How to Integrate Cellulose Acetate into Circular Economy Models?

Cellulose Acetate Circular Economy Integration Goals

The integration of cellulose acetate into circular economy models represents a critical step towards sustainable materials management. The primary goal is to transform the linear lifecycle of cellulose acetate products into a closed-loop system, minimizing waste and maximizing resource efficiency. This integration aims to address the environmental concerns associated with the production and disposal of cellulose acetate, particularly in industries such as textiles, packaging, and consumer goods.

A key objective is to develop and implement effective recycling technologies specifically tailored for cellulose acetate. This involves creating processes that can efficiently separate cellulose acetate from other materials, break it down into its constituent components, and regenerate it into new products without significant loss of quality. The goal is to establish a robust recycling infrastructure that can handle various forms of cellulose acetate waste, from industrial scraps to post-consumer products.

Another crucial aim is to redesign cellulose acetate products with circularity in mind. This entails creating products that are easier to disassemble, recycle, or biodegrade at the end of their life cycle. The focus is on developing innovative product designs that facilitate the separation of cellulose acetate from other materials, making recycling more efficient and economically viable.

Enhancing the biodegradability of cellulose acetate is also a significant goal. While cellulose acetate is derived from natural sources, its biodegradation can be slow under certain conditions. Research efforts are directed towards modifying the material composition or developing additives that can accelerate the biodegradation process without compromising the material's performance during its intended use.

Furthermore, the integration aims to establish new business models that support the circular use of cellulose acetate. This includes developing take-back programs, leasing models, and product-as-a-service offerings that encourage the return and reuse of cellulose acetate products. The goal is to create economic incentives for both producers and consumers to participate in circular economy practices.

Lastly, a critical objective is to raise awareness and educate stakeholders about the importance of circular economy principles in the context of cellulose acetate. This involves engaging with manufacturers, consumers, policymakers, and waste management entities to foster a collective understanding of the material's lifecycle and the benefits of circular approaches. The ultimate goal is to create a supportive ecosystem that facilitates the widespread adoption of circular economy practices for cellulose acetate across various industries and applications.

Market Demand for Sustainable Cellulose Acetate Products

The market demand for sustainable cellulose acetate products has been steadily increasing in recent years, driven by growing environmental awareness and stricter regulations on plastic use. Cellulose acetate, derived from natural cellulose, offers a promising alternative to traditional petroleum-based plastics in various applications.

In the packaging industry, there is a significant demand for biodegradable and compostable materials. Cellulose acetate films and sheets are gaining traction as sustainable alternatives to conventional plastic packaging. The food and beverage sector, in particular, shows strong interest in cellulose acetate-based packaging solutions that can maintain product freshness while reducing environmental impact.

The textile industry is another key market for sustainable cellulose acetate products. As consumers become more conscious of the environmental footprint of their clothing, there is a growing demand for eco-friendly fibers. Cellulose acetate yarns and fabrics offer a renewable and biodegradable option for fashion and home textiles, appealing to environmentally conscious consumers and brands alike.

In the personal care and cosmetics sector, the push for sustainable packaging has led to increased interest in cellulose acetate-based containers and applicators. These products align with the industry's efforts to reduce plastic waste and appeal to consumers seeking more environmentally responsible choices.

The automotive industry is exploring cellulose acetate composites as lightweight, recyclable alternatives to traditional plastic components. This trend is driven by the need to reduce vehicle weight for improved fuel efficiency and to meet increasingly stringent environmental regulations.

The electronics industry is also showing interest in cellulose acetate-based materials for casings and components, as manufacturers seek to improve the recyclability and biodegradability of their products. This aligns with the growing consumer demand for more sustainable electronic devices.

Market analysts project that the global demand for sustainable cellulose acetate products will continue to grow at a compound annual growth rate of over 5% in the coming years. This growth is supported by ongoing research and development efforts to improve the performance and cost-effectiveness of cellulose acetate-based materials, making them more competitive with traditional plastics across a wider range of applications.

As circular economy models gain prominence, the recyclability and biodegradability of cellulose acetate products become increasingly valuable. Companies are investing in developing closed-loop systems for cellulose acetate production and recycling, further enhancing the material's sustainability credentials and market appeal.

Current State and Challenges in Cellulose Acetate Recycling

Cellulose acetate, a versatile bioplastic, faces significant challenges in its integration into circular economy models. Currently, the recycling of cellulose acetate is limited, with most products ending up in landfills or incineration facilities. The primary obstacle lies in the lack of established recycling infrastructure specifically designed for this material.

The chemical composition of cellulose acetate presents a unique challenge. Unlike conventional plastics, it is a semi-synthetic polymer derived from natural cellulose. This composition makes it difficult to recycle using traditional mechanical recycling methods employed for other plastics. As a result, cellulose acetate products are often mistakenly disposed of with general plastic waste, leading to contamination in recycling streams.

Another significant hurdle is the variety of additives and plasticizers used in cellulose acetate products. These additives, while enhancing the material's properties for specific applications, complicate the recycling process. The presence of these varied compounds necessitates more complex separation and purification steps, increasing the cost and complexity of recycling efforts.

The current state of cellulose acetate recycling is further hampered by the lack of widespread collection systems. Many regions do not have dedicated collection points or programs for cellulose acetate products, such as cigarette filters or textile fibers. This absence of proper collection mechanisms results in a significant portion of cellulose acetate waste being improperly disposed of or littered.

From a technological standpoint, the development of efficient and cost-effective recycling processes for cellulose acetate is still in its infancy. While some chemical recycling methods show promise, they are not yet commercially viable on a large scale. The energy-intensive nature of these processes and the need for specialized equipment pose economic challenges to their widespread adoption.

Consumer awareness and behavior also play a crucial role in the current state of cellulose acetate recycling. Many users are unaware of the material's recyclability or proper disposal methods, leading to improper waste management practices. This lack of awareness contributes to the low recycling rates and hinders the establishment of effective circular economy models for cellulose acetate.

Regulatory frameworks and policy support for cellulose acetate recycling are currently inadequate in many regions. The absence of specific guidelines or incentives for recycling this material leaves it in a regulatory gray area, often resulting in its treatment as general waste rather than a recyclable resource.

Existing Circular Economy Models for Cellulose Acetate

01 Production methods for cellulose acetate

Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production for different applications.- Cellulose acetate production methods: Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production for different applications.

- Cellulose acetate fiber applications: Cellulose acetate fibers are utilized in diverse applications such as textiles, filters, and membranes. The patents discuss modifications to improve fiber properties, processing techniques, and novel uses in various industries.

- Cellulose acetate film and coating technologies: Innovations in cellulose acetate film and coating technologies are presented, including improved formulations, manufacturing processes, and applications in packaging, optical films, and protective coatings.

- Cellulose acetate modification and derivatives: Methods for modifying cellulose acetate and creating novel derivatives are described. These modifications aim to enhance properties such as biodegradability, thermal stability, and compatibility with other materials for various applications.

- Cellulose acetate in composite materials: The use of cellulose acetate in composite materials is explored, including its incorporation into polymer blends, nanocomposites, and hybrid materials. These composites offer improved mechanical, thermal, and functional properties for diverse applications.

02 Cellulose acetate fibers and films

Techniques for manufacturing cellulose acetate fibers and films are detailed, covering aspects such as spinning processes, film formation, and modification of properties. These innovations contribute to the development of improved cellulose acetate-based materials for textiles, packaging, and other applications.Expand Specific Solutions03 Cellulose acetate composites and blends

Development of cellulose acetate composites and blends with other materials to enhance properties such as strength, flexibility, or biodegradability. These innovations expand the range of applications for cellulose acetate in various industries.Expand Specific Solutions04 Modification and functionalization of cellulose acetate

Methods for modifying and functionalizing cellulose acetate to impart specific properties or introduce new functionalities. These techniques allow for the tailoring of cellulose acetate for specialized applications in areas such as filtration, drug delivery, or smart materials.Expand Specific Solutions05 Cellulose acetate in membrane technology

Applications of cellulose acetate in membrane technology, including the development of novel membrane structures, surface modifications, and performance enhancements. These innovations contribute to advancements in separation processes, water treatment, and gas purification.Expand Specific Solutions

Key Players in Cellulose Acetate Circular Economy

The integration of cellulose acetate into circular economy models is in its early development stage, with growing market potential driven by sustainability concerns. The global cellulose acetate market is expected to reach $7.2 billion by 2027, indicating significant opportunities. Companies like Daicel Corp., Eastman Chemical Co., and Infinited Fiber Co. Oy are at the forefront of technological advancements, focusing on recycling and bio-based production methods. Research institutions such as the Institute of Process Engineering, Chinese Academy of Sciences, and Nanjing Forestry University are contributing to the development of innovative circular economy solutions. While the technology is progressing, challenges in scalability and cost-effectiveness remain, suggesting a moderate level of technological maturity in this field.

Daicel Corp.

Eastman Chemical Co.

Innovative Recycling Technologies for Cellulose Acetate

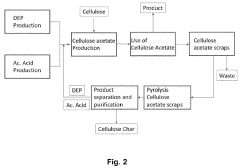

- A pyrolysis process is employed to decompose cellulose acetate waste at medium temperatures, selectively producing acetic acid and diethyl phthalate, which can then be easily separated and reused, reducing the need for new polymer synthesis and lowering environmental impact.

- Incorporating a compatibilizer with active multifunctional groups, such as epoxy or maleic anhydride, to react with cellulose acetate and biodegradable polyester, enhancing their interfacial compatibility and mechanical properties through extrusion, thereby modifying the thermos-processable cellulose acetate to improve thermal processing and mechanical performance.

Environmental Impact Assessment

The integration of cellulose acetate into circular economy models necessitates a comprehensive environmental impact assessment. This evaluation is crucial for understanding the potential ecological consequences and sustainability benefits of incorporating this biodegradable material into circular production systems.

Cellulose acetate, derived from natural cellulose sources, offers several environmental advantages over traditional petroleum-based plastics. Its biodegradability significantly reduces the persistence of waste in ecosystems, potentially mitigating the long-term environmental impacts associated with plastic pollution. However, the production process of cellulose acetate involves chemical modifications that require careful consideration of resource consumption and emissions.

In terms of carbon footprint, the lifecycle analysis of cellulose acetate in circular economy models shows promising results. The material's ability to be recycled or composted at end-of-life stages contributes to reduced greenhouse gas emissions compared to linear production models. Furthermore, the utilization of renewable cellulose sources can lead to a lower overall carbon impact, especially when sustainable forestry practices are employed.

Water usage and quality are critical factors in the environmental assessment of cellulose acetate integration. While the production process requires water, circular economy models can implement closed-loop systems to minimize water consumption and treat effluents effectively. This approach not only conserves water resources but also prevents the release of potentially harmful chemicals into aquatic ecosystems.

The impact on biodiversity must also be carefully evaluated. Sustainable sourcing of cellulose can support forest conservation efforts and maintain habitat integrity. However, increased demand for cellulose-based materials may lead to land-use changes, necessitating stringent monitoring and management practices to prevent negative impacts on local ecosystems.

Energy consumption in the production and recycling of cellulose acetate is another crucial aspect of the environmental impact assessment. Circular economy models can optimize energy efficiency through innovative manufacturing processes and the use of renewable energy sources, further reducing the overall environmental footprint of cellulose acetate products.

Waste reduction is a key benefit of integrating cellulose acetate into circular economy models. The material's biodegradability and recyclability contribute to a significant decrease in landfill waste and marine pollution. However, the effectiveness of this waste reduction depends on the implementation of proper collection and processing systems within the circular economy framework.

In conclusion, the environmental impact assessment of integrating cellulose acetate into circular economy models reveals both opportunities and challenges. While the material offers substantial benefits in terms of biodegradability and reduced carbon footprint, careful management of production processes, resource consumption, and end-of-life handling is essential to maximize its positive environmental impact and minimize potential drawbacks.

Policy and Regulatory Framework

The integration of cellulose acetate into circular economy models requires a robust policy and regulatory framework to ensure successful implementation and widespread adoption. Governments and regulatory bodies play a crucial role in creating an enabling environment for circular economy practices, particularly for materials like cellulose acetate.

One of the key policy areas that need addressing is the establishment of extended producer responsibility (EPR) schemes. These schemes would require manufacturers of cellulose acetate products to take responsibility for the entire lifecycle of their products, including collection, recycling, and disposal. Implementing EPR policies can incentivize companies to design products with circularity in mind, making them easier to recycle or reuse.

Standardization of cellulose acetate recycling processes is another critical aspect that requires regulatory attention. Developing and enforcing industry-wide standards for the collection, sorting, and recycling of cellulose acetate can ensure consistency and quality in recycled materials. This standardization can also facilitate the creation of a more efficient and cost-effective recycling infrastructure.

Tax incentives and subsidies can be powerful tools to encourage the adoption of circular economy practices for cellulose acetate. Governments can offer tax breaks or financial incentives to companies that incorporate recycled cellulose acetate into their production processes or invest in recycling technologies. Such policies can help offset the initial costs associated with transitioning to more sustainable practices.

Regulatory frameworks should also address the issue of waste management and landfill policies. Implementing stricter regulations on the disposal of cellulose acetate products can encourage recycling and reuse. This could include bans on landfilling cellulose acetate waste or implementing higher landfill taxes for non-recycled materials.

Public procurement policies can be leveraged to create demand for products made from recycled cellulose acetate. Governments can set targets for the use of recycled materials in public sector purchases, thereby stimulating the market for circular cellulose acetate products.

Education and awareness campaigns, supported by policy initiatives, are essential for promoting the circular economy concept among consumers and businesses. Regulatory bodies can mandate clear labeling of cellulose acetate products, including information on recyclability and proper disposal methods, to empower consumers to make informed choices.

International cooperation and harmonization of regulations regarding cellulose acetate circularity are crucial for creating a global circular economy. Aligning policies across borders can facilitate the movement of recycled materials and promote consistent standards worldwide.