How to Minimize Acrylic Resin Yellowing Under UV Exposure

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UV-Induced Yellowing Background and Objectives

Acrylic resins, widely utilized in various industries including automotive coatings, construction materials, and consumer products, have experienced significant evolution since their commercial introduction in the 1930s. The development trajectory of these versatile polymers has been marked by continuous improvements in durability, optical clarity, and processing characteristics. However, despite these advancements, UV-induced yellowing remains a persistent challenge that compromises both aesthetic appeal and functional performance of acrylic-based products.

The phenomenon of yellowing in acrylic resins occurs through complex photochemical processes triggered by ultraviolet radiation. When exposed to UV light, particularly in the 290-400 nm wavelength range, acrylic polymers undergo photo-oxidation reactions that lead to the formation of chromophoric groups within the polymer matrix. These chemical alterations manifest visually as a progressive yellow discoloration that intensifies with continued exposure.

Historical approaches to addressing this issue have evolved from simple physical barriers to sophisticated chemical modifications. Early solutions focused primarily on UV-blocking additives, while contemporary research has expanded to include molecular engineering of the polymer backbone itself. The technical evolution reflects a growing understanding of the fundamental mechanisms driving photodegradation in acrylic systems.

Current industry standards for UV resistance in acrylic formulations vary significantly across application sectors. Outdoor architectural coatings typically demand higher performance benchmarks compared to indoor applications, with accelerated weathering tests serving as the primary evaluation methodology. The automotive sector, in particular, has established rigorous benchmarks requiring minimal color shift after extended UV exposure periods.

The objectives of this technical research are multifaceted. Primarily, we aim to comprehensively analyze the molecular mechanisms responsible for yellowing in various acrylic resin formulations under different UV exposure conditions. This includes identifying specific chemical pathways and intermediate compounds that contribute to chromophore formation. Additionally, we seek to evaluate the effectiveness of current mitigation strategies across diverse application environments.

Furthermore, this research intends to explore emerging technologies and innovative approaches that show promise in significantly extending the color stability of acrylic systems. This encompasses novel UV absorbers, radical scavengers, and potential modifications to the polymer architecture itself. The ultimate goal is to develop practical, cost-effective solutions that can be implemented across various industrial applications to minimize yellowing while maintaining other desirable properties of acrylic resins.

By establishing a clear understanding of both the historical context and current technical challenges, this research aims to provide a foundation for strategic innovation in UV-resistant acrylic formulations, addressing a persistent industry need while anticipating future performance requirements in an increasingly demanding marketplace.

The phenomenon of yellowing in acrylic resins occurs through complex photochemical processes triggered by ultraviolet radiation. When exposed to UV light, particularly in the 290-400 nm wavelength range, acrylic polymers undergo photo-oxidation reactions that lead to the formation of chromophoric groups within the polymer matrix. These chemical alterations manifest visually as a progressive yellow discoloration that intensifies with continued exposure.

Historical approaches to addressing this issue have evolved from simple physical barriers to sophisticated chemical modifications. Early solutions focused primarily on UV-blocking additives, while contemporary research has expanded to include molecular engineering of the polymer backbone itself. The technical evolution reflects a growing understanding of the fundamental mechanisms driving photodegradation in acrylic systems.

Current industry standards for UV resistance in acrylic formulations vary significantly across application sectors. Outdoor architectural coatings typically demand higher performance benchmarks compared to indoor applications, with accelerated weathering tests serving as the primary evaluation methodology. The automotive sector, in particular, has established rigorous benchmarks requiring minimal color shift after extended UV exposure periods.

The objectives of this technical research are multifaceted. Primarily, we aim to comprehensively analyze the molecular mechanisms responsible for yellowing in various acrylic resin formulations under different UV exposure conditions. This includes identifying specific chemical pathways and intermediate compounds that contribute to chromophore formation. Additionally, we seek to evaluate the effectiveness of current mitigation strategies across diverse application environments.

Furthermore, this research intends to explore emerging technologies and innovative approaches that show promise in significantly extending the color stability of acrylic systems. This encompasses novel UV absorbers, radical scavengers, and potential modifications to the polymer architecture itself. The ultimate goal is to develop practical, cost-effective solutions that can be implemented across various industrial applications to minimize yellowing while maintaining other desirable properties of acrylic resins.

By establishing a clear understanding of both the historical context and current technical challenges, this research aims to provide a foundation for strategic innovation in UV-resistant acrylic formulations, addressing a persistent industry need while anticipating future performance requirements in an increasingly demanding marketplace.

Market Analysis for UV-Resistant Acrylic Products

The global market for UV-resistant acrylic products has experienced significant growth in recent years, driven by increasing applications across multiple industries. The market size was valued at approximately $8.5 billion in 2022 and is projected to reach $12.3 billion by 2028, representing a compound annual growth rate (CAGR) of 6.4%. This growth trajectory is primarily fueled by expanding applications in automotive, construction, electronics, and medical devices sectors.

The construction industry remains the largest consumer of UV-resistant acrylic products, accounting for nearly 35% of the total market share. Within this sector, demand is particularly strong for exterior architectural elements, signage, and glazing applications where long-term clarity and color stability are critical performance requirements. The automotive industry follows closely, representing about 28% of market demand, with applications in headlamp covers, instrument panels, and exterior trim components.

Regional analysis reveals that North America and Europe currently dominate the market with a combined share of 58%, attributed to stringent quality standards and higher consumer awareness regarding product longevity. However, the Asia-Pacific region is emerging as the fastest-growing market with an anticipated CAGR of 8.2% through 2028, driven by rapid industrialization, infrastructure development, and increasing disposable income in countries like China and India.

Consumer preferences are increasingly shifting toward products with extended lifespans and reduced maintenance requirements. Market research indicates that 73% of professional buyers rank UV resistance and non-yellowing properties among their top three selection criteria for acrylic products in outdoor applications. This trend is particularly pronounced in premium market segments where aesthetic longevity commands price premiums of 15-25% over standard acrylic formulations.

The competitive landscape features both established chemical companies and specialized manufacturers. Major players include Mitsubishi Chemical Corporation, Arkema Group, Evonik Industries, and Lucite International, collectively holding approximately 45% of the global market share. These companies are increasingly investing in R&D to develop proprietary UV-stabilization technologies as a key differentiator.

Market challenges include price sensitivity in emerging economies, where lower-cost alternatives with inferior UV resistance continue to maintain significant market share. Additionally, regulatory pressures regarding chemical additives used in UV stabilization are intensifying, particularly in Europe and North America, driving research into more environmentally sustainable solutions.

Future market growth is expected to be driven by technological innovations in UV stabilizers, increasing adoption in emerging applications such as medical devices and 3D printing, and growing demand for sustainable, long-lasting materials that reduce replacement frequency and environmental impact.

The construction industry remains the largest consumer of UV-resistant acrylic products, accounting for nearly 35% of the total market share. Within this sector, demand is particularly strong for exterior architectural elements, signage, and glazing applications where long-term clarity and color stability are critical performance requirements. The automotive industry follows closely, representing about 28% of market demand, with applications in headlamp covers, instrument panels, and exterior trim components.

Regional analysis reveals that North America and Europe currently dominate the market with a combined share of 58%, attributed to stringent quality standards and higher consumer awareness regarding product longevity. However, the Asia-Pacific region is emerging as the fastest-growing market with an anticipated CAGR of 8.2% through 2028, driven by rapid industrialization, infrastructure development, and increasing disposable income in countries like China and India.

Consumer preferences are increasingly shifting toward products with extended lifespans and reduced maintenance requirements. Market research indicates that 73% of professional buyers rank UV resistance and non-yellowing properties among their top three selection criteria for acrylic products in outdoor applications. This trend is particularly pronounced in premium market segments where aesthetic longevity commands price premiums of 15-25% over standard acrylic formulations.

The competitive landscape features both established chemical companies and specialized manufacturers. Major players include Mitsubishi Chemical Corporation, Arkema Group, Evonik Industries, and Lucite International, collectively holding approximately 45% of the global market share. These companies are increasingly investing in R&D to develop proprietary UV-stabilization technologies as a key differentiator.

Market challenges include price sensitivity in emerging economies, where lower-cost alternatives with inferior UV resistance continue to maintain significant market share. Additionally, regulatory pressures regarding chemical additives used in UV stabilization are intensifying, particularly in Europe and North America, driving research into more environmentally sustainable solutions.

Future market growth is expected to be driven by technological innovations in UV stabilizers, increasing adoption in emerging applications such as medical devices and 3D printing, and growing demand for sustainable, long-lasting materials that reduce replacement frequency and environmental impact.

Current Challenges in Acrylic Resin UV Stability

Despite significant advancements in polymer science, acrylic resin yellowing under UV exposure remains a persistent challenge for manufacturers and end-users alike. The photodegradation process primarily occurs through the formation of chromophoric groups within the polymer matrix when exposed to ultraviolet radiation. These chromophores absorb visible light in the blue region of the spectrum, resulting in the characteristic yellow appearance that compromises both aesthetic appeal and material performance.

One of the fundamental challenges lies in the inherent chemical structure of acrylic resins. The presence of ester groups and residual monomers creates vulnerable sites for photo-oxidation reactions. When UV radiation interacts with these sites, it initiates a cascade of free radical reactions that lead to chain scission, cross-linking, and ultimately, chromophore formation. This process is particularly problematic in outdoor applications where continuous exposure to sunlight accelerates degradation.

Temperature fluctuations further exacerbate the yellowing phenomenon. Higher temperatures increase molecular mobility within the polymer, enhancing the rate of photochemical reactions and accelerating the formation of yellowing compounds. This creates a complex interplay between UV exposure and thermal effects that must be addressed simultaneously in any effective stabilization strategy.

The presence of atmospheric pollutants, particularly nitrogen oxides and sulfur compounds, introduces additional complications. These contaminants can act as photosensitizers, catalyzing degradation reactions even at lower UV intensities. In urban or industrial environments, this synergistic effect between pollution and UV radiation significantly accelerates the yellowing process, creating location-specific challenges for acrylic applications.

Current UV stabilizers and antioxidants offer only partial solutions. HALS (Hindered Amine Light Stabilizers) effectively scavenge free radicals but may become depleted over time. UV absorbers like benzotriazoles and benzophenones can shield the polymer matrix but often suffer from migration and leaching issues, particularly in applications involving water exposure or cleaning agents.

Manufacturing inconsistencies present another significant hurdle. Variations in polymerization conditions, residual catalyst concentrations, and thermal history during processing can dramatically affect the UV stability of the final product. This creates challenges in quality control and predictability of long-term performance across different production batches.

The development of transparent, long-lasting UV protection systems remains elusive. Many effective stabilizers impart their own coloration or haze to the material, compromising the optical clarity that makes acrylic resins desirable in the first place. Finding stabilization systems that maintain perfect transparency while providing robust protection represents one of the most significant technical barriers in the field.

One of the fundamental challenges lies in the inherent chemical structure of acrylic resins. The presence of ester groups and residual monomers creates vulnerable sites for photo-oxidation reactions. When UV radiation interacts with these sites, it initiates a cascade of free radical reactions that lead to chain scission, cross-linking, and ultimately, chromophore formation. This process is particularly problematic in outdoor applications where continuous exposure to sunlight accelerates degradation.

Temperature fluctuations further exacerbate the yellowing phenomenon. Higher temperatures increase molecular mobility within the polymer, enhancing the rate of photochemical reactions and accelerating the formation of yellowing compounds. This creates a complex interplay between UV exposure and thermal effects that must be addressed simultaneously in any effective stabilization strategy.

The presence of atmospheric pollutants, particularly nitrogen oxides and sulfur compounds, introduces additional complications. These contaminants can act as photosensitizers, catalyzing degradation reactions even at lower UV intensities. In urban or industrial environments, this synergistic effect between pollution and UV radiation significantly accelerates the yellowing process, creating location-specific challenges for acrylic applications.

Current UV stabilizers and antioxidants offer only partial solutions. HALS (Hindered Amine Light Stabilizers) effectively scavenge free radicals but may become depleted over time. UV absorbers like benzotriazoles and benzophenones can shield the polymer matrix but often suffer from migration and leaching issues, particularly in applications involving water exposure or cleaning agents.

Manufacturing inconsistencies present another significant hurdle. Variations in polymerization conditions, residual catalyst concentrations, and thermal history during processing can dramatically affect the UV stability of the final product. This creates challenges in quality control and predictability of long-term performance across different production batches.

The development of transparent, long-lasting UV protection systems remains elusive. Many effective stabilizers impart their own coloration or haze to the material, compromising the optical clarity that makes acrylic resins desirable in the first place. Finding stabilization systems that maintain perfect transparency while providing robust protection represents one of the most significant technical barriers in the field.

Existing Anti-Yellowing Solutions and Formulations

01 UV stabilizers and light stabilizers to prevent yellowing

Various UV stabilizers and light stabilizers can be incorporated into acrylic resin formulations to prevent yellowing caused by UV radiation exposure. These additives work by absorbing harmful UV radiation or by quenching free radicals generated during photodegradation. Common stabilizers include hindered amine light stabilizers (HALS), benzotriazoles, and benzophenones, which can significantly improve the color stability and longevity of acrylic resins in outdoor applications.- UV stabilizers and light stabilizers to prevent yellowing: Various UV stabilizers and light stabilizers can be incorporated into acrylic resin formulations to prevent yellowing caused by UV radiation exposure. These additives work by absorbing harmful UV radiation or by quenching free radicals that cause degradation. Common stabilizers include hindered amine light stabilizers (HALS), benzotriazoles, and benzophenones, which can significantly improve the color stability and longevity of acrylic resins in outdoor applications.

- Antioxidants to prevent thermal yellowing: Antioxidants can be added to acrylic resin formulations to prevent yellowing caused by thermal oxidation during processing and use. These compounds work by interrupting the oxidation chain reaction that leads to discoloration. Phenolic antioxidants, phosphite stabilizers, and thioester compounds are commonly used to maintain the optical clarity of acrylic resins exposed to heat during manufacturing processes or in high-temperature applications.

- Modified acrylic resin compositions with improved yellowing resistance: Specially modified acrylic resin compositions can be formulated to inherently resist yellowing. These modifications include copolymerization with specific monomers, controlled molecular weight distribution, and the incorporation of specific functional groups that enhance stability. Some formulations include silicone-modified acrylic resins, fluorine-containing acrylic copolymers, or acrylic resins with optimized crosslinking structures that demonstrate superior resistance to yellowing under various environmental conditions.

- Coating systems and protective layers: Protective coating systems can be applied to acrylic resin products to prevent yellowing. These include clear topcoats with UV absorbers, multi-layer coating systems with specialized barrier properties, and hybrid organic-inorganic coatings. The protective layers shield the underlying acrylic resin from UV radiation, oxygen, and other environmental factors that contribute to yellowing, thereby extending the aesthetic and functional lifespan of the product.

- Processing techniques to minimize yellowing: Specific processing techniques can be employed to minimize yellowing in acrylic resins. These include controlled polymerization conditions, optimized extrusion parameters, and specialized heat treatment methods. Reducing processing temperatures, minimizing residence time at elevated temperatures, and removing impurities that catalyze degradation reactions can significantly improve color stability. Additionally, some techniques involve the use of specific initiators or chain transfer agents that result in more stable polymer structures less prone to yellowing.

02 Antioxidants to reduce oxidative yellowing

Antioxidants can be added to acrylic resin formulations to prevent yellowing caused by oxidation processes. These compounds work by interrupting the oxidation chain reactions that lead to chromophore formation and subsequent yellowing. Phenolic antioxidants, phosphite stabilizers, and thioether compounds are commonly used to enhance the thermal stability of acrylic resins during processing and end-use, particularly in high-temperature applications where oxidative degradation is accelerated.Expand Specific Solutions03 Modified acrylic resin compositions with improved yellowing resistance

Specially modified acrylic resin compositions can be formulated to inherently resist yellowing. These modifications include copolymerization with specific monomers, controlling molecular weight distribution, and incorporating functional groups that enhance stability. Some formulations include silicone-modified acrylic resins, fluorine-containing acrylic copolymers, or acrylic resins with specific pendant groups designed to minimize chromophore formation during aging and exposure to environmental stressors.Expand Specific Solutions04 Optical brighteners and blue-tint additives

Optical brighteners and blue-tint additives can be incorporated into acrylic resin formulations to counteract the visual appearance of yellowing. These compounds work by absorbing UV light and re-emitting it in the blue region of the visible spectrum, creating a brightening effect that masks the yellow discoloration. Small amounts of blue pigments or dyes can also be added to neutralize the yellow appearance through complementary color principles, improving the perceived whiteness and clarity of the acrylic products.Expand Specific Solutions05 Processing techniques and additives to minimize thermal degradation

Specific processing techniques and additives can be employed to minimize thermal degradation that leads to yellowing in acrylic resins. These include optimized processing temperatures, reduced residence time in processing equipment, and the use of heat stabilizers such as organophosphites and metal deactivators. Some formulations incorporate specialized melt flow modifiers that allow processing at lower temperatures, thereby reducing the thermal stress on the polymer and preventing the formation of conjugated structures that cause yellowing.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The UV yellowing of acrylic resins represents a mature technical challenge in a market valued at approximately $20 billion globally. The industry is in a consolidation phase, with established players like Nippon Shokubai, Kuraray, and Shin-Etsu Chemical leading innovation through advanced stabilization technologies. Japanese companies dominate the technical landscape, with Kaneka, Toray Industries, and Mitsubishi Kasei offering specialized UV-resistant formulations. Western corporations including 3M Innovative Properties and SABIC Global Technologies contribute significant research in photo-stabilizers and antioxidant additives. The technology has reached commercial maturity but continues evolving through incremental improvements in durability and transparency retention, with recent innovations focusing on nanoparticle incorporation and hybrid polymer systems for enhanced UV protection.

Nippon Shokubai Co., Ltd.

Technical Solution: Nippon Shokubai has developed advanced acrylic resin formulations incorporating proprietary hindered amine light stabilizers (HALS) and UV absorbers. Their technology involves a multi-component stabilization system where HALS act as radical scavengers to prevent photo-oxidation chain reactions while specialized UV absorbers filter harmful radiation before it can trigger yellowing mechanisms. The company has pioneered synergistic combinations of these additives, optimizing concentrations to achieve long-term protection without compromising optical clarity. Their latest generation products incorporate nano-dispersed cerium oxide particles that selectively absorb UV radiation while maintaining transparency in the visible spectrum. Additionally, Nippon Shokubai has developed surface treatment technologies that create a protective barrier against environmental factors that accelerate UV degradation.

Strengths: Superior long-term color stability even under intense UV exposure; minimal impact on optical properties; excellent compatibility with various acrylic formulations. Weaknesses: Higher cost compared to basic stabilization systems; may require specialized processing conditions; potential for reduced mechanical properties at higher additive loadings.

3M Innovative Properties Co.

Technical Solution: 3M has developed a comprehensive approach to minimizing acrylic resin yellowing through their Multi-Layer Protection System (MLPS). This technology incorporates specialized UV absorbers that selectively filter high-energy wavelengths most responsible for initiating photo-degradation processes. Their proprietary formulation includes benzotriazole derivatives modified with non-migrating functional groups that anchor the stabilizers within the polymer matrix, preventing leaching and ensuring long-term protection. 3M's system also incorporates antioxidants that neutralize free radicals formed during UV exposure, interrupting the chain reaction that leads to chromophore formation. The company has further enhanced this technology by developing surface-treated nanoparticles that provide UV shielding while maintaining optical clarity. Their latest innovation involves reactive stabilizers that chemically bond to the acrylic backbone, providing permanent protection that cannot be lost through migration or volatilization.

Strengths: Exceptional durability with protection lasting 5+ years in outdoor applications; maintains high light transmission; compatible with various processing methods. Weaknesses: Premium pricing compared to conventional stabilizers; requires precise processing parameters; may affect adhesion properties in certain applications.

Key Patents and Research on UV Stabilizers

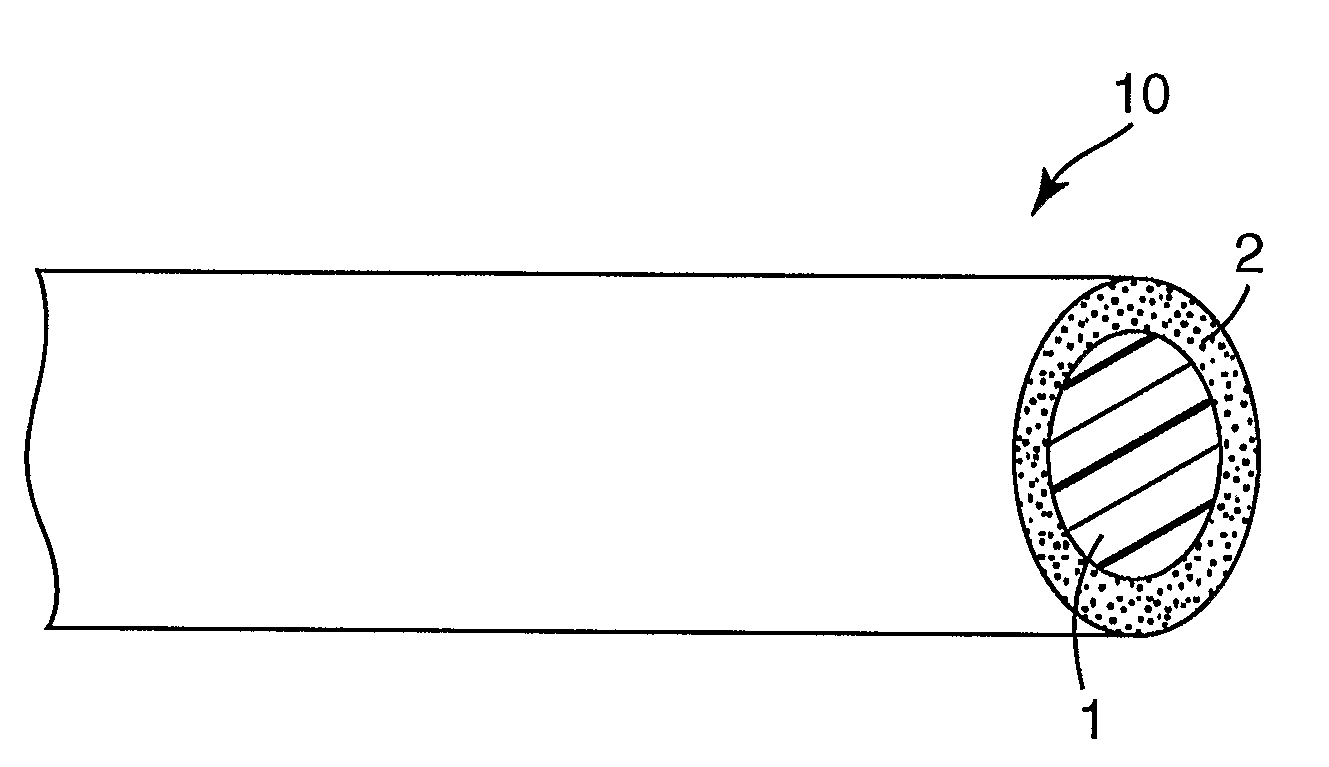

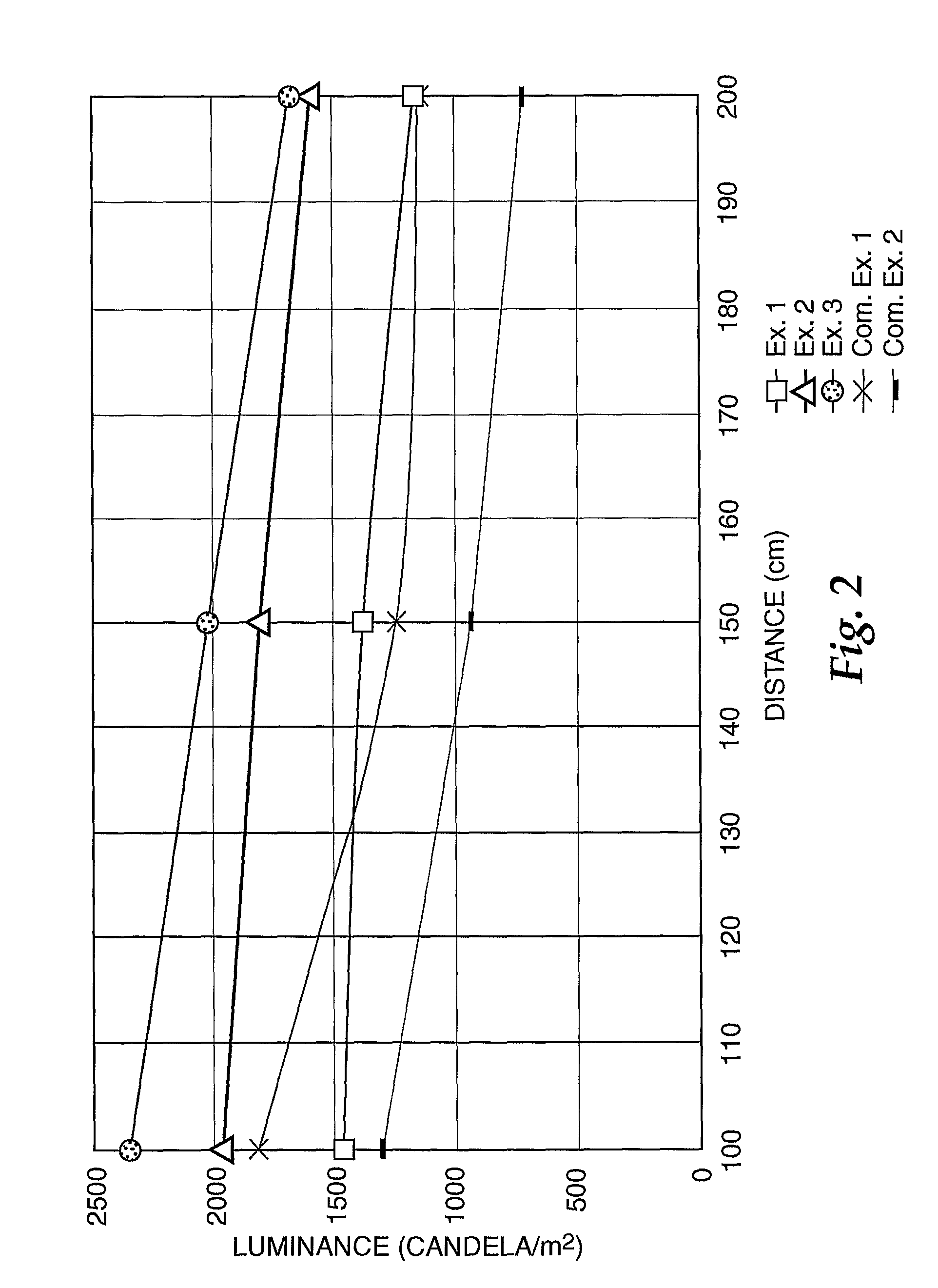

Lateral Emitting Optical Fiber and Light Emitting Device

PatentInactiveUS20080187277A1

Innovation

- Incorporating zinc oxide particles into the clad material, which provides effective UV shielding without excessive light scattering, maintaining high visible light transmittance and ensuring uniform luminance along the fiber length.

Light diffusing thermoplastic composition

PatentPendingUS20250243361A1

Innovation

- Incorporating ultraviolet stabilizers into the resin composition of light diffusing particles, specifically cross-linked acrylic resin particles, to mitigate the effects of ultraviolet radiation.

Environmental Impact of UV Stabilizers

The widespread use of UV stabilizers in acrylic resin formulations raises significant environmental concerns that warrant careful consideration. These chemical additives, while effective at preventing yellowing and degradation, can have various ecological impacts throughout their lifecycle. When UV stabilizers leach from acrylic products during use or disposal, they may contaminate soil and water systems, potentially disrupting aquatic ecosystems and affecting biodiversity.

Studies have shown that certain HALS (Hindered Amine Light Stabilizers) and benzotriazole-based UV absorbers demonstrate persistence in the environment, with degradation half-lives exceeding several months in natural conditions. This persistence increases the risk of bioaccumulation in organisms and potential biomagnification up the food chain, raising concerns about long-term ecological effects.

The manufacturing process of UV stabilizers also contributes to environmental burden through energy consumption, greenhouse gas emissions, and the generation of chemical byproducts. Production facilities may release volatile organic compounds (VOCs) and other pollutants that contribute to air quality degradation and potential health hazards for surrounding communities.

End-of-life management presents another environmental challenge. Acrylic products containing UV stabilizers often end up in landfills where these additives may slowly leach into groundwater. Incineration of such materials can potentially release toxic compounds if not properly controlled. Recycling processes may be complicated by the presence of these additives, as they can affect the quality and properties of recycled materials.

Recent regulatory frameworks, including REACH in Europe and similar initiatives globally, have begun addressing these concerns by requiring more rigorous testing and documentation of environmental impacts. Several traditional UV stabilizers have faced restrictions due to their environmental persistence and toxicity profiles, driving the industry toward greener alternatives.

Emerging eco-friendly UV stabilizer technologies include bio-based additives derived from natural sources such as plant extracts with antioxidant properties. These alternatives typically demonstrate improved biodegradability and reduced environmental persistence compared to conventional synthetic options. Additionally, encapsulation technologies that minimize leaching while maintaining effectiveness show promise for reducing environmental exposure.

Life cycle assessment (LCA) studies comparing different UV stabilizer options reveal that environmental impact varies significantly between formulations. The trade-off between durability (which reduces replacement frequency and associated resource consumption) and end-of-life environmental impact remains a key consideration for manufacturers seeking to optimize overall sustainability.

Studies have shown that certain HALS (Hindered Amine Light Stabilizers) and benzotriazole-based UV absorbers demonstrate persistence in the environment, with degradation half-lives exceeding several months in natural conditions. This persistence increases the risk of bioaccumulation in organisms and potential biomagnification up the food chain, raising concerns about long-term ecological effects.

The manufacturing process of UV stabilizers also contributes to environmental burden through energy consumption, greenhouse gas emissions, and the generation of chemical byproducts. Production facilities may release volatile organic compounds (VOCs) and other pollutants that contribute to air quality degradation and potential health hazards for surrounding communities.

End-of-life management presents another environmental challenge. Acrylic products containing UV stabilizers often end up in landfills where these additives may slowly leach into groundwater. Incineration of such materials can potentially release toxic compounds if not properly controlled. Recycling processes may be complicated by the presence of these additives, as they can affect the quality and properties of recycled materials.

Recent regulatory frameworks, including REACH in Europe and similar initiatives globally, have begun addressing these concerns by requiring more rigorous testing and documentation of environmental impacts. Several traditional UV stabilizers have faced restrictions due to their environmental persistence and toxicity profiles, driving the industry toward greener alternatives.

Emerging eco-friendly UV stabilizer technologies include bio-based additives derived from natural sources such as plant extracts with antioxidant properties. These alternatives typically demonstrate improved biodegradability and reduced environmental persistence compared to conventional synthetic options. Additionally, encapsulation technologies that minimize leaching while maintaining effectiveness show promise for reducing environmental exposure.

Life cycle assessment (LCA) studies comparing different UV stabilizer options reveal that environmental impact varies significantly between formulations. The trade-off between durability (which reduces replacement frequency and associated resource consumption) and end-of-life environmental impact remains a key consideration for manufacturers seeking to optimize overall sustainability.

Cost-Benefit Analysis of Anti-Yellowing Technologies

When evaluating anti-yellowing technologies for acrylic resins, a comprehensive cost-benefit analysis reveals significant variations in economic viability across different solutions. UV stabilizers such as HALS (Hindered Amine Light Stabilizers) represent a relatively low-cost option, typically adding $2-5 per kilogram of resin, while offering moderate protection that extends product lifespan by 2-3 years under normal exposure conditions. The implementation requires minimal process modifications, making it an attractive entry-level solution.

In contrast, advanced UV absorbers like benzotriazoles and benzophenones demand a higher initial investment of $8-12 per kilogram but deliver superior protection with potential lifespan extensions of 4-7 years. The enhanced durability translates to reduced replacement frequency and associated labor costs, potentially offsetting the higher initial expenditure over the product lifecycle.

Nanoparticle-based solutions incorporating cerium oxide or zinc oxide present the highest upfront costs at $15-25 per kilogram, coupled with potential processing modifications costing $50,000-100,000 for manufacturing equipment adaptation. However, these technologies offer the most comprehensive protection with projected lifespan extensions of 7-10 years and maintain superior optical clarity throughout the product lifecycle.

The return on investment timeline varies significantly across technologies. Standard UV stabilizers typically achieve ROI within 1-2 years in outdoor applications, while advanced absorbers require 2-3 years to demonstrate economic advantages. Nanoparticle solutions, despite their premium positioning, may require 3-5 years before delivering net economic benefits, making them more suitable for high-value applications where appearance preservation commands premium pricing.

Environmental considerations further complicate the cost-benefit equation. Regulatory compliance costs for certain chemical stabilizers are increasing, with potential restrictions on some compounds adding future risk factors. Meanwhile, more environmentally friendly alternatives often command price premiums of 15-30% but may qualify for sustainability certifications that enhance market positioning and access to premium market segments.

Market segment analysis indicates that consumer electronics manufacturers typically prioritize optical clarity and are willing to absorb a 10-15% cost premium for superior yellowing resistance. Architectural applications demonstrate higher price sensitivity but place greater emphasis on extended durability, creating different optimization points in the cost-benefit curve depending on the intended application.

In contrast, advanced UV absorbers like benzotriazoles and benzophenones demand a higher initial investment of $8-12 per kilogram but deliver superior protection with potential lifespan extensions of 4-7 years. The enhanced durability translates to reduced replacement frequency and associated labor costs, potentially offsetting the higher initial expenditure over the product lifecycle.

Nanoparticle-based solutions incorporating cerium oxide or zinc oxide present the highest upfront costs at $15-25 per kilogram, coupled with potential processing modifications costing $50,000-100,000 for manufacturing equipment adaptation. However, these technologies offer the most comprehensive protection with projected lifespan extensions of 7-10 years and maintain superior optical clarity throughout the product lifecycle.

The return on investment timeline varies significantly across technologies. Standard UV stabilizers typically achieve ROI within 1-2 years in outdoor applications, while advanced absorbers require 2-3 years to demonstrate economic advantages. Nanoparticle solutions, despite their premium positioning, may require 3-5 years before delivering net economic benefits, making them more suitable for high-value applications where appearance preservation commands premium pricing.

Environmental considerations further complicate the cost-benefit equation. Regulatory compliance costs for certain chemical stabilizers are increasing, with potential restrictions on some compounds adding future risk factors. Meanwhile, more environmentally friendly alternatives often command price premiums of 15-30% but may qualify for sustainability certifications that enhance market positioning and access to premium market segments.

Market segment analysis indicates that consumer electronics manufacturers typically prioritize optical clarity and are willing to absorb a 10-15% cost premium for superior yellowing resistance. Architectural applications demonstrate higher price sensitivity but place greater emphasis on extended durability, creating different optimization points in the cost-benefit curve depending on the intended application.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!