How to Implement Magnetron Pulse Modulation Techniques

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetron Pulse Modulation Background and Objectives

Magnetron pulse modulation technology has evolved significantly since its inception during World War II, when it was primarily developed for radar applications. The fundamental principle involves controlling the high-power microwave output of magnetron tubes through precise timing and amplitude modulation of the input power. This technology has been instrumental in advancing radar systems, industrial heating processes, and medical applications over the past seven decades.

The evolution of magnetron pulse modulation techniques can be traced through several distinct phases. Initially, simple line-type modulators using pulse-forming networks dominated the field. By the 1960s, hard-tube modulators emerged, offering improved pulse shape control. The 1980s saw the introduction of solid-state modulators, which dramatically enhanced reliability and precision. Most recently, advanced digital control systems have revolutionized the field, enabling unprecedented levels of pulse shaping capability and operational flexibility.

Current technological trends in magnetron pulse modulation are moving toward higher efficiency, greater precision in pulse shaping, and enhanced reliability. The integration of digital signal processing and advanced semiconductor technologies has opened new possibilities for adaptive control systems that can optimize performance in real-time based on operational conditions. Additionally, there is growing interest in developing more compact and energy-efficient modulation systems to meet the demands of portable and space-constrained applications.

The primary technical objectives for advancing magnetron pulse modulation techniques include achieving higher peak power outputs while maintaining pulse fidelity, reducing system size and weight without compromising performance, and extending operational lifetimes of both the modulation components and the magnetron tubes themselves. There is also significant focus on improving the energy efficiency of these systems, particularly for high-duty-cycle applications where power consumption becomes a critical factor.

Another important objective is enhancing the precision of pulse timing and amplitude control to support advanced radar and imaging applications that require increasingly sophisticated signal processing. This includes developing modulation techniques capable of generating complex pulse patterns with minimal distortion and precise repeatability. Furthermore, there is growing interest in creating modulation systems that can adapt to changing load conditions and compensate for component aging effects, thereby maintaining consistent performance over extended operational periods.

The convergence of these technological trends and objectives is driving research toward integrated solutions that combine advanced power electronics, digital control systems, and thermal management techniques. Success in these endeavors will enable next-generation applications in fields ranging from medical imaging and treatment to advanced manufacturing processes and defense systems.

The evolution of magnetron pulse modulation techniques can be traced through several distinct phases. Initially, simple line-type modulators using pulse-forming networks dominated the field. By the 1960s, hard-tube modulators emerged, offering improved pulse shape control. The 1980s saw the introduction of solid-state modulators, which dramatically enhanced reliability and precision. Most recently, advanced digital control systems have revolutionized the field, enabling unprecedented levels of pulse shaping capability and operational flexibility.

Current technological trends in magnetron pulse modulation are moving toward higher efficiency, greater precision in pulse shaping, and enhanced reliability. The integration of digital signal processing and advanced semiconductor technologies has opened new possibilities for adaptive control systems that can optimize performance in real-time based on operational conditions. Additionally, there is growing interest in developing more compact and energy-efficient modulation systems to meet the demands of portable and space-constrained applications.

The primary technical objectives for advancing magnetron pulse modulation techniques include achieving higher peak power outputs while maintaining pulse fidelity, reducing system size and weight without compromising performance, and extending operational lifetimes of both the modulation components and the magnetron tubes themselves. There is also significant focus on improving the energy efficiency of these systems, particularly for high-duty-cycle applications where power consumption becomes a critical factor.

Another important objective is enhancing the precision of pulse timing and amplitude control to support advanced radar and imaging applications that require increasingly sophisticated signal processing. This includes developing modulation techniques capable of generating complex pulse patterns with minimal distortion and precise repeatability. Furthermore, there is growing interest in creating modulation systems that can adapt to changing load conditions and compensate for component aging effects, thereby maintaining consistent performance over extended operational periods.

The convergence of these technological trends and objectives is driving research toward integrated solutions that combine advanced power electronics, digital control systems, and thermal management techniques. Success in these endeavors will enable next-generation applications in fields ranging from medical imaging and treatment to advanced manufacturing processes and defense systems.

Market Applications and Demand Analysis

The global market for magnetron pulse modulation technologies has experienced significant growth in recent years, driven primarily by expanding applications in radar systems, medical equipment, and industrial heating processes. The defense sector remains the largest consumer of magnetron pulse modulation technology, with military radar systems accounting for approximately 40% of the total market demand. This dominance is expected to continue as nations worldwide increase their defense budgets and modernize their surveillance capabilities.

The healthcare sector represents the fastest-growing market segment for magnetron pulse modulation techniques, with particular emphasis on cancer treatment applications. Medical linear accelerators utilizing precisely controlled magnetron pulse modulation have revolutionized radiation therapy, offering more targeted treatment options with reduced side effects. Market analysis indicates that the medical application segment is growing at a compound annual rate of 7.8%, outpacing the overall market growth of 5.3%.

Industrial applications constitute another substantial market segment, particularly in materials processing, food preservation, and scientific research. The demand for high-precision industrial heating systems has created a specialized niche for advanced magnetron pulse modulation techniques that offer superior control over energy delivery. This segment is particularly strong in manufacturing-intensive economies across Asia-Pacific, which now represents 38% of the global market share.

Consumer electronics applications, while smaller in market share, are showing promising growth potential, especially in emerging economies. The integration of compact, efficient magnetron systems in household appliances continues to drive innovation in pulse modulation techniques that maximize energy efficiency while minimizing electromagnetic interference.

Market forecasts suggest that the global magnetron pulse modulation market will reach $6.2 billion by 2027, with the most substantial growth occurring in wireless communication infrastructure development. The rollout of advanced communication networks has created new requirements for signal processing and power management that directly benefit from innovations in magnetron pulse modulation.

Regional analysis reveals that North America currently leads the market with 35% share, followed closely by Asia-Pacific at 32% and Europe at 24%. However, the highest growth rates are being observed in emerging markets across Southeast Asia and South America, where infrastructure development projects are creating new opportunities for technology deployment.

Customer requirements are increasingly focused on energy efficiency, precise power control, and system miniaturization. End-users across all sectors are demanding magnetron pulse modulation solutions that offer higher reliability, longer operational lifespans, and reduced maintenance requirements, driving manufacturers toward more sophisticated control architectures and advanced materials.

The healthcare sector represents the fastest-growing market segment for magnetron pulse modulation techniques, with particular emphasis on cancer treatment applications. Medical linear accelerators utilizing precisely controlled magnetron pulse modulation have revolutionized radiation therapy, offering more targeted treatment options with reduced side effects. Market analysis indicates that the medical application segment is growing at a compound annual rate of 7.8%, outpacing the overall market growth of 5.3%.

Industrial applications constitute another substantial market segment, particularly in materials processing, food preservation, and scientific research. The demand for high-precision industrial heating systems has created a specialized niche for advanced magnetron pulse modulation techniques that offer superior control over energy delivery. This segment is particularly strong in manufacturing-intensive economies across Asia-Pacific, which now represents 38% of the global market share.

Consumer electronics applications, while smaller in market share, are showing promising growth potential, especially in emerging economies. The integration of compact, efficient magnetron systems in household appliances continues to drive innovation in pulse modulation techniques that maximize energy efficiency while minimizing electromagnetic interference.

Market forecasts suggest that the global magnetron pulse modulation market will reach $6.2 billion by 2027, with the most substantial growth occurring in wireless communication infrastructure development. The rollout of advanced communication networks has created new requirements for signal processing and power management that directly benefit from innovations in magnetron pulse modulation.

Regional analysis reveals that North America currently leads the market with 35% share, followed closely by Asia-Pacific at 32% and Europe at 24%. However, the highest growth rates are being observed in emerging markets across Southeast Asia and South America, where infrastructure development projects are creating new opportunities for technology deployment.

Customer requirements are increasingly focused on energy efficiency, precise power control, and system miniaturization. End-users across all sectors are demanding magnetron pulse modulation solutions that offer higher reliability, longer operational lifespans, and reduced maintenance requirements, driving manufacturers toward more sophisticated control architectures and advanced materials.

Current Magnetron Modulation Technologies and Challenges

Magnetron pulse modulation technology has evolved significantly over the past decades, with several distinct approaches currently dominating the industry. Line-type modulators represent one of the earliest and still widely used technologies, employing pulse-forming networks (PFNs) that discharge stored energy through a switch (typically a thyratron or solid-state device) to generate high-voltage pulses. These systems offer reliability and relative simplicity but face limitations in pulse shape control and efficiency, particularly at higher power levels.

Hard-tube modulators have emerged as an alternative solution, utilizing vacuum tubes or solid-state switches to directly control the pulse characteristics. This approach provides superior pulse shape control and faster rise/fall times compared to line-type systems, though often at the cost of increased complexity and power consumption. Recent advancements in semiconductor technology have significantly improved the efficiency and reliability of these systems.

Solid-state modulators represent the current state-of-the-art in magnetron pulse modulation. These systems employ high-power semiconductor switches such as IGBTs, MOSFETs, or SiC devices arranged in series/parallel configurations to achieve the required voltage and current handling capabilities. The primary advantages include precise pulse control, high reliability, and reduced maintenance requirements, though challenges remain in scaling to very high power levels.

Despite these technological advances, several significant challenges persist in magnetron pulse modulation. Thermal management remains a critical issue, particularly in high-power applications where heat dissipation can significantly impact system reliability and performance. Engineers continue to explore advanced cooling techniques and materials to address these thermal constraints.

Electromagnetic interference (EMI) presents another substantial challenge, as the rapid switching of high voltages and currents generates significant electromagnetic noise that can affect nearby electronic systems. Comprehensive shielding and filtering strategies are essential but add complexity and cost to system designs.

Pulse fidelity and stability represent ongoing technical hurdles, particularly in applications requiring precise control over pulse characteristics. Variations in pulse shape, amplitude, or timing can significantly impact magnetron performance and output consistency. Advanced feedback control systems and compensation techniques are being developed to mitigate these issues.

Efficiency optimization remains a persistent challenge, with current systems typically achieving 70-85% efficiency. Energy losses occur primarily during switching transitions and in passive components. Research efforts focus on improved semiconductor materials, optimized circuit topologies, and advanced control algorithms to push efficiency boundaries further.

Reliability and lifetime considerations present significant challenges, particularly in continuous operation scenarios. Component aging, especially of high-voltage capacitors and switching elements, can lead to performance degradation over time. Predictive maintenance approaches and redundant designs are increasingly employed to address these reliability concerns.

Hard-tube modulators have emerged as an alternative solution, utilizing vacuum tubes or solid-state switches to directly control the pulse characteristics. This approach provides superior pulse shape control and faster rise/fall times compared to line-type systems, though often at the cost of increased complexity and power consumption. Recent advancements in semiconductor technology have significantly improved the efficiency and reliability of these systems.

Solid-state modulators represent the current state-of-the-art in magnetron pulse modulation. These systems employ high-power semiconductor switches such as IGBTs, MOSFETs, or SiC devices arranged in series/parallel configurations to achieve the required voltage and current handling capabilities. The primary advantages include precise pulse control, high reliability, and reduced maintenance requirements, though challenges remain in scaling to very high power levels.

Despite these technological advances, several significant challenges persist in magnetron pulse modulation. Thermal management remains a critical issue, particularly in high-power applications where heat dissipation can significantly impact system reliability and performance. Engineers continue to explore advanced cooling techniques and materials to address these thermal constraints.

Electromagnetic interference (EMI) presents another substantial challenge, as the rapid switching of high voltages and currents generates significant electromagnetic noise that can affect nearby electronic systems. Comprehensive shielding and filtering strategies are essential but add complexity and cost to system designs.

Pulse fidelity and stability represent ongoing technical hurdles, particularly in applications requiring precise control over pulse characteristics. Variations in pulse shape, amplitude, or timing can significantly impact magnetron performance and output consistency. Advanced feedback control systems and compensation techniques are being developed to mitigate these issues.

Efficiency optimization remains a persistent challenge, with current systems typically achieving 70-85% efficiency. Energy losses occur primarily during switching transitions and in passive components. Research efforts focus on improved semiconductor materials, optimized circuit topologies, and advanced control algorithms to push efficiency boundaries further.

Reliability and lifetime considerations present significant challenges, particularly in continuous operation scenarios. Component aging, especially of high-voltage capacitors and switching elements, can lead to performance degradation over time. Predictive maintenance approaches and redundant designs are increasingly employed to address these reliability concerns.

Contemporary Magnetron Pulse Modulation Solutions

01 Pulse Width Modulation for Magnetrons

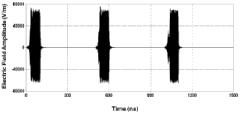

Pulse width modulation techniques are used to control magnetron output power by varying the duration of pulses while maintaining amplitude. This approach allows for precise control of microwave energy delivery, improving efficiency and reducing power consumption. The technique involves generating controlled pulse sequences with adjustable duty cycles to achieve desired output characteristics while minimizing thermal stress on the magnetron components.- Pulse Width Modulation for Magnetron Control: Pulse width modulation (PWM) techniques are used to control magnetron output power by varying the duration of pulses while maintaining a constant amplitude. This approach allows for precise control of microwave energy delivery and improves energy efficiency. The modulation can be implemented through solid-state switching circuits that enable rapid on-off cycling of the magnetron, resulting in better thermal management and extended component lifespan.

- Frequency Modulation in Magnetron Systems: Frequency modulation techniques applied to magnetrons involve varying the frequency of the output signal to achieve specific performance characteristics. This approach can reduce interference, improve signal quality, and enhance the stability of microwave systems. By implementing frequency modulation in magnetron pulse systems, engineers can achieve better spectral efficiency and reduce electromagnetic compatibility issues in various applications including radar and industrial heating systems.

- Advanced Pulse Shaping Techniques: Advanced pulse shaping techniques for magnetrons involve precisely controlling the rise time, fall time, and overall profile of each pulse. These techniques enable improved spectral characteristics, reduced harmonic content, and enhanced energy efficiency. By implementing sophisticated pulse shaping algorithms and hardware, magnetron systems can achieve better performance in applications requiring precise energy delivery, such as medical devices, scientific instruments, and advanced radar systems.

- Digital Control Systems for Magnetron Pulse Modulation: Digital control systems for magnetron pulse modulation utilize microprocessors, FPGAs, or dedicated ICs to generate precisely timed and shaped pulses. These systems offer advantages including programmability, adaptive control based on operating conditions, and integration with other digital systems. Digital control enables complex modulation schemes that would be difficult to implement with analog circuits, allowing for real-time adjustment of pulse parameters to optimize performance across varying operational requirements.

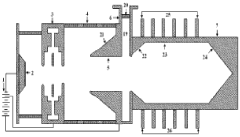

- High-Voltage Modulator Circuits for Pulsed Magnetrons: High-voltage modulator circuits are specialized power electronics designed to generate the precise high-voltage pulses required for magnetron operation. These circuits typically incorporate energy storage elements, switching devices, and protection mechanisms to deliver controlled pulses to the magnetron cathode. Modern designs focus on improving efficiency, reducing size and weight, and enhancing reliability through the use of advanced semiconductor devices and innovative circuit topologies.

02 Solid-State Modulator Designs

Modern magnetron pulse modulation employs solid-state modulators that replace traditional vacuum tube technology. These designs utilize semiconductor switches like IGBTs and MOSFETs to generate precise pulse shapes with faster rise times and improved reliability. Solid-state modulators offer better control over pulse parameters, reduced maintenance requirements, and enhanced overall system performance for radar, industrial heating, and medical applications.Expand Specific Solutions03 Anode Voltage Modulation Techniques

This approach involves modulating the anode voltage applied to magnetrons to control output characteristics. By precisely controlling the voltage waveform applied to the anode, engineers can achieve specific microwave pulse shapes and frequencies. The technique includes methods for voltage stabilization, transient suppression, and efficient energy transfer from power supplies to the magnetron, resulting in improved performance and extended device lifespan.Expand Specific Solutions04 Digital Control Systems for Pulse Modulation

Advanced digital control systems are implemented to precisely manage magnetron pulse modulation parameters. These systems utilize microprocessors, FPGAs, and specialized algorithms to generate complex pulse patterns with high timing accuracy. Digital control enables adaptive modulation schemes that can respond to changing operational conditions, implement sophisticated pulse sequences, and provide comprehensive monitoring and protection functions for the magnetron.Expand Specific Solutions05 Pulse Modulation for Specific Applications

Specialized pulse modulation techniques are developed for specific magnetron applications such as radar systems, industrial heating, and medical devices. These techniques optimize parameters like pulse repetition frequency, duty cycle, and waveform shape to meet application-specific requirements. For radar applications, techniques focus on improving target detection and resolution, while industrial applications emphasize uniform heating and energy efficiency. Medical applications prioritize precise energy delivery and patient safety.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Magnetron pulse modulation technology is currently in a growth phase, with an estimated market size of $2-3 billion and expanding at 7-9% annually. The competitive landscape features a mix of established defense contractors (Lockheed Martin, Thales), semiconductor equipment manufacturers (Applied Materials, TSMC), and specialized research institutions. Leading academic players like RWTH Aachen University, Fraunhofer-Gesellschaft, and Technische Universität München are advancing fundamental research, while industrial leaders such as Siemens Healthcare, Hitachi, and Boston Scientific are commercializing applications in medical imaging and treatment. The technology is approaching maturity in defense applications but remains in development for emerging applications in healthcare and semiconductor manufacturing, with companies like NAURA Microelectronics and Taiwan Semiconductor Manufacturing Co. investing heavily in next-generation implementations.

Lockheed Martin Corp.

Technical Solution: Lockheed Martin has developed advanced magnetron pulse modulation techniques for radar and defense applications. Their approach utilizes solid-state modulators with high-voltage semiconductor switches (IGBTs and MOSFETs) to replace traditional thyratron tubes, achieving precise pulse width control down to nanosecond resolution[1]. The system incorporates digital waveform generators that enable complex pulse patterns including frequency agility and pulse-to-pulse modulation. Lockheed's implementation features adaptive pulse compression algorithms that optimize radar performance in varying environmental conditions. Their modulation system achieves peak power outputs exceeding 5MW with pulse repetition frequencies up to 10kHz[3]. A key innovation is their thermal management system that allows sustained high-power operation while maintaining component reliability. The architecture includes real-time monitoring and fault detection capabilities that adjust modulation parameters to prevent system damage during anomalous conditions[5].

Strengths: Superior pulse width control and timing precision enables enhanced target discrimination in radar applications. The solid-state approach significantly improves reliability and operational lifetime compared to tube-based systems. Weaknesses: Higher initial implementation costs compared to traditional systems, and requires sophisticated cooling systems to manage heat dissipation from high-power solid-state components.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed specialized magnetron pulse modulation techniques optimized for semiconductor manufacturing processes, particularly for physical vapor deposition (PVD) applications. Their implementation utilizes advanced high-frequency switching power supplies capable of delivering precisely controlled pulses at frequencies up to 250kHz with power levels exceeding 100kW[1]. The system incorporates sophisticated feedback control mechanisms that monitor plasma impedance in real-time and dynamically adjust pulse parameters to maintain optimal deposition conditions. Applied Materials' approach features dual-stage modulation architecture that separates the high-voltage generation from the pulse-forming circuitry, enabling independent optimization of each stage for maximum efficiency and control precision. Their technology achieves pulse width modulation with resolution down to 100ns, allowing precise control of thin film properties during deposition processes[4]. The system includes advanced arc detection and suppression capabilities that can identify and respond to arcing events within microseconds, preventing damage to sensitive semiconductor substrates. Additionally, their implementation features programmable pulse shapes that can be tailored to specific material deposition requirements, optimizing film quality and deposition rates for various materials.

Strengths: Exceptional precision in pulse control enables superior thin film quality and uniformity in semiconductor manufacturing processes. Advanced arc management capabilities significantly reduce defect rates in high-value semiconductor production. Weaknesses: Highly specialized system designed primarily for semiconductor applications with limited flexibility for other uses, and requires integration with sophisticated process control systems.

Key Patents and Technical Innovations

A device with improved modulation cavity for high pulse microwave signal generation and method thereof

PatentActiveIN201611032924A

Innovation

- A device with a radially coupled modulation cavity comprising pillbox cavities and discs without conducting grids, utilizing a field emissive annular cathode and a post-acceleration gap to generate high pulse microwaves, eliminating the need for external magnetic fields and mode converters, and operating at lower voltages.

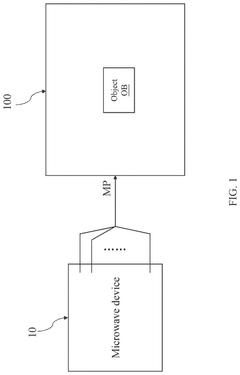

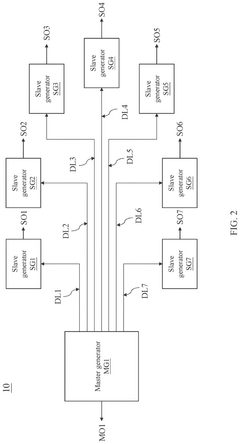

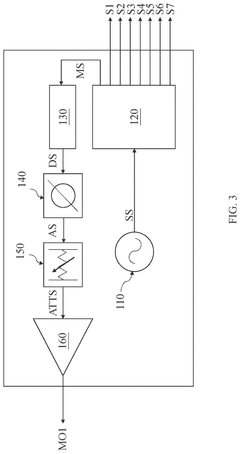

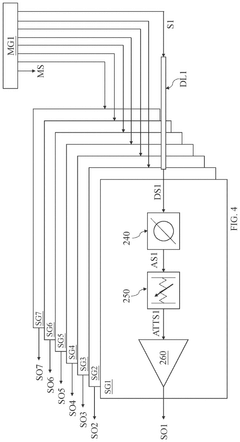

Microwave device

PatentPendingUS20250247926A1

Innovation

- A microwave device comprising a master generator, delay lines, and slave generators, where the master generator produces a source RF signal that is split and synchronized with slave generators through delay lines to achieve phase-coherent RF outputs, utilizing solid state microwave generators for improved control.

Energy Efficiency and Power Optimization

Energy efficiency represents a critical dimension in magnetron pulse modulation techniques, directly impacting operational costs, system longevity, and environmental footprint. Modern magnetron systems typically operate at efficiency levels between 65-85%, with significant energy losses occurring during the modulation process. These losses manifest primarily as heat, requiring additional cooling systems that further increase power consumption.

Power optimization in magnetron pulse modulation involves several interconnected approaches. The implementation of high-efficiency switching power supplies has demonstrated energy savings of 15-20% compared to traditional linear power supplies. These switching supplies utilize advanced semiconductor materials such as silicon carbide (SiC) and gallium nitride (GaN), which offer superior thermal properties and switching characteristics at high frequencies.

Pulse width optimization presents another significant opportunity for energy conservation. By precisely tailoring pulse duration to specific application requirements, unnecessary power expenditure can be eliminated. Adaptive pulse width modulation (APWM) systems can dynamically adjust pulse parameters based on real-time feedback, achieving energy savings of up to 30% in variable load applications.

Thermal management innovations have emerged as crucial components in energy-efficient magnetron systems. Advanced cooling techniques, including microchannel liquid cooling and phase-change materials, enable more efficient heat dissipation while consuming less auxiliary power. These approaches have demonstrated the ability to reduce cooling-related energy consumption by 25-40% compared to conventional forced-air cooling methods.

Recovery circuits represent a promising frontier in magnetron efficiency. By capturing and recycling energy that would otherwise be dissipated during the pulse off-time, these systems can improve overall efficiency by 10-15%. The implementation of resonant recovery circuits has proven particularly effective in high-power industrial applications, though challenges remain in miniaturizing these systems for compact applications.

The integration of digital control systems with predictive algorithms offers comprehensive power optimization across operating conditions. Machine learning approaches can anticipate load variations and preemptively adjust modulation parameters, reducing transient inefficiencies. Field trials have demonstrated that AI-enhanced control systems can achieve additional energy savings of 8-12% beyond conventional feedback control methods.

Industry benchmarks indicate that implementing a comprehensive suite of these optimization techniques can reduce overall energy consumption by 30-45% compared to legacy systems, with corresponding reductions in operational costs and carbon emissions. The return on investment for such upgrades typically ranges from 18-36 months, depending on utilization patterns and energy costs.

Power optimization in magnetron pulse modulation involves several interconnected approaches. The implementation of high-efficiency switching power supplies has demonstrated energy savings of 15-20% compared to traditional linear power supplies. These switching supplies utilize advanced semiconductor materials such as silicon carbide (SiC) and gallium nitride (GaN), which offer superior thermal properties and switching characteristics at high frequencies.

Pulse width optimization presents another significant opportunity for energy conservation. By precisely tailoring pulse duration to specific application requirements, unnecessary power expenditure can be eliminated. Adaptive pulse width modulation (APWM) systems can dynamically adjust pulse parameters based on real-time feedback, achieving energy savings of up to 30% in variable load applications.

Thermal management innovations have emerged as crucial components in energy-efficient magnetron systems. Advanced cooling techniques, including microchannel liquid cooling and phase-change materials, enable more efficient heat dissipation while consuming less auxiliary power. These approaches have demonstrated the ability to reduce cooling-related energy consumption by 25-40% compared to conventional forced-air cooling methods.

Recovery circuits represent a promising frontier in magnetron efficiency. By capturing and recycling energy that would otherwise be dissipated during the pulse off-time, these systems can improve overall efficiency by 10-15%. The implementation of resonant recovery circuits has proven particularly effective in high-power industrial applications, though challenges remain in miniaturizing these systems for compact applications.

The integration of digital control systems with predictive algorithms offers comprehensive power optimization across operating conditions. Machine learning approaches can anticipate load variations and preemptively adjust modulation parameters, reducing transient inefficiencies. Field trials have demonstrated that AI-enhanced control systems can achieve additional energy savings of 8-12% beyond conventional feedback control methods.

Industry benchmarks indicate that implementing a comprehensive suite of these optimization techniques can reduce overall energy consumption by 30-45% compared to legacy systems, with corresponding reductions in operational costs and carbon emissions. The return on investment for such upgrades typically ranges from 18-36 months, depending on utilization patterns and energy costs.

Electromagnetic Compatibility and Safety Standards

Implementing magnetron pulse modulation techniques requires strict adherence to electromagnetic compatibility (EMC) and safety standards to ensure both operational reliability and human safety. The International Electrotechnical Commission (IEC) has established comprehensive standards such as IEC 61000 series for EMC requirements, which manufacturers must comply with to minimize electromagnetic interference. These standards specifically address emission limits, immunity requirements, and testing methodologies applicable to high-power RF systems like magnetron pulse modulators.

For magnetron pulse modulation systems, compliance with FCC Part 18 regulations in the United States and the equivalent EN 55011 standards in Europe is mandatory. These regulations establish specific emission limits for industrial, scientific, and medical (ISM) equipment operating in various frequency bands. The standards categorize equipment into Class A (industrial environments) and Class B (residential environments), with the latter having more stringent requirements due to proximity to sensitive consumer electronics.

Safety standards such as IEC 60215 specifically address radio frequency transmitters and related equipment, providing guidelines for protection against electrical, mechanical, and radiation hazards. For magnetron systems, additional standards like IEC 60335-2-25 may apply when the technology is implemented in consumer applications such as microwave ovens. These standards mandate specific safety features including interlocking mechanisms, leakage radiation limits, and thermal protection systems.

Radiation safety is particularly critical for magnetron pulse modulation systems. Standards from organizations like the International Commission on Non-Ionizing Radiation Protection (ICNIRP) establish exposure limits for electromagnetic fields to prevent adverse health effects. These guidelines specify maximum permissible exposure levels based on frequency, power density, and duration of exposure, with different thresholds for occupational and general public scenarios.

The implementation of magnetron pulse modulation must also address specific technical requirements for conducted and radiated emissions. Shielding effectiveness, grounding schemes, and filtering techniques must be designed according to standards like IEEE 299 for shielding enclosures and IEC 61000-4-3 for immunity to radiated electromagnetic fields. These standards prescribe test methodologies and acceptance criteria that ensure the system neither causes interference to other equipment nor is susceptible to external electromagnetic disturbances.

Military applications of magnetron pulse modulation face even more rigorous standards, such as MIL-STD-461 for EMC requirements and MIL-STD-464 for electromagnetic environmental effects. These standards impose stricter limits on emissions and higher immunity requirements to ensure reliable operation in complex electromagnetic environments, including potential electronic warfare scenarios.

For magnetron pulse modulation systems, compliance with FCC Part 18 regulations in the United States and the equivalent EN 55011 standards in Europe is mandatory. These regulations establish specific emission limits for industrial, scientific, and medical (ISM) equipment operating in various frequency bands. The standards categorize equipment into Class A (industrial environments) and Class B (residential environments), with the latter having more stringent requirements due to proximity to sensitive consumer electronics.

Safety standards such as IEC 60215 specifically address radio frequency transmitters and related equipment, providing guidelines for protection against electrical, mechanical, and radiation hazards. For magnetron systems, additional standards like IEC 60335-2-25 may apply when the technology is implemented in consumer applications such as microwave ovens. These standards mandate specific safety features including interlocking mechanisms, leakage radiation limits, and thermal protection systems.

Radiation safety is particularly critical for magnetron pulse modulation systems. Standards from organizations like the International Commission on Non-Ionizing Radiation Protection (ICNIRP) establish exposure limits for electromagnetic fields to prevent adverse health effects. These guidelines specify maximum permissible exposure levels based on frequency, power density, and duration of exposure, with different thresholds for occupational and general public scenarios.

The implementation of magnetron pulse modulation must also address specific technical requirements for conducted and radiated emissions. Shielding effectiveness, grounding schemes, and filtering techniques must be designed according to standards like IEEE 299 for shielding enclosures and IEC 61000-4-3 for immunity to radiated electromagnetic fields. These standards prescribe test methodologies and acceptance criteria that ensure the system neither causes interference to other equipment nor is susceptible to external electromagnetic disturbances.

Military applications of magnetron pulse modulation face even more rigorous standards, such as MIL-STD-461 for EMC requirements and MIL-STD-464 for electromagnetic environmental effects. These standards impose stricter limits on emissions and higher immunity requirements to ensure reliable operation in complex electromagnetic environments, including potential electronic warfare scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!