How to Integrate Turbocharger with V8 Engine Systems?

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbocharger-V8 Integration Background and Objectives

The integration of turbochargers with V8 engine systems represents a significant milestone in automotive engineering, combining the power and prestige of V8 engines with the efficiency and performance enhancements of forced induction. This technological fusion has its roots in the early 20th century, with turbochargers first developed for aircraft engines. However, their application to automotive V8 engines gained momentum in the 1960s and 1970s, driven by the need for improved fuel efficiency without sacrificing performance.

The evolution of this integration has been marked by continuous advancements in materials science, electronic control systems, and aerodynamics. Early challenges included issues with turbo lag, heat management, and durability under high-stress conditions. As technology progressed, these obstacles were gradually overcome, leading to more refined and efficient turbocharger-V8 combinations.

Today, the primary objective of integrating turbochargers with V8 engines is to achieve a balance between high performance and improved fuel economy. This goal has become increasingly important in the face of stringent emissions regulations and growing consumer demand for environmentally friendly vehicles that do not compromise on power delivery.

The technical aims of this integration are multifaceted. Engineers strive to optimize boost pressure for maximum power output while ensuring engine longevity. They seek to minimize turbo lag for responsive acceleration across the entire RPM range. Additionally, there is a focus on thermal efficiency, aiming to harness exhaust energy effectively while managing heat dissipation to prevent component degradation.

Another critical objective is the seamless integration of turbocharger systems with the V8 engine's electronic control unit (ECU). This integration allows for precise control of boost pressure, fuel injection, and ignition timing, resulting in optimized performance under various driving conditions. Advanced control algorithms are developed to manage the complex interplay between the turbocharger and the engine, ensuring smooth power delivery and minimizing fuel consumption.

Looking forward, the trajectory of turbocharger-V8 integration is likely to be influenced by emerging technologies such as electric turbochargers and hybrid powertrains. These innovations promise to further enhance performance while meeting increasingly stringent environmental standards. The ultimate goal remains to push the boundaries of what is possible with internal combustion engines, extending their relevance in an era of automotive electrification.

The evolution of this integration has been marked by continuous advancements in materials science, electronic control systems, and aerodynamics. Early challenges included issues with turbo lag, heat management, and durability under high-stress conditions. As technology progressed, these obstacles were gradually overcome, leading to more refined and efficient turbocharger-V8 combinations.

Today, the primary objective of integrating turbochargers with V8 engines is to achieve a balance between high performance and improved fuel economy. This goal has become increasingly important in the face of stringent emissions regulations and growing consumer demand for environmentally friendly vehicles that do not compromise on power delivery.

The technical aims of this integration are multifaceted. Engineers strive to optimize boost pressure for maximum power output while ensuring engine longevity. They seek to minimize turbo lag for responsive acceleration across the entire RPM range. Additionally, there is a focus on thermal efficiency, aiming to harness exhaust energy effectively while managing heat dissipation to prevent component degradation.

Another critical objective is the seamless integration of turbocharger systems with the V8 engine's electronic control unit (ECU). This integration allows for precise control of boost pressure, fuel injection, and ignition timing, resulting in optimized performance under various driving conditions. Advanced control algorithms are developed to manage the complex interplay between the turbocharger and the engine, ensuring smooth power delivery and minimizing fuel consumption.

Looking forward, the trajectory of turbocharger-V8 integration is likely to be influenced by emerging technologies such as electric turbochargers and hybrid powertrains. These innovations promise to further enhance performance while meeting increasingly stringent environmental standards. The ultimate goal remains to push the boundaries of what is possible with internal combustion engines, extending their relevance in an era of automotive electrification.

Market Analysis for Turbocharged V8 Engines

The market for turbocharged V8 engines has experienced significant growth in recent years, driven by the increasing demand for high-performance vehicles that offer both power and efficiency. This trend is particularly evident in the luxury and sports car segments, where manufacturers are leveraging turbocharging technology to meet stringent emissions regulations while maintaining the performance characteristics that consumers expect from V8 engines.

In the luxury car market, turbocharged V8 engines have become a staple offering, with brands like BMW, Mercedes-Benz, and Audi incorporating this technology into their flagship models. These engines provide the smooth power delivery and refined sound that luxury car buyers desire, while also improving fuel efficiency compared to naturally aspirated counterparts. The market for luxury vehicles equipped with turbocharged V8 engines is expected to continue growing, especially in regions with a strong preference for high-end automobiles, such as North America, Europe, and China.

The sports car segment has also embraced turbocharged V8 engines, with manufacturers like Ferrari, McLaren, and Porsche utilizing this technology to achieve remarkable power outputs and performance figures. These engines allow sports cars to maintain their iconic V8 sound and character while meeting increasingly strict environmental standards. The market for high-performance sports cars with turbocharged V8 engines remains robust, particularly among enthusiasts and collectors who value the combination of traditional V8 appeal and cutting-edge turbocharging technology.

In the SUV market, turbocharged V8 engines have found a growing niche, especially in the high-end and performance-oriented segments. Luxury SUVs from brands like Range Rover, Bentley, and Lamborghini often feature turbocharged V8 powerplants, catering to customers who demand both utility and high performance. This market segment is expected to expand further as more manufacturers enter the luxury SUV space and existing players continue to refine their offerings.

The aftermarket and tuning industry has also benefited from the proliferation of turbocharged V8 engines. Tuning companies and performance parts manufacturers have developed a wide range of products and services tailored to these engines, allowing enthusiasts to further enhance power output and performance. This has created a thriving ecosystem of aftermarket support, contributing to the overall market growth for turbocharged V8 engines.

However, the market for turbocharged V8 engines faces challenges from emerging technologies and shifting consumer preferences. The increasing focus on electrification and the gradual transition towards hybrid and fully electric powertrains pose a long-term threat to the dominance of internal combustion engines, including turbocharged V8s. Additionally, some markets are experiencing a shift towards smaller, more efficient engines, which could impact the demand for larger V8 powerplants in certain vehicle segments.

In the luxury car market, turbocharged V8 engines have become a staple offering, with brands like BMW, Mercedes-Benz, and Audi incorporating this technology into their flagship models. These engines provide the smooth power delivery and refined sound that luxury car buyers desire, while also improving fuel efficiency compared to naturally aspirated counterparts. The market for luxury vehicles equipped with turbocharged V8 engines is expected to continue growing, especially in regions with a strong preference for high-end automobiles, such as North America, Europe, and China.

The sports car segment has also embraced turbocharged V8 engines, with manufacturers like Ferrari, McLaren, and Porsche utilizing this technology to achieve remarkable power outputs and performance figures. These engines allow sports cars to maintain their iconic V8 sound and character while meeting increasingly strict environmental standards. The market for high-performance sports cars with turbocharged V8 engines remains robust, particularly among enthusiasts and collectors who value the combination of traditional V8 appeal and cutting-edge turbocharging technology.

In the SUV market, turbocharged V8 engines have found a growing niche, especially in the high-end and performance-oriented segments. Luxury SUVs from brands like Range Rover, Bentley, and Lamborghini often feature turbocharged V8 powerplants, catering to customers who demand both utility and high performance. This market segment is expected to expand further as more manufacturers enter the luxury SUV space and existing players continue to refine their offerings.

The aftermarket and tuning industry has also benefited from the proliferation of turbocharged V8 engines. Tuning companies and performance parts manufacturers have developed a wide range of products and services tailored to these engines, allowing enthusiasts to further enhance power output and performance. This has created a thriving ecosystem of aftermarket support, contributing to the overall market growth for turbocharged V8 engines.

However, the market for turbocharged V8 engines faces challenges from emerging technologies and shifting consumer preferences. The increasing focus on electrification and the gradual transition towards hybrid and fully electric powertrains pose a long-term threat to the dominance of internal combustion engines, including turbocharged V8s. Additionally, some markets are experiencing a shift towards smaller, more efficient engines, which could impact the demand for larger V8 powerplants in certain vehicle segments.

Current Challenges in Turbocharger-V8 Integration

The integration of turbochargers with V8 engine systems presents several significant challenges that engineers and manufacturers must overcome. One of the primary difficulties lies in managing the increased heat generated by the turbocharger. V8 engines already produce substantial heat, and the addition of a turbocharger further exacerbates this issue. This excess heat can lead to reduced engine efficiency, increased wear on components, and potential reliability issues if not properly addressed.

Another major challenge is the packaging constraints within the engine bay. V8 engines typically occupy a large portion of the available space, leaving limited room for additional components. Integrating a turbocharger system, which includes the turbocharger itself, intercooler, and associated piping, requires careful design considerations to ensure proper fitment without compromising other essential systems or affecting vehicle balance.

Turbocharger lag is a persistent issue that engineers must contend with when integrating these systems. V8 engines are known for their immediate power delivery, and the introduction of turbocharging can potentially introduce a delay in throttle response. Mitigating this lag while maintaining the characteristic V8 performance is a delicate balancing act that requires sophisticated engine management systems and precise tuning.

The increased pressure and stress on engine components due to turbocharging also pose significant challenges. V8 engines must be reinforced to withstand the higher cylinder pressures and temperatures associated with forced induction. This often necessitates upgrades to the engine block, head gaskets, pistons, and connecting rods, which can substantially increase production costs and complexity.

Emissions control presents another hurdle in turbocharger-V8 integration. While turbocharging can improve fuel efficiency, it can also lead to increased NOx emissions due to higher combustion temperatures. Engineers must implement advanced emission control technologies and fine-tune the engine management system to ensure compliance with increasingly stringent environmental regulations.

Lastly, maintaining the distinctive V8 sound signature while incorporating a turbocharger system is a challenge that should not be underestimated. The turbocharger can muffle the engine's natural exhaust note, potentially diminishing the auditory experience that many enthusiasts associate with V8 engines. Developing exhaust systems that preserve the V8's characteristic sound while accommodating the turbocharger requires innovative acoustic engineering solutions.

Another major challenge is the packaging constraints within the engine bay. V8 engines typically occupy a large portion of the available space, leaving limited room for additional components. Integrating a turbocharger system, which includes the turbocharger itself, intercooler, and associated piping, requires careful design considerations to ensure proper fitment without compromising other essential systems or affecting vehicle balance.

Turbocharger lag is a persistent issue that engineers must contend with when integrating these systems. V8 engines are known for their immediate power delivery, and the introduction of turbocharging can potentially introduce a delay in throttle response. Mitigating this lag while maintaining the characteristic V8 performance is a delicate balancing act that requires sophisticated engine management systems and precise tuning.

The increased pressure and stress on engine components due to turbocharging also pose significant challenges. V8 engines must be reinforced to withstand the higher cylinder pressures and temperatures associated with forced induction. This often necessitates upgrades to the engine block, head gaskets, pistons, and connecting rods, which can substantially increase production costs and complexity.

Emissions control presents another hurdle in turbocharger-V8 integration. While turbocharging can improve fuel efficiency, it can also lead to increased NOx emissions due to higher combustion temperatures. Engineers must implement advanced emission control technologies and fine-tune the engine management system to ensure compliance with increasingly stringent environmental regulations.

Lastly, maintaining the distinctive V8 sound signature while incorporating a turbocharger system is a challenge that should not be underestimated. The turbocharger can muffle the engine's natural exhaust note, potentially diminishing the auditory experience that many enthusiasts associate with V8 engines. Developing exhaust systems that preserve the V8's characteristic sound while accommodating the turbocharger requires innovative acoustic engineering solutions.

Existing Turbocharger-V8 Integration Solutions

01 Turbocharger design and configuration

This category focuses on the overall design and configuration of turbochargers, including improvements in compressor and turbine wheel designs, housing configurations, and integration with engine systems. These advancements aim to enhance efficiency, reduce lag, and improve overall engine performance.- Turbocharger design and configuration: This category focuses on the overall design and configuration of turbochargers, including improvements in compressor and turbine wheel designs, housing structures, and integration with engine systems. These advancements aim to enhance efficiency, reduce lag, and optimize performance across various operating conditions.

- Variable geometry turbocharger systems: Variable geometry turbocharger systems allow for adjustable turbine geometry to optimize performance across a wide range of engine speeds and loads. This technology includes movable vanes or nozzles that can alter the flow of exhaust gases, improving low-end torque and reducing turbo lag while maintaining high-end performance.

- Electric turbocharger integration: Electric turbochargers, also known as e-turbos, incorporate an electric motor to assist in spooling up the turbocharger at low engine speeds. This technology aims to eliminate turbo lag and improve overall engine responsiveness. The integration of electric turbochargers with conventional engine systems presents unique challenges and opportunities for performance enhancement.

- Multi-stage turbocharging systems: Multi-stage turbocharging systems involve the use of two or more turbochargers working in series or parallel to optimize performance across a broader range of engine operating conditions. These systems can include combinations of differently sized turbochargers or variable geometry turbochargers to achieve better low-end response and high-end power.

- Turbocharger cooling and lubrication integration: This category addresses the integration of cooling and lubrication systems for turbochargers. Proper cooling and lubrication are crucial for turbocharger longevity and performance, especially in high-performance applications. Innovations in this area include improved oil flow designs, water-cooled bearings, and integrated cooling passages within the turbocharger housing.

02 Variable geometry turbocharger systems

Variable geometry turbocharger systems allow for adjustable turbine geometry to optimize performance across a wide range of engine operating conditions. This technology includes movable vanes or nozzles that can be adjusted to control exhaust gas flow, improving boost response and efficiency.Expand Specific Solutions03 Turbocharger integration with exhaust systems

This category covers the integration of turbochargers with exhaust systems, including exhaust manifold designs, wastegate configurations, and exhaust gas recirculation (EGR) systems. These integrations aim to optimize exhaust flow, reduce backpressure, and improve overall engine efficiency.Expand Specific Solutions04 Electric-assisted turbocharging systems

Electric-assisted turbocharging systems incorporate electric motors to supplement the turbocharger's operation, reducing turbo lag and improving low-end torque. These systems can include electric compressors or motor-generators integrated into the turbocharger shaft.Expand Specific Solutions05 Turbocharger control and monitoring systems

This category encompasses advanced control and monitoring systems for turbochargers, including sensors, actuators, and electronic control units. These systems optimize turbocharger performance, manage boost pressure, and integrate with engine management systems for improved efficiency and reliability.Expand Specific Solutions

Key Players in Turbocharged V8 Engine Market

The integration of turbochargers with V8 engine systems is a mature technology in the automotive industry, with the market currently in a growth phase. The global turbocharger market size is projected to reach $24.1 billion by 2025, driven by increasing demand for fuel-efficient vehicles. Key players like BorgWarner, Garrett Motion, and Honeywell dominate the market, leveraging their extensive experience and R&D capabilities. Emerging companies such as SuperTurbo Technologies are also innovating in this space. Major automakers including BMW, Ford, and Toyota are actively incorporating advanced turbocharging technologies into their V8 engines to meet stringent emissions regulations while maintaining performance. The technology continues to evolve, with a focus on improving efficiency, reducing lag, and integrating with hybrid powertrains.

BorgWarner, Inc.

Technical Solution: BorgWarner's advanced turbocharger integration with V8 engine systems focuses on their eTurbo™ technology. This electrically assisted turbocharger combines a traditional turbocharger with an electric motor, allowing for faster response times and improved low-end torque. The system utilizes a high-speed electric motor directly coupled to the turbocharger shaft, which can spin up the compressor wheel rapidly, eliminating turbo lag[1]. BorgWarner's solution also incorporates advanced materials such as titanium impellers and ceramic ball bearings to withstand high temperatures and rotational speeds, enhancing durability and performance[2]. The company's dual volute turbine housing design further optimizes exhaust gas flow, improving overall engine efficiency[3].

Strengths: Reduced turbo lag, improved low-end torque, and enhanced overall engine efficiency. Weaknesses: Higher system complexity and potential increased costs due to the addition of electrical components.

GM Global Technology Operations LLC

Technical Solution: GM's approach to integrating turbochargers with V8 engine systems is exemplified in their LT4 supercharged 6.2L V8 engine, which utilizes a unique hybrid forced induction system. This system combines a traditional supercharger with elements of turbocharging technology. The LT4 engine employs an Eaton R1740 TVS supercharger with a compact intercooler, capable of spinning at up to 20,000 RPM[4]. To manage heat and improve efficiency, GM incorporates a charge air cooler integrated within the supercharger housing. The system also features active fuel management and variable valve timing to optimize performance and fuel economy[5]. GM's design allows for a broader torque curve and improved throttle response compared to traditional turbocharged systems.

Strengths: Immediate throttle response, broad torque curve, and packaging efficiency. Weaknesses: Potentially higher parasitic losses at low engine speeds compared to pure turbocharging systems.

Core Innovations in Turbocharger-V8 Systems

Turbocharger system for an internal combustion engine

PatentInactiveEP1625290A2

Innovation

- A two-stage turbocharger system with radial-type compressors and turbines, featuring backswept blades with a blade angle of at least 40 degrees, a short intermediate duct connecting the high-pressure and low-pressure turbines, and inlet guide rails for optimized energy extraction and air pressurization, achieving efficiencies between 65% and 70%.

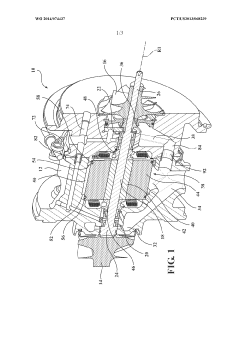

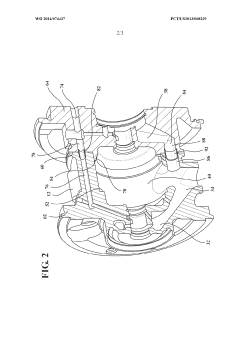

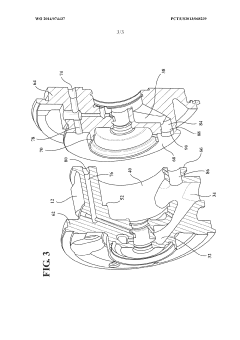

Method for joining bearing housing segments of a turbocharger incorporating an electric motor

PatentWO2014074437A1

Innovation

- A split bearing housing design is implemented, comprising two segments with aligned channels and dowels to facilitate the assembly of the electric motor components, ensuring fluid flow and maintaining angular orientation, allowing for the insertion and secure positioning of the rotor and stator within the housing.

Environmental Impact and Regulations

The integration of turbochargers with V8 engine systems has significant environmental implications and is subject to increasingly stringent regulations. Turbocharging technology has emerged as a key solution for improving engine efficiency and reducing emissions, particularly in high-performance V8 engines. By forcing more air into the combustion chamber, turbochargers enable engines to burn fuel more efficiently, resulting in improved power output and reduced fuel consumption.

From an environmental perspective, the implementation of turbochargers in V8 engines has led to notable reductions in greenhouse gas emissions. Carbon dioxide (CO2) emissions, which are directly linked to fuel consumption, have seen substantial decreases in turbocharged V8 engines compared to their naturally aspirated counterparts. This improvement aligns with global efforts to combat climate change and meets increasingly strict emissions standards set by regulatory bodies worldwide.

Nitrogen oxide (NOx) emissions, a major concern for air quality and public health, have also been addressed through turbocharging technology. Advanced turbocharger designs, coupled with precise engine management systems, have enabled manufacturers to optimize combustion processes, resulting in lower NOx emissions without compromising performance. This has been crucial in meeting stringent emissions regulations such as Euro 6 in Europe and Tier 3 in the United States.

Regulatory frameworks governing vehicle emissions have played a significant role in driving the adoption of turbocharging technology in V8 engines. The Corporate Average Fuel Economy (CAFE) standards in the United States and similar regulations in other regions have pushed manufacturers to seek innovative solutions for improving fuel efficiency. Turbocharging has emerged as a cost-effective means of meeting these standards while maintaining the power and performance characteristics expected from V8 engines.

However, the integration of turbochargers with V8 engines is not without challenges from an environmental standpoint. The increased thermal load associated with turbocharging can lead to higher engine temperatures, potentially increasing the formation of certain pollutants. To address this, manufacturers have had to invest in advanced cooling systems and thermal management strategies, adding complexity and cost to engine designs.

Looking ahead, the environmental impact of turbocharged V8 engines will continue to be scrutinized as regulations evolve. Future emissions standards are expected to become even more stringent, potentially driving further innovations in turbocharger technology and engine design. This may include the development of electric turbochargers, which could offer improved response times and efficiency, further reducing emissions and fuel consumption.

From an environmental perspective, the implementation of turbochargers in V8 engines has led to notable reductions in greenhouse gas emissions. Carbon dioxide (CO2) emissions, which are directly linked to fuel consumption, have seen substantial decreases in turbocharged V8 engines compared to their naturally aspirated counterparts. This improvement aligns with global efforts to combat climate change and meets increasingly strict emissions standards set by regulatory bodies worldwide.

Nitrogen oxide (NOx) emissions, a major concern for air quality and public health, have also been addressed through turbocharging technology. Advanced turbocharger designs, coupled with precise engine management systems, have enabled manufacturers to optimize combustion processes, resulting in lower NOx emissions without compromising performance. This has been crucial in meeting stringent emissions regulations such as Euro 6 in Europe and Tier 3 in the United States.

Regulatory frameworks governing vehicle emissions have played a significant role in driving the adoption of turbocharging technology in V8 engines. The Corporate Average Fuel Economy (CAFE) standards in the United States and similar regulations in other regions have pushed manufacturers to seek innovative solutions for improving fuel efficiency. Turbocharging has emerged as a cost-effective means of meeting these standards while maintaining the power and performance characteristics expected from V8 engines.

However, the integration of turbochargers with V8 engines is not without challenges from an environmental standpoint. The increased thermal load associated with turbocharging can lead to higher engine temperatures, potentially increasing the formation of certain pollutants. To address this, manufacturers have had to invest in advanced cooling systems and thermal management strategies, adding complexity and cost to engine designs.

Looking ahead, the environmental impact of turbocharged V8 engines will continue to be scrutinized as regulations evolve. Future emissions standards are expected to become even more stringent, potentially driving further innovations in turbocharger technology and engine design. This may include the development of electric turbochargers, which could offer improved response times and efficiency, further reducing emissions and fuel consumption.

Performance Optimization Strategies

Integrating a turbocharger with a V8 engine system requires careful consideration of various performance optimization strategies to maximize the benefits of forced induction while maintaining reliability and efficiency. One key approach is to optimize the turbocharger sizing and configuration. This involves selecting a turbocharger with the appropriate compressor and turbine sizes to match the engine's airflow requirements across its operating range. Proper sizing ensures quick spool-up for responsive low-end torque while providing sufficient airflow at higher RPMs.

Another critical strategy is the implementation of advanced boost control systems. These systems utilize electronic wastegates or variable geometry turbochargers to precisely regulate boost pressure based on engine load, speed, and environmental conditions. By dynamically adjusting boost levels, the engine can maintain optimal performance and efficiency across various driving scenarios.

Intercooling plays a vital role in performance optimization for turbocharged V8 engines. An efficient intercooler system reduces the temperature of the compressed air, increasing its density and allowing for higher boost pressures without risking detonation. Careful design of the intercooler's size, placement, and airflow characteristics is essential to minimize pressure drop and maximize cooling effectiveness.

Fuel system upgrades are often necessary to support the increased airflow and power output of a turbocharged V8. This may include higher-flow fuel injectors, an upgraded fuel pump, and revised fuel mapping to ensure proper air-fuel ratios under boosted conditions. Additionally, implementing direct fuel injection can improve charge cooling and allow for higher compression ratios, further enhancing performance and efficiency.

Engine management system calibration is crucial for optimizing the performance of a turbocharged V8. This involves fine-tuning parameters such as ignition timing, fuel injection duration, and boost control to maximize power output while maintaining reliability. Advanced features like anti-lag systems and launch control can be integrated to improve transient response and acceleration performance.

Exhaust system design is another critical aspect of performance optimization. A well-designed exhaust manifold and downpipe can reduce backpressure and improve turbine efficiency. Variable exhaust systems, such as switchable valves or active mufflers, can provide an optimal balance between performance, sound, and emissions compliance across different operating conditions.

Lastly, thermal management strategies are essential for maintaining consistent performance and longevity in turbocharged V8 engines. This may include upgraded cooling systems, heat shielding, and oil cooling solutions to manage the increased heat generated by forced induction. Implementing advanced materials and coatings can also improve heat dissipation and reduce thermal stress on critical components.

Another critical strategy is the implementation of advanced boost control systems. These systems utilize electronic wastegates or variable geometry turbochargers to precisely regulate boost pressure based on engine load, speed, and environmental conditions. By dynamically adjusting boost levels, the engine can maintain optimal performance and efficiency across various driving scenarios.

Intercooling plays a vital role in performance optimization for turbocharged V8 engines. An efficient intercooler system reduces the temperature of the compressed air, increasing its density and allowing for higher boost pressures without risking detonation. Careful design of the intercooler's size, placement, and airflow characteristics is essential to minimize pressure drop and maximize cooling effectiveness.

Fuel system upgrades are often necessary to support the increased airflow and power output of a turbocharged V8. This may include higher-flow fuel injectors, an upgraded fuel pump, and revised fuel mapping to ensure proper air-fuel ratios under boosted conditions. Additionally, implementing direct fuel injection can improve charge cooling and allow for higher compression ratios, further enhancing performance and efficiency.

Engine management system calibration is crucial for optimizing the performance of a turbocharged V8. This involves fine-tuning parameters such as ignition timing, fuel injection duration, and boost control to maximize power output while maintaining reliability. Advanced features like anti-lag systems and launch control can be integrated to improve transient response and acceleration performance.

Exhaust system design is another critical aspect of performance optimization. A well-designed exhaust manifold and downpipe can reduce backpressure and improve turbine efficiency. Variable exhaust systems, such as switchable valves or active mufflers, can provide an optimal balance between performance, sound, and emissions compliance across different operating conditions.

Lastly, thermal management strategies are essential for maintaining consistent performance and longevity in turbocharged V8 engines. This may include upgraded cooling systems, heat shielding, and oil cooling solutions to manage the increased heat generated by forced induction. Implementing advanced materials and coatings can also improve heat dissipation and reduce thermal stress on critical components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!