How to Implement Robust Recycling With Cellulose Acetate?

Cellulose Acetate Recycling Background and Objectives

Cellulose acetate, a versatile biopolymer derived from cellulose, has been widely used in various industries for over a century. Its journey began in the late 19th century when it was first synthesized, marking a significant milestone in the development of synthetic materials. Since then, cellulose acetate has found applications in textiles, films, cigarette filters, and numerous other products due to its unique properties and biodegradability.

The evolution of cellulose acetate technology has been driven by the increasing demand for sustainable and eco-friendly materials. As environmental concerns have grown, so has the focus on developing efficient recycling methods for this polymer. The current technological landscape presents both opportunities and challenges in implementing robust recycling processes for cellulose acetate.

The primary objective of this research is to explore and evaluate cutting-edge approaches to cellulose acetate recycling. We aim to identify innovative techniques that can overcome existing limitations and improve the overall efficiency of the recycling process. This includes investigating novel chemical and mechanical methods, as well as exploring potential biotechnological solutions.

One of the key goals is to develop a comprehensive understanding of the degradation mechanisms of cellulose acetate under various conditions. This knowledge is crucial for designing more effective recycling strategies that can handle diverse forms of cellulose acetate waste. Additionally, we seek to explore ways to enhance the quality of recycled cellulose acetate, ensuring its suitability for high-value applications.

Another important aspect of our research is to assess the economic viability and scalability of different recycling approaches. We aim to identify methods that not only offer superior technical performance but also demonstrate potential for large-scale implementation in industrial settings. This involves evaluating factors such as energy consumption, processing time, and overall cost-effectiveness.

Furthermore, we intend to explore the integration of cellulose acetate recycling with other waste management systems. This holistic approach could lead to more efficient resource utilization and contribute to the development of circular economy models. By examining the entire lifecycle of cellulose acetate products, we hope to identify opportunities for improvement at every stage, from production to disposal and recycling.

Lastly, our research aims to address the environmental impact of cellulose acetate recycling processes. We will investigate methods to minimize the use of harmful chemicals and reduce the carbon footprint associated with recycling operations. This aligns with the growing global emphasis on sustainable practices and the need for environmentally responsible solutions in waste management.

Market Demand for Sustainable Cellulose Acetate Solutions

The market demand for sustainable cellulose acetate solutions has been steadily increasing in recent years, driven by growing environmental concerns and stricter regulations on plastic waste. Cellulose acetate, a biodegradable material derived from natural sources, has emerged as a promising alternative to conventional plastics in various industries.

In the packaging sector, there is a significant demand for cellulose acetate-based materials as companies seek to reduce their environmental footprint. Food and beverage manufacturers are particularly interested in sustainable packaging solutions that maintain product integrity while being eco-friendly. The textile industry also shows a strong interest in cellulose acetate fibers as a more sustainable alternative to synthetic materials.

Consumer awareness of environmental issues has led to increased demand for products made from renewable and biodegradable materials. This trend is especially prominent in the personal care and cosmetics industry, where cellulose acetate is being used in items such as toothbrushes, combs, and cosmetic packaging. The automotive sector is exploring cellulose acetate composites for interior components, aiming to reduce vehicle weight and improve fuel efficiency.

The global market for cellulose acetate is expected to grow substantially in the coming years. This growth is fueled by the material's versatility, biodegradability, and potential for recycling. Industries are actively seeking ways to incorporate cellulose acetate into their products and processes to meet sustainability goals and comply with evolving environmental regulations.

However, the market demand for sustainable cellulose acetate solutions is not without challenges. The cost of production and processing compared to traditional plastics remains a concern for some industries. Additionally, there is a need for improved recycling infrastructure and technologies to fully realize the material's potential for circular economy applications.

Despite these challenges, the overall market trajectory for sustainable cellulose acetate solutions is positive. Governments worldwide are implementing policies to reduce plastic waste, creating opportunities for alternative materials. This regulatory landscape, combined with changing consumer preferences, is driving innovation in cellulose acetate applications and recycling technologies.

As industries continue to prioritize sustainability, the demand for cellulose acetate is expected to expand into new markets and applications. Research and development efforts are focusing on enhancing the material's properties and developing more efficient recycling methods to meet this growing demand. The market for sustainable cellulose acetate solutions represents a significant opportunity for businesses to align with global sustainability trends and gain a competitive edge in their respective industries.

Current Challenges in Cellulose Acetate Recycling

Cellulose acetate recycling faces several significant challenges that hinder widespread implementation and efficiency. One of the primary obstacles is the complex chemical structure of cellulose acetate, which makes it resistant to conventional recycling methods. Unlike simpler plastics, cellulose acetate requires specialized processes to break down and recover its constituent materials effectively.

The contamination of cellulose acetate products with other materials poses another major challenge. Many cellulose acetate items, such as cigarette filters, often contain additives or are mixed with other substances during use. This contamination complicates the recycling process, as it necessitates additional sorting and purification steps to isolate the cellulose acetate component.

Collection and sorting present logistical hurdles in the recycling chain. Cellulose acetate products are often small, dispersed, and mixed with general waste, making it difficult to gather sufficient quantities for economically viable recycling operations. The lack of established collection systems specifically for cellulose acetate further exacerbates this issue.

The energy-intensive nature of cellulose acetate recycling processes is another significant challenge. Current methods often require high temperatures and chemical treatments, which can be costly and environmentally unfriendly. This energy requirement not only impacts the economic feasibility of recycling but also raises questions about its overall environmental benefits.

Market demand for recycled cellulose acetate remains limited, creating a circular problem. Without strong demand for recycled materials, there is less incentive to invest in and improve recycling technologies. This lack of market pull slows down the development of more efficient and cost-effective recycling solutions.

Technological limitations in current recycling methods also present challenges. Many existing processes struggle to maintain the quality and properties of the recycled cellulose acetate, potentially limiting its applications in new products. Developing technologies that can produce high-quality recycled materials consistently is crucial for expanding the use of recycled cellulose acetate.

Regulatory frameworks and policy support for cellulose acetate recycling are often inadequate or non-existent in many regions. The lack of clear guidelines, incentives, or mandates for recycling this specific material hampers investment and innovation in the field. Establishing supportive policies could significantly accelerate the development and adoption of robust recycling solutions.

Addressing these challenges requires a multifaceted approach, combining technological innovation, policy support, and market development. Overcoming these obstacles is essential for implementing robust recycling systems for cellulose acetate and moving towards a more circular economy for this widely used material.

Existing Robust Recycling Methods for Cellulose Acetate

01 Chemical recycling of cellulose acetate

Chemical recycling methods are used to break down cellulose acetate into its constituent components. This process typically involves deacetylation, where the acetyl groups are removed from the cellulose backbone. The resulting products can be further processed or used as raw materials for new cellulose acetate production.- Chemical recycling methods: Chemical recycling methods are used to break down cellulose acetate into its basic components. These processes typically involve deacetylation, where the acetyl groups are removed from the cellulose backbone. The resulting products can be used to produce new cellulose acetate or other cellulose-based materials. This approach allows for the recovery of valuable chemical components and reduces waste.

- Mechanical recycling techniques: Mechanical recycling techniques involve physical processing of cellulose acetate waste without changing its chemical structure. This can include grinding, melting, and reforming the material into new products. These methods are often less energy-intensive than chemical recycling and can be used to produce a variety of recycled cellulose acetate products, such as fibers or films.

- Biological recycling processes: Biological recycling processes utilize microorganisms or enzymes to break down cellulose acetate. These methods can be more environmentally friendly than chemical or mechanical approaches. Enzymes can selectively remove acetyl groups, while certain bacteria can metabolize cellulose acetate. The resulting products can be used as feedstock for various applications or further processed into new materials.

- Solvent-based recycling methods: Solvent-based recycling methods involve dissolving cellulose acetate in specific solvents, followed by precipitation or regeneration to recover the material. This approach allows for the removal of impurities and can be used to produce high-quality recycled cellulose acetate. The choice of solvent and process conditions are crucial for optimizing the recycling efficiency and minimizing environmental impact.

- Thermal recycling and energy recovery: Thermal recycling and energy recovery methods involve the controlled combustion of cellulose acetate waste to generate heat or electricity. While not a material recycling approach, this method can be used to recover energy from cellulose acetate waste that is not suitable for other recycling processes. Advanced incineration technologies can minimize emissions and maximize energy recovery efficiency.

02 Mechanical recycling of cellulose acetate

Mechanical recycling involves physical processes such as grinding, melting, and reforming cellulose acetate waste into new products. This method is often used for recycling cellulose acetate fibers from textiles or film waste from packaging materials. The recycled material can be used in various applications, including new fibers or plastic products.Expand Specific Solutions03 Biodegradation and composting of cellulose acetate

Some cellulose acetate products can be designed for biodegradation or composting. This approach involves modifying the cellulose acetate structure or incorporating additives to enhance its susceptibility to microbial breakdown. The resulting materials can be disposed of in industrial composting facilities or biodegradable waste streams.Expand Specific Solutions04 Solvent-based recycling of cellulose acetate

Solvent-based recycling methods involve dissolving cellulose acetate waste in appropriate solvents, followed by precipitation or regeneration of the polymer. This process can be used to recover high-quality cellulose acetate for reuse in new products. The choice of solvent and process conditions are critical for maintaining the polymer's properties.Expand Specific Solutions05 Upcycling and repurposing of cellulose acetate waste

Upcycling involves transforming cellulose acetate waste into higher-value products. This can include using waste materials in artistic or design applications, or incorporating them into composite materials. Repurposing may involve using cellulose acetate waste in new applications without significant chemical or physical modification.Expand Specific Solutions

Key Players in Cellulose Acetate Recycling Industry

The implementation of robust recycling with cellulose acetate is in a developing stage, with growing market potential driven by increasing environmental concerns. The global cellulose acetate market is expected to expand significantly in the coming years, reflecting the rising demand for sustainable materials. Technologically, the field is advancing rapidly, with companies like Eastman Chemical Co., Daicel Corp., and Lenzing AG leading the way in research and development. These industry leaders are focusing on improving recycling processes and developing more eco-friendly cellulose acetate products. Emerging players such as Infinited Fiber Co. Oy and TBM Co., Ltd. are also contributing innovative solutions, indicating a competitive and dynamic landscape. The involvement of academic institutions like Kobe University and Washington State University further underscores the ongoing technological advancements in this field.

Eastman Chemical Co.

Daicel Corp.

Innovative Approaches in Cellulose Acetate Recycling

- A method involving pelleting and extrusion processes to convert cellulose acetate-containing materials into higher-density pellets and granules, allowing for cost-effective storage and transportation, and enabling the reuse of production rejects and cigarette filter waste by maintaining temperatures below the glass transition temperature of cellulose acetate during processing.

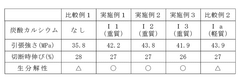

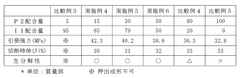

- A biodegradable resin composition is developed by blending cellulose acetate with heavy calcium carbonate in a mass ratio of 10:90 to 70:30, which enhances biodegradability and mechanical properties while reducing costs, utilizing heavy calcium carbonate particles with a high specific surface area and amorphous shape to create a matrix with the resin, improving decomposition efficiency.

Environmental Impact Assessment of Recycling Processes

The environmental impact assessment of recycling processes for cellulose acetate is a critical component in implementing robust recycling systems. This assessment evaluates the potential environmental consequences of various recycling methods and helps identify the most sustainable approaches.

Cellulose acetate recycling processes typically involve chemical or mechanical treatments to break down the material into its constituent components. The environmental impact of these processes can be significant, affecting air quality, water resources, and energy consumption. Chemical recycling methods often utilize solvents to dissolve the cellulose acetate, which can lead to the release of volatile organic compounds (VOCs) into the atmosphere. These emissions may contribute to air pollution and pose potential health risks to workers and nearby communities.

Water usage is another crucial factor in the environmental assessment. Both chemical and mechanical recycling processes require substantial amounts of water for washing and purification steps. The resulting wastewater may contain chemical residues, microplastics, and other contaminants that need proper treatment before discharge. Implementing closed-loop water systems and advanced filtration technologies can help mitigate these impacts and reduce overall water consumption.

Energy consumption is a significant consideration in the environmental impact assessment. Mechanical recycling processes, such as grinding and shredding, require substantial energy inputs. Chemical recycling methods often involve heating and cooling cycles, which also contribute to energy usage. Evaluating the energy efficiency of different recycling technologies and exploring opportunities for renewable energy integration can help minimize the carbon footprint of the recycling process.

The assessment should also consider the potential for material recovery and waste reduction. Efficient recycling processes can significantly reduce the amount of cellulose acetate waste sent to landfills or incineration facilities. This not only conserves valuable resources but also reduces greenhouse gas emissions associated with waste disposal.

Life cycle assessment (LCA) methodologies play a crucial role in comprehensively evaluating the environmental impacts of cellulose acetate recycling. LCA considers the entire lifecycle of the material, from raw material extraction to end-of-life disposal, providing a holistic view of the environmental consequences. This approach helps identify hotspots in the recycling process where environmental impacts are most significant and guides the development of targeted improvement strategies.

Furthermore, the assessment should consider the potential for creating secondary pollutants or byproducts during the recycling process. Some chemical treatments may generate hazardous waste that requires special handling and disposal. Evaluating these potential risks and developing appropriate mitigation measures is essential for ensuring the overall environmental sustainability of the recycling system.

Economic Viability of Cellulose Acetate Recycling Systems

The economic viability of cellulose acetate recycling systems is a critical factor in determining the feasibility and sustainability of implementing robust recycling processes for this material. Cellulose acetate, commonly used in products such as cigarette filters, textiles, and photographic films, presents unique challenges and opportunities in recycling.

One of the primary considerations in assessing the economic viability is the cost of collection and sorting. Establishing an efficient collection system for cellulose acetate products, particularly those with short lifespans like cigarette filters, requires significant investment in infrastructure and public awareness campaigns. The dispersed nature of these products often results in higher collection costs compared to more centralized waste streams.

Processing costs form another crucial component of the economic equation. The deacetylation process, necessary to break down cellulose acetate into its constituent components, involves chemical treatments and energy-intensive steps. While technological advancements have improved the efficiency of this process, the operational costs remain substantial. These costs must be weighed against the value of the recovered materials, primarily cellulose and acetic acid.

Market demand for recycled cellulose acetate and its derivatives plays a pivotal role in determining economic viability. The quality of recycled materials often influences their market value, with higher-grade recycled cellulose commanding better prices. Developing markets for recycled cellulose acetate in various industries, such as textiles or packaging, can significantly enhance the economic prospects of recycling systems.

Regulatory frameworks and government incentives can substantially impact the economic landscape of cellulose acetate recycling. Policies promoting extended producer responsibility, recycling targets, or tax incentives for using recycled materials can create a more favorable economic environment for recycling initiatives. These measures can help offset initial investment costs and encourage long-term commitment to recycling programs.

Scale of operations is another critical factor affecting economic viability. Larger-scale recycling facilities can benefit from economies of scale, reducing per-unit processing costs. However, this must be balanced against transportation costs, as centralized facilities may require longer-distance transport of collected materials.

Technological innovation in recycling processes can significantly influence economic viability. Advancements in chemical recycling techniques, such as improved catalysts or more efficient deacetylation methods, can reduce processing costs and improve the quality of recovered materials. Ongoing research in this area holds promise for enhancing the economic attractiveness of cellulose acetate recycling.