How to Implement Alkyl Strategies for Emission Reduction?

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Alkyl Emission Reduction Background and Objectives

Alkyl strategies for emission reduction have emerged as a critical focus in the ongoing global efforts to combat climate change and improve air quality. These strategies encompass a range of techniques and technologies aimed at reducing harmful emissions from various sources, particularly in the industrial and transportation sectors. The development of alkyl-based solutions has been driven by the increasing awareness of the environmental impact of traditional fossil fuels and the urgent need for cleaner, more sustainable alternatives.

The evolution of alkyl emission reduction technologies can be traced back to the early 1990s when environmental regulations began to tighten globally. Initially, the focus was primarily on reducing sulfur content in fuels, which led to the development of alkylation processes to produce cleaner-burning gasoline. As environmental concerns grew, the scope of alkyl strategies expanded to address a broader range of emissions, including volatile organic compounds (VOCs), particulate matter, and greenhouse gases.

The primary objective of implementing alkyl strategies for emission reduction is to minimize the release of harmful pollutants into the atmosphere while maintaining or improving the performance of existing systems. This goal aligns with broader environmental targets set by international agreements such as the Paris Agreement and various national clean air initiatives. Specifically, alkyl-based solutions aim to reduce emissions of criteria pollutants, toxic air contaminants, and greenhouse gases from both mobile and stationary sources.

Key technological objectives in this field include developing more efficient alkylation processes, improving the stability and effectiveness of alkyl-based additives, and expanding the application of alkyl technologies to new sectors and emission sources. Additionally, there is a growing emphasis on creating alkyl solutions that are not only environmentally beneficial but also economically viable and easily integrable into existing infrastructure.

The implementation of alkyl strategies for emission reduction intersects with several other technological domains, including catalysis, fuel chemistry, and advanced materials science. This interdisciplinary nature has led to rapid advancements in recent years, with innovations ranging from novel alkyl-based fuel additives to advanced alkylation catalysts for industrial processes. The ongoing research in this field is expected to play a crucial role in achieving global emission reduction targets and transitioning towards a more sustainable energy landscape.

The evolution of alkyl emission reduction technologies can be traced back to the early 1990s when environmental regulations began to tighten globally. Initially, the focus was primarily on reducing sulfur content in fuels, which led to the development of alkylation processes to produce cleaner-burning gasoline. As environmental concerns grew, the scope of alkyl strategies expanded to address a broader range of emissions, including volatile organic compounds (VOCs), particulate matter, and greenhouse gases.

The primary objective of implementing alkyl strategies for emission reduction is to minimize the release of harmful pollutants into the atmosphere while maintaining or improving the performance of existing systems. This goal aligns with broader environmental targets set by international agreements such as the Paris Agreement and various national clean air initiatives. Specifically, alkyl-based solutions aim to reduce emissions of criteria pollutants, toxic air contaminants, and greenhouse gases from both mobile and stationary sources.

Key technological objectives in this field include developing more efficient alkylation processes, improving the stability and effectiveness of alkyl-based additives, and expanding the application of alkyl technologies to new sectors and emission sources. Additionally, there is a growing emphasis on creating alkyl solutions that are not only environmentally beneficial but also economically viable and easily integrable into existing infrastructure.

The implementation of alkyl strategies for emission reduction intersects with several other technological domains, including catalysis, fuel chemistry, and advanced materials science. This interdisciplinary nature has led to rapid advancements in recent years, with innovations ranging from novel alkyl-based fuel additives to advanced alkylation catalysts for industrial processes. The ongoing research in this field is expected to play a crucial role in achieving global emission reduction targets and transitioning towards a more sustainable energy landscape.

Market Demand for Alkyl Emission Reduction Technologies

The market demand for alkyl emission reduction technologies has been steadily growing in recent years, driven by increasingly stringent environmental regulations and a global push towards sustainability. Industries across various sectors, particularly automotive, petrochemical, and manufacturing, are actively seeking innovative solutions to reduce their carbon footprint and comply with emission standards.

In the automotive industry, there is a significant demand for alkyl-based technologies that can effectively reduce emissions from internal combustion engines. This demand is fueled by the need to meet stringent Euro 6 and Tier 3 emission standards in Europe and North America, respectively. Manufacturers are investing heavily in research and development to incorporate alkyl-based additives and catalysts into their fuel systems and exhaust treatment processes.

The petrochemical sector also presents a substantial market for alkyl emission reduction technologies. Refineries and chemical plants are under pressure to minimize their environmental impact, leading to increased adoption of alkylation processes that produce cleaner-burning fuels and reduce sulfur content. This trend is particularly pronounced in regions with strict sulfur content regulations, such as the European Union and parts of Asia.

Manufacturing industries, especially those involved in the production of paints, coatings, and adhesives, are showing growing interest in alkyl-based low-VOC (Volatile Organic Compound) formulations. This demand is driven by both regulatory requirements and consumer preferences for environmentally friendly products. The construction and automotive coating segments are particularly active in adopting these technologies.

The power generation sector is another key market for alkyl emission reduction technologies. As countries transition towards cleaner energy sources, there is a rising demand for alkyl-based solutions that can reduce emissions from existing fossil fuel power plants. This includes technologies for flue gas treatment and fuel additives that enhance combustion efficiency.

Geographically, the market demand is most robust in developed regions such as North America and Europe, where environmental regulations are the strictest. However, rapidly industrializing countries in Asia-Pacific, particularly China and India, are emerging as significant markets due to their increasing focus on air quality improvement and commitment to international climate agreements.

The market is also seeing a shift towards integrated solutions that combine alkyl technologies with other emission reduction methods, such as selective catalytic reduction (SCR) and particulate filters. This trend is driven by the need for comprehensive emission control strategies that address multiple pollutants simultaneously.

In the automotive industry, there is a significant demand for alkyl-based technologies that can effectively reduce emissions from internal combustion engines. This demand is fueled by the need to meet stringent Euro 6 and Tier 3 emission standards in Europe and North America, respectively. Manufacturers are investing heavily in research and development to incorporate alkyl-based additives and catalysts into their fuel systems and exhaust treatment processes.

The petrochemical sector also presents a substantial market for alkyl emission reduction technologies. Refineries and chemical plants are under pressure to minimize their environmental impact, leading to increased adoption of alkylation processes that produce cleaner-burning fuels and reduce sulfur content. This trend is particularly pronounced in regions with strict sulfur content regulations, such as the European Union and parts of Asia.

Manufacturing industries, especially those involved in the production of paints, coatings, and adhesives, are showing growing interest in alkyl-based low-VOC (Volatile Organic Compound) formulations. This demand is driven by both regulatory requirements and consumer preferences for environmentally friendly products. The construction and automotive coating segments are particularly active in adopting these technologies.

The power generation sector is another key market for alkyl emission reduction technologies. As countries transition towards cleaner energy sources, there is a rising demand for alkyl-based solutions that can reduce emissions from existing fossil fuel power plants. This includes technologies for flue gas treatment and fuel additives that enhance combustion efficiency.

Geographically, the market demand is most robust in developed regions such as North America and Europe, where environmental regulations are the strictest. However, rapidly industrializing countries in Asia-Pacific, particularly China and India, are emerging as significant markets due to their increasing focus on air quality improvement and commitment to international climate agreements.

The market is also seeing a shift towards integrated solutions that combine alkyl technologies with other emission reduction methods, such as selective catalytic reduction (SCR) and particulate filters. This trend is driven by the need for comprehensive emission control strategies that address multiple pollutants simultaneously.

Current State and Challenges in Alkyl Emission Control

The current state of alkyl emission control is characterized by a complex interplay of technological advancements, regulatory pressures, and industry initiatives. Globally, there is a growing recognition of the need to reduce alkyl emissions, particularly in industrial processes and automotive applications. However, the implementation of effective control strategies faces several significant challenges.

One of the primary obstacles is the diverse nature of alkyl compounds and their emission sources. Alkyl emissions can originate from various industrial processes, including petrochemical production, solvent use, and fuel combustion. This diversity necessitates a multi-faceted approach to emission control, as no single solution can address all sources effectively.

Technological limitations also pose a substantial challenge. While advancements have been made in emission control technologies, such as catalytic converters and scrubbers, many existing solutions struggle to achieve high efficiency across a wide range of alkyl compounds. The development of more versatile and efficient control technologies remains an ongoing challenge for researchers and engineers in the field.

Cost considerations present another significant hurdle. Many advanced emission control technologies come with high implementation and operational costs, making them economically unfeasible for smaller businesses or developing economies. This economic barrier often leads to a disparity in emission control practices across different regions and industries.

Regulatory frameworks play a crucial role in shaping the current state of alkyl emission control. While some countries have implemented stringent emission standards, others lag behind, creating a patchwork of regulations globally. This inconsistency in regulatory approaches complicates efforts for multinational corporations and hinders the development of standardized control strategies.

The lack of comprehensive data on alkyl emissions and their environmental impact presents an additional challenge. Without accurate and up-to-date information, it becomes difficult to prioritize control efforts and assess the effectiveness of implemented strategies. This data gap hampers evidence-based decision-making and policy formulation.

Industry resistance to change also contributes to the challenges in alkyl emission control. Many businesses are reluctant to invest in new technologies or modify existing processes due to concerns about operational disruptions and economic impacts. Overcoming this resistance requires a combination of regulatory pressure, economic incentives, and education about the long-term benefits of emission reduction.

Looking ahead, the field of alkyl emission control is poised for significant advancements. Emerging technologies, such as advanced catalysts, nanotechnology-based filters, and real-time monitoring systems, show promise in addressing some of the current challenges. However, their widespread adoption and integration into existing industrial processes remain a complex task that will require collaborative efforts from industry, academia, and regulatory bodies.

One of the primary obstacles is the diverse nature of alkyl compounds and their emission sources. Alkyl emissions can originate from various industrial processes, including petrochemical production, solvent use, and fuel combustion. This diversity necessitates a multi-faceted approach to emission control, as no single solution can address all sources effectively.

Technological limitations also pose a substantial challenge. While advancements have been made in emission control technologies, such as catalytic converters and scrubbers, many existing solutions struggle to achieve high efficiency across a wide range of alkyl compounds. The development of more versatile and efficient control technologies remains an ongoing challenge for researchers and engineers in the field.

Cost considerations present another significant hurdle. Many advanced emission control technologies come with high implementation and operational costs, making them economically unfeasible for smaller businesses or developing economies. This economic barrier often leads to a disparity in emission control practices across different regions and industries.

Regulatory frameworks play a crucial role in shaping the current state of alkyl emission control. While some countries have implemented stringent emission standards, others lag behind, creating a patchwork of regulations globally. This inconsistency in regulatory approaches complicates efforts for multinational corporations and hinders the development of standardized control strategies.

The lack of comprehensive data on alkyl emissions and their environmental impact presents an additional challenge. Without accurate and up-to-date information, it becomes difficult to prioritize control efforts and assess the effectiveness of implemented strategies. This data gap hampers evidence-based decision-making and policy formulation.

Industry resistance to change also contributes to the challenges in alkyl emission control. Many businesses are reluctant to invest in new technologies or modify existing processes due to concerns about operational disruptions and economic impacts. Overcoming this resistance requires a combination of regulatory pressure, economic incentives, and education about the long-term benefits of emission reduction.

Looking ahead, the field of alkyl emission control is poised for significant advancements. Emerging technologies, such as advanced catalysts, nanotechnology-based filters, and real-time monitoring systems, show promise in addressing some of the current challenges. However, their widespread adoption and integration into existing industrial processes remain a complex task that will require collaborative efforts from industry, academia, and regulatory bodies.

Existing Alkyl Emission Reduction Solutions

01 Emission reduction strategies for alkyl compounds

Various strategies are employed to reduce emissions of alkyl compounds in industrial processes. These may include optimizing reaction conditions, implementing catalytic converters, and using advanced scrubbing technologies. Such approaches aim to minimize the release of volatile organic compounds and improve overall environmental performance.- Emission reduction strategies for alkyl compounds: Various strategies are employed to reduce emissions of alkyl compounds in industrial processes. These may include optimizing reaction conditions, implementing catalytic converters, and using advanced scrubbing technologies. Such approaches aim to minimize the release of volatile organic compounds and improve overall environmental performance.

- Monitoring and analysis of alkyl emissions: Advanced monitoring and analysis techniques are utilized to accurately measure and characterize alkyl emissions. This involves the use of sophisticated sensors, data analytics, and modeling tools to track emission levels, identify sources, and assess environmental impact. Real-time monitoring systems enable prompt response to emission events.

- Regulatory compliance and reporting for alkyl emissions: Companies implement comprehensive systems to ensure compliance with regulations governing alkyl emissions. This includes developing robust reporting mechanisms, maintaining accurate records, and utilizing software solutions for managing environmental data. Such systems help organizations meet legal requirements and demonstrate environmental responsibility.

- Alkyl emission control in manufacturing processes: Innovative technologies and process modifications are applied in manufacturing to control alkyl emissions at the source. This may involve redesigning production lines, implementing closed-loop systems, and utilizing alternative materials or solvents with lower emission profiles. Such approaches aim to minimize environmental impact while maintaining production efficiency.

- Carbon footprint reduction through alkyl emission management: Organizations implement comprehensive strategies to reduce their carbon footprint by managing alkyl emissions. This involves assessing the entire value chain, identifying emission hotspots, and implementing targeted reduction measures. Advanced analytics and lifecycle assessment tools are used to quantify and optimize emission reduction efforts.

02 Monitoring and analysis of alkyl emissions

Advanced monitoring systems and analytical techniques are developed to accurately measure and characterize alkyl emissions. These methods may involve real-time sensors, gas chromatography, and mass spectrometry to identify and quantify specific alkyl compounds in exhaust streams or ambient air.Expand Specific Solutions03 Regulatory compliance and reporting for alkyl emissions

Systems and methods are designed to ensure compliance with environmental regulations regarding alkyl emissions. These may include automated data collection, analysis, and reporting tools to track emissions levels, generate compliance reports, and facilitate communication with regulatory agencies.Expand Specific Solutions04 Alkyl emission prediction and modeling

Predictive models and simulation tools are developed to forecast alkyl emissions under various operating conditions. These models may incorporate machine learning algorithms, historical data analysis, and process parameters to optimize emission control strategies and support decision-making in industrial operations.Expand Specific Solutions05 Alkyl emission trading and carbon offset strategies

Market-based approaches are implemented to manage and reduce alkyl emissions on a broader scale. These may include emission trading schemes, carbon offset programs, and financial incentives for companies to adopt cleaner technologies and practices in relation to alkyl compound emissions.Expand Specific Solutions

Key Players in Alkyl Emission Reduction Industry

The implementation of alkyl strategies for emission reduction is currently in a transitional phase, with the market showing significant growth potential. The global focus on environmental sustainability is driving increased investment and research in this area. The technology's maturity varies across different applications, with some sectors more advanced than others. Key players like China Petroleum & Chemical Corp., GM Global Technology Operations LLC, and TotalEnergies OneTech SAS are leading the way in developing and implementing these strategies. Their efforts are complemented by research institutions such as Sinopec Research Institute of Petroleum Processing and the University of Connecticut, which are contributing to the advancement of alkyl-based emission reduction technologies. As the industry progresses, collaboration between corporations and academic institutions is likely to accelerate innovation and market adoption.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has implemented a comprehensive alkyl strategy for emission reduction. Their approach includes the development of alkylation technologies for cleaner fuel production. Sinopec has invested in alkylation units that produce high-octane, low-sulfur gasoline blending components[1]. These units utilize isobutane and light olefins to create alkylate, which is a valuable gasoline blending component with zero sulfur, nitrogen, and aromatics content[2]. Additionally, Sinopec has been exploring the use of ionic liquid alkylation technology, which offers improved efficiency and reduced environmental impact compared to traditional sulfuric acid alkylation processes[3]. The company has also focused on optimizing their refining processes to reduce overall emissions, including the implementation of energy-efficient alkylation reactors and catalysts.

Strengths: Large-scale implementation capability, access to advanced technologies, and integrated supply chain. Weaknesses: High initial investment costs and potential challenges in retrofitting existing facilities.

TotalEnergies OneTech SAS

Technical Solution: TotalEnergies OneTech SAS has developed a multi-faceted alkyl strategy for emission reduction. Their approach includes the implementation of advanced alkylation technologies in their refineries to produce cleaner-burning fuels. TotalEnergies has invested in solid acid alkylation technology, which eliminates the need for corrosive liquid acids and reduces environmental risks[4]. The company has also focused on the production of renewable alkyl-based fuels, such as hydrotreated vegetable oil (HVO) and bio-paraffins, which can significantly reduce lifecycle CO2 emissions[5]. Additionally, TotalEnergies has been researching the use of alkyl-functionalized materials for carbon capture and utilization (CCU) applications, aiming to convert CO2 into valuable chemicals and fuels[6]. Their strategy also includes the development of alkyl-based lubricants with improved efficiency, contributing to reduced friction and fuel consumption in various applications.

Strengths: Diverse portfolio of alkyl-based solutions, strong R&D capabilities, and global market presence. Weaknesses: Dependence on fossil fuel infrastructure and potential regulatory challenges in some markets.

Core Innovations in Alkyl Emission Control Technologies

Method of reducing the proportion of pollutants in industrial flue gases and method of preparing a composition that is used for same

PatentWO2007010069A9

Innovation

- A method involving a liquid composition of aqueous extracts from plant matrix polysaccharides, specifically algae, is sprayed onto combustion gases to form a catalytic cloud with high reactivity and surface area, reducing NOx, SOx, and dioxins without the need for catalysts or high temperatures.

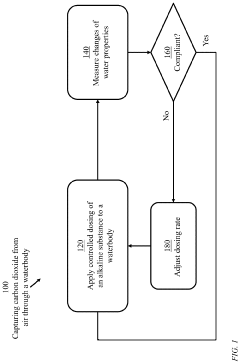

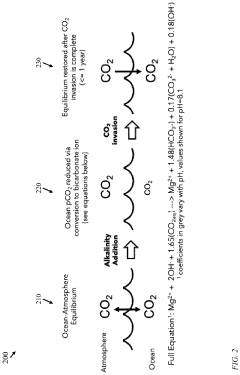

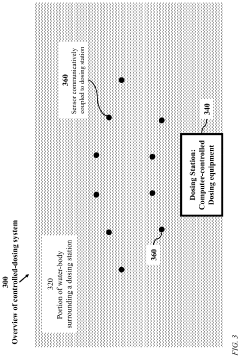

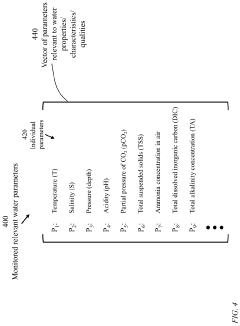

Methods and system for alkalizing a body of water and removing carbon dioxide, and a dosing station therefor

PatentPendingUS20240190733A1

Innovation

- A method and system involving a dosing station that automatically adjusts the dispensing of CO2-reactive alkalinity, such as magnesium hydroxide, in water bodies based on pH and other parameters, using sensors to monitor and adjust the dosing rate, and calculating net CO2 removal while accounting for uncertainties and emissions.

Environmental Regulations and Compliance

Environmental regulations and compliance play a crucial role in the implementation of alkyl strategies for emission reduction. Governments worldwide have established stringent guidelines to mitigate the environmental impact of industrial processes, particularly in the petrochemical sector. These regulations often set specific targets for reducing emissions of volatile organic compounds (VOCs), greenhouse gases, and other pollutants associated with alkylation processes.

In the United States, the Environmental Protection Agency (EPA) has implemented the Clean Air Act, which mandates strict emission control measures for industrial facilities. This legislation requires companies to adopt Best Available Control Technology (BACT) and to continuously monitor and report their emissions. The EPA's New Source Performance Standards (NSPS) and National Emission Standards for Hazardous Air Pollutants (NESHAP) specifically address emissions from alkylation units in refineries and petrochemical plants.

The European Union has similarly stringent regulations under the Industrial Emissions Directive (IED). This directive employs an integrated approach to pollution prevention and control, requiring industrial facilities to obtain permits based on the application of Best Available Techniques (BAT). For alkylation processes, these techniques often include advanced catalytic systems, improved reactor designs, and enhanced monitoring and control systems.

Compliance with these regulations necessitates significant investments in emission reduction technologies. Companies must implement sophisticated leak detection and repair (LDAR) programs to identify and address fugitive emissions from valves, pumps, and other equipment. Advanced process control systems and real-time monitoring technologies are essential for maintaining compliance and optimizing alkylation processes to minimize emissions.

Furthermore, many jurisdictions have implemented cap-and-trade systems or carbon taxes to incentivize emission reductions. These market-based mechanisms create financial incentives for companies to invest in cleaner technologies and more efficient processes. As a result, the development and implementation of innovative alkyl strategies for emission reduction have become not only an environmental imperative but also a competitive advantage in the global marketplace.

To ensure compliance, companies must establish comprehensive environmental management systems (EMS) that integrate emission reduction strategies into their overall operations. This includes regular audits, employee training programs, and continuous improvement initiatives. The ISO 14001 standard provides a framework for developing and maintaining an effective EMS, which can help organizations systematically address their environmental impacts and demonstrate compliance with regulatory requirements.

As regulations continue to evolve and become more stringent, companies must stay ahead of the curve by investing in research and development of new alkyl technologies that can further reduce emissions. This proactive approach not only ensures compliance but also positions organizations as industry leaders in environmental stewardship.

In the United States, the Environmental Protection Agency (EPA) has implemented the Clean Air Act, which mandates strict emission control measures for industrial facilities. This legislation requires companies to adopt Best Available Control Technology (BACT) and to continuously monitor and report their emissions. The EPA's New Source Performance Standards (NSPS) and National Emission Standards for Hazardous Air Pollutants (NESHAP) specifically address emissions from alkylation units in refineries and petrochemical plants.

The European Union has similarly stringent regulations under the Industrial Emissions Directive (IED). This directive employs an integrated approach to pollution prevention and control, requiring industrial facilities to obtain permits based on the application of Best Available Techniques (BAT). For alkylation processes, these techniques often include advanced catalytic systems, improved reactor designs, and enhanced monitoring and control systems.

Compliance with these regulations necessitates significant investments in emission reduction technologies. Companies must implement sophisticated leak detection and repair (LDAR) programs to identify and address fugitive emissions from valves, pumps, and other equipment. Advanced process control systems and real-time monitoring technologies are essential for maintaining compliance and optimizing alkylation processes to minimize emissions.

Furthermore, many jurisdictions have implemented cap-and-trade systems or carbon taxes to incentivize emission reductions. These market-based mechanisms create financial incentives for companies to invest in cleaner technologies and more efficient processes. As a result, the development and implementation of innovative alkyl strategies for emission reduction have become not only an environmental imperative but also a competitive advantage in the global marketplace.

To ensure compliance, companies must establish comprehensive environmental management systems (EMS) that integrate emission reduction strategies into their overall operations. This includes regular audits, employee training programs, and continuous improvement initiatives. The ISO 14001 standard provides a framework for developing and maintaining an effective EMS, which can help organizations systematically address their environmental impacts and demonstrate compliance with regulatory requirements.

As regulations continue to evolve and become more stringent, companies must stay ahead of the curve by investing in research and development of new alkyl technologies that can further reduce emissions. This proactive approach not only ensures compliance but also positions organizations as industry leaders in environmental stewardship.

Economic Impact of Alkyl Emission Reduction Strategies

The implementation of alkyl strategies for emission reduction has significant economic implications across various sectors. These strategies, aimed at reducing harmful emissions through the modification of alkyl compounds, can lead to substantial changes in industrial processes, energy consumption, and overall economic structures.

In the short term, the adoption of alkyl-based emission reduction technologies may result in increased costs for industries, particularly those heavily reliant on fossil fuels or chemical processes. This initial investment in new equipment, research and development, and workforce training can create a temporary economic burden. However, these costs are often offset by long-term benefits and potential government incentives designed to encourage the transition to cleaner technologies.

The automotive and transportation sectors are likely to experience significant economic impacts. As regulations tighten and consumer preferences shift towards cleaner vehicles, manufacturers investing in alkyl-based emission reduction technologies may gain a competitive edge. This could lead to a redistribution of market share within the industry, favoring companies that adapt quickly to new environmental standards.

In the energy sector, the implementation of alkyl strategies could accelerate the transition away from traditional fossil fuels. While this may negatively impact some segments of the oil and gas industry, it also creates opportunities for growth in renewable energy and clean technology sectors. The development and production of advanced catalysts and materials for alkyl-based emission reduction could become a new source of economic activity and job creation.

The chemical industry stands to benefit from the increased demand for specialized alkyl compounds and related technologies. This could stimulate innovation and lead to the emergence of new sub-sectors focused on environmentally friendly chemical processes. Additionally, companies that develop proprietary alkyl-based emission reduction technologies may find new revenue streams through licensing or consulting services.

On a macroeconomic level, the successful implementation of alkyl strategies for emission reduction could lead to improved public health outcomes, potentially reducing healthcare costs and increasing workforce productivity. The reduction in air pollution and associated health risks could result in significant savings for governments and individuals alike.

Furthermore, countries and regions that take the lead in developing and implementing these technologies may gain a competitive advantage in the global market. This could influence international trade patterns and potentially shift the balance of economic power towards nations at the forefront of environmental innovation.

In the short term, the adoption of alkyl-based emission reduction technologies may result in increased costs for industries, particularly those heavily reliant on fossil fuels or chemical processes. This initial investment in new equipment, research and development, and workforce training can create a temporary economic burden. However, these costs are often offset by long-term benefits and potential government incentives designed to encourage the transition to cleaner technologies.

The automotive and transportation sectors are likely to experience significant economic impacts. As regulations tighten and consumer preferences shift towards cleaner vehicles, manufacturers investing in alkyl-based emission reduction technologies may gain a competitive edge. This could lead to a redistribution of market share within the industry, favoring companies that adapt quickly to new environmental standards.

In the energy sector, the implementation of alkyl strategies could accelerate the transition away from traditional fossil fuels. While this may negatively impact some segments of the oil and gas industry, it also creates opportunities for growth in renewable energy and clean technology sectors. The development and production of advanced catalysts and materials for alkyl-based emission reduction could become a new source of economic activity and job creation.

The chemical industry stands to benefit from the increased demand for specialized alkyl compounds and related technologies. This could stimulate innovation and lead to the emergence of new sub-sectors focused on environmentally friendly chemical processes. Additionally, companies that develop proprietary alkyl-based emission reduction technologies may find new revenue streams through licensing or consulting services.

On a macroeconomic level, the successful implementation of alkyl strategies for emission reduction could lead to improved public health outcomes, potentially reducing healthcare costs and increasing workforce productivity. The reduction in air pollution and associated health risks could result in significant savings for governments and individuals alike.

Furthermore, countries and regions that take the lead in developing and implementing these technologies may gain a competitive advantage in the global market. This could influence international trade patterns and potentially shift the balance of economic power towards nations at the forefront of environmental innovation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!