How to Implement Safety Measures for Fluoroantimonic Acid?

JUN 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fluoroantimonic Acid Safety Background and Objectives

Fluoroantimonic acid, a superacid formed by combining hydrogen fluoride and antimony pentafluoride, is one of the strongest known acids. Its extreme corrosiveness and reactivity pose significant safety challenges in handling and storage. The development of safety measures for this compound has been an ongoing process, driven by the need to protect personnel and equipment in research and industrial settings.

The evolution of safety protocols for fluoroantimonic acid can be traced back to the mid-20th century when superacids were first synthesized and studied. Initially, safety measures were rudimentary, focusing primarily on basic personal protective equipment. As understanding of the acid's properties grew, so did the sophistication of safety approaches.

Current safety objectives for fluoroantimonic acid handling encompass multiple aspects. These include developing advanced containment systems to prevent leaks and spills, designing specialized personal protective equipment resistant to extreme corrosion, and implementing rigorous handling procedures to minimize exposure risks. Additionally, there is a focus on creating emergency response protocols tailored to the unique properties of this superacid.

The technical goals in this field extend beyond mere containment. Researchers aim to develop materials that can withstand prolonged exposure to fluoroantimonic acid, potentially revolutionizing storage and transport methods. There is also a push towards creating more sensitive detection systems capable of identifying minute quantities of the acid in the air or on surfaces, enabling faster response to potential leaks.

Another key objective is the improvement of neutralization techniques. Given the acid's extreme reactivity, conventional neutralization methods are often inadequate. Developing efficient and safe neutralization processes is crucial for both routine handling and emergency situations.

The field of fluoroantimonic acid safety is closely tied to advancements in materials science, chemical engineering, and industrial hygiene. As new materials and technologies emerge, they are rapidly evaluated for their potential application in enhancing safety measures. This interdisciplinary approach reflects the complex nature of the challenges posed by this superacid.

Looking ahead, the trajectory of safety measure development for fluoroantimonic acid is likely to focus on automation and remote handling techniques. The goal is to minimize direct human interaction with the acid, reducing the risk of exposure. This may involve the development of robotic systems capable of manipulating the acid in sealed environments, as well as advanced monitoring systems that can detect and respond to potential hazards autonomously.

The evolution of safety protocols for fluoroantimonic acid can be traced back to the mid-20th century when superacids were first synthesized and studied. Initially, safety measures were rudimentary, focusing primarily on basic personal protective equipment. As understanding of the acid's properties grew, so did the sophistication of safety approaches.

Current safety objectives for fluoroantimonic acid handling encompass multiple aspects. These include developing advanced containment systems to prevent leaks and spills, designing specialized personal protective equipment resistant to extreme corrosion, and implementing rigorous handling procedures to minimize exposure risks. Additionally, there is a focus on creating emergency response protocols tailored to the unique properties of this superacid.

The technical goals in this field extend beyond mere containment. Researchers aim to develop materials that can withstand prolonged exposure to fluoroantimonic acid, potentially revolutionizing storage and transport methods. There is also a push towards creating more sensitive detection systems capable of identifying minute quantities of the acid in the air or on surfaces, enabling faster response to potential leaks.

Another key objective is the improvement of neutralization techniques. Given the acid's extreme reactivity, conventional neutralization methods are often inadequate. Developing efficient and safe neutralization processes is crucial for both routine handling and emergency situations.

The field of fluoroantimonic acid safety is closely tied to advancements in materials science, chemical engineering, and industrial hygiene. As new materials and technologies emerge, they are rapidly evaluated for their potential application in enhancing safety measures. This interdisciplinary approach reflects the complex nature of the challenges posed by this superacid.

Looking ahead, the trajectory of safety measure development for fluoroantimonic acid is likely to focus on automation and remote handling techniques. The goal is to minimize direct human interaction with the acid, reducing the risk of exposure. This may involve the development of robotic systems capable of manipulating the acid in sealed environments, as well as advanced monitoring systems that can detect and respond to potential hazards autonomously.

Industrial Demand for Superacid Handling

The industrial demand for superacid handling, particularly fluoroantimonic acid, has been steadily increasing due to its unique properties and applications in various sectors. This powerful superacid, known for its extreme corrosiveness and reactivity, finds extensive use in petrochemical industries, semiconductor manufacturing, and advanced materials research. The petrochemical sector relies on fluoroantimonic acid for catalyzing reactions in the production of high-octane gasoline and other refined petroleum products, driving a significant portion of the demand.

In the semiconductor industry, the acid plays a crucial role in etching and cleaning processes, essential for the production of advanced microchips and electronic components. As the global demand for electronic devices continues to surge, the need for efficient and precise superacid handling in semiconductor fabrication has grown proportionally. This trend is further amplified by the ongoing miniaturization of electronic components, requiring more sophisticated etching techniques.

The materials science and research sector also contributes to the industrial demand for fluoroantimonic acid. Its unique properties make it valuable in the development of new materials, including super-strong polymers and advanced composites. The aerospace and defense industries, in particular, have shown increased interest in these materials, further driving the demand for safe and efficient superacid handling techniques.

However, the extreme reactivity and corrosiveness of fluoroantimonic acid present significant challenges in terms of storage, transportation, and handling. This has led to a growing demand for advanced safety measures and specialized equipment in industries utilizing this superacid. Companies are increasingly investing in robust containment systems, specialized protective gear, and advanced monitoring technologies to ensure safe handling and minimize the risk of accidents or environmental contamination.

The pharmaceutical industry has also emerged as a notable consumer of fluoroantimonic acid, particularly in the synthesis of complex organic compounds and drug precursors. As drug discovery and development processes become more sophisticated, the demand for superacids in pharmaceutical research and production is expected to rise, further contributing to the overall industrial demand for safe superacid handling solutions.

In the semiconductor industry, the acid plays a crucial role in etching and cleaning processes, essential for the production of advanced microchips and electronic components. As the global demand for electronic devices continues to surge, the need for efficient and precise superacid handling in semiconductor fabrication has grown proportionally. This trend is further amplified by the ongoing miniaturization of electronic components, requiring more sophisticated etching techniques.

The materials science and research sector also contributes to the industrial demand for fluoroantimonic acid. Its unique properties make it valuable in the development of new materials, including super-strong polymers and advanced composites. The aerospace and defense industries, in particular, have shown increased interest in these materials, further driving the demand for safe and efficient superacid handling techniques.

However, the extreme reactivity and corrosiveness of fluoroantimonic acid present significant challenges in terms of storage, transportation, and handling. This has led to a growing demand for advanced safety measures and specialized equipment in industries utilizing this superacid. Companies are increasingly investing in robust containment systems, specialized protective gear, and advanced monitoring technologies to ensure safe handling and minimize the risk of accidents or environmental contamination.

The pharmaceutical industry has also emerged as a notable consumer of fluoroantimonic acid, particularly in the synthesis of complex organic compounds and drug precursors. As drug discovery and development processes become more sophisticated, the demand for superacids in pharmaceutical research and production is expected to rise, further contributing to the overall industrial demand for safe superacid handling solutions.

Current Challenges in Fluoroantimonic Acid Management

The management of fluoroantimonic acid presents several significant challenges due to its extreme corrosivity and reactivity. One of the primary concerns is the acid's ability to react violently with water, producing highly toxic and corrosive hydrogen fluoride gas. This necessitates stringent moisture control measures throughout handling, storage, and disposal processes.

Material compatibility is another critical issue. Fluoroantimonic acid rapidly degrades most common materials, including many metals and plastics. This limits the options for containment vessels, transfer systems, and personal protective equipment. Specialized materials such as fluoropolymers (e.g., PTFE) or certain high-purity alloys are required, but even these can degrade over time, necessitating frequent inspections and replacements.

The extreme reactivity of fluoroantimonic acid also poses significant risks during transportation and storage. Any breach in containment could lead to catastrophic reactions with environmental moisture or other substances. This requires robust, multi-layered containment systems and rigorous protocols for movement and storage.

Worker safety is a paramount concern. The acid's ability to cause severe, potentially fatal burns even with minimal exposure demands comprehensive personal protective equipment and highly trained personnel. However, the limitations of protective materials against such a corrosive substance create ongoing challenges in ensuring adequate protection.

Disposal of fluoroantimonic acid and contaminated materials presents another set of challenges. Neutralization is complex due to the acid's extreme strength, and traditional waste treatment methods are often inadequate. Specialized facilities and processes are required, which can be costly and limited in availability.

Environmental concerns add another layer of complexity. Any release of fluoroantimonic acid could have severe ecological consequences, potentially contaminating soil and water sources. This necessitates robust spill containment and remediation plans, as well as stringent monitoring systems.

The lack of standardized safety protocols specific to fluoroantimonic acid management is an ongoing issue. While general guidelines for handling strong acids exist, the unique properties of this superacid often require case-by-case risk assessments and custom safety measures.

Regulatory compliance presents challenges due to the acid's classification as an extremely hazardous substance. Navigating the complex landscape of local, national, and international regulations requires significant resources and expertise, particularly for organizations operating across multiple jurisdictions.

Material compatibility is another critical issue. Fluoroantimonic acid rapidly degrades most common materials, including many metals and plastics. This limits the options for containment vessels, transfer systems, and personal protective equipment. Specialized materials such as fluoropolymers (e.g., PTFE) or certain high-purity alloys are required, but even these can degrade over time, necessitating frequent inspections and replacements.

The extreme reactivity of fluoroantimonic acid also poses significant risks during transportation and storage. Any breach in containment could lead to catastrophic reactions with environmental moisture or other substances. This requires robust, multi-layered containment systems and rigorous protocols for movement and storage.

Worker safety is a paramount concern. The acid's ability to cause severe, potentially fatal burns even with minimal exposure demands comprehensive personal protective equipment and highly trained personnel. However, the limitations of protective materials against such a corrosive substance create ongoing challenges in ensuring adequate protection.

Disposal of fluoroantimonic acid and contaminated materials presents another set of challenges. Neutralization is complex due to the acid's extreme strength, and traditional waste treatment methods are often inadequate. Specialized facilities and processes are required, which can be costly and limited in availability.

Environmental concerns add another layer of complexity. Any release of fluoroantimonic acid could have severe ecological consequences, potentially contaminating soil and water sources. This necessitates robust spill containment and remediation plans, as well as stringent monitoring systems.

The lack of standardized safety protocols specific to fluoroantimonic acid management is an ongoing issue. While general guidelines for handling strong acids exist, the unique properties of this superacid often require case-by-case risk assessments and custom safety measures.

Regulatory compliance presents challenges due to the acid's classification as an extremely hazardous substance. Navigating the complex landscape of local, national, and international regulations requires significant resources and expertise, particularly for organizations operating across multiple jurisdictions.

Existing Safety Measures for Fluoroantimonic Acid

01 Personal Protective Equipment (PPE)

When handling fluoroantimonic acid, proper PPE is crucial. This includes chemical-resistant gloves, protective clothing, safety goggles, and respiratory protection. The use of appropriate PPE helps prevent skin contact, inhalation, and eye exposure to this highly corrosive and toxic substance.- Personal Protective Equipment (PPE): When handling fluoroantimonic acid, proper PPE is essential. This includes chemical-resistant gloves, protective clothing, safety goggles, and respiratory protection. A face shield may also be necessary. The specific type of PPE should be selected based on the concentration and quantity of acid being handled.

- Containment and Storage: Fluoroantimonic acid must be stored in specially designed containers made of materials resistant to its corrosive properties, such as PTFE or certain fluoropolymers. The storage area should be well-ventilated, cool, and dry. Proper labeling and segregation from incompatible materials are crucial. Secondary containment measures should be implemented to prevent spills.

- Emergency Response and Spill Management: In case of a spill, immediate evacuation of the area is necessary. Only trained personnel with appropriate PPE should handle the cleanup. Neutralization with suitable bases should be done carefully. An emergency shower and eyewash station must be readily accessible. Proper ventilation systems and gas detectors should be in place to monitor for potential leaks or vapors.

- Training and Standard Operating Procedures: Comprehensive training for all personnel handling fluoroantimonic acid is crucial. This should cover proper handling techniques, emergency procedures, and the use of safety equipment. Detailed standard operating procedures (SOPs) should be developed and strictly followed. Regular safety drills and refresher courses are recommended to maintain preparedness.

- Waste Disposal and Environmental Considerations: Proper disposal of fluoroantimonic acid waste is critical to prevent environmental contamination. Neutralization should be performed before disposal, following local regulations. Waste containers must be compatible with the acid and properly labeled. Environmental monitoring may be necessary in areas where the acid is used or stored to detect any potential leaks or emissions.

02 Containment and Storage

Fluoroantimonic acid must be stored in specially designed containers made of materials resistant to its corrosive properties. Proper containment measures include using sealed, non-reactive vessels and storing them in well-ventilated areas away from incompatible materials. Secondary containment systems should be in place to prevent spills.Expand Specific Solutions03 Emergency Response and Spill Management

Developing and implementing emergency response procedures for fluoroantimonic acid spills is essential. This includes having neutralizing agents readily available, proper spill containment equipment, and trained personnel to handle emergencies. Evacuation plans and decontamination procedures should also be established.Expand Specific Solutions04 Ventilation and Exposure Control

Adequate ventilation is crucial when working with fluoroantimonic acid. This includes the use of fume hoods, local exhaust systems, and proper air filtration to minimize exposure risks. Regular air quality monitoring and exposure assessments should be conducted to ensure safety compliance.Expand Specific Solutions05 Training and Safety Protocols

Comprehensive training programs for personnel handling fluoroantimonic acid are essential. This includes education on the properties of the acid, proper handling techniques, emergency procedures, and the use of safety equipment. Regular safety drills and updates to protocols should be conducted to maintain preparedness.Expand Specific Solutions

Key Players in Superacid Industry and Research

The implementation of safety measures for fluoroantimonic acid is a critical concern in the advanced chemical industry, currently in a mature development stage. The market for this highly corrosive superacid is relatively niche but growing, driven by its applications in petrochemistry and materials science. Companies like Mitsubishi Gas Chemical Co., Inc. and UBE Corp. are at the forefront of developing safety protocols, while research institutions such as Central South University and Centre National de la Recherche Scientifique contribute to advancing the understanding of handling techniques. The technology's maturity is evident in the involvement of diverse players, including pharmaceutical companies like Glaxo Group Ltd., indicating a cross-industry relevance for safety innovations in extreme acid management.

Mitsubishi Gas Chemical Co., Inc.

Technical Solution: Mitsubishi Gas Chemical has focused on developing a holistic safety ecosystem for fluoroantimonic acid handling. Their approach combines advanced materials science with smart monitoring systems. They have created a new class of fluorine-doped carbon materials that show exceptional resistance to fluoroantimonic acid, which are used in the construction of handling equipment and protective gear. Additionally, they have implemented an AI-driven safety monitoring system that uses multiple sensors to detect minute changes in environmental conditions, predicting potential hazards before they occur. This system is integrated with automated emergency response mechanisms for rapid containment of any incidents.

Strengths: Comprehensive approach combining materials innovation and smart technologies, potential for predictive safety measures. Weaknesses: Complex system integration may lead to higher maintenance requirements and potential points of failure.

UBE Corp.

Technical Solution: UBE Corp. has developed a unique cryogenic approach to fluoroantimonic acid safety. Their system involves handling and storing the acid at extremely low temperatures, significantly reducing its reactivity and volatility. They have designed specialized cryogenic vessels and transfer systems that maintain the acid at temperatures close to its freezing point. This approach is complemented by the use of advanced insulation materials and fail-safe cooling systems. UBE has also developed a rapid neutralization system using cryogenically stored alkaline solutions for emergency response. Their safety protocols include extensive training on cryogenic handling and specialized emergency procedures.

Strengths: Innovative approach that fundamentally alters the acid's hazardous properties, potential for safer long-term storage. Weaknesses: High energy costs for maintaining cryogenic conditions, potential risks associated with equipment failure.

Innovative Containment and Neutralization Techniques

Composition for treatment of a hydrofluoric acid burn

PatentInactiveEP1758570A1

Innovation

- A composition comprising a non-toxic calcium compound like calcium levulinate, combined with a carrier such as water, dimethyl sulphoxide, or urea, which rapidly delivers calcium ions to neutralize fluoride ions and trap hydrogen ions, effectively treating superficial and deeper hydrofluoric acid burns.

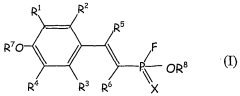

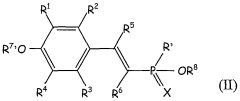

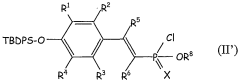

Fluorophosphonocinnamic compounds, synthesis and uses for treating disorders caused by oxidative stress

PatentWO2006037869A2

Innovation

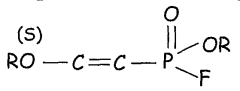

- A process involving a complex formed between a tertiary amine and hydrogen fluoride is used to fluorinate phosphonocinnamic compounds, allowing for the production of fluorophosphonocinnamic compounds with improved antioxidant activity, using easily accessible and safer reagents at room temperature or lower temperatures.

Regulatory Framework for Hazardous Chemical Handling

The regulatory framework for handling hazardous chemicals, particularly fluoroantimonic acid, is a complex and multi-layered system designed to ensure the safety of workers, the public, and the environment. At the international level, the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a foundation for standardizing hazard communication. This system is widely adopted and influences national regulations worldwide.

In the United States, the Occupational Safety and Health Administration (OSHA) plays a crucial role in regulating workplace safety for hazardous chemicals. OSHA's Hazard Communication Standard (HCS) aligns with GHS and mandates specific requirements for labeling, safety data sheets, and employee training. For fluoroantimonic acid, which is classified as an extremely corrosive and reactive substance, OSHA's standards on personal protective equipment (PPE) and process safety management are particularly relevant.

The Environmental Protection Agency (EPA) also contributes to the regulatory framework through the Toxic Substances Control Act (TSCA) and the Resource Conservation and Recovery Act (RCRA). These acts govern the production, use, and disposal of hazardous chemicals, including fluoroantimonic acid. The EPA's regulations focus on preventing environmental contamination and ensuring proper waste management.

At the state and local levels, additional regulations may apply, often more stringent than federal standards. For instance, California's Proposition 65 requires businesses to provide warnings about significant exposures to chemicals that cause cancer, birth defects, or other reproductive harm. Local fire codes and zoning laws may also impose restrictions on the storage and handling of highly hazardous chemicals.

Industry-specific standards, such as those developed by the American Chemistry Council's Responsible Care program, provide voluntary guidelines that often exceed regulatory requirements. These standards emphasize continuous improvement in safety, health, and environmental performance.

For transportation of fluoroantimonic acid, the Department of Transportation (DOT) enforces strict regulations under the Hazardous Materials Regulations (HMR). These rules cover packaging, labeling, and documentation requirements for shipments by road, rail, air, and sea.

Compliance with this regulatory framework requires a comprehensive approach, including regular risk assessments, implementation of engineering controls, development of standard operating procedures, and ongoing employee training. Companies handling fluoroantimonic acid must also maintain detailed records and be prepared for inspections by regulatory agencies.

As regulations evolve in response to new scientific knowledge and changing societal expectations, organizations must stay informed and adapt their safety measures accordingly. This dynamic nature of the regulatory landscape underscores the importance of proactive safety management and continuous improvement in handling hazardous chemicals like fluoroantimonic acid.

In the United States, the Occupational Safety and Health Administration (OSHA) plays a crucial role in regulating workplace safety for hazardous chemicals. OSHA's Hazard Communication Standard (HCS) aligns with GHS and mandates specific requirements for labeling, safety data sheets, and employee training. For fluoroantimonic acid, which is classified as an extremely corrosive and reactive substance, OSHA's standards on personal protective equipment (PPE) and process safety management are particularly relevant.

The Environmental Protection Agency (EPA) also contributes to the regulatory framework through the Toxic Substances Control Act (TSCA) and the Resource Conservation and Recovery Act (RCRA). These acts govern the production, use, and disposal of hazardous chemicals, including fluoroantimonic acid. The EPA's regulations focus on preventing environmental contamination and ensuring proper waste management.

At the state and local levels, additional regulations may apply, often more stringent than federal standards. For instance, California's Proposition 65 requires businesses to provide warnings about significant exposures to chemicals that cause cancer, birth defects, or other reproductive harm. Local fire codes and zoning laws may also impose restrictions on the storage and handling of highly hazardous chemicals.

Industry-specific standards, such as those developed by the American Chemistry Council's Responsible Care program, provide voluntary guidelines that often exceed regulatory requirements. These standards emphasize continuous improvement in safety, health, and environmental performance.

For transportation of fluoroantimonic acid, the Department of Transportation (DOT) enforces strict regulations under the Hazardous Materials Regulations (HMR). These rules cover packaging, labeling, and documentation requirements for shipments by road, rail, air, and sea.

Compliance with this regulatory framework requires a comprehensive approach, including regular risk assessments, implementation of engineering controls, development of standard operating procedures, and ongoing employee training. Companies handling fluoroantimonic acid must also maintain detailed records and be prepared for inspections by regulatory agencies.

As regulations evolve in response to new scientific knowledge and changing societal expectations, organizations must stay informed and adapt their safety measures accordingly. This dynamic nature of the regulatory landscape underscores the importance of proactive safety management and continuous improvement in handling hazardous chemicals like fluoroantimonic acid.

Environmental Impact of Fluoroantimonic Acid Use

The environmental impact of fluoroantimonic acid use is a critical concern due to its extreme corrosiveness and reactivity. This superacid, composed of a mixture of hydrogen fluoride and antimony pentafluoride, poses significant risks to ecosystems and human health if not properly managed.

When released into the environment, fluoroantimonic acid can cause severe damage to soil and water systems. Its highly acidic nature can lead to rapid soil degradation, altering pH levels and destroying essential microorganisms crucial for maintaining soil health. This can result in long-term damage to vegetation and agricultural productivity in affected areas.

Water contamination is another major concern. Even small amounts of fluoroantimonic acid can dramatically lower the pH of water bodies, making them uninhabitable for aquatic life. The acid's components, particularly fluoride and antimony, can persist in water systems, potentially entering the food chain and accumulating in organisms.

Air pollution is also a risk, especially if the acid is heated or aerosolized. Vapors or mists containing fluoroantimonic acid can contribute to acid rain formation, further exacerbating environmental damage over a wider area. Additionally, these airborne particles can pose respiratory hazards to both humans and wildlife.

The production and disposal of fluoroantimonic acid also present environmental challenges. Manufacturing processes may release harmful byproducts, while improper disposal can lead to contamination of landfills and groundwater. Strict protocols for handling, storage, and waste management are essential to minimize these risks.

Long-term environmental effects of fluoroantimonic acid exposure are not fully understood, but potential impacts include bioaccumulation of fluoride and antimony in ecosystems, disruption of natural chemical cycles, and alterations to local biodiversity. The acid's extreme reactivity means it can potentially interact with other pollutants, creating complex and unpredictable environmental consequences.

Given these significant environmental risks, the use of fluoroantimonic acid in industrial processes requires careful consideration and stringent safety measures. Alternatives should be explored where possible, and when its use is necessary, comprehensive environmental impact assessments and mitigation strategies must be implemented to protect ecosystems and public health.

When released into the environment, fluoroantimonic acid can cause severe damage to soil and water systems. Its highly acidic nature can lead to rapid soil degradation, altering pH levels and destroying essential microorganisms crucial for maintaining soil health. This can result in long-term damage to vegetation and agricultural productivity in affected areas.

Water contamination is another major concern. Even small amounts of fluoroantimonic acid can dramatically lower the pH of water bodies, making them uninhabitable for aquatic life. The acid's components, particularly fluoride and antimony, can persist in water systems, potentially entering the food chain and accumulating in organisms.

Air pollution is also a risk, especially if the acid is heated or aerosolized. Vapors or mists containing fluoroantimonic acid can contribute to acid rain formation, further exacerbating environmental damage over a wider area. Additionally, these airborne particles can pose respiratory hazards to both humans and wildlife.

The production and disposal of fluoroantimonic acid also present environmental challenges. Manufacturing processes may release harmful byproducts, while improper disposal can lead to contamination of landfills and groundwater. Strict protocols for handling, storage, and waste management are essential to minimize these risks.

Long-term environmental effects of fluoroantimonic acid exposure are not fully understood, but potential impacts include bioaccumulation of fluoride and antimony in ecosystems, disruption of natural chemical cycles, and alterations to local biodiversity. The acid's extreme reactivity means it can potentially interact with other pollutants, creating complex and unpredictable environmental consequences.

Given these significant environmental risks, the use of fluoroantimonic acid in industrial processes requires careful consideration and stringent safety measures. Alternatives should be explored where possible, and when its use is necessary, comprehensive environmental impact assessments and mitigation strategies must be implemented to protect ecosystems and public health.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!