How to Improve V8 Engine Longevity: Strategies?

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution and Longevity Goals

The V8 engine, a powerful and iconic powerplant, has undergone significant evolution since its inception. Originally designed for high-performance vehicles, it has become a symbol of automotive engineering excellence. The primary goal in V8 engine development has been to balance power output with efficiency and longevity, a challenge that has driven continuous innovation in the field.

Over the years, V8 engines have seen remarkable improvements in materials, design, and manufacturing processes. Early V8s were primarily cast iron blocks with simple valve trains, while modern iterations utilize lightweight aluminum alloys, advanced cylinder head designs, and sophisticated valve control systems. These advancements have not only increased power output but also contributed to improved durability and fuel efficiency.

The pursuit of longevity in V8 engines has been a consistent focus for manufacturers. Key strategies have included enhancing lubrication systems, improving cooling efficiency, and developing more robust internal components. The introduction of variable valve timing and cylinder deactivation technologies has further extended engine life by reducing wear and optimizing performance across various operating conditions.

Recent technological trends in V8 engine development have centered on meeting stringent emissions standards while maintaining performance. This has led to the integration of direct fuel injection, turbocharging, and even hybrid electric systems in some V8 configurations. These innovations aim to extend the viability of V8 engines in an increasingly environmentally conscious automotive landscape.

Looking ahead, the goals for V8 engine longevity are multifaceted. Engineers are focusing on developing more heat-resistant materials to withstand higher combustion temperatures, which can improve efficiency but also increase stress on engine components. Advanced lubricants and filtration systems are being researched to reduce friction and wear, potentially extending engine life significantly.

Another area of focus is the implementation of predictive maintenance technologies. By integrating sensors and AI-driven analytics, future V8 engines could self-diagnose potential issues before they lead to major failures, thereby extending their operational lifespan. This proactive approach to maintenance aligns with the broader trend of smart, connected vehicles.

In conclusion, the evolution of V8 engines reflects a continuous drive towards improved performance, efficiency, and longevity. As the automotive industry faces new challenges and opportunities, the goals for V8 engine longevity will likely expand to include adaptability to alternative fuels, integration with electrification technologies, and further enhancements in durability and reliability. The future of V8 engines lies in striking a balance between traditional power and modern sustainability demands.

Over the years, V8 engines have seen remarkable improvements in materials, design, and manufacturing processes. Early V8s were primarily cast iron blocks with simple valve trains, while modern iterations utilize lightweight aluminum alloys, advanced cylinder head designs, and sophisticated valve control systems. These advancements have not only increased power output but also contributed to improved durability and fuel efficiency.

The pursuit of longevity in V8 engines has been a consistent focus for manufacturers. Key strategies have included enhancing lubrication systems, improving cooling efficiency, and developing more robust internal components. The introduction of variable valve timing and cylinder deactivation technologies has further extended engine life by reducing wear and optimizing performance across various operating conditions.

Recent technological trends in V8 engine development have centered on meeting stringent emissions standards while maintaining performance. This has led to the integration of direct fuel injection, turbocharging, and even hybrid electric systems in some V8 configurations. These innovations aim to extend the viability of V8 engines in an increasingly environmentally conscious automotive landscape.

Looking ahead, the goals for V8 engine longevity are multifaceted. Engineers are focusing on developing more heat-resistant materials to withstand higher combustion temperatures, which can improve efficiency but also increase stress on engine components. Advanced lubricants and filtration systems are being researched to reduce friction and wear, potentially extending engine life significantly.

Another area of focus is the implementation of predictive maintenance technologies. By integrating sensors and AI-driven analytics, future V8 engines could self-diagnose potential issues before they lead to major failures, thereby extending their operational lifespan. This proactive approach to maintenance aligns with the broader trend of smart, connected vehicles.

In conclusion, the evolution of V8 engines reflects a continuous drive towards improved performance, efficiency, and longevity. As the automotive industry faces new challenges and opportunities, the goals for V8 engine longevity will likely expand to include adaptability to alternative fuels, integration with electrification technologies, and further enhancements in durability and reliability. The future of V8 engines lies in striking a balance between traditional power and modern sustainability demands.

Market Demand for Durable V8 Engines

The market demand for durable V8 engines has been steadily growing, driven by various factors in both consumer and industrial sectors. In the automotive industry, there is a significant segment of enthusiasts and professionals who prioritize longevity and reliability in high-performance vehicles. These consumers are willing to invest in V8-powered vehicles that offer extended service life and reduced maintenance costs over time.

The commercial transportation sector, including heavy-duty trucks and specialized vehicles, also contributes to the demand for durable V8 engines. Fleet operators and logistics companies seek engines that can withstand long hours of operation and high mileage while maintaining performance and fuel efficiency. This demand is particularly strong in regions with developing infrastructure, where vehicles often face challenging road conditions and limited maintenance facilities.

Marine applications represent another substantial market for durable V8 engines. Boat owners and commercial marine operators require engines that can withstand harsh saltwater environments and provide reliable performance over extended periods. The ability to resist corrosion and maintain power output in demanding conditions is crucial in this sector.

In the industrial sector, there is a growing need for robust V8 engines in stationary power generation applications. These engines are used in backup power systems for critical infrastructure, remote industrial sites, and emergency services. The demand for reliable, long-lasting engines in this sector is driven by the need for uninterrupted power supply and the high costs associated with downtime and replacements.

The agricultural and construction industries also contribute to the market demand for durable V8 engines. Heavy machinery and equipment used in these sectors require powerful engines that can operate consistently under challenging conditions. Farmers and construction companies value engines that offer extended service intervals and reduced total cost of ownership over the equipment's lifecycle.

Environmental regulations and fuel efficiency standards have also influenced the market demand for durable V8 engines. As emissions requirements become more stringent, there is an increasing focus on developing V8 engines that not only last longer but also maintain their efficiency and emissions performance over time. This has led to a market segment that values engines designed with advanced materials and technologies to meet both durability and environmental standards.

The aftermarket and remanufacturing sectors further underscore the demand for durable V8 engines. There is a significant market for high-quality replacement parts and rebuilt engines, indicating a consumer base that seeks to extend the life of their V8-powered vehicles rather than replace them entirely. This trend is supported by the growing emphasis on sustainability and resource conservation in various industries.

The commercial transportation sector, including heavy-duty trucks and specialized vehicles, also contributes to the demand for durable V8 engines. Fleet operators and logistics companies seek engines that can withstand long hours of operation and high mileage while maintaining performance and fuel efficiency. This demand is particularly strong in regions with developing infrastructure, where vehicles often face challenging road conditions and limited maintenance facilities.

Marine applications represent another substantial market for durable V8 engines. Boat owners and commercial marine operators require engines that can withstand harsh saltwater environments and provide reliable performance over extended periods. The ability to resist corrosion and maintain power output in demanding conditions is crucial in this sector.

In the industrial sector, there is a growing need for robust V8 engines in stationary power generation applications. These engines are used in backup power systems for critical infrastructure, remote industrial sites, and emergency services. The demand for reliable, long-lasting engines in this sector is driven by the need for uninterrupted power supply and the high costs associated with downtime and replacements.

The agricultural and construction industries also contribute to the market demand for durable V8 engines. Heavy machinery and equipment used in these sectors require powerful engines that can operate consistently under challenging conditions. Farmers and construction companies value engines that offer extended service intervals and reduced total cost of ownership over the equipment's lifecycle.

Environmental regulations and fuel efficiency standards have also influenced the market demand for durable V8 engines. As emissions requirements become more stringent, there is an increasing focus on developing V8 engines that not only last longer but also maintain their efficiency and emissions performance over time. This has led to a market segment that values engines designed with advanced materials and technologies to meet both durability and environmental standards.

The aftermarket and remanufacturing sectors further underscore the demand for durable V8 engines. There is a significant market for high-quality replacement parts and rebuilt engines, indicating a consumer base that seeks to extend the life of their V8-powered vehicles rather than replace them entirely. This trend is supported by the growing emphasis on sustainability and resource conservation in various industries.

Current V8 Engine Challenges and Limitations

V8 engines, renowned for their power and performance, face several challenges and limitations that impact their longevity. One of the primary issues is thermal management. The high operating temperatures of V8 engines can lead to accelerated wear on components, particularly in the combustion chambers and cylinder walls. This thermal stress can cause premature breakdown of lubricants, leading to increased friction and potential engine damage over time.

Another significant challenge is the complexity of V8 engines, which often results in higher maintenance requirements and increased potential for mechanical failures. The intricate design, with more moving parts compared to smaller engines, means there are more components that can wear out or malfunction. This complexity also translates to higher repair costs and more frequent maintenance intervals, which can be a deterrent for long-term ownership.

Fuel efficiency remains a persistent limitation for V8 engines. Their larger displacement and higher fuel consumption rates make them less economical to operate, especially in an era of increasing environmental consciousness and stricter emissions regulations. This inefficiency not only impacts the engine's longevity from a cost perspective but also puts pressure on manufacturers to develop more fuel-efficient V8 designs without compromising performance.

The weight of V8 engines presents another challenge, particularly in terms of vehicle dynamics and overall efficiency. The heavier engine puts additional stress on other vehicle components, such as suspension systems and transmissions, potentially reducing their lifespan. Furthermore, the increased weight can negatively impact handling and braking performance, which may lead to faster wear on tires and brake components.

Emissions control is an ongoing challenge for V8 engines. Stricter environmental regulations require sophisticated emission control systems, which can add complexity and potential points of failure to the engine. These systems, while necessary, can sometimes reduce engine efficiency and performance, creating a balancing act between power output and environmental compliance.

Lastly, the advent of electric and hybrid technologies poses a significant challenge to the longevity of V8 engines in the automotive market. As manufacturers and consumers shift towards more sustainable and efficient powertrains, the development and improvement of V8 engines may see reduced investment, potentially limiting future advancements in their longevity and performance.

Another significant challenge is the complexity of V8 engines, which often results in higher maintenance requirements and increased potential for mechanical failures. The intricate design, with more moving parts compared to smaller engines, means there are more components that can wear out or malfunction. This complexity also translates to higher repair costs and more frequent maintenance intervals, which can be a deterrent for long-term ownership.

Fuel efficiency remains a persistent limitation for V8 engines. Their larger displacement and higher fuel consumption rates make them less economical to operate, especially in an era of increasing environmental consciousness and stricter emissions regulations. This inefficiency not only impacts the engine's longevity from a cost perspective but also puts pressure on manufacturers to develop more fuel-efficient V8 designs without compromising performance.

The weight of V8 engines presents another challenge, particularly in terms of vehicle dynamics and overall efficiency. The heavier engine puts additional stress on other vehicle components, such as suspension systems and transmissions, potentially reducing their lifespan. Furthermore, the increased weight can negatively impact handling and braking performance, which may lead to faster wear on tires and brake components.

Emissions control is an ongoing challenge for V8 engines. Stricter environmental regulations require sophisticated emission control systems, which can add complexity and potential points of failure to the engine. These systems, while necessary, can sometimes reduce engine efficiency and performance, creating a balancing act between power output and environmental compliance.

Lastly, the advent of electric and hybrid technologies poses a significant challenge to the longevity of V8 engines in the automotive market. As manufacturers and consumers shift towards more sustainable and efficient powertrains, the development and improvement of V8 engines may see reduced investment, potentially limiting future advancements in their longevity and performance.

Existing V8 Longevity Enhancement Techniques

01 Engine design optimization

Improving V8 engine longevity through optimized design features, including enhanced cooling systems, reinforced components, and advanced materials. These design improvements aim to reduce wear and tear, increase durability, and extend the overall lifespan of V8 engines.- Engine design optimization: Improving V8 engine longevity through optimized design features, including enhanced cooling systems, reinforced components, and advanced materials. These design improvements aim to reduce wear and tear, increase durability, and extend the overall lifespan of V8 engines.

- Lubrication system enhancements: Developing advanced lubrication systems and oil formulations specifically for V8 engines to reduce friction, minimize wear, and improve overall engine performance. These enhancements contribute to increased engine longevity by protecting critical components and maintaining optimal operating conditions.

- Predictive maintenance and diagnostics: Implementing advanced diagnostic systems and predictive maintenance algorithms to monitor V8 engine health, detect potential issues early, and schedule timely maintenance. This proactive approach helps prevent major failures and extends engine life through data-driven maintenance strategies.

- Fuel efficiency and emissions control: Developing technologies to improve fuel efficiency and reduce emissions in V8 engines, such as advanced fuel injection systems, variable valve timing, and exhaust gas recirculation. These innovations contribute to engine longevity by reducing stress on components and improving overall engine performance.

- Materials science advancements: Utilizing cutting-edge materials and surface treatments to enhance the durability and performance of V8 engine components. This includes the use of advanced alloys, ceramic coatings, and nanocomposites to reduce wear, improve heat resistance, and extend the lifespan of critical engine parts.

02 Lubrication system enhancements

Developing advanced lubrication systems and oil formulations specifically for V8 engines to reduce friction, minimize wear, and improve overall engine performance. These enhancements contribute to increased engine longevity by protecting critical components and maintaining optimal operating conditions.Expand Specific Solutions03 Electronic control and monitoring

Implementing sophisticated electronic control systems and monitoring technologies to optimize V8 engine performance, detect potential issues early, and adjust operating parameters in real-time. These systems help maintain engine health and extend its lifespan through proactive management and preventive maintenance.Expand Specific Solutions04 Advanced materials and manufacturing techniques

Utilizing cutting-edge materials and manufacturing processes to produce more durable and heat-resistant engine components. This approach enhances the overall strength and longevity of V8 engines, allowing them to withstand higher stresses and operate efficiently for extended periods.Expand Specific Solutions05 Predictive maintenance and diagnostics

Developing predictive maintenance algorithms and diagnostic tools specifically for V8 engines to identify potential issues before they become critical. These technologies enable proactive maintenance strategies, reducing unexpected failures and extending the operational life of V8 engines.Expand Specific Solutions

Key V8 Engine Manufacturers and Innovators

The V8 engine longevity improvement landscape is characterized by a mature market with steady growth, driven by increasing demand for durable and efficient engines. The global automotive industry, led by major players like GM, Toyota, Ford, and Honda, is investing heavily in research and development to enhance V8 engine performance and lifespan. These companies are leveraging advanced materials, innovative cooling systems, and sophisticated engine management technologies to address longevity challenges. Emerging players like Guangxi Yuchai Machinery and Great Wall Motor are also contributing to the competitive landscape, particularly in developing markets. The technology is well-established but continually evolving, with a focus on integrating digital solutions and eco-friendly practices to meet stringent emissions standards while maintaining engine durability.

GM Global Technology Operations LLC

Technical Solution: GM has developed a comprehensive approach to improve V8 engine longevity, focusing on advanced materials and innovative design. They have implemented a new cylinder liner technology using a plasma-transferred wire arc coating process, which significantly reduces friction and wear[1]. This coating is applied to the cylinder bores, creating a durable surface that can withstand high temperatures and pressures. Additionally, GM has introduced variable valve timing and lift systems that optimize engine performance and efficiency across different operating conditions[2]. Their latest V8 engines also feature direct fuel injection and advanced cooling systems to maintain optimal operating temperatures and reduce thermal stress on engine components[3].

Strengths: Cutting-edge materials technology, comprehensive approach to engine design. Weaknesses: Potentially higher production costs, complexity in manufacturing processes.

Toyota Motor Corp.

Technical Solution: Toyota's strategy for improving V8 engine longevity centers on their D-4S (Direct injection 4-stroke gasoline engine Superior version) technology. This system combines direct and port fuel injection, allowing for precise fuel delivery and improved combustion efficiency[4]. Toyota has also implemented an advanced thermal management system that rapidly brings the engine to optimal operating temperature, reducing wear during cold starts. Their V8 engines feature a high-strength aluminum alloy block with cast-in iron cylinder liners for durability[5]. Toyota's Dual VVT-i (Variable Valve Timing-intelligent) system optimizes valve timing for both intake and exhaust camshafts, enhancing performance and reducing emissions across the engine's operating range[6].

Strengths: Efficient fuel injection system, advanced thermal management. Weaknesses: Potential complexity in maintenance, higher initial cost compared to simpler engine designs.

Breakthrough Technologies for V8 Durability

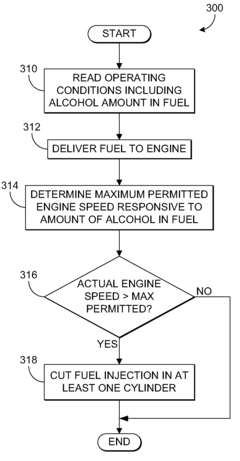

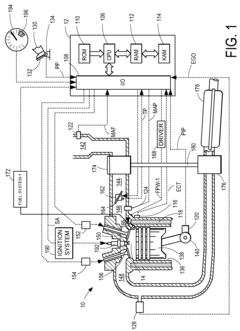

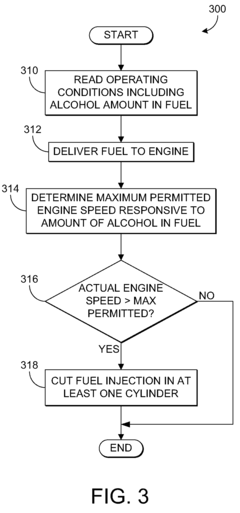

Engine control responsive to varying amounts of alcohol in fuel

PatentInactiveUS7826957B2

Innovation

- Implementing a control system that limits engine speed based on the alcohol content in the fuel, using either an absolute or soft speed limit, and adjusting the shift schedule to prevent engine degradation, while maintaining common bearing designs and fuel economy.

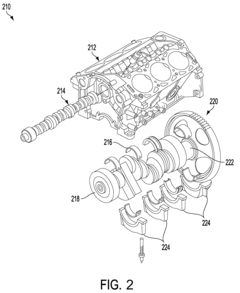

V8 engine

PatentWO2021171405A1

Innovation

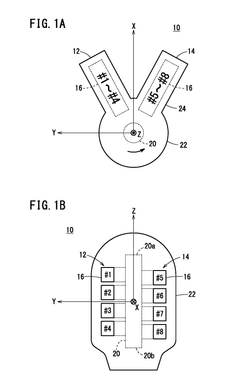

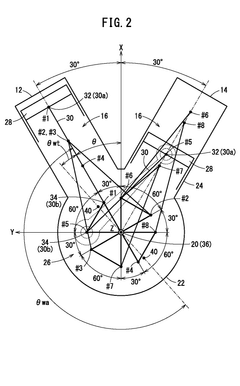

- The engine is configured with a 60° bank angle, where crank pins on one bank are arranged at 90° intervals and offset by 60° from the other bank, allowing for cancellation of the primary inertia couple without additional special parts, and the ignition timing is set to achieve balanced explosions similar to conventional V8 engines.

Environmental Impact of Extended V8 Lifespans

The environmental impact of extending V8 engine lifespans is a multifaceted issue that warrants careful consideration. Prolonging the operational life of V8 engines can have both positive and negative effects on the environment, necessitating a comprehensive analysis of the various factors involved.

One of the primary benefits of extending V8 engine longevity is the reduction in resource consumption and waste generation associated with manufacturing new engines. By increasing the lifespan of existing engines, fewer raw materials are required for production, leading to decreased mining and processing activities. This, in turn, results in reduced energy consumption and greenhouse gas emissions throughout the supply chain.

Furthermore, extended engine lifespans can contribute to a decrease in the overall carbon footprint of vehicles. As engines are designed to operate more efficiently over longer periods, they maintain optimal performance levels for extended durations, potentially reducing fuel consumption and emissions over the vehicle's lifetime. This improved efficiency can lead to a net positive environmental impact, particularly when considering the cumulative effects across a large fleet of vehicles.

However, it is crucial to consider potential drawbacks as well. Older engines, even with improved longevity, may not meet the latest emission standards and could potentially contribute more to air pollution compared to newer, more advanced models. This raises questions about the trade-offs between extending the life of existing engines and adopting newer, cleaner technologies.

The disposal and recycling of engine components at the end of their extended lifespan also present environmental challenges. While longer-lasting engines may reduce the frequency of disposal, the eventual recycling process must be carefully managed to minimize environmental impact. This includes proper handling of potentially hazardous materials and ensuring efficient recycling practices to recover valuable resources.

Additionally, the environmental impact of maintenance activities required to extend engine life must be taken into account. Increased use of lubricants, coolants, and replacement parts over an extended period may offset some of the environmental benefits gained from prolonged engine use. It is essential to develop and implement environmentally friendly maintenance practices to mitigate these effects.

In conclusion, while extending V8 engine longevity can offer significant environmental benefits through reduced resource consumption and improved efficiency, it is crucial to balance these advantages against potential drawbacks. A holistic approach that considers the entire lifecycle of the engine, from production to disposal, is necessary to fully understand and optimize the environmental impact of extended V8 lifespans.

One of the primary benefits of extending V8 engine longevity is the reduction in resource consumption and waste generation associated with manufacturing new engines. By increasing the lifespan of existing engines, fewer raw materials are required for production, leading to decreased mining and processing activities. This, in turn, results in reduced energy consumption and greenhouse gas emissions throughout the supply chain.

Furthermore, extended engine lifespans can contribute to a decrease in the overall carbon footprint of vehicles. As engines are designed to operate more efficiently over longer periods, they maintain optimal performance levels for extended durations, potentially reducing fuel consumption and emissions over the vehicle's lifetime. This improved efficiency can lead to a net positive environmental impact, particularly when considering the cumulative effects across a large fleet of vehicles.

However, it is crucial to consider potential drawbacks as well. Older engines, even with improved longevity, may not meet the latest emission standards and could potentially contribute more to air pollution compared to newer, more advanced models. This raises questions about the trade-offs between extending the life of existing engines and adopting newer, cleaner technologies.

The disposal and recycling of engine components at the end of their extended lifespan also present environmental challenges. While longer-lasting engines may reduce the frequency of disposal, the eventual recycling process must be carefully managed to minimize environmental impact. This includes proper handling of potentially hazardous materials and ensuring efficient recycling practices to recover valuable resources.

Additionally, the environmental impact of maintenance activities required to extend engine life must be taken into account. Increased use of lubricants, coolants, and replacement parts over an extended period may offset some of the environmental benefits gained from prolonged engine use. It is essential to develop and implement environmentally friendly maintenance practices to mitigate these effects.

In conclusion, while extending V8 engine longevity can offer significant environmental benefits through reduced resource consumption and improved efficiency, it is crucial to balance these advantages against potential drawbacks. A holistic approach that considers the entire lifecycle of the engine, from production to disposal, is necessary to fully understand and optimize the environmental impact of extended V8 lifespans.

Cost-Benefit Analysis of V8 Longevity Strategies

Improving V8 engine longevity involves various strategies, each with associated costs and benefits. This analysis aims to evaluate these strategies from a financial and performance perspective, providing insights into their overall effectiveness and return on investment.

Regular maintenance is a fundamental strategy for extending V8 engine life. While it incurs ongoing costs for parts and labor, the benefits far outweigh the expenses. Routine oil changes, filter replacements, and tune-ups can significantly reduce wear and tear, preventing costly repairs and prolonging engine life. The cost-benefit ratio is highly favorable, as the investment in maintenance is typically a fraction of potential repair or replacement costs.

Upgrading to high-quality components is another effective strategy. Although premium parts come with a higher initial cost, they often result in improved performance and durability. For instance, using synthetic oil may cost more upfront but offers better engine protection and longer intervals between changes. Similarly, investing in high-grade filters and spark plugs can enhance engine efficiency and reduce long-term wear. The cost-benefit analysis here shows a positive outcome, especially for high-performance or frequently used V8 engines.

Engine management system optimization is a more advanced strategy with potentially significant benefits. While it may require specialized expertise and equipment, resulting in higher initial costs, the improvements in fuel efficiency, power output, and engine longevity can be substantial. This strategy often yields a favorable cost-benefit ratio for performance-oriented applications or fleet operations where fuel savings and reduced downtime can offset the initial investment.

Implementing advanced cooling systems is another consideration. Enhanced cooling can significantly reduce thermal stress on engine components, potentially extending their lifespan. The costs involve not only the cooling system itself but also installation and potential modifications. However, the benefits of improved thermal management, especially in high-stress applications, can lead to reduced wear and fewer heat-related failures, justifying the investment in many cases.

Lastly, engine rebuilding or remanufacturing presents a comprehensive approach to longevity. While it involves substantial upfront costs, potentially approaching those of a new engine, the benefits can be significant. A properly rebuilt engine can offer performance and reliability comparable to a new unit at a fraction of the cost. This strategy is particularly beneficial for older or rare V8 engines where replacement options are limited or expensive.

In conclusion, the cost-benefit analysis of V8 longevity strategies reveals that most approaches offer positive returns when implemented appropriately. The optimal strategy depends on factors such as the engine's age, intended use, and the owner's long-term goals. Regular maintenance and high-quality components generally offer the most universally applicable benefits, while more advanced strategies like engine management optimization and rebuilding can provide substantial returns in specific scenarios.

Regular maintenance is a fundamental strategy for extending V8 engine life. While it incurs ongoing costs for parts and labor, the benefits far outweigh the expenses. Routine oil changes, filter replacements, and tune-ups can significantly reduce wear and tear, preventing costly repairs and prolonging engine life. The cost-benefit ratio is highly favorable, as the investment in maintenance is typically a fraction of potential repair or replacement costs.

Upgrading to high-quality components is another effective strategy. Although premium parts come with a higher initial cost, they often result in improved performance and durability. For instance, using synthetic oil may cost more upfront but offers better engine protection and longer intervals between changes. Similarly, investing in high-grade filters and spark plugs can enhance engine efficiency and reduce long-term wear. The cost-benefit analysis here shows a positive outcome, especially for high-performance or frequently used V8 engines.

Engine management system optimization is a more advanced strategy with potentially significant benefits. While it may require specialized expertise and equipment, resulting in higher initial costs, the improvements in fuel efficiency, power output, and engine longevity can be substantial. This strategy often yields a favorable cost-benefit ratio for performance-oriented applications or fleet operations where fuel savings and reduced downtime can offset the initial investment.

Implementing advanced cooling systems is another consideration. Enhanced cooling can significantly reduce thermal stress on engine components, potentially extending their lifespan. The costs involve not only the cooling system itself but also installation and potential modifications. However, the benefits of improved thermal management, especially in high-stress applications, can lead to reduced wear and fewer heat-related failures, justifying the investment in many cases.

Lastly, engine rebuilding or remanufacturing presents a comprehensive approach to longevity. While it involves substantial upfront costs, potentially approaching those of a new engine, the benefits can be significant. A properly rebuilt engine can offer performance and reliability comparable to a new unit at a fraction of the cost. This strategy is particularly beneficial for older or rare V8 engines where replacement options are limited or expensive.

In conclusion, the cost-benefit analysis of V8 longevity strategies reveals that most approaches offer positive returns when implemented appropriately. The optimal strategy depends on factors such as the engine's age, intended use, and the owner's long-term goals. Regular maintenance and high-quality components generally offer the most universally applicable benefits, while more advanced strategies like engine management optimization and rebuilding can provide substantial returns in specific scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!