The implementation of alkyl compounds in polymer engineering is in a mature stage of development, with a substantial market size and established technological applications. Key players in this field include major chemical companies such as BASF Corp., ExxonMobil Technology & Engineering Co., and Dow Global Technologies LLC, which have extensive research and development capabilities. The technology's maturity is evident in its widespread use across various industries, including automotive, construction, and consumer goods. However, ongoing research by companies like Sinopec (Dalian) Petrochemical Research Institute Co., Ltd. and academic institutions such as Xi'an Jiaotong University suggests potential for further innovation and market growth in specialized applications of alkyl compounds in polymer engineering.

3M Innovative Properties Co.

Technical Solution: 3M has developed unique approaches to implement alkyl compounds in polymer engineering. They have patented a method for creating alkyl-modified fluoropolymers with enhanced oil and water repellency[7]. This involves grafting alkyl chains onto the fluoropolymer backbone using controlled radical polymerization. 3M has also innovated in the field of alkyl-functional adhesives, developing pressure-sensitive adhesives with tunable tack and peel strength based on alkyl side chain length[9]. Their research extends to alkyl-modified nanocomposites for advanced barrier materials in packaging applications[11].

Strengths: Diverse technology portfolio, strong focus on specialty materials, and extensive experience in adhesives and coatings. Weaknesses: Higher production costs for some specialty alkyl-modified polymers and potential environmental concerns with fluoropolymers.

BASF Corp.

Technical Solution: BASF has developed innovative approaches to implement alkyl compounds in polymer engineering. They utilize controlled radical polymerization techniques to incorporate alkyl-functional monomers into polymer chains[1]. This allows precise control over the distribution and density of alkyl groups. BASF has also pioneered the use of alkyl-modified nanoparticles as polymer additives to enhance properties like hydrophobicity and chemical resistance[3]. Their patented process for producing alkyl-terminated polyethers enables the creation of novel surfactants and compatibilizers for polymer blends[5].

Strengths: Extensive R&D capabilities, broad product portfolio, and global manufacturing presence. Weaknesses: High dependence on petrochemical feedstocks and potential environmental concerns with some alkyl compounds.

Innovative Approaches in Alkyl-Polymer Synthesis

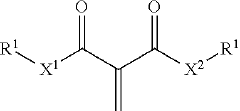

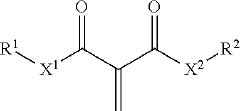

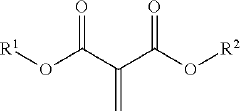

Method for producing polymers and copolymers of alpha-substituted acrylic compounds

PatentWO2001072852A1

Innovation

- A process using in situ formed rare earth metal organometallic complexes, specifically lanthanocenamide complexes, for polymerization in aprotic solvents at moderate temperatures, allowing for broad monomer compatibility and simplified industrial implementation.

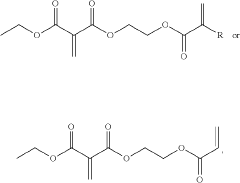

Methylene malonate monomers and multifunctional macromers as additives during plastics processing

PatentInactiveUS20210309780A1

Innovation

- The use of nucleophilic groups on polymer surfaces in melts to initiate 1,1-dicarbonyl-1-alkene polymerization, allowing for chain extension and cross-linking without conventional additives, thereby enhancing mechanical and aesthetic properties of the resulting polymers.

Environmental Impact of Alkyl-Modified Polymers

The implementation of alkyl compounds in polymer engineering has significant environmental implications that warrant careful consideration. Alkyl-modified polymers, while offering enhanced performance characteristics, can potentially impact ecosystems and human health throughout their lifecycle.

During the production phase, the synthesis of alkyl compounds often involves the use of petrochemical feedstocks, contributing to the depletion of non-renewable resources. The manufacturing processes may release volatile organic compounds (VOCs) and other pollutants, necessitating stringent emission control measures. Additionally, the energy-intensive nature of polymer production contributes to greenhouse gas emissions, exacerbating climate change concerns.

In their use phase, alkyl-modified polymers demonstrate improved durability and resistance to degradation, which can lead to extended product lifespans. This longevity potentially reduces the frequency of replacement and, consequently, the overall environmental footprint of products. However, the enhanced stability of these materials also raises concerns about their persistence in the environment post-disposal.

The end-of-life stage presents significant challenges for alkyl-modified polymers. Their resistance to degradation complicates recycling processes and extends the time required for natural decomposition. This persistence can lead to accumulation in landfills or, more alarmingly, in natural ecosystems if improperly disposed of. Marine environments are particularly vulnerable, as these polymers may contribute to microplastic pollution, posing threats to aquatic life and potentially entering the food chain.

Efforts to mitigate the environmental impact of alkyl-modified polymers focus on several key areas. Research into bio-based alkyl compounds aims to reduce reliance on petrochemical sources, potentially lowering the carbon footprint of production. Advancements in green chemistry seek to develop less toxic and more environmentally benign synthesis methods. Additionally, the design of polymers with improved recyclability or controlled degradation pathways is gaining traction, aiming to address end-of-life concerns.

The regulatory landscape surrounding alkyl-modified polymers is evolving, with increasing emphasis on lifecycle assessments and extended producer responsibility. These frameworks encourage manufacturers to consider environmental impacts from cradle to grave, promoting more sustainable product design and management practices. As awareness of environmental issues grows, there is a push towards developing alternatives that balance performance requirements with ecological considerations.

In conclusion, while alkyl-modified polymers offer valuable properties for various applications, their environmental impact necessitates ongoing research and innovation. Balancing the benefits of these materials with their potential environmental costs remains a critical challenge for polymer engineers and environmental scientists alike. The future of alkyl compounds in polymer engineering will likely be shaped by advancements in sustainable chemistry, circular economy principles, and stricter environmental regulations.

During the production phase, the synthesis of alkyl compounds often involves the use of petrochemical feedstocks, contributing to the depletion of non-renewable resources. The manufacturing processes may release volatile organic compounds (VOCs) and other pollutants, necessitating stringent emission control measures. Additionally, the energy-intensive nature of polymer production contributes to greenhouse gas emissions, exacerbating climate change concerns.

In their use phase, alkyl-modified polymers demonstrate improved durability and resistance to degradation, which can lead to extended product lifespans. This longevity potentially reduces the frequency of replacement and, consequently, the overall environmental footprint of products. However, the enhanced stability of these materials also raises concerns about their persistence in the environment post-disposal.

The end-of-life stage presents significant challenges for alkyl-modified polymers. Their resistance to degradation complicates recycling processes and extends the time required for natural decomposition. This persistence can lead to accumulation in landfills or, more alarmingly, in natural ecosystems if improperly disposed of. Marine environments are particularly vulnerable, as these polymers may contribute to microplastic pollution, posing threats to aquatic life and potentially entering the food chain.

Efforts to mitigate the environmental impact of alkyl-modified polymers focus on several key areas. Research into bio-based alkyl compounds aims to reduce reliance on petrochemical sources, potentially lowering the carbon footprint of production. Advancements in green chemistry seek to develop less toxic and more environmentally benign synthesis methods. Additionally, the design of polymers with improved recyclability or controlled degradation pathways is gaining traction, aiming to address end-of-life concerns.

The regulatory landscape surrounding alkyl-modified polymers is evolving, with increasing emphasis on lifecycle assessments and extended producer responsibility. These frameworks encourage manufacturers to consider environmental impacts from cradle to grave, promoting more sustainable product design and management practices. As awareness of environmental issues grows, there is a push towards developing alternatives that balance performance requirements with ecological considerations.

In conclusion, while alkyl-modified polymers offer valuable properties for various applications, their environmental impact necessitates ongoing research and innovation. Balancing the benefits of these materials with their potential environmental costs remains a critical challenge for polymer engineers and environmental scientists alike. The future of alkyl compounds in polymer engineering will likely be shaped by advancements in sustainable chemistry, circular economy principles, and stricter environmental regulations.

Regulatory Framework for Alkyl-Polymer Products

The regulatory framework for alkyl-polymer products is a complex and evolving landscape that plays a crucial role in the implementation of alkyl compounds in polymer engineering. This framework encompasses various regulations, standards, and guidelines set forth by governmental bodies and industry organizations to ensure the safety, quality, and environmental sustainability of these products.

At the international level, organizations such as the International Organization for Standardization (ISO) and the European Chemicals Agency (ECHA) have established comprehensive guidelines for the production, use, and disposal of alkyl-polymer products. These guidelines often serve as a foundation for national and regional regulations, promoting consistency in product safety and environmental protection across borders.

In the United States, the Environmental Protection Agency (EPA) oversees the regulation of alkyl-polymer products under the Toxic Substances Control Act (TSCA). The TSCA requires manufacturers to submit premanufacture notices (PMNs) for new chemical substances, including novel alkyl-polymer compounds, before they can be introduced into commerce. This process involves rigorous safety assessments and risk evaluations to ensure that these products do not pose unreasonable risks to human health or the environment.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to alkyl-polymer products manufactured or imported into the EU. REACH mandates that companies register their substances with the ECHA and provide detailed information on their properties, hazards, and safe use. This regulation aims to improve the protection of human health and the environment while promoting innovation and competitiveness in the chemical industry.

In addition to these overarching regulations, specific industry sectors may have their own set of standards and guidelines for alkyl-polymer products. For instance, the food packaging industry must comply with regulations set by the Food and Drug Administration (FDA) in the US or the European Food Safety Authority (EFSA) in the EU, which govern the use of alkyl-polymer materials in food contact applications.

As environmental concerns continue to grow, regulatory frameworks are increasingly focusing on the sustainability and recyclability of alkyl-polymer products. Many jurisdictions have implemented extended producer responsibility (EPR) programs, which require manufacturers to take responsibility for the entire lifecycle of their products, including disposal and recycling. This shift towards circular economy principles is driving innovation in the design and production of alkyl-polymer materials that are more easily recyclable or biodegradable.

Compliance with these regulatory frameworks presents both challenges and opportunities for companies involved in the implementation of alkyl compounds in polymer engineering. While adherence to these regulations can be resource-intensive, it also drives innovation and promotes the development of safer, more sustainable products. Companies that successfully navigate this regulatory landscape can gain a competitive advantage by demonstrating their commitment to product safety and environmental stewardship.

At the international level, organizations such as the International Organization for Standardization (ISO) and the European Chemicals Agency (ECHA) have established comprehensive guidelines for the production, use, and disposal of alkyl-polymer products. These guidelines often serve as a foundation for national and regional regulations, promoting consistency in product safety and environmental protection across borders.

In the United States, the Environmental Protection Agency (EPA) oversees the regulation of alkyl-polymer products under the Toxic Substances Control Act (TSCA). The TSCA requires manufacturers to submit premanufacture notices (PMNs) for new chemical substances, including novel alkyl-polymer compounds, before they can be introduced into commerce. This process involves rigorous safety assessments and risk evaluations to ensure that these products do not pose unreasonable risks to human health or the environment.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to alkyl-polymer products manufactured or imported into the EU. REACH mandates that companies register their substances with the ECHA and provide detailed information on their properties, hazards, and safe use. This regulation aims to improve the protection of human health and the environment while promoting innovation and competitiveness in the chemical industry.

In addition to these overarching regulations, specific industry sectors may have their own set of standards and guidelines for alkyl-polymer products. For instance, the food packaging industry must comply with regulations set by the Food and Drug Administration (FDA) in the US or the European Food Safety Authority (EFSA) in the EU, which govern the use of alkyl-polymer materials in food contact applications.

As environmental concerns continue to grow, regulatory frameworks are increasingly focusing on the sustainability and recyclability of alkyl-polymer products. Many jurisdictions have implemented extended producer responsibility (EPR) programs, which require manufacturers to take responsibility for the entire lifecycle of their products, including disposal and recycling. This shift towards circular economy principles is driving innovation in the design and production of alkyl-polymer materials that are more easily recyclable or biodegradable.

Compliance with these regulatory frameworks presents both challenges and opportunities for companies involved in the implementation of alkyl compounds in polymer engineering. While adherence to these regulations can be resource-intensive, it also drives innovation and promotes the development of safer, more sustainable products. Companies that successfully navigate this regulatory landscape can gain a competitive advantage by demonstrating their commitment to product safety and environmental stewardship.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!