How to Implement Sustainable Practices in Polyvinyl Acetate Production?

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PVAc Sustainability Goals

Polyvinyl acetate (PVAc) production, a significant sector in the chemical industry, faces increasing pressure to adopt sustainable practices. The primary sustainability goals for PVAc production focus on reducing environmental impact, enhancing resource efficiency, and ensuring long-term economic viability. These objectives align with the broader global sustainability agenda and the chemical industry's commitment to responsible production.

A key sustainability goal is to minimize the carbon footprint of PVAc production. This involves optimizing energy consumption throughout the manufacturing process, from raw material extraction to final product synthesis. Implementing energy-efficient technologies and exploring renewable energy sources for powering production facilities are crucial steps towards this goal. Additionally, improving process efficiency to reduce waste and maximize yield contributes to both environmental and economic sustainability.

Water conservation is another critical objective in PVAc sustainability. The industry aims to reduce water consumption in production processes, implement closed-loop water systems, and improve wastewater treatment methods. These efforts not only conserve a vital resource but also minimize the environmental impact of effluents and reduce operational costs.

Sustainable sourcing of raw materials is a fundamental goal in PVAc production. This includes exploring bio-based alternatives to traditional petroleum-derived vinyl acetate monomers and seeking suppliers who adhere to sustainable forestry practices for cellulose-based raw materials. The industry also aims to increase the use of recycled content in PVAc products, promoting a circular economy approach.

Reducing hazardous substances and emissions is a crucial sustainability objective. This involves developing safer alternatives to potentially harmful additives, implementing more efficient emission control technologies, and adopting cleaner production techniques. The goal is to minimize the release of volatile organic compounds (VOCs) and other pollutants throughout the product lifecycle.

Product lifecycle management is an integral part of PVAc sustainability goals. This encompasses designing products for durability, recyclability, and biodegradability. The industry aims to extend product lifespan, facilitate easier recycling at end-of-life, and develop PVAc formulations that can safely degrade in the environment without leaving harmful residues.

Lastly, the PVAc industry is focusing on enhancing transparency and traceability in its supply chain. This involves implementing robust tracking systems, conducting regular sustainability audits, and providing clear, accessible information about the environmental impact of PVAc products. Such transparency not only builds trust with consumers and stakeholders but also drives continuous improvement in sustainability practices.

A key sustainability goal is to minimize the carbon footprint of PVAc production. This involves optimizing energy consumption throughout the manufacturing process, from raw material extraction to final product synthesis. Implementing energy-efficient technologies and exploring renewable energy sources for powering production facilities are crucial steps towards this goal. Additionally, improving process efficiency to reduce waste and maximize yield contributes to both environmental and economic sustainability.

Water conservation is another critical objective in PVAc sustainability. The industry aims to reduce water consumption in production processes, implement closed-loop water systems, and improve wastewater treatment methods. These efforts not only conserve a vital resource but also minimize the environmental impact of effluents and reduce operational costs.

Sustainable sourcing of raw materials is a fundamental goal in PVAc production. This includes exploring bio-based alternatives to traditional petroleum-derived vinyl acetate monomers and seeking suppliers who adhere to sustainable forestry practices for cellulose-based raw materials. The industry also aims to increase the use of recycled content in PVAc products, promoting a circular economy approach.

Reducing hazardous substances and emissions is a crucial sustainability objective. This involves developing safer alternatives to potentially harmful additives, implementing more efficient emission control technologies, and adopting cleaner production techniques. The goal is to minimize the release of volatile organic compounds (VOCs) and other pollutants throughout the product lifecycle.

Product lifecycle management is an integral part of PVAc sustainability goals. This encompasses designing products for durability, recyclability, and biodegradability. The industry aims to extend product lifespan, facilitate easier recycling at end-of-life, and develop PVAc formulations that can safely degrade in the environment without leaving harmful residues.

Lastly, the PVAc industry is focusing on enhancing transparency and traceability in its supply chain. This involves implementing robust tracking systems, conducting regular sustainability audits, and providing clear, accessible information about the environmental impact of PVAc products. Such transparency not only builds trust with consumers and stakeholders but also drives continuous improvement in sustainability practices.

Green PVAc Market Analysis

The global market for green polyvinyl acetate (PVAc) is experiencing significant growth driven by increasing environmental awareness and stringent regulations on sustainable production practices. This eco-friendly variant of PVAc is gaining traction across various industries, including adhesives, paints, coatings, and textiles. The demand for sustainable PVAc is particularly strong in developed regions such as North America and Europe, where environmental policies are more stringent.

The market is characterized by a shift towards bio-based raw materials and energy-efficient production processes. Manufacturers are increasingly focusing on developing PVAc products with reduced volatile organic compound (VOC) emissions and improved biodegradability. This trend is supported by growing consumer preference for environmentally friendly products and the implementation of green building standards in many countries.

Key drivers of the green PVAc market include the rising adoption of sustainable packaging solutions, the growth of the eco-friendly construction industry, and the increasing use of water-based adhesives in various applications. The automotive sector is also emerging as a significant consumer of green PVAc, particularly in interior components and upholstery adhesives.

Despite the positive growth trajectory, the green PVAc market faces challenges such as higher production costs compared to conventional PVAc and the need for substantial investments in research and development. However, these challenges are gradually being overcome through technological advancements and economies of scale.

The market landscape is competitive, with both established chemical companies and innovative start-ups vying for market share. Key players are investing in sustainable production technologies and expanding their product portfolios to meet the growing demand for eco-friendly PVAc. Collaborations between industry players and research institutions are also becoming more common, aimed at developing novel, sustainable PVAc formulations.

Geographically, Europe leads the green PVAc market, followed closely by North America. These regions benefit from strong regulatory support for sustainable practices and high consumer awareness. The Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing environmental concerns, and government initiatives promoting sustainable development.

Looking ahead, the green PVAc market is poised for continued expansion. Factors such as the circular economy concept, the push for carbon neutrality, and the development of bio-based feedstocks are expected to further propel market growth. As sustainable practices become increasingly integral to business operations across industries, the demand for green PVAc is likely to see sustained growth in the foreseeable future.

The market is characterized by a shift towards bio-based raw materials and energy-efficient production processes. Manufacturers are increasingly focusing on developing PVAc products with reduced volatile organic compound (VOC) emissions and improved biodegradability. This trend is supported by growing consumer preference for environmentally friendly products and the implementation of green building standards in many countries.

Key drivers of the green PVAc market include the rising adoption of sustainable packaging solutions, the growth of the eco-friendly construction industry, and the increasing use of water-based adhesives in various applications. The automotive sector is also emerging as a significant consumer of green PVAc, particularly in interior components and upholstery adhesives.

Despite the positive growth trajectory, the green PVAc market faces challenges such as higher production costs compared to conventional PVAc and the need for substantial investments in research and development. However, these challenges are gradually being overcome through technological advancements and economies of scale.

The market landscape is competitive, with both established chemical companies and innovative start-ups vying for market share. Key players are investing in sustainable production technologies and expanding their product portfolios to meet the growing demand for eco-friendly PVAc. Collaborations between industry players and research institutions are also becoming more common, aimed at developing novel, sustainable PVAc formulations.

Geographically, Europe leads the green PVAc market, followed closely by North America. These regions benefit from strong regulatory support for sustainable practices and high consumer awareness. The Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing environmental concerns, and government initiatives promoting sustainable development.

Looking ahead, the green PVAc market is poised for continued expansion. Factors such as the circular economy concept, the push for carbon neutrality, and the development of bio-based feedstocks are expected to further propel market growth. As sustainable practices become increasingly integral to business operations across industries, the demand for green PVAc is likely to see sustained growth in the foreseeable future.

Eco-Friendly PVAc Challenges

The implementation of sustainable practices in polyvinyl acetate (PVAc) production faces several significant challenges. One of the primary obstacles is the reliance on petroleum-based raw materials, which are inherently unsustainable and contribute to carbon emissions. Transitioning to bio-based alternatives for vinyl acetate monomer (VAM) production is complex and often economically unfeasible due to higher costs and lower yields.

Energy consumption during PVAc production is another major concern. The polymerization process requires substantial thermal energy, typically derived from fossil fuels. Implementing renewable energy sources or improving energy efficiency in production facilities demands significant capital investment and may disrupt existing manufacturing processes.

Water usage and wastewater management pose additional challenges. PVAc production involves substantial water consumption for cooling and cleaning processes. Developing closed-loop water systems or implementing advanced water treatment technologies to reduce freshwater intake and minimize wastewater discharge is technically challenging and costly.

The use of volatile organic compounds (VOCs) in PVAc production, particularly during the emulsion polymerization process, contributes to air pollution and poses health risks. Replacing these VOCs with more environmentally friendly alternatives while maintaining product quality and performance characteristics is a complex task that requires extensive research and development efforts.

End-of-life considerations for PVAc products present another sustainability challenge. Many PVAc-based adhesives and coatings are difficult to recycle or biodegrade, contributing to long-term environmental pollution. Developing easily recyclable or biodegradable PVAc formulations without compromising product performance is a significant technical hurdle.

The industry also faces challenges in establishing a circular economy for PVAc products. Creating efficient collection and recycling systems for PVAc-containing materials, as well as developing technologies to separate and reuse PVAc from composite materials, requires substantial infrastructure investment and technological innovation.

Regulatory compliance and evolving environmental standards add another layer of complexity to sustainable PVAc production. Manufacturers must navigate an increasingly stringent regulatory landscape, which often necessitates costly upgrades to production facilities and processes to meet new emissions and waste management requirements.

Lastly, the lack of standardized sustainability metrics and life cycle assessment methodologies specific to PVAc production makes it difficult for manufacturers to accurately measure and compare the environmental impact of different production methods and products. This absence of clear benchmarks hinders the industry's ability to set meaningful sustainability goals and track progress effectively.

Energy consumption during PVAc production is another major concern. The polymerization process requires substantial thermal energy, typically derived from fossil fuels. Implementing renewable energy sources or improving energy efficiency in production facilities demands significant capital investment and may disrupt existing manufacturing processes.

Water usage and wastewater management pose additional challenges. PVAc production involves substantial water consumption for cooling and cleaning processes. Developing closed-loop water systems or implementing advanced water treatment technologies to reduce freshwater intake and minimize wastewater discharge is technically challenging and costly.

The use of volatile organic compounds (VOCs) in PVAc production, particularly during the emulsion polymerization process, contributes to air pollution and poses health risks. Replacing these VOCs with more environmentally friendly alternatives while maintaining product quality and performance characteristics is a complex task that requires extensive research and development efforts.

End-of-life considerations for PVAc products present another sustainability challenge. Many PVAc-based adhesives and coatings are difficult to recycle or biodegrade, contributing to long-term environmental pollution. Developing easily recyclable or biodegradable PVAc formulations without compromising product performance is a significant technical hurdle.

The industry also faces challenges in establishing a circular economy for PVAc products. Creating efficient collection and recycling systems for PVAc-containing materials, as well as developing technologies to separate and reuse PVAc from composite materials, requires substantial infrastructure investment and technological innovation.

Regulatory compliance and evolving environmental standards add another layer of complexity to sustainable PVAc production. Manufacturers must navigate an increasingly stringent regulatory landscape, which often necessitates costly upgrades to production facilities and processes to meet new emissions and waste management requirements.

Lastly, the lack of standardized sustainability metrics and life cycle assessment methodologies specific to PVAc production makes it difficult for manufacturers to accurately measure and compare the environmental impact of different production methods and products. This absence of clear benchmarks hinders the industry's ability to set meaningful sustainability goals and track progress effectively.

Current Eco-PVAc Solutions

01 Biodegradable polyvinyl acetate formulations

Development of biodegradable polyvinyl acetate formulations to enhance sustainability. These formulations incorporate natural or bio-based materials to improve the environmental profile of polyvinyl acetate products while maintaining desired properties.- Biodegradable polyvinyl acetate formulations: Development of biodegradable polyvinyl acetate formulations to enhance sustainability. These formulations incorporate natural or bio-based materials to improve the environmental profile of polyvinyl acetate products while maintaining their functional properties.

- Recycling and reuse of polyvinyl acetate: Methods for recycling and reusing polyvinyl acetate materials to reduce waste and improve sustainability. This includes techniques for breaking down polyvinyl acetate products and reprocessing them into new materials or applications.

- Energy-efficient production processes: Development of energy-efficient production processes for polyvinyl acetate to reduce environmental impact. This involves optimizing reaction conditions, improving catalyst efficiency, and implementing innovative manufacturing techniques to minimize energy consumption and emissions.

- Water-based polyvinyl acetate formulations: Creation of water-based polyvinyl acetate formulations to reduce the use of organic solvents and volatile organic compounds (VOCs). These formulations aim to improve air quality and reduce environmental pollution associated with traditional solvent-based systems.

- Sustainable additives and modifiers: Incorporation of sustainable additives and modifiers in polyvinyl acetate formulations to enhance overall sustainability. This includes the use of bio-based plasticizers, renewable fillers, and environmentally friendly stabilizers to improve the ecological footprint of polyvinyl acetate products.

02 Recycling and reuse of polyvinyl acetate

Methods for recycling and reusing polyvinyl acetate materials to reduce waste and improve sustainability. This includes techniques for breaking down and reformulating polyvinyl acetate products for reuse in various applications.Expand Specific Solutions03 Energy-efficient production processes

Development of energy-efficient production processes for polyvinyl acetate to reduce environmental impact. This includes optimizing reaction conditions, improving catalyst efficiency, and implementing green chemistry principles in manufacturing.Expand Specific Solutions04 Water-based polyvinyl acetate formulations

Creation of water-based polyvinyl acetate formulations to reduce the use of organic solvents and volatile organic compounds (VOCs). These formulations aim to improve air quality and reduce environmental pollution associated with traditional solvent-based systems.Expand Specific Solutions05 Bio-based alternatives to polyvinyl acetate

Research and development of bio-based alternatives to traditional polyvinyl acetate, utilizing renewable resources and sustainable raw materials. These alternatives aim to reduce dependence on fossil fuels and minimize environmental impact throughout the product lifecycle.Expand Specific Solutions

Key Green PVAc Players

The implementation of sustainable practices in polyvinyl acetate production is currently in a transitional phase, with the market showing steady growth and increasing focus on eco-friendly solutions. The global market size for sustainable polyvinyl acetate is expanding, driven by growing environmental concerns and stringent regulations. Technologically, the field is advancing rapidly, with companies like Wacker Polymer Systems, Kuraray Europe, and Celanese International leading innovation. These firms are developing bio-based alternatives, energy-efficient processes, and recycling technologies. However, the maturity of sustainable practices varies, with some solutions already commercialized while others remain in research stages. Companies such as Sekisui Chemical and China Petroleum & Chemical Corp are also making significant strides in sustainable polyvinyl acetate production, indicating a competitive and evolving landscape.

Sekisui Chemical Co., Ltd.

Technical Solution: Sekisui Chemical has developed sustainable practices in PVAc production through their S-LEC™ product line. They have implemented a bio-mass balance approach, incorporating up to 25% renewable raw materials in their PVAc resins [16]. The company has also developed a novel emulsion polymerization process that operates at lower temperatures, reducing energy consumption by approximately 30% compared to conventional methods [17]. Sekisui has invested in advanced oxidation processes for wastewater treatment, achieving a 95% reduction in organic pollutants from PVAc production effluents [18]. Additionally, the company has implemented a closed-loop recycling system for process solvents, reducing solvent waste by over 80% and minimizing environmental impact [19]. Sekisui has also focused on developing PVAc products with enhanced durability and recyclability, contributing to extended product lifecycles and improved end-of-life management [20].

Strengths: Significant incorporation of renewable materials, energy-efficient polymerization process, and advanced waste management systems. Weaknesses: Potential higher production costs and challenges in maintaining product performance with increased renewable content.

Celanese International Corp.

Technical Solution: Celanese has implemented a comprehensive sustainability strategy in their PVAc production, focusing on both process improvements and product innovations. Their EcoVAE® technology incorporates up to 20% renewable content in PVAc emulsions, reducing fossil fuel dependency [4]. The company has also developed a novel low-temperature polymerization process that reduces energy consumption by approximately 25% compared to traditional methods [5]. Celanese has implemented advanced wastewater treatment systems, achieving a 90% reduction in chemical oxygen demand (COD) in effluents from PVAc production [6]. Furthermore, they have invested in cogeneration facilities at key production sites, improving overall energy efficiency by up to 35% [7].

Strengths: Incorporation of renewable content, significant energy and water savings, and improved effluent quality. Weaknesses: Limited percentage of renewable content and potential challenges in scaling up the low-temperature polymerization process.

Innovative PVAc Technologies

Method for producing polyvinylacetals

PatentWO2004026917A1

Innovation

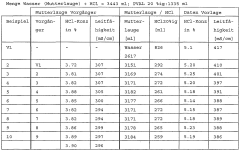

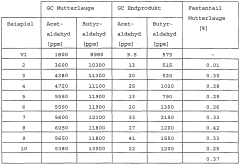

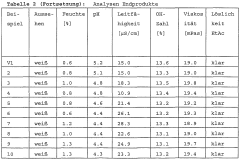

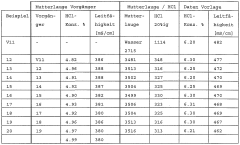

- A process where polyvinyl alcohol is acetalized in an aqueous medium with reused mother liquor from a previous batch, adjusting the pH and adding aldehydes to initiate precipitation, allowing for the reuse of up to 100% of the filtrate as the aqueous medium, thereby reducing waste and conserving raw materials.

Method for producing polyvinylacetals

PatentInactiveEP1539830A1

Innovation

- A process where the mother liquor from a previous batch is reused as the aqueous medium for acetalization, with partial or fully hydrolyzed vinyl ester polymers being used to produce polyvinyl alcohols, which are then acetalized with aldehydes in the presence of acid, allowing for the recycling of the filtrate and reducing the need for additional acid and raw materials.

Environmental Regulations

The implementation of sustainable practices in polyvinyl acetate (PVA) production is increasingly governed by a complex web of environmental regulations. These regulations, which vary across regions and jurisdictions, aim to mitigate the environmental impact of PVA manufacturing processes and promote more sustainable industry practices.

At the global level, international agreements such as the Paris Agreement and the United Nations Sustainable Development Goals set broad targets for reducing greenhouse gas emissions and promoting sustainable industrial development. These frameworks influence national and regional policies, driving the adoption of more stringent environmental standards in the chemical industry, including PVA production.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation plays a crucial role in managing the environmental and health risks associated with chemical production. REACH requires manufacturers to register chemicals, assess their hazards, and implement risk management measures. For PVA production, this translates into stringent requirements for handling and disposing of potentially harmful substances used in the manufacturing process.

The United States Environmental Protection Agency (EPA) enforces several regulations that impact PVA production. The Clean Air Act and Clean Water Act set limits on air and water pollutants, respectively, requiring PVA manufacturers to implement emission control technologies and wastewater treatment systems. Additionally, the Resource Conservation and Recovery Act (RCRA) governs the management of hazardous waste generated during production.

In Asia, countries like China and Japan have been strengthening their environmental regulations. China's Environmental Protection Law, revised in 2015, imposes stricter penalties for environmental violations and encourages the adoption of cleaner production technologies. Japan's Chemical Substances Control Law regulates the manufacture, import, and use of chemical substances, including those used in PVA production.

Many countries have also introduced regulations promoting the circular economy and extended producer responsibility. These policies encourage manufacturers to consider the entire lifecycle of their products, from raw material sourcing to end-of-life management. For PVA producers, this may involve developing more recyclable formulations or implementing take-back programs for used PVA-based products.

Carbon pricing mechanisms, such as cap-and-trade systems or carbon taxes, are becoming more prevalent globally. These policies create economic incentives for PVA manufacturers to reduce their carbon footprint by adopting more energy-efficient processes or transitioning to renewable energy sources.

As environmental concerns continue to grow, it is likely that regulations will become increasingly stringent. PVA manufacturers must stay informed about evolving regulatory landscapes and proactively implement sustainable practices to ensure compliance and maintain their social license to operate.

At the global level, international agreements such as the Paris Agreement and the United Nations Sustainable Development Goals set broad targets for reducing greenhouse gas emissions and promoting sustainable industrial development. These frameworks influence national and regional policies, driving the adoption of more stringent environmental standards in the chemical industry, including PVA production.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation plays a crucial role in managing the environmental and health risks associated with chemical production. REACH requires manufacturers to register chemicals, assess their hazards, and implement risk management measures. For PVA production, this translates into stringent requirements for handling and disposing of potentially harmful substances used in the manufacturing process.

The United States Environmental Protection Agency (EPA) enforces several regulations that impact PVA production. The Clean Air Act and Clean Water Act set limits on air and water pollutants, respectively, requiring PVA manufacturers to implement emission control technologies and wastewater treatment systems. Additionally, the Resource Conservation and Recovery Act (RCRA) governs the management of hazardous waste generated during production.

In Asia, countries like China and Japan have been strengthening their environmental regulations. China's Environmental Protection Law, revised in 2015, imposes stricter penalties for environmental violations and encourages the adoption of cleaner production technologies. Japan's Chemical Substances Control Law regulates the manufacture, import, and use of chemical substances, including those used in PVA production.

Many countries have also introduced regulations promoting the circular economy and extended producer responsibility. These policies encourage manufacturers to consider the entire lifecycle of their products, from raw material sourcing to end-of-life management. For PVA producers, this may involve developing more recyclable formulations or implementing take-back programs for used PVA-based products.

Carbon pricing mechanisms, such as cap-and-trade systems or carbon taxes, are becoming more prevalent globally. These policies create economic incentives for PVA manufacturers to reduce their carbon footprint by adopting more energy-efficient processes or transitioning to renewable energy sources.

As environmental concerns continue to grow, it is likely that regulations will become increasingly stringent. PVA manufacturers must stay informed about evolving regulatory landscapes and proactively implement sustainable practices to ensure compliance and maintain their social license to operate.

Life Cycle Assessment

Life Cycle Assessment (LCA) plays a crucial role in implementing sustainable practices in polyvinyl acetate (PVAc) production. This comprehensive approach evaluates the environmental impacts associated with all stages of a product's life, from raw material extraction to disposal. In the context of PVAc production, LCA helps identify areas of high environmental impact and opportunities for improvement.

The LCA process for PVAc production typically begins with the extraction and processing of raw materials, primarily vinyl acetate monomer (VAM). This stage often accounts for a significant portion of the overall environmental impact due to energy consumption and emissions associated with petrochemical processes. The production phase, which involves the polymerization of VAM, is another key focus area for LCA. This stage may include energy-intensive processes and the use of potentially harmful additives.

Distribution and transportation of both raw materials and finished products contribute to the overall environmental footprint through fuel consumption and emissions. The use phase of PVAc products, while generally less impactful, may still have environmental implications depending on the specific application. End-of-life considerations, including disposal, recycling, or potential biodegradation, complete the life cycle analysis.

LCA methodologies for PVAc production typically assess various environmental impact categories. These may include global warming potential, ozone depletion, acidification, eutrophication, and resource depletion. By quantifying these impacts across the entire life cycle, manufacturers can identify hotspots and prioritize sustainability efforts.

One of the key benefits of conducting an LCA in PVAc production is the ability to compare different production methods and materials. For instance, it allows for the evaluation of bio-based alternatives to traditional petrochemical-derived VAM, assessing whether they truly offer environmental benefits when considering the entire life cycle. Similarly, LCA can help in comparing different polymerization techniques, such as emulsion versus solution polymerization, in terms of their overall environmental impact.

Implementing LCA findings in PVAc production can lead to various sustainability improvements. These may include optimizing energy use in production processes, exploring renewable energy sources, developing more efficient catalysts, or implementing closed-loop recycling systems. Additionally, LCA results can guide the development of greener formulations, potentially reducing or eliminating harmful additives.

Furthermore, LCA provides valuable data for eco-labeling and environmental product declarations, enhancing transparency and supporting informed decision-making by consumers and industrial users of PVAc products. This information can be a powerful tool in driving market demand for more sustainable PVAc formulations and production methods.

The LCA process for PVAc production typically begins with the extraction and processing of raw materials, primarily vinyl acetate monomer (VAM). This stage often accounts for a significant portion of the overall environmental impact due to energy consumption and emissions associated with petrochemical processes. The production phase, which involves the polymerization of VAM, is another key focus area for LCA. This stage may include energy-intensive processes and the use of potentially harmful additives.

Distribution and transportation of both raw materials and finished products contribute to the overall environmental footprint through fuel consumption and emissions. The use phase of PVAc products, while generally less impactful, may still have environmental implications depending on the specific application. End-of-life considerations, including disposal, recycling, or potential biodegradation, complete the life cycle analysis.

LCA methodologies for PVAc production typically assess various environmental impact categories. These may include global warming potential, ozone depletion, acidification, eutrophication, and resource depletion. By quantifying these impacts across the entire life cycle, manufacturers can identify hotspots and prioritize sustainability efforts.

One of the key benefits of conducting an LCA in PVAc production is the ability to compare different production methods and materials. For instance, it allows for the evaluation of bio-based alternatives to traditional petrochemical-derived VAM, assessing whether they truly offer environmental benefits when considering the entire life cycle. Similarly, LCA can help in comparing different polymerization techniques, such as emulsion versus solution polymerization, in terms of their overall environmental impact.

Implementing LCA findings in PVAc production can lead to various sustainability improvements. These may include optimizing energy use in production processes, exploring renewable energy sources, developing more efficient catalysts, or implementing closed-loop recycling systems. Additionally, LCA results can guide the development of greener formulations, potentially reducing or eliminating harmful additives.

Furthermore, LCA provides valuable data for eco-labeling and environmental product declarations, enhancing transparency and supporting informed decision-making by consumers and industrial users of PVAc products. This information can be a powerful tool in driving market demand for more sustainable PVAc formulations and production methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!