How to Innovate with Cellulose Acetate in Consumer Electronics?

Cellulose Acetate in Electronics: Background and Objectives

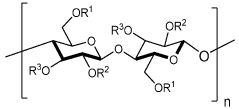

Cellulose acetate, a versatile biopolymer derived from natural sources, has been a staple material in various industries for over a century. Its journey in consumer electronics began in the early 20th century, primarily as a component in photographic films and later in audio tapes. As technology advanced, the potential applications of cellulose acetate in electronics expanded, driven by its unique properties and environmental advantages.

The evolution of cellulose acetate in electronics has been marked by significant milestones. Initially used in simple components like casings and insulators, it has gradually found its way into more sophisticated applications. The material's biodegradability and renewable sourcing have become increasingly relevant in recent years, aligning with the growing emphasis on sustainable and eco-friendly technologies in the consumer electronics sector.

Current technological trends are pushing the boundaries of cellulose acetate's capabilities in electronics. Research is focused on enhancing its electrical and thermal properties, improving its durability, and exploring novel manufacturing techniques. The goal is to position cellulose acetate as a viable alternative to traditional petroleum-based plastics in various electronic components and devices.

The primary objective of innovating with cellulose acetate in consumer electronics is to address the pressing need for sustainable materials without compromising performance. This involves developing new formulations and processing methods to overcome the material's inherent limitations, such as moisture sensitivity and lower heat resistance compared to some synthetic polymers.

Another key aim is to leverage cellulose acetate's unique properties to create innovative electronic products. Its optical clarity, for instance, opens up possibilities in display technologies, while its biodegradability could revolutionize the approach to electronic waste management. Researchers are also exploring ways to incorporate cellulose acetate into flexible and wearable electronics, capitalizing on its malleability and biocompatibility.

The pursuit of innovation in this field is driven by both environmental concerns and market demands. As consumers become more environmentally conscious, there is a growing market for electronics with reduced environmental impact. This shift in consumer preferences aligns with regulatory pressures pushing for more sustainable practices in the electronics industry.

Looking ahead, the trajectory of cellulose acetate in consumer electronics is poised for significant advancement. The convergence of material science, electronics engineering, and sustainability principles is expected to yield breakthrough applications. From biodegradable smartphone components to eco-friendly wearable devices, the potential for cellulose acetate to transform the landscape of consumer electronics is vast and promising.

Market Analysis for Sustainable Electronics Materials

The market for sustainable electronics materials is experiencing significant growth, driven by increasing consumer awareness of environmental issues and stricter regulations on electronic waste. Cellulose acetate, a biodegradable and renewable material derived from wood pulp or cotton fibers, is emerging as a promising alternative to traditional plastics in consumer electronics.

The global market for sustainable electronics materials is projected to expand rapidly in the coming years. This growth is fueled by the rising demand for eco-friendly products and the push for circular economy principles in the electronics industry. Major consumer electronics manufacturers are actively seeking sustainable materials to reduce their environmental footprint and meet consumer expectations for greener products.

Cellulose acetate offers several advantages in the consumer electronics market. Its biodegradability addresses the growing concern of electronic waste accumulation, while its renewable sourcing aligns with sustainability goals. The material's versatility allows for various applications in electronics, including casings, components, and packaging.

The adoption of cellulose acetate in consumer electronics is still in its early stages, presenting significant opportunities for innovation and market growth. Current applications include smartphone cases, headphone components, and packaging materials. However, there is potential for expanded use in areas such as wearable devices, smart home products, and computer peripherals.

Market trends indicate a shift towards more sustainable practices in the electronics industry. This includes the use of bio-based materials, design for recyclability, and extended product lifecycles. Cellulose acetate aligns well with these trends, positioning it as a material of interest for manufacturers looking to improve their sustainability credentials.

Consumer demand for sustainable electronics is on the rise, particularly among younger demographics who prioritize environmental considerations in their purchasing decisions. This trend is creating new market segments and driving established brands to reevaluate their material choices and production processes.

Challenges in the market include the need for further research and development to enhance the performance characteristics of cellulose acetate for electronics applications. Additionally, scaling up production and integrating the material into existing manufacturing processes present hurdles that need to be addressed.

The competitive landscape is evolving, with both established materials companies and startups entering the sustainable electronics materials space. Collaborations between material scientists, electronics manufacturers, and sustainability experts are becoming more common, fostering innovation in this field.

Current Applications and Challenges in Consumer Electronics

Cellulose acetate has found its way into various consumer electronics applications, primarily due to its unique properties such as transparency, durability, and biodegradability. In the realm of display technologies, cellulose acetate films are utilized as protective layers for LCD screens, offering scratch resistance and anti-glare properties. These films enhance the visual quality and longevity of electronic devices, including smartphones, tablets, and laptops.

Another significant application is in the production of electronic components. Cellulose acetate's electrical insulation properties make it suitable for manufacturing capacitors and other electronic parts. Its ability to withstand high temperatures without deforming also contributes to its use in circuit boards and internal device structures.

In the audio industry, cellulose acetate is employed in the production of high-quality headphone and speaker diaphragms. Its lightweight nature and excellent acoustic properties result in clear sound reproduction, making it a preferred material for audiophile-grade equipment.

Despite these applications, the use of cellulose acetate in consumer electronics faces several challenges. One primary concern is its moisture sensitivity, which can lead to dimensional instability in humid environments. This characteristic limits its use in certain electronic components that require strict dimensional tolerances.

Another challenge lies in the material's relatively high production cost compared to synthetic alternatives. While cellulose acetate offers environmental benefits, the economic considerations often favor cheaper, petroleum-based plastics in mass-produced consumer electronics.

The flammability of cellulose acetate poses safety concerns in electronic devices, particularly those that generate heat during operation. This necessitates the development of flame-retardant additives or alternative formulations to meet stringent safety standards in the electronics industry.

Furthermore, the biodegradability of cellulose acetate, while environmentally advantageous, presents challenges in terms of long-term durability. Electronic devices are expected to have extended lifespans, and the potential degradation of cellulose acetate components over time could impact product longevity and reliability.

Lastly, the integration of cellulose acetate into existing manufacturing processes presents technical hurdles. Many production lines are optimized for working with traditional plastics, and retooling for cellulose acetate can be costly and time-consuming. This resistance to change in established manufacturing ecosystems slows the widespread adoption of cellulose acetate in consumer electronics.

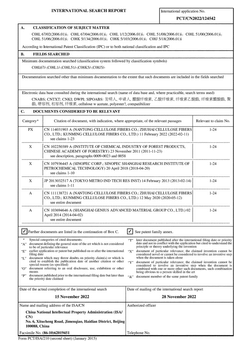

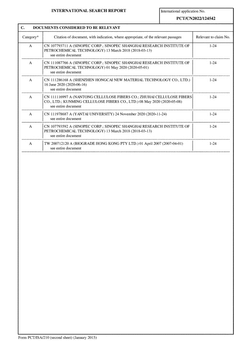

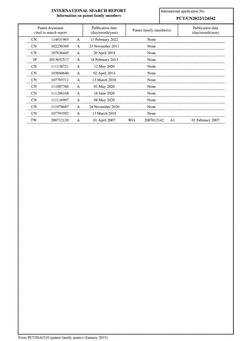

Existing Cellulose Acetate Solutions in Electronics

01 Cellulose acetate production methods

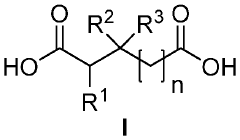

Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production for different applications.- Cellulose acetate production methods: Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production, potentially leading to better material properties for diverse applications.

- Cellulose acetate fiber applications: Cellulose acetate fibers find applications in textiles, filters, and other products. Innovations in fiber production, spinning techniques, and post-treatment processes are explored to improve the performance and versatility of cellulose acetate fibers in various end-use scenarios.

- Cellulose acetate film and membrane technology: Advancements in cellulose acetate film and membrane technology are presented, focusing on improved formulations, manufacturing processes, and surface modifications. These developments enhance the performance of cellulose acetate in applications such as separation membranes, packaging materials, and optical films.

- Cellulose acetate blends and composites: Research on cellulose acetate blends and composites with other polymers or materials is discussed. These combinations aim to enhance properties such as mechanical strength, thermal stability, or biodegradability, expanding the potential applications of cellulose acetate-based materials.

- Biodegradable and sustainable cellulose acetate products: Innovations in developing biodegradable and sustainable cellulose acetate products are explored. This includes modifications to improve environmental compatibility, reduce environmental impact, and create eco-friendly alternatives to traditional plastics in various consumer and industrial applications.

02 Cellulose acetate fiber applications

Cellulose acetate fibers are utilized in diverse applications, such as textiles, filters, and packaging materials. The properties of these fibers can be tailored through modifications in the production process or post-treatment methods to suit specific end-use requirements.Expand Specific Solutions03 Cellulose acetate film and membrane technology

Advancements in cellulose acetate film and membrane technology focus on improving properties such as permeability, selectivity, and mechanical strength. These developments are particularly relevant for applications in separation processes, water treatment, and gas purification.Expand Specific Solutions04 Cellulose acetate composites and blends

Research on cellulose acetate composites and blends aims to enhance material properties by combining cellulose acetate with other polymers or additives. This approach can lead to improved mechanical, thermal, or functional characteristics for various applications.Expand Specific Solutions05 Biodegradable and sustainable cellulose acetate products

Development of biodegradable and sustainable cellulose acetate products focuses on improving environmental compatibility while maintaining desired material properties. This includes research on modified cellulose acetates and their applications in eco-friendly packaging and disposable items.Expand Specific Solutions

Key Players in Cellulose Acetate and Electronics Industries

The innovation landscape for cellulose acetate in consumer electronics is in a growth phase, with increasing market size driven by demand for sustainable materials. The technology maturity varies across applications, with established players like Eastman Chemical Co. and Daicel Corp. leading in traditional uses. Emerging companies such as Nantong Cellulose Fibers Co. Ltd. and Zhuhai Cellulose Fibers Co. Ltd. are exploring novel applications. Research institutions like Guilin University of Technology and the Institute of Process Engineering, Chinese Academy of Sciences are advancing the field through collaborative efforts. The competitive landscape is characterized by a mix of large chemical corporations, specialized manufacturers, and academic institutions, indicating a dynamic environment for innovation in this sector.

Daicel Corp.

Eastman Chemical Co.

Innovative Cellulose Acetate Formulations and Properties

- Incorporating a compatibilizer with active multifunctional groups, such as epoxy or maleic anhydride, to enhance the interfacial compatibility and mechanical properties of cellulose acetate and biodegradable polyester blends through reaction extrusion, allowing for improved thermal processing and film production.

- Development of melt-stable cellulose acetates with specific characteristics, such as a heated intrinsic viscosity of at least 0.9 and a metals-to-sulfur molar ratio of at least 1.35, which are combined with plasticizers to create compositions that exhibit reduced color formation and molecular weight retention during processing.

Environmental Impact and Sustainability Assessment

The integration of cellulose acetate in consumer electronics presents a significant opportunity for enhancing environmental sustainability in the industry. Cellulose acetate, derived from natural sources, offers a biodegradable alternative to traditional petroleum-based plastics, potentially reducing the environmental footprint of electronic devices throughout their lifecycle.

In terms of production, cellulose acetate requires less energy to manufacture compared to conventional plastics, resulting in lower greenhouse gas emissions. The raw materials for cellulose acetate, primarily wood pulp and cotton linters, are renewable resources, further contributing to its sustainability profile. However, the acetylation process involves the use of acetic anhydride, which requires careful handling and disposal to prevent environmental contamination.

During the use phase, cellulose acetate-based components in consumer electronics demonstrate favorable durability and heat resistance properties, potentially extending product lifespans and reducing electronic waste. The material's inherent flame-retardant characteristics also eliminate the need for additional harmful chemical treatments often used in conventional plastics.

End-of-life management of cellulose acetate presents both opportunities and challenges. While the material is biodegradable under specific conditions, it may not decompose readily in typical landfill environments. Proper disposal and recycling infrastructure are crucial to fully realize its environmental benefits. Advanced recycling technologies, such as chemical depolymerization, could enable the recovery and reuse of cellulose acetate, creating a more circular economy for electronic components.

The adoption of cellulose acetate in consumer electronics could significantly reduce the industry's reliance on fossil fuel-based materials, aligning with global efforts to mitigate climate change. However, a comprehensive life cycle assessment (LCA) is essential to quantify the overall environmental impact, considering factors such as water usage, land use changes, and potential impacts on biodiversity associated with increased demand for cellulose-based materials.

To maximize the sustainability benefits of cellulose acetate in consumer electronics, industry stakeholders must collaborate to develop eco-design principles, optimize manufacturing processes, and establish effective recycling systems. Additionally, consumer education on proper disposal and the environmental advantages of cellulose acetate-based electronics will be crucial for driving market acceptance and ensuring responsible end-of-life management.

Regulatory Landscape for Bio-based Materials in Electronics

The regulatory landscape for bio-based materials in consumer electronics is evolving rapidly as governments and industry bodies recognize the potential of sustainable alternatives like cellulose acetate. In the European Union, the Eco-design Directive and the Restriction of Hazardous Substances (RoHS) Directive are key regulations impacting the use of bio-based materials in electronics. These directives aim to reduce the environmental impact of products throughout their lifecycle and restrict the use of certain hazardous substances in electrical and electronic equipment.

In the United States, the Environmental Protection Agency (EPA) has implemented the Toxic Substances Control Act (TSCA), which regulates the introduction of new or already existing chemicals. This act has implications for the use of cellulose acetate and other bio-based materials in consumer electronics. Additionally, the Federal Trade Commission (FTC) has established guidelines for environmental marketing claims, which manufacturers must adhere to when promoting products made with bio-based materials.

Japan, a leader in electronics manufacturing, has introduced the Home Appliance Recycling Law and the Law for Promotion of Effective Utilization of Resources. These regulations encourage the use of recyclable and eco-friendly materials in electronic products, potentially favoring the adoption of bio-based materials like cellulose acetate.

China, another major player in the electronics industry, has implemented the Restriction of Hazardous Substances (China RoHS) regulation, which is similar to the EU's RoHS directive. This regulation impacts the use of materials in electronic products and may influence the adoption of bio-based alternatives.

Globally, the International Electrotechnical Commission (IEC) has developed standards for environmentally conscious design of electrical and electronic products. These standards, such as IEC 62430, provide guidelines for incorporating environmental considerations into the design and development of electronic products, potentially encouraging the use of sustainable materials like cellulose acetate.

Industry-specific certifications and standards also play a crucial role in shaping the regulatory landscape. For instance, the EPEAT (Electronic Product Environmental Assessment Tool) certification system evaluates electronic products based on various environmental criteria, including the use of bio-based plastics. Such certifications can drive the adoption of sustainable materials in consumer electronics.

As the demand for sustainable products grows, regulatory bodies are likely to introduce more stringent requirements for the use of eco-friendly materials in electronics. This evolving regulatory landscape presents both challenges and opportunities for innovating with cellulose acetate in consumer electronics, necessitating a proactive approach to compliance and sustainability in product development.