How to Minimize Monomer Residues in Polyvinyl Acetate Production?

JUL 30, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PVAc Monomer Residue Reduction Objectives

The primary objective of minimizing monomer residues in polyvinyl acetate (PVAc) production is to enhance product quality, safety, and environmental sustainability. This goal is driven by increasing regulatory pressures, consumer demands for safer products, and industry-wide efforts to improve manufacturing processes.

One key aim is to reduce the concentration of residual vinyl acetate monomer (VAM) in the final PVAc product. Industry standards typically require VAM levels below 1000 ppm, but many manufacturers strive for even lower levels, often targeting less than 500 ppm. Achieving these low residual levels is crucial for applications in food packaging, adhesives, and other consumer-facing products where monomer migration could pose health risks.

Another important objective is to optimize the polymerization process to maximize monomer conversion. This not only reduces residual monomer content but also improves production efficiency and reduces raw material waste. Manufacturers aim to achieve conversion rates above 99%, with some advanced processes pushing towards 99.9% conversion.

Minimizing monomer residues also contributes to improved product stability and performance. Lower residual monomer content can lead to better adhesion properties, increased thermal stability, and reduced odor in PVAc-based products. These improvements expand the potential applications for PVAc and enhance its competitiveness against alternative materials.

Environmental considerations form another critical aspect of monomer residue reduction objectives. Lowering VAM emissions during production and reducing the potential for post-production off-gassing align with sustainability goals and stricter environmental regulations. Manufacturers are increasingly focused on developing closed-loop systems and improving VOC capture technologies to minimize environmental impact.

Cost reduction is an additional driver for minimizing monomer residues. By improving conversion efficiency and reducing waste, manufacturers can lower raw material costs and potentially decrease energy consumption in downstream processing steps, such as drying and purification.

Lastly, achieving consistently low monomer residue levels is essential for meeting various international standards and certifications. This includes compliance with food contact regulations, such as those set by the FDA and EU, as well as industry-specific standards for construction materials, paints, and adhesives. Meeting these standards opens up new market opportunities and enhances brand reputation for PVAc producers.

One key aim is to reduce the concentration of residual vinyl acetate monomer (VAM) in the final PVAc product. Industry standards typically require VAM levels below 1000 ppm, but many manufacturers strive for even lower levels, often targeting less than 500 ppm. Achieving these low residual levels is crucial for applications in food packaging, adhesives, and other consumer-facing products where monomer migration could pose health risks.

Another important objective is to optimize the polymerization process to maximize monomer conversion. This not only reduces residual monomer content but also improves production efficiency and reduces raw material waste. Manufacturers aim to achieve conversion rates above 99%, with some advanced processes pushing towards 99.9% conversion.

Minimizing monomer residues also contributes to improved product stability and performance. Lower residual monomer content can lead to better adhesion properties, increased thermal stability, and reduced odor in PVAc-based products. These improvements expand the potential applications for PVAc and enhance its competitiveness against alternative materials.

Environmental considerations form another critical aspect of monomer residue reduction objectives. Lowering VAM emissions during production and reducing the potential for post-production off-gassing align with sustainability goals and stricter environmental regulations. Manufacturers are increasingly focused on developing closed-loop systems and improving VOC capture technologies to minimize environmental impact.

Cost reduction is an additional driver for minimizing monomer residues. By improving conversion efficiency and reducing waste, manufacturers can lower raw material costs and potentially decrease energy consumption in downstream processing steps, such as drying and purification.

Lastly, achieving consistently low monomer residue levels is essential for meeting various international standards and certifications. This includes compliance with food contact regulations, such as those set by the FDA and EU, as well as industry-specific standards for construction materials, paints, and adhesives. Meeting these standards opens up new market opportunities and enhances brand reputation for PVAc producers.

Market Demand for Low-Residue PVAc

The market demand for low-residue polyvinyl acetate (PVAc) has been steadily increasing in recent years, driven by stringent regulations, growing environmental awareness, and the need for higher quality end products. Industries such as adhesives, paints, coatings, and textiles are particularly interested in PVAc with minimal monomer residues due to its improved performance characteristics and reduced health risks.

In the adhesives sector, which accounts for a significant portion of PVAc consumption, there is a strong push for low-residue formulations. This demand is fueled by the construction industry's need for safer, more environmentally friendly products, especially in indoor applications where off-gassing can be a concern. The packaging industry also requires low-residue PVAc for food-contact adhesives, aligning with increasingly strict food safety regulations worldwide.

The paints and coatings industry represents another major market for low-residue PVAc. As consumers become more health-conscious, there is a growing preference for low-VOC (volatile organic compound) and low-odor products. PVAc with minimal monomer residues contributes to reduced emissions and improved indoor air quality, making it highly desirable for both residential and commercial applications.

In the textile industry, the demand for low-residue PVAc is driven by the need for safer fabric finishes and coatings. This is particularly important in the production of children's clothing and home textiles, where exposure to harmful chemicals is a significant concern for consumers and regulators alike.

The pharmaceutical and personal care industries are also showing increased interest in low-residue PVAc. Its use in controlled-release drug formulations and cosmetic products requires exceptionally pure grades to ensure product safety and efficacy. The reduction of monomer residues is crucial in meeting the stringent quality standards of these sectors.

Geographically, the demand for low-residue PVAc is strongest in developed regions such as North America, Europe, and Japan, where environmental regulations are most advanced. However, emerging economies in Asia-Pacific and Latin America are rapidly adopting similar standards, expanding the global market for high-purity PVAc products.

The market trend clearly indicates a shift towards higher quality, safer PVAc products across various industries. Manufacturers who can effectively minimize monomer residues in their PVAc production are likely to gain a competitive edge, as they can command premium prices and access new market segments that prioritize product purity and environmental responsibility.

In the adhesives sector, which accounts for a significant portion of PVAc consumption, there is a strong push for low-residue formulations. This demand is fueled by the construction industry's need for safer, more environmentally friendly products, especially in indoor applications where off-gassing can be a concern. The packaging industry also requires low-residue PVAc for food-contact adhesives, aligning with increasingly strict food safety regulations worldwide.

The paints and coatings industry represents another major market for low-residue PVAc. As consumers become more health-conscious, there is a growing preference for low-VOC (volatile organic compound) and low-odor products. PVAc with minimal monomer residues contributes to reduced emissions and improved indoor air quality, making it highly desirable for both residential and commercial applications.

In the textile industry, the demand for low-residue PVAc is driven by the need for safer fabric finishes and coatings. This is particularly important in the production of children's clothing and home textiles, where exposure to harmful chemicals is a significant concern for consumers and regulators alike.

The pharmaceutical and personal care industries are also showing increased interest in low-residue PVAc. Its use in controlled-release drug formulations and cosmetic products requires exceptionally pure grades to ensure product safety and efficacy. The reduction of monomer residues is crucial in meeting the stringent quality standards of these sectors.

Geographically, the demand for low-residue PVAc is strongest in developed regions such as North America, Europe, and Japan, where environmental regulations are most advanced. However, emerging economies in Asia-Pacific and Latin America are rapidly adopting similar standards, expanding the global market for high-purity PVAc products.

The market trend clearly indicates a shift towards higher quality, safer PVAc products across various industries. Manufacturers who can effectively minimize monomer residues in their PVAc production are likely to gain a competitive edge, as they can command premium prices and access new market segments that prioritize product purity and environmental responsibility.

Current Challenges in PVAc Polymerization

Polyvinyl acetate (PVAc) production faces several significant challenges in minimizing monomer residues, which are critical for product quality and safety. One of the primary issues is the incomplete conversion of vinyl acetate monomer (VAM) during polymerization. Despite advancements in reaction conditions and catalysts, achieving 100% conversion remains elusive, leading to residual monomers in the final product.

The presence of these residual monomers poses potential health and environmental risks, as VAM is classified as a possible human carcinogen. This necessitates stringent regulatory compliance and quality control measures, adding complexity and cost to the production process. Manufacturers must invest in sophisticated analytical techniques to accurately quantify and monitor monomer levels throughout production and in the final product.

Another challenge lies in the balance between polymerization efficiency and residual monomer content. Pushing for higher conversion rates can lead to increased reaction times and energy consumption, potentially compromising production efficiency and cost-effectiveness. Additionally, aggressive polymerization conditions may result in undesired side reactions or polymer degradation, affecting the overall quality of the PVAc product.

The removal of residual monomers post-polymerization presents its own set of difficulties. Traditional methods such as steam stripping or vacuum distillation can be energy-intensive and may affect the polymer's properties. Moreover, these processes can be less effective for high molecular weight PVAc, where monomers may be trapped within the polymer matrix.

Temperature control during polymerization is another critical factor. Fluctuations in reaction temperature can lead to inconsistent monomer conversion rates, resulting in varying levels of residual monomers across batches. Maintaining precise temperature control in large-scale industrial reactors poses significant engineering challenges.

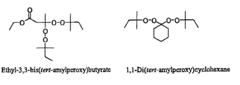

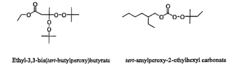

The choice of initiator system also impacts residual monomer levels. While more reactive initiators can improve conversion rates, they may lead to broader molecular weight distributions or introduce unwanted by-products. Balancing initiator reactivity with product quality requirements adds another layer of complexity to the polymerization process.

Lastly, the increasing demand for eco-friendly and low-VOC (volatile organic compound) products puts additional pressure on manufacturers to minimize residual monomers. This trend necessitates continuous innovation in polymerization techniques and post-processing methods to meet stringent environmental standards while maintaining product performance and economic viability.

The presence of these residual monomers poses potential health and environmental risks, as VAM is classified as a possible human carcinogen. This necessitates stringent regulatory compliance and quality control measures, adding complexity and cost to the production process. Manufacturers must invest in sophisticated analytical techniques to accurately quantify and monitor monomer levels throughout production and in the final product.

Another challenge lies in the balance between polymerization efficiency and residual monomer content. Pushing for higher conversion rates can lead to increased reaction times and energy consumption, potentially compromising production efficiency and cost-effectiveness. Additionally, aggressive polymerization conditions may result in undesired side reactions or polymer degradation, affecting the overall quality of the PVAc product.

The removal of residual monomers post-polymerization presents its own set of difficulties. Traditional methods such as steam stripping or vacuum distillation can be energy-intensive and may affect the polymer's properties. Moreover, these processes can be less effective for high molecular weight PVAc, where monomers may be trapped within the polymer matrix.

Temperature control during polymerization is another critical factor. Fluctuations in reaction temperature can lead to inconsistent monomer conversion rates, resulting in varying levels of residual monomers across batches. Maintaining precise temperature control in large-scale industrial reactors poses significant engineering challenges.

The choice of initiator system also impacts residual monomer levels. While more reactive initiators can improve conversion rates, they may lead to broader molecular weight distributions or introduce unwanted by-products. Balancing initiator reactivity with product quality requirements adds another layer of complexity to the polymerization process.

Lastly, the increasing demand for eco-friendly and low-VOC (volatile organic compound) products puts additional pressure on manufacturers to minimize residual monomers. This trend necessitates continuous innovation in polymerization techniques and post-processing methods to meet stringent environmental standards while maintaining product performance and economic viability.

Existing Monomer Residue Reduction Methods

01 Reduction of residual monomer content in polyvinyl acetate

Various methods are employed to reduce the amount of residual vinyl acetate monomer in polyvinyl acetate products. These techniques include post-polymerization treatments, optimization of reaction conditions, and the use of specific catalysts or additives to enhance monomer conversion.- Reduction of residual monomer content in polyvinyl acetate: Various methods are employed to reduce the amount of residual vinyl acetate monomer in polyvinyl acetate products. These techniques include post-polymerization treatments, optimization of reaction conditions, and the use of specific catalysts or additives to enhance monomer conversion.

- Emulsion polymerization techniques for polyvinyl acetate: Emulsion polymerization is a common method for producing polyvinyl acetate with low residual monomer content. This process involves the use of surfactants, initiators, and controlled reaction conditions to achieve high monomer conversion and minimize residual monomers in the final product.

- Analysis and detection of residual vinyl acetate monomers: Various analytical techniques are used to detect and quantify residual vinyl acetate monomers in polyvinyl acetate products. These methods include gas chromatography, high-performance liquid chromatography, and spectroscopic techniques, which help ensure product quality and compliance with regulatory standards.

- Copolymerization strategies to reduce residual monomers: Copolymerization of vinyl acetate with other monomers is explored as a strategy to reduce residual monomer content in the final product. This approach can lead to improved conversion rates and enhanced properties of the resulting polymer, while minimizing the presence of unreacted vinyl acetate.

- Post-treatment processes for residual monomer removal: Various post-treatment processes are employed to remove residual vinyl acetate monomers from polyvinyl acetate products. These methods include steam stripping, vacuum distillation, and chemical treatments, which help achieve lower residual monomer levels and improve product quality.

02 Emulsion polymerization techniques for minimizing monomer residues

Emulsion polymerization processes are developed to minimize the formation of residual monomers in polyvinyl acetate. These methods often involve careful control of reaction parameters, such as temperature, pH, and initiator concentration, to achieve high monomer conversion rates.Expand Specific Solutions03 Analysis and detection of residual vinyl acetate monomers

Analytical techniques are developed to accurately measure and detect residual vinyl acetate monomers in polyvinyl acetate products. These methods may include gas chromatography, high-performance liquid chromatography, or spectroscopic techniques to ensure product quality and safety.Expand Specific Solutions04 Copolymerization strategies to reduce monomer residues

Copolymerization of vinyl acetate with other monomers is explored as a means to reduce residual monomer content. This approach can lead to improved conversion rates and altered polymer properties, potentially reducing the amount of unreacted vinyl acetate in the final product.Expand Specific Solutions05 Post-treatment processes for removing residual monomers

Various post-treatment processes are developed to remove or further reduce residual vinyl acetate monomers in polyvinyl acetate products. These may include steam stripping, vacuum distillation, or chemical treatments to convert or extract unreacted monomers from the polymer matrix.Expand Specific Solutions

Key Players in PVAc Manufacturing Industry

The market for minimizing monomer residues in polyvinyl acetate production is in a mature stage, with established players and well-developed technologies. The global polyvinyl acetate market size is substantial, driven by demand in adhesives, paints, and coatings industries. Technologically, companies like Celanese, Wacker Chemie, and BASF are at the forefront, having developed advanced processes for reducing residual monomers. Kuraray and Denka also contribute significantly to innovation in this field. The competition is intense, with these major players continuously investing in R&D to improve product quality and meet stringent regulatory standards for monomer content in end products.

Celanese International Corp.

Technical Solution: Celanese has developed an innovative approach to minimize monomer residues in PVAc production, leveraging their extensive experience in acetyl chemistry. Their process incorporates a modified suspension polymerization technique with optimized initiator systems to achieve high monomer conversion rates[15]. Celanese utilizes a proprietary stabilizer package that enhances colloidal stability during polymerization, reducing the formation of coagulum and improving overall conversion efficiency[17]. Post-polymerization, they employ a multi-stage stripping process combining vacuum and steam distillation to remove residual monomers[19]. Celanese has also implemented an advanced process control system using artificial intelligence to optimize reaction conditions in real-time, further reducing monomer residues[21].

Strengths: High product consistency, adaptability to various PVAc grades, and potential for process automation. Weaknesses: May require significant investment in AI and control systems.

Kuraray Co., Ltd.

Technical Solution: Kuraray has developed a unique approach to minimize monomer residues in PVAc production, focusing on their expertise in specialty polymers. Their process involves a controlled radical polymerization technique using RAFT (Reversible Addition-Fragmentation chain Transfer) agents[10]. This method allows for better control over molecular weight distribution and end-group functionality, resulting in lower residual monomer content[12]. Kuraray also employs a post-polymerization treatment using supercritical carbon dioxide extraction, which effectively removes residual monomers without the need for organic solvents[14]. Additionally, they have implemented an online gas chromatography system for continuous monitoring of monomer levels during production[16].

Strengths: High-quality product with precise control over polymer properties, environmentally friendly extraction process. Weaknesses: Potentially higher production costs due to specialized reagents and equipment.

Innovative Approaches to Residue Minimization

Process for removing monomers from aqueous polymer dispersions of polyvinylesters

PatentInactiveEP0563726A1

Innovation

- A process involving selective alkaline saponification of alkaline saponifiable residual vinyl ester monomers, followed by distillation to remove unsaponified monomers and acetaldehyde, which can be performed simultaneously or in stages, effectively reducing residual monomer content to below 0.05% by weight while maintaining the dispersion's application properties.

A method of reducing a content of a residual styrene monomer in a polyol

PatentInactiveEP1657273A1

Innovation

- A method involving the introduction of a peroxide to polymerize residual styrene monomers in polyols, followed by the application of a vacuum to separate the polymerized monomers, reducing the content to less than 20 parts per million.

Environmental Impact of PVAc Production

The environmental impact of polyvinyl acetate (PVAc) production is a critical concern in the polymer industry, particularly in relation to the minimization of monomer residues. The manufacturing process of PVAc involves several stages that can potentially contribute to environmental pollution if not properly managed. One of the primary environmental concerns is the release of volatile organic compounds (VOCs), including unreacted vinyl acetate monomers, into the atmosphere during production and processing.

These emissions can lead to air quality degradation and contribute to the formation of ground-level ozone, a key component of smog. Additionally, the presence of monomer residues in the final product can result in off-gassing over time, affecting indoor air quality in applications such as adhesives and paints. The improper disposal of PVAc waste containing residual monomers can contaminate soil and water resources, posing risks to aquatic ecosystems and potentially entering the food chain.

Water pollution is another significant environmental issue associated with PVAc production. The polymerization process often requires large volumes of water for cooling and washing, which can become contaminated with monomers, catalysts, and other chemicals used in the production process. If not adequately treated before discharge, this wastewater can harm aquatic life and potentially impact drinking water sources.

Energy consumption during PVAc production also contributes to its environmental footprint. The polymerization reaction and subsequent processing steps require substantial energy inputs, often derived from fossil fuels, leading to greenhouse gas emissions and contributing to climate change. Efforts to minimize monomer residues often involve additional processing steps or more intensive reaction conditions, which may further increase energy demands.

The production of vinyl acetate monomer, the precursor to PVAc, also has environmental implications. This process typically involves the reaction of ethylene and acetic acid over a palladium catalyst, which can result in the generation of byproducts and waste streams that require proper management and disposal. The extraction and processing of raw materials for monomer production, such as natural gas and petroleum derivatives, also contribute to the overall environmental impact of PVAc.

Addressing these environmental concerns requires a multifaceted approach. Implementing more efficient polymerization techniques, such as improved reactor designs and optimized reaction conditions, can help reduce monomer residues and minimize waste generation. Advanced emission control technologies, including scrubbers and thermal oxidizers, can significantly reduce VOC emissions from production facilities. Additionally, closed-loop water recycling systems and advanced wastewater treatment processes can mitigate water pollution risks associated with PVAc production.

These emissions can lead to air quality degradation and contribute to the formation of ground-level ozone, a key component of smog. Additionally, the presence of monomer residues in the final product can result in off-gassing over time, affecting indoor air quality in applications such as adhesives and paints. The improper disposal of PVAc waste containing residual monomers can contaminate soil and water resources, posing risks to aquatic ecosystems and potentially entering the food chain.

Water pollution is another significant environmental issue associated with PVAc production. The polymerization process often requires large volumes of water for cooling and washing, which can become contaminated with monomers, catalysts, and other chemicals used in the production process. If not adequately treated before discharge, this wastewater can harm aquatic life and potentially impact drinking water sources.

Energy consumption during PVAc production also contributes to its environmental footprint. The polymerization reaction and subsequent processing steps require substantial energy inputs, often derived from fossil fuels, leading to greenhouse gas emissions and contributing to climate change. Efforts to minimize monomer residues often involve additional processing steps or more intensive reaction conditions, which may further increase energy demands.

The production of vinyl acetate monomer, the precursor to PVAc, also has environmental implications. This process typically involves the reaction of ethylene and acetic acid over a palladium catalyst, which can result in the generation of byproducts and waste streams that require proper management and disposal. The extraction and processing of raw materials for monomer production, such as natural gas and petroleum derivatives, also contribute to the overall environmental impact of PVAc.

Addressing these environmental concerns requires a multifaceted approach. Implementing more efficient polymerization techniques, such as improved reactor designs and optimized reaction conditions, can help reduce monomer residues and minimize waste generation. Advanced emission control technologies, including scrubbers and thermal oxidizers, can significantly reduce VOC emissions from production facilities. Additionally, closed-loop water recycling systems and advanced wastewater treatment processes can mitigate water pollution risks associated with PVAc production.

Regulatory Standards for PVAc Residues

Regulatory standards for polyvinyl acetate (PVAc) residues have become increasingly stringent in recent years, reflecting growing concerns about consumer safety and environmental impact. These standards are primarily focused on limiting the amount of residual vinyl acetate monomer (VAM) in PVAc products, as VAM is classified as a potential carcinogen.

In the European Union, the European Food Safety Authority (EFSA) has set strict limits for VAM residues in food contact materials. The specific migration limit (SML) for vinyl acetate is 12 mg/kg, as outlined in Commission Regulation (EU) No 10/2011. This regulation applies to all plastic materials and articles intended to come into contact with food, including those containing PVAc.

The United States Food and Drug Administration (FDA) also regulates PVAc residues, particularly in food packaging and adhesives. Under 21 CFR 175.105, the FDA specifies that adhesives containing PVAc must not exceed 0.2% residual vinyl acetate monomer. For food packaging applications, the FDA requires that the finished food-contact article yield no more than 0.5 ppm of vinyl acetate monomer when extracted with water or heptane.

In Japan, the Ministry of Health, Labour and Welfare has established standards for food packaging materials containing PVAc. The Japanese Positive List System for food contact materials sets a limit of 1 mg/kg for vinyl acetate migration from PVAc-based materials.

China's National Standard GB 9685-2016 regulates the use of additives in food contact materials, including PVAc. This standard sets a specific migration limit of 12 mg/kg for vinyl acetate, aligning with EU regulations.

International organizations such as the World Health Organization (WHO) and the International Agency for Research on Cancer (IARC) have also contributed to the regulatory landscape by providing risk assessments and classifications for vinyl acetate. These assessments often inform national and regional regulatory decisions.

To comply with these diverse regulatory standards, PVAc manufacturers must implement rigorous quality control measures and advanced production techniques. This includes optimizing polymerization processes, employing efficient post-production treatments, and utilizing sensitive analytical methods for residue detection. As regulatory bodies continue to refine their standards, the PVAc industry must remain adaptable and committed to ongoing improvements in residue minimization techniques.

In the European Union, the European Food Safety Authority (EFSA) has set strict limits for VAM residues in food contact materials. The specific migration limit (SML) for vinyl acetate is 12 mg/kg, as outlined in Commission Regulation (EU) No 10/2011. This regulation applies to all plastic materials and articles intended to come into contact with food, including those containing PVAc.

The United States Food and Drug Administration (FDA) also regulates PVAc residues, particularly in food packaging and adhesives. Under 21 CFR 175.105, the FDA specifies that adhesives containing PVAc must not exceed 0.2% residual vinyl acetate monomer. For food packaging applications, the FDA requires that the finished food-contact article yield no more than 0.5 ppm of vinyl acetate monomer when extracted with water or heptane.

In Japan, the Ministry of Health, Labour and Welfare has established standards for food packaging materials containing PVAc. The Japanese Positive List System for food contact materials sets a limit of 1 mg/kg for vinyl acetate migration from PVAc-based materials.

China's National Standard GB 9685-2016 regulates the use of additives in food contact materials, including PVAc. This standard sets a specific migration limit of 12 mg/kg for vinyl acetate, aligning with EU regulations.

International organizations such as the World Health Organization (WHO) and the International Agency for Research on Cancer (IARC) have also contributed to the regulatory landscape by providing risk assessments and classifications for vinyl acetate. These assessments often inform national and regional regulatory decisions.

To comply with these diverse regulatory standards, PVAc manufacturers must implement rigorous quality control measures and advanced production techniques. This includes optimizing polymerization processes, employing efficient post-production treatments, and utilizing sensitive analytical methods for residue detection. As regulatory bodies continue to refine their standards, the PVAc industry must remain adaptable and committed to ongoing improvements in residue minimization techniques.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!