How to Mitigate Risks with Fluoroantimonic Acid Usage?

JUN 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fluoroantimonic Acid Background and Safety Objectives

Fluoroantimonic acid, a superacid formed by combining hydrogen fluoride and antimony pentafluoride, stands as one of the most potent and corrosive substances known to science. Its extreme acidity, surpassing that of pure sulfuric acid by orders of magnitude, has made it a subject of intense research and cautious application in various industrial processes.

The development of fluoroantimonic acid traces back to the mid-20th century, with significant advancements in understanding its properties and potential applications occurring in the 1960s and 1970s. Initially, its primary use was confined to specialized laboratory settings due to its highly reactive nature and the challenges associated with its handling and storage.

As industrial processes evolved, the unique properties of fluoroantimonic acid began to attract attention in sectors such as petrochemical refining and organic synthesis. Its ability to catalyze certain reactions at unprecedented rates opened new avenues for chemical production and material processing.

However, the extraordinary reactivity of fluoroantimonic acid also presents significant safety and environmental concerns. Its corrosive nature poses severe risks to human health and infrastructure, necessitating stringent safety protocols and specialized containment systems. The potential for catastrophic accidents and long-term environmental damage has driven ongoing research into safer handling methods and alternative technologies.

The primary objective in mitigating risks associated with fluoroantimonic acid usage centers on developing comprehensive safety strategies that address its entire lifecycle - from production and transportation to application and disposal. This includes engineering advanced containment systems capable of withstanding its extreme corrosivity, implementing robust emergency response protocols, and training personnel in specialized handling techniques.

Furthermore, there is a growing emphasis on exploring less hazardous alternatives that can achieve similar catalytic or processing outcomes. This research aims to balance the industrial benefits of fluoroantimonic acid with the imperative of minimizing potential harm to human health and the environment.

As technology advances, the focus is increasingly shifting towards developing smart monitoring systems that can detect minute leaks or changes in containment integrity, coupled with automated safety responses. Additionally, there is ongoing work to improve personal protective equipment specifically designed to withstand exposure to superacids.

The ultimate goal in this field is to establish a framework that allows for the controlled and safe utilization of fluoroantimonic acid's unique properties while minimizing the associated risks to an acceptable level. This requires a multidisciplinary approach, combining advances in materials science, chemical engineering, and safety technology to create a holistic risk mitigation strategy.

The development of fluoroantimonic acid traces back to the mid-20th century, with significant advancements in understanding its properties and potential applications occurring in the 1960s and 1970s. Initially, its primary use was confined to specialized laboratory settings due to its highly reactive nature and the challenges associated with its handling and storage.

As industrial processes evolved, the unique properties of fluoroantimonic acid began to attract attention in sectors such as petrochemical refining and organic synthesis. Its ability to catalyze certain reactions at unprecedented rates opened new avenues for chemical production and material processing.

However, the extraordinary reactivity of fluoroantimonic acid also presents significant safety and environmental concerns. Its corrosive nature poses severe risks to human health and infrastructure, necessitating stringent safety protocols and specialized containment systems. The potential for catastrophic accidents and long-term environmental damage has driven ongoing research into safer handling methods and alternative technologies.

The primary objective in mitigating risks associated with fluoroantimonic acid usage centers on developing comprehensive safety strategies that address its entire lifecycle - from production and transportation to application and disposal. This includes engineering advanced containment systems capable of withstanding its extreme corrosivity, implementing robust emergency response protocols, and training personnel in specialized handling techniques.

Furthermore, there is a growing emphasis on exploring less hazardous alternatives that can achieve similar catalytic or processing outcomes. This research aims to balance the industrial benefits of fluoroantimonic acid with the imperative of minimizing potential harm to human health and the environment.

As technology advances, the focus is increasingly shifting towards developing smart monitoring systems that can detect minute leaks or changes in containment integrity, coupled with automated safety responses. Additionally, there is ongoing work to improve personal protective equipment specifically designed to withstand exposure to superacids.

The ultimate goal in this field is to establish a framework that allows for the controlled and safe utilization of fluoroantimonic acid's unique properties while minimizing the associated risks to an acceptable level. This requires a multidisciplinary approach, combining advances in materials science, chemical engineering, and safety technology to create a holistic risk mitigation strategy.

Industrial Demand for Superacid Applications

The industrial demand for superacid applications has been steadily growing, driven by the unique properties and capabilities of these highly acidic substances. Fluoroantimonic acid, being one of the strongest known superacids, finds significant applications in various industrial sectors. The petrochemical industry, in particular, relies heavily on superacids for catalytic processes in the production of high-octane gasoline and other petroleum-based products.

In the field of materials science and engineering, superacids play a crucial role in the synthesis of novel materials and the modification of existing ones. The electronics industry utilizes superacids in the etching of semiconductor materials and the production of advanced electronic components. Additionally, the pharmaceutical sector employs superacids in the synthesis of complex organic compounds and drug intermediates.

The demand for superacids in industrial applications is further fueled by the increasing focus on energy efficiency and sustainability. Superacids enable more efficient chemical reactions, often reducing the number of steps required in manufacturing processes and minimizing waste production. This aligns with the global trend towards greener and more sustainable industrial practices.

However, the use of superacids, especially fluoroantimonic acid, comes with significant challenges and risks. The extreme corrosiveness and reactivity of these substances necessitate specialized handling equipment and stringent safety protocols. This has led to a growing demand for innovative containment solutions and safety technologies in industries that rely on superacids.

The aerospace and defense sectors also contribute to the industrial demand for superacids. These substances are used in the development of high-performance materials and coatings that can withstand extreme conditions. The ongoing research and development in these fields continue to expand the potential applications of superacids, further driving industrial demand.

As environmental regulations become more stringent, there is an increasing need for superacid-based technologies that can help in pollution control and waste treatment. This has opened up new avenues for superacid applications in environmental remediation and industrial waste management.

The global market for superacids is expected to grow significantly in the coming years, with Asia-Pacific region showing the highest growth potential due to rapid industrialization and increasing investments in research and development. North America and Europe continue to be major consumers of superacids, particularly in high-tech industries and advanced manufacturing sectors.

In the field of materials science and engineering, superacids play a crucial role in the synthesis of novel materials and the modification of existing ones. The electronics industry utilizes superacids in the etching of semiconductor materials and the production of advanced electronic components. Additionally, the pharmaceutical sector employs superacids in the synthesis of complex organic compounds and drug intermediates.

The demand for superacids in industrial applications is further fueled by the increasing focus on energy efficiency and sustainability. Superacids enable more efficient chemical reactions, often reducing the number of steps required in manufacturing processes and minimizing waste production. This aligns with the global trend towards greener and more sustainable industrial practices.

However, the use of superacids, especially fluoroantimonic acid, comes with significant challenges and risks. The extreme corrosiveness and reactivity of these substances necessitate specialized handling equipment and stringent safety protocols. This has led to a growing demand for innovative containment solutions and safety technologies in industries that rely on superacids.

The aerospace and defense sectors also contribute to the industrial demand for superacids. These substances are used in the development of high-performance materials and coatings that can withstand extreme conditions. The ongoing research and development in these fields continue to expand the potential applications of superacids, further driving industrial demand.

As environmental regulations become more stringent, there is an increasing need for superacid-based technologies that can help in pollution control and waste treatment. This has opened up new avenues for superacid applications in environmental remediation and industrial waste management.

The global market for superacids is expected to grow significantly in the coming years, with Asia-Pacific region showing the highest growth potential due to rapid industrialization and increasing investments in research and development. North America and Europe continue to be major consumers of superacids, particularly in high-tech industries and advanced manufacturing sectors.

Current Challenges in Fluoroantimonic Acid Handling

Fluoroantimonic acid, known as the world's strongest superacid, presents significant challenges in handling and usage due to its extreme corrosiveness and reactivity. The primary concern is its ability to react violently with water and most organic compounds, making containment and storage a critical issue. Standard laboratory glassware and many common materials are unsuitable for handling this acid, as it can rapidly degrade them.

One of the major challenges is finding appropriate containment materials. Fluoroantimonic acid reacts with glass, most metals, and even many plastics. Currently, only a few materials such as Teflon (PTFE) and certain fluoropolymers can withstand its corrosive nature. This limitation severely restricts the design of storage vessels and reaction apparatus, complicating both research and industrial applications.

Worker safety is another paramount concern. The acid's extreme corrosiveness poses severe health risks, including severe burns and potential organ damage upon exposure. Conventional personal protective equipment (PPE) may not provide adequate protection, necessitating specialized gear and handling protocols. The development of more effective protective measures and safety protocols remains an ongoing challenge in the field.

Environmental risks associated with fluoroantimonic acid usage are also significant. Accidental releases could have devastating effects on ecosystems due to the acid's extreme reactivity with water and organic matter. Proper disposal methods are limited and complex, requiring specialized facilities and procedures to neutralize and handle the acid safely.

The transportation of fluoroantimonic acid presents another set of challenges. Its reactivity makes it a hazardous material for shipping, requiring specialized containers and strict adherence to transportation regulations. The risk of accidents during transit necessitates careful planning and risk mitigation strategies.

In research and industrial settings, the precise control of reactions involving fluoroantimonic acid is challenging due to its extreme reactivity. This makes it difficult to harness its potential in certain chemical processes without risking uncontrolled reactions or equipment damage. Developing more robust control mechanisms and reaction vessels remains an area of active research.

Lastly, the limited availability and high cost of fluoroantimonic acid pose challenges for widespread adoption in industrial processes. Its production requires specialized facilities and precautions, contributing to its scarcity and expense. This economic factor, combined with the safety and handling challenges, often limits its use to specialized applications where alternative acids are insufficient.

One of the major challenges is finding appropriate containment materials. Fluoroantimonic acid reacts with glass, most metals, and even many plastics. Currently, only a few materials such as Teflon (PTFE) and certain fluoropolymers can withstand its corrosive nature. This limitation severely restricts the design of storage vessels and reaction apparatus, complicating both research and industrial applications.

Worker safety is another paramount concern. The acid's extreme corrosiveness poses severe health risks, including severe burns and potential organ damage upon exposure. Conventional personal protective equipment (PPE) may not provide adequate protection, necessitating specialized gear and handling protocols. The development of more effective protective measures and safety protocols remains an ongoing challenge in the field.

Environmental risks associated with fluoroantimonic acid usage are also significant. Accidental releases could have devastating effects on ecosystems due to the acid's extreme reactivity with water and organic matter. Proper disposal methods are limited and complex, requiring specialized facilities and procedures to neutralize and handle the acid safely.

The transportation of fluoroantimonic acid presents another set of challenges. Its reactivity makes it a hazardous material for shipping, requiring specialized containers and strict adherence to transportation regulations. The risk of accidents during transit necessitates careful planning and risk mitigation strategies.

In research and industrial settings, the precise control of reactions involving fluoroantimonic acid is challenging due to its extreme reactivity. This makes it difficult to harness its potential in certain chemical processes without risking uncontrolled reactions or equipment damage. Developing more robust control mechanisms and reaction vessels remains an area of active research.

Lastly, the limited availability and high cost of fluoroantimonic acid pose challenges for widespread adoption in industrial processes. Its production requires specialized facilities and precautions, contributing to its scarcity and expense. This economic factor, combined with the safety and handling challenges, often limits its use to specialized applications where alternative acids are insufficient.

Existing Risk Mitigation Strategies for Fluoroantimonic Acid

01 Extreme corrosiveness and reactivity

Fluoroantimonic acid is known for its extreme corrosiveness and high reactivity. It can react violently with water and many organic compounds, posing significant risks in handling and storage. Special containment materials and strict safety protocols are necessary when working with this superacid.- Extreme corrosiveness and reactivity: Fluoroantimonic acid is known for its extreme corrosiveness and high reactivity. It can react violently with water and many organic compounds, posing significant risks in handling and storage. Its corrosive nature can cause severe damage to skin, eyes, and respiratory system upon exposure.

- Environmental hazards: The use and disposal of fluoroantimonic acid present serious environmental concerns. It can cause severe contamination of soil and water sources, potentially leading to long-term ecological damage. Proper containment and disposal methods are crucial to mitigate these risks.

- Safety protocols and protective equipment: Handling fluoroantimonic acid requires stringent safety measures. This includes the use of specialized protective equipment, such as chemical-resistant suits, gloves, and respiratory protection. Proper training and adherence to safety protocols are essential for personnel working with this substance.

- Storage and transportation challenges: The storage and transportation of fluoroantimonic acid pose significant challenges due to its highly reactive nature. Special containers and handling procedures are necessary to prevent accidental release or reactions during storage and transit. This includes using materials resistant to its corrosive properties.

- Industrial applications and alternatives: Despite its risks, fluoroantimonic acid has specific industrial applications. However, due to its hazardous nature, research into safer alternatives or modified processes that reduce exposure risks is ongoing. This includes exploring less dangerous catalysts or reaction pathways in relevant industrial processes.

02 Health hazards and toxicity

Exposure to fluoroantimonic acid can cause severe health hazards, including chemical burns, respiratory issues, and potential long-term effects. Its toxicity requires specialized personal protective equipment and emergency response procedures to mitigate risks to human health.Expand Specific Solutions03 Environmental impact and disposal challenges

The use and disposal of fluoroantimonic acid present significant environmental risks. Its high reactivity can lead to harmful emissions and contamination of soil and water sources. Proper disposal methods and containment strategies are crucial to prevent environmental damage.Expand Specific Solutions04 Safety measures in industrial applications

Industrial use of fluoroantimonic acid requires extensive safety measures, including specialized equipment, containment systems, and rigorous handling procedures. Risk assessment and management strategies are essential to prevent accidents and ensure worker safety in facilities using this superacid.Expand Specific Solutions05 Regulatory compliance and transportation risks

The transportation and use of fluoroantimonic acid are subject to strict regulatory controls due to its hazardous nature. Compliance with international and local regulations is crucial, and special considerations must be given to its transportation to minimize risks of accidents or spills during transit.Expand Specific Solutions

Key Players in Superacid Production and Research

The competitive landscape for mitigating risks with fluoroantimonic acid usage is in its early development stage, with a relatively small but growing market. The technology maturity is still evolving, as evidenced by the diverse range of companies involved, including pharmaceutical giants like Novartis AG, Sanofi, and Bayer AG, as well as research institutions such as Centre National de la Recherche Scientifique and German Cancer Research Center. The presence of specialized chemical companies like P2 Science, Inc. and environmental firms like Hunan Kinglv Environmental Protection Co., Ltd. indicates a multidisciplinary approach to addressing the challenges. This diverse ecosystem suggests that while progress is being made, standardized solutions are still emerging, presenting opportunities for innovation and market leadership.

Novartis AG

Technical Solution: Novartis has implemented a holistic risk mitigation strategy for fluoroantimonic acid usage that combines advanced engineering controls with comprehensive administrative and personal protective measures. Their approach includes the development of fully automated handling systems housed within multiple containment layers, each equipped with independent ventilation and neutralization capabilities. Novartis has also invested in creating a specialized emergency response team trained in handling extreme acid incidents, and has developed partnerships with local authorities to ensure coordinated response in case of larger scale events.

Strengths: Comprehensive approach combining multiple layers of protection, specialized emergency response capabilities, and strong focus on collaborative safety measures. Weaknesses: High operational costs and potential for complacency due to multiple safety layers.

Sanofi

Technical Solution: Sanofi has developed a multi-faceted approach to mitigating risks associated with fluoroantimonic acid usage. Their strategy involves the use of advanced materials science to create ultra-resistant containment vessels and handling equipment, coupled with the implementation of a sophisticated atmospheric control system that maintains a controlled environment to prevent acid vaporization. Sanofi has also pioneered the use of AI-driven predictive maintenance systems to anticipate and prevent equipment failures before they occur, significantly reducing the risk of accidental releases.

Strengths: Strong focus on materials innovation, advanced predictive maintenance capabilities, and comprehensive environmental control. Weaknesses: Complexity of the system may require specialized maintenance and potential for over-reliance on technology.

Innovative Containment and Neutralization Techniques

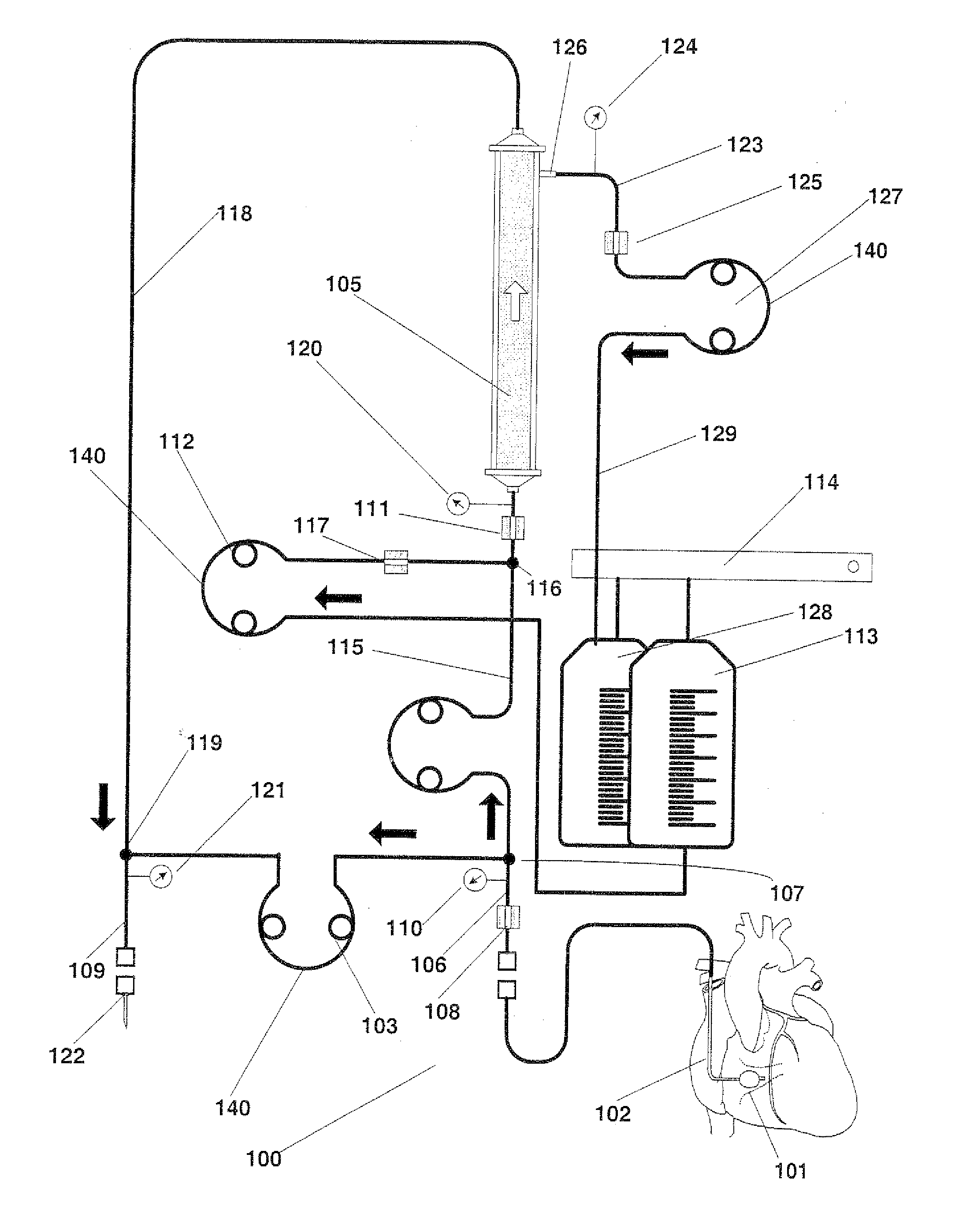

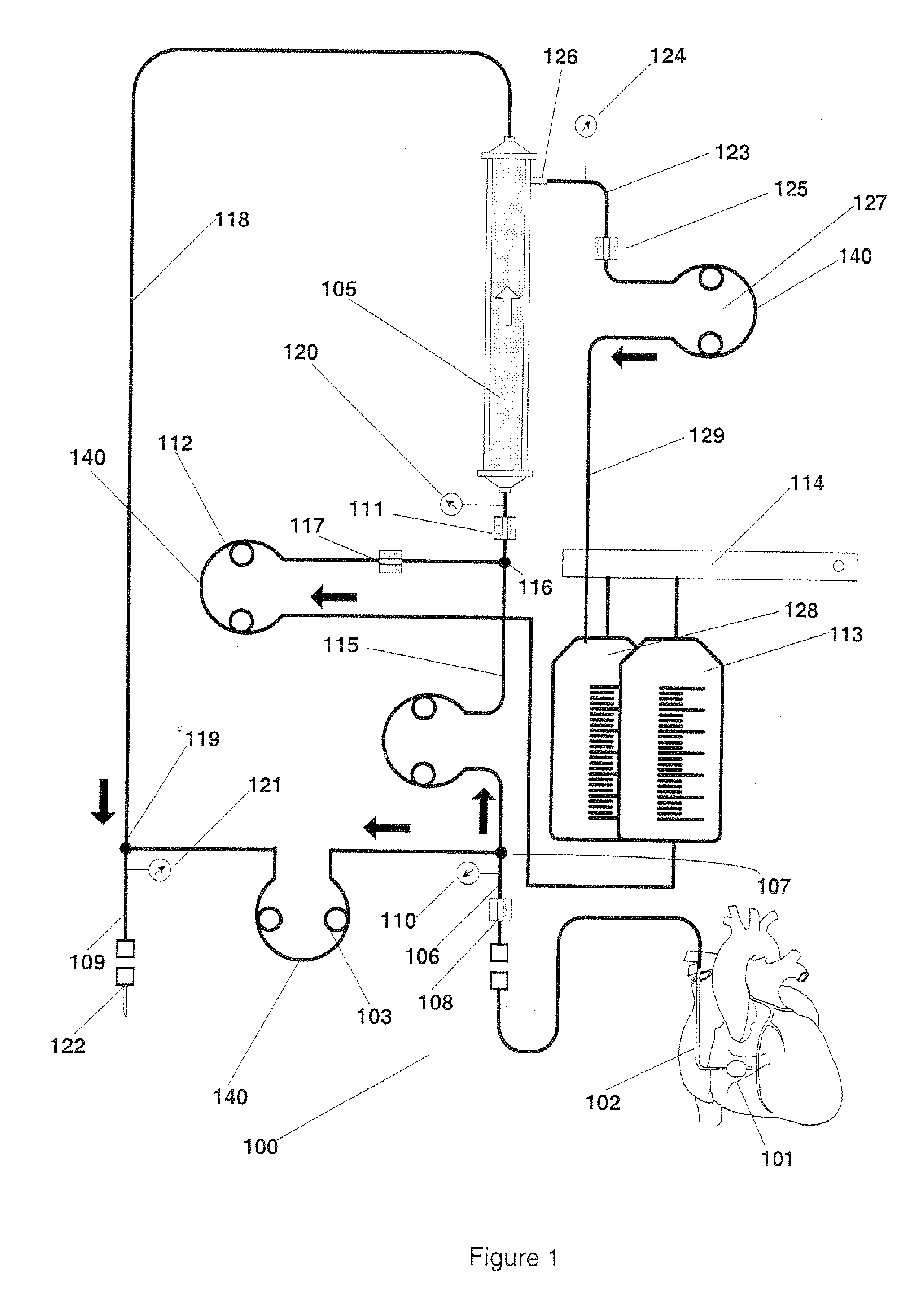

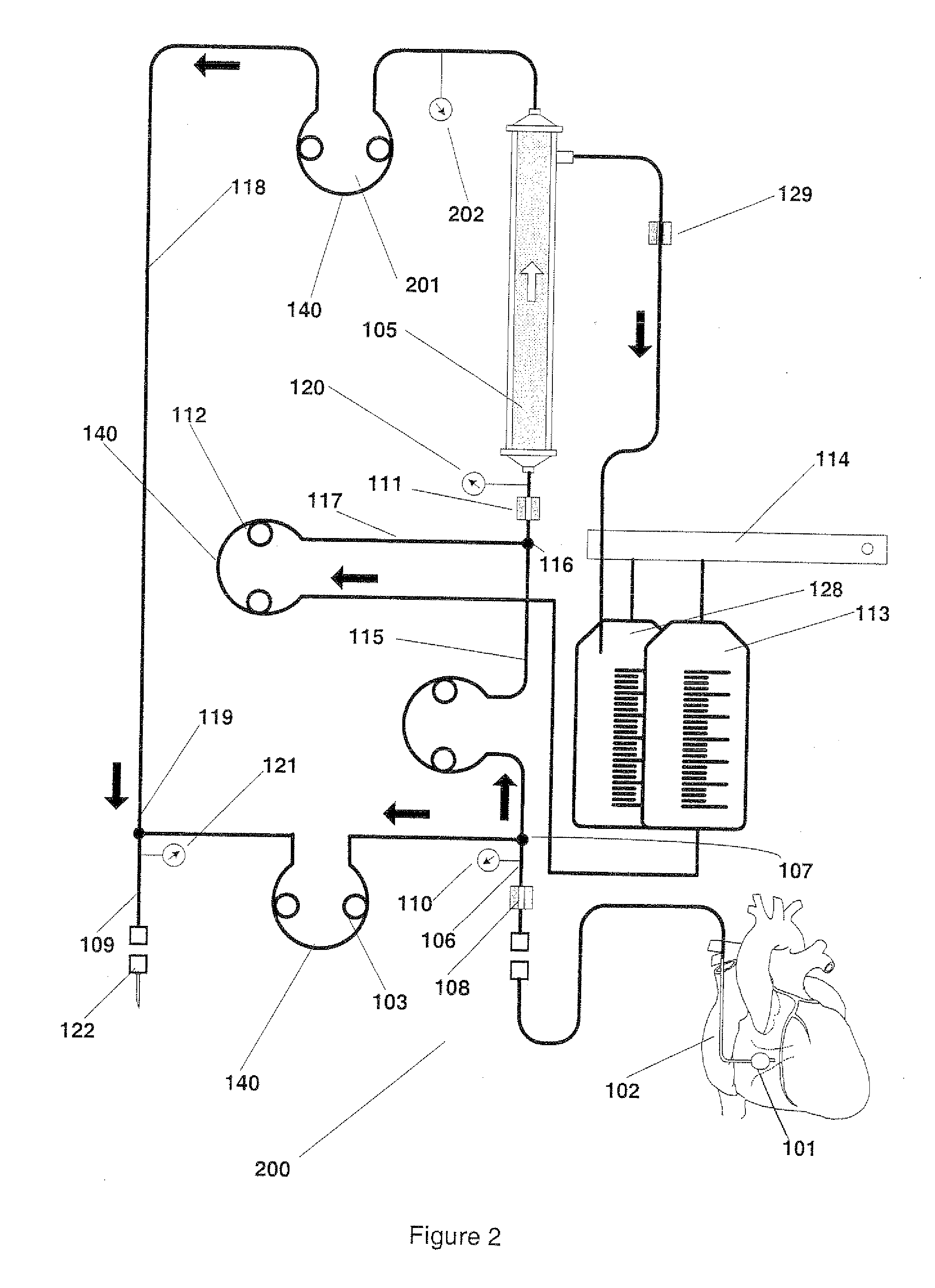

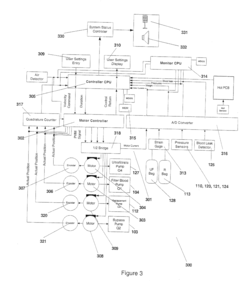

Method and device for removal of radiocontrast media from blood

PatentInactiveUS20070123838A1

Innovation

- A novel blood withdrawal and infusion system that uses a coronary sinus catheter with an occluding balloon to continuously pump blood through a filter, allowing for the detection and removal of contrast agents via a bypass pump, ensuring continuous coronary sinus blood flow and minimizing collateral blood flow loss, thereby reducing the concentration of contrast media in the blood.

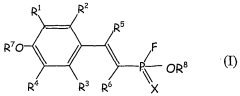

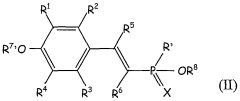

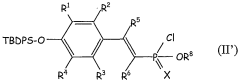

Fluorophosphonocinnamic compounds, synthesis and uses for treating disorders caused by oxidative stress

PatentWO2006037869A2

Innovation

- A process involving a complex formed between a tertiary amine and hydrogen fluoride is used to fluorinate phosphonocinnamic compounds, allowing for the production of fluorophosphonocinnamic compounds with improved antioxidant activity, using easily accessible and safer reagents at room temperature or lower temperatures.

Environmental Impact and Waste Management

Fluoroantimonic acid, known as the world's strongest superacid, poses significant environmental risks and waste management challenges. Its extreme corrosiveness and reactivity necessitate stringent handling protocols to prevent ecological damage and ensure worker safety. When released into the environment, fluoroantimonic acid can cause severe harm to ecosystems, contaminating soil and water sources, and potentially leading to long-term ecological imbalances.

To mitigate these risks, comprehensive waste management strategies are crucial. Neutralization is a primary method for treating fluoroantimonic acid waste. This process involves carefully adding the acid to a large volume of cold water or ice, followed by neutralization with bases such as sodium hydroxide or calcium hydroxide. The resulting salt solution can then be further treated or disposed of according to local regulations.

Containment is another critical aspect of managing fluoroantimonic acid waste. Specialized containers made of materials resistant to superacids, such as PTFE (Teflon) or certain grades of stainless steel, must be used for storage and transportation. These containers should be regularly inspected for integrity to prevent leaks or spills.

Implementing a closed-loop system for fluoroantimonic acid usage can significantly reduce waste generation and environmental impact. This approach involves recovering and recycling the acid whenever possible, minimizing the amount of waste that requires disposal. Advanced purification techniques, such as distillation or membrane separation, can be employed to regenerate the acid for reuse.

Emergency response planning is essential for mitigating the environmental impact of potential spills or accidents. This includes having specialized spill kits on hand, training personnel in proper response procedures, and establishing clear communication channels with local environmental authorities and emergency services.

Monitoring and documentation play a crucial role in environmental protection and waste management. Regular environmental assessments, including soil and water testing in areas where fluoroantimonic acid is used or stored, can help detect and address contamination early. Maintaining detailed records of acid usage, waste generation, and disposal methods is not only a regulatory requirement in many jurisdictions but also aids in optimizing waste reduction strategies over time.

Research into alternative technologies or less hazardous substitutes for processes that currently rely on fluoroantimonic acid should be an ongoing effort. While challenging due to the unique properties of this superacid, advancements in green chemistry and process engineering may yield safer alternatives that can reduce or eliminate the environmental risks associated with its use.

To mitigate these risks, comprehensive waste management strategies are crucial. Neutralization is a primary method for treating fluoroantimonic acid waste. This process involves carefully adding the acid to a large volume of cold water or ice, followed by neutralization with bases such as sodium hydroxide or calcium hydroxide. The resulting salt solution can then be further treated or disposed of according to local regulations.

Containment is another critical aspect of managing fluoroantimonic acid waste. Specialized containers made of materials resistant to superacids, such as PTFE (Teflon) or certain grades of stainless steel, must be used for storage and transportation. These containers should be regularly inspected for integrity to prevent leaks or spills.

Implementing a closed-loop system for fluoroantimonic acid usage can significantly reduce waste generation and environmental impact. This approach involves recovering and recycling the acid whenever possible, minimizing the amount of waste that requires disposal. Advanced purification techniques, such as distillation or membrane separation, can be employed to regenerate the acid for reuse.

Emergency response planning is essential for mitigating the environmental impact of potential spills or accidents. This includes having specialized spill kits on hand, training personnel in proper response procedures, and establishing clear communication channels with local environmental authorities and emergency services.

Monitoring and documentation play a crucial role in environmental protection and waste management. Regular environmental assessments, including soil and water testing in areas where fluoroantimonic acid is used or stored, can help detect and address contamination early. Maintaining detailed records of acid usage, waste generation, and disposal methods is not only a regulatory requirement in many jurisdictions but also aids in optimizing waste reduction strategies over time.

Research into alternative technologies or less hazardous substitutes for processes that currently rely on fluoroantimonic acid should be an ongoing effort. While challenging due to the unique properties of this superacid, advancements in green chemistry and process engineering may yield safer alternatives that can reduce or eliminate the environmental risks associated with its use.

Regulatory Framework for Hazardous Chemical Handling

The regulatory framework for handling hazardous chemicals, particularly fluoroantimonic acid, is a critical aspect of risk mitigation in industrial and research settings. Governments and international organizations have established comprehensive guidelines and regulations to ensure the safe use, storage, and disposal of such dangerous substances. These regulations typically encompass several key areas, including worker safety, environmental protection, and public health.

In the United States, the Occupational Safety and Health Administration (OSHA) sets forth stringent requirements for handling hazardous chemicals. The Hazard Communication Standard (HCS) mandates that employers provide information about chemical hazards and associated protective measures to their workers. This includes proper labeling, safety data sheets, and training programs. For fluoroantimonic acid, which is classified as an extremely corrosive and reactive substance, additional precautions are required under OSHA's Laboratory Standard and Process Safety Management regulations.

The Environmental Protection Agency (EPA) also plays a crucial role in regulating hazardous chemicals. Under the Toxic Substances Control Act (TSCA), the EPA has the authority to require reporting, record-keeping, and testing of chemicals that may pose environmental or health risks. For fluoroantimonic acid, strict controls on production, use, and disposal are enforced to prevent environmental contamination and protect ecosystems.

Internationally, the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to chemical hazard communication. This system has been widely adopted, facilitating consistent safety practices across borders. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation further exemplifies the global trend towards comprehensive chemical management.

Transportation of hazardous chemicals like fluoroantimonic acid is governed by specific regulations to ensure public safety. In the US, the Department of Transportation (DOT) enforces the Hazardous Materials Regulations (HMR), which dictate packaging, labeling, and shipping requirements. Similarly, international air and sea transport are regulated by the International Air Transport Association (IATA) and the International Maritime Dangerous Goods (IMDG) Code, respectively.

Compliance with these regulatory frameworks is essential for organizations working with fluoroantimonic acid. This includes implementing robust safety management systems, conducting regular risk assessments, and maintaining detailed documentation of chemical handling procedures. Failure to adhere to these regulations can result in severe penalties, including fines and legal liabilities.

In the United States, the Occupational Safety and Health Administration (OSHA) sets forth stringent requirements for handling hazardous chemicals. The Hazard Communication Standard (HCS) mandates that employers provide information about chemical hazards and associated protective measures to their workers. This includes proper labeling, safety data sheets, and training programs. For fluoroantimonic acid, which is classified as an extremely corrosive and reactive substance, additional precautions are required under OSHA's Laboratory Standard and Process Safety Management regulations.

The Environmental Protection Agency (EPA) also plays a crucial role in regulating hazardous chemicals. Under the Toxic Substances Control Act (TSCA), the EPA has the authority to require reporting, record-keeping, and testing of chemicals that may pose environmental or health risks. For fluoroantimonic acid, strict controls on production, use, and disposal are enforced to prevent environmental contamination and protect ecosystems.

Internationally, the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to chemical hazard communication. This system has been widely adopted, facilitating consistent safety practices across borders. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation further exemplifies the global trend towards comprehensive chemical management.

Transportation of hazardous chemicals like fluoroantimonic acid is governed by specific regulations to ensure public safety. In the US, the Department of Transportation (DOT) enforces the Hazardous Materials Regulations (HMR), which dictate packaging, labeling, and shipping requirements. Similarly, international air and sea transport are regulated by the International Air Transport Association (IATA) and the International Maritime Dangerous Goods (IMDG) Code, respectively.

Compliance with these regulatory frameworks is essential for organizations working with fluoroantimonic acid. This includes implementing robust safety management systems, conducting regular risk assessments, and maintaining detailed documentation of chemical handling procedures. Failure to adhere to these regulations can result in severe penalties, including fines and legal liabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!