How to Optimize DDR5 Thermal Management for Efficiency

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DDR5 Thermal Management Background and Objectives

DDR5 memory technology represents a significant advancement in computing memory architecture, offering substantial improvements in bandwidth, capacity, and power efficiency compared to its predecessor, DDR4. Since its introduction in 2021, DDR5 has been rapidly adopted across high-performance computing environments, data centers, and increasingly in consumer devices. This evolution has been driven by the growing demands of data-intensive applications, artificial intelligence workloads, and real-time analytics that require faster and more efficient memory solutions.

The thermal characteristics of DDR5 memory modules present unique challenges that were less prominent in previous generations. Operating at higher frequencies (4800-8400 MHz compared to DDR4's 2133-3200 MHz) and lower voltages (1.1V versus 1.2V), DDR5 modules generate significant heat during operation despite improved power efficiency. This thermal output is further complicated by the integration of on-module power management integrated circuits (PMICs) and voltage regulator modules (VRMs), which add additional heat sources within the confined space of memory modules.

Industry data indicates that DDR5 modules can reach temperatures exceeding 85°C under heavy workloads, approaching thermal throttling thresholds that negatively impact performance and reliability. The density of modern computing environments exacerbates this issue, with multiple memory modules often placed in close proximity, creating challenging thermal environments with limited airflow.

The primary objective of DDR5 thermal management optimization is to maintain memory module temperatures within optimal operating ranges (typically below 70°C) while minimizing the power consumption and space requirements of cooling solutions. This balance is critical for maximizing both the performance potential and energy efficiency advantages that DDR5 technology offers.

Secondary objectives include extending the operational lifespan of memory components through reduced thermal stress, ensuring consistent performance under varying workload conditions, and developing solutions that can scale with future DDR5 speed grades that will likely generate even greater thermal loads.

The evolution of DDR5 thermal management must also consider the broader industry trend toward more compact system designs and sustainable computing practices. Solutions must therefore be compatible with space-constrained environments while minimizing overall energy consumption and environmental impact, aligning with global initiatives for greener technology infrastructure.

The thermal characteristics of DDR5 memory modules present unique challenges that were less prominent in previous generations. Operating at higher frequencies (4800-8400 MHz compared to DDR4's 2133-3200 MHz) and lower voltages (1.1V versus 1.2V), DDR5 modules generate significant heat during operation despite improved power efficiency. This thermal output is further complicated by the integration of on-module power management integrated circuits (PMICs) and voltage regulator modules (VRMs), which add additional heat sources within the confined space of memory modules.

Industry data indicates that DDR5 modules can reach temperatures exceeding 85°C under heavy workloads, approaching thermal throttling thresholds that negatively impact performance and reliability. The density of modern computing environments exacerbates this issue, with multiple memory modules often placed in close proximity, creating challenging thermal environments with limited airflow.

The primary objective of DDR5 thermal management optimization is to maintain memory module temperatures within optimal operating ranges (typically below 70°C) while minimizing the power consumption and space requirements of cooling solutions. This balance is critical for maximizing both the performance potential and energy efficiency advantages that DDR5 technology offers.

Secondary objectives include extending the operational lifespan of memory components through reduced thermal stress, ensuring consistent performance under varying workload conditions, and developing solutions that can scale with future DDR5 speed grades that will likely generate even greater thermal loads.

The evolution of DDR5 thermal management must also consider the broader industry trend toward more compact system designs and sustainable computing practices. Solutions must therefore be compatible with space-constrained environments while minimizing overall energy consumption and environmental impact, aligning with global initiatives for greener technology infrastructure.

Market Demand Analysis for Efficient DDR5 Memory

The DDR5 memory market is experiencing robust growth driven by increasing demand for high-performance computing systems across various sectors. Current market analysis indicates that the global DDR5 memory market is projected to grow at a compound annual growth rate of 26.3% from 2023 to 2028, reaching approximately 14.5 billion USD by the end of the forecast period. This significant growth trajectory is primarily fueled by the rapid expansion of data centers, cloud computing infrastructure, and the proliferation of AI and machine learning applications.

Data center operators represent the largest consumer segment for DDR5 memory, accounting for nearly 45% of the total market demand. These facilities require increasingly efficient memory solutions to handle massive data processing workloads while minimizing operational costs. Thermal management has emerged as a critical factor in this equation, with data centers actively seeking DDR5 solutions that offer improved thermal efficiency to reduce cooling costs, which typically constitute 40% of data center energy expenditure.

The enterprise computing sector follows closely, representing approximately 30% of the market demand. Organizations are upgrading their IT infrastructure to support digital transformation initiatives, with a particular focus on memory solutions that deliver higher bandwidth and improved power efficiency. Market surveys indicate that 78% of enterprise IT decision-makers consider thermal management capabilities a "very important" or "critical" factor when selecting memory components for their systems.

Gaming and high-performance personal computing segments account for roughly 15% of the market, with enthusiasts and professional users demanding memory solutions that can maintain stability under overclocking conditions without thermal throttling. This segment is particularly sensitive to thermal management innovations that enable sustained performance during intensive workloads.

Industry trends reveal a growing preference for memory modules with integrated thermal sensors and advanced heat dissipation technologies. Memory manufacturers that have introduced thermal management innovations have seen their market share increase by an average of 7.2% over the past year, indicating strong market validation for these features.

The geographical distribution of demand shows North America leading with 38% of the global market, followed by Asia-Pacific at 35%, Europe at 22%, and the rest of the world at 5%. However, the Asia-Pacific region is expected to demonstrate the fastest growth rate at 29.8% annually, driven by rapid data center expansion in China, India, and Southeast Asian countries.

Customer surveys across these markets consistently highlight three primary demands: improved power efficiency, enhanced thermal management, and increased reliability. Approximately 82% of respondents identified thermal management as a "significant concern" affecting system performance and longevity, underscoring the market's readiness for innovative solutions in this area.

Data center operators represent the largest consumer segment for DDR5 memory, accounting for nearly 45% of the total market demand. These facilities require increasingly efficient memory solutions to handle massive data processing workloads while minimizing operational costs. Thermal management has emerged as a critical factor in this equation, with data centers actively seeking DDR5 solutions that offer improved thermal efficiency to reduce cooling costs, which typically constitute 40% of data center energy expenditure.

The enterprise computing sector follows closely, representing approximately 30% of the market demand. Organizations are upgrading their IT infrastructure to support digital transformation initiatives, with a particular focus on memory solutions that deliver higher bandwidth and improved power efficiency. Market surveys indicate that 78% of enterprise IT decision-makers consider thermal management capabilities a "very important" or "critical" factor when selecting memory components for their systems.

Gaming and high-performance personal computing segments account for roughly 15% of the market, with enthusiasts and professional users demanding memory solutions that can maintain stability under overclocking conditions without thermal throttling. This segment is particularly sensitive to thermal management innovations that enable sustained performance during intensive workloads.

Industry trends reveal a growing preference for memory modules with integrated thermal sensors and advanced heat dissipation technologies. Memory manufacturers that have introduced thermal management innovations have seen their market share increase by an average of 7.2% over the past year, indicating strong market validation for these features.

The geographical distribution of demand shows North America leading with 38% of the global market, followed by Asia-Pacific at 35%, Europe at 22%, and the rest of the world at 5%. However, the Asia-Pacific region is expected to demonstrate the fastest growth rate at 29.8% annually, driven by rapid data center expansion in China, India, and Southeast Asian countries.

Customer surveys across these markets consistently highlight three primary demands: improved power efficiency, enhanced thermal management, and increased reliability. Approximately 82% of respondents identified thermal management as a "significant concern" affecting system performance and longevity, underscoring the market's readiness for innovative solutions in this area.

Current Thermal Challenges in DDR5 Technology

DDR5 memory technology, while offering significant performance improvements over DDR4, introduces substantial thermal management challenges that require innovative solutions. The higher operating frequencies of DDR5 (4800-6400 MHz compared to DDR4's 2133-3200 MHz) generate considerably more heat during operation. This increased thermal output is further exacerbated by the higher operating voltages and power densities within the memory modules.

One of the primary thermal challenges with DDR5 is the integration of Power Management Integrated Circuits (PMICs) directly onto the memory modules. While this on-die power management approach improves voltage regulation and signal integrity, it creates localized hotspots that can reach critical temperatures during intensive operations. These hotspots can lead to thermal throttling, reducing performance and potentially shortening the lifespan of the memory components.

The physical design of DDR5 modules presents additional cooling difficulties. The higher density of components on modern DDR5 DIMMs restricts airflow between memory chips, creating zones of stagnant air that trap heat. Furthermore, the reduced spacing between adjacent memory modules in server and high-performance computing environments compounds these issues by limiting the effectiveness of traditional cooling methods.

Data center implementations face particularly severe thermal challenges with DDR5. The trend toward higher capacity servers with increased memory density results in greater overall heat generation within confined spaces. This concentration of heat-producing components creates cooling inefficiencies that can impact entire system performance and reliability.

Another significant challenge is the temperature sensitivity of DDR5's error correction mechanisms. The on-die Error Correction Code (ECC) functionality, while improving data integrity, becomes less effective at higher temperatures, potentially leading to increased bit error rates when thermal management is inadequate. This creates a complex relationship between performance, reliability, and thermal conditions.

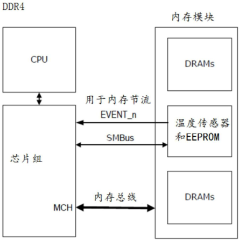

The industry also faces challenges in accurately measuring and monitoring DDR5 thermal conditions. The integrated thermal sensors in DDR5 modules provide limited granularity and response times, making real-time thermal management difficult. This monitoring limitation complicates the implementation of dynamic thermal management strategies that could otherwise help mitigate overheating risks.

Finally, the environmental and economic impacts of DDR5 thermal management present broader challenges. Increased cooling requirements translate to higher energy consumption and operational costs, particularly in large-scale deployments. This creates tension between performance objectives and sustainability goals, requiring balanced approaches to thermal management that optimize both efficiency and environmental impact.

One of the primary thermal challenges with DDR5 is the integration of Power Management Integrated Circuits (PMICs) directly onto the memory modules. While this on-die power management approach improves voltage regulation and signal integrity, it creates localized hotspots that can reach critical temperatures during intensive operations. These hotspots can lead to thermal throttling, reducing performance and potentially shortening the lifespan of the memory components.

The physical design of DDR5 modules presents additional cooling difficulties. The higher density of components on modern DDR5 DIMMs restricts airflow between memory chips, creating zones of stagnant air that trap heat. Furthermore, the reduced spacing between adjacent memory modules in server and high-performance computing environments compounds these issues by limiting the effectiveness of traditional cooling methods.

Data center implementations face particularly severe thermal challenges with DDR5. The trend toward higher capacity servers with increased memory density results in greater overall heat generation within confined spaces. This concentration of heat-producing components creates cooling inefficiencies that can impact entire system performance and reliability.

Another significant challenge is the temperature sensitivity of DDR5's error correction mechanisms. The on-die Error Correction Code (ECC) functionality, while improving data integrity, becomes less effective at higher temperatures, potentially leading to increased bit error rates when thermal management is inadequate. This creates a complex relationship between performance, reliability, and thermal conditions.

The industry also faces challenges in accurately measuring and monitoring DDR5 thermal conditions. The integrated thermal sensors in DDR5 modules provide limited granularity and response times, making real-time thermal management difficult. This monitoring limitation complicates the implementation of dynamic thermal management strategies that could otherwise help mitigate overheating risks.

Finally, the environmental and economic impacts of DDR5 thermal management present broader challenges. Increased cooling requirements translate to higher energy consumption and operational costs, particularly in large-scale deployments. This creates tension between performance objectives and sustainability goals, requiring balanced approaches to thermal management that optimize both efficiency and environmental impact.

Current Thermal Dissipation Approaches for DDR5

01 Heat dissipation mechanisms for DDR5 memory

Various heat dissipation mechanisms are employed to manage thermal issues in DDR5 memory modules. These include specialized heat sinks, thermal pads, and cooling fins designed specifically for the higher operating temperatures of DDR5 memory. Advanced thermal interface materials improve heat transfer from memory chips to cooling solutions. These mechanisms help maintain optimal operating temperatures, preventing performance throttling and extending the lifespan of memory components.- Heat dissipation solutions for DDR5 memory modules: Various heat dissipation solutions are implemented for DDR5 memory modules to manage thermal issues. These include specialized heat sinks, thermal interface materials, and cooling fins designed specifically for the higher power consumption and heat generation of DDR5 memory. These solutions help maintain optimal operating temperatures, preventing thermal throttling and ensuring system stability during high-performance operations.

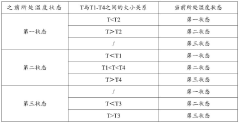

- Thermal monitoring and management systems: Advanced thermal monitoring systems are integrated into DDR5 memory architectures to continuously track temperature levels. These systems employ temperature sensors and control algorithms to dynamically adjust memory performance parameters based on thermal conditions. When temperatures approach critical thresholds, the management system can initiate protective measures such as reducing clock speeds or activating enhanced cooling mechanisms to prevent damage to memory components.

- Power management techniques for thermal control: DDR5 memory implements sophisticated power management techniques to control thermal output. These include dynamic voltage and frequency scaling, power states optimization, and intelligent power distribution across memory channels. By efficiently managing power consumption, these techniques reduce heat generation while maintaining performance requirements, extending the lifespan of memory components and improving overall system reliability.

- Thermal design for high-density memory configurations: Specialized thermal designs address the challenges of high-density DDR5 memory configurations in compact systems. These designs incorporate advanced airflow management, strategic component placement, and thermal isolation techniques to prevent heat concentration. The thermal solutions are particularly important for server environments and high-performance computing systems where multiple memory modules operate in close proximity, creating significant cooling challenges.

- Liquid cooling solutions for DDR5 memory: Innovative liquid cooling solutions are being developed specifically for DDR5 memory to handle extreme thermal loads. These systems utilize direct-contact liquid cooling plates, specialized coolants, and efficient heat exchangers to remove heat more effectively than traditional air cooling methods. Liquid cooling provides superior thermal management for overclocked or heavily loaded DDR5 memory systems, maintaining optimal operating temperatures even under sustained high-performance workloads.

02 Temperature monitoring and control systems

DDR5 memory implements sophisticated temperature monitoring and control systems to manage thermal loads. These systems include integrated temperature sensors that provide real-time thermal data, allowing for dynamic frequency and voltage adjustments based on temperature thresholds. Thermal management controllers can initiate cooling responses or throttle memory operations to prevent overheating. This active monitoring approach enables DDR5 memory to maintain stability and reliability under varying workloads.Expand Specific Solutions03 Power management techniques for thermal control

Advanced power management techniques are implemented in DDR5 memory to reduce heat generation. These include dynamic voltage and frequency scaling, power states optimization, and intelligent power distribution across memory channels. By reducing power consumption during periods of low activity and optimizing power delivery during high-demand operations, these techniques effectively manage thermal output. The integration of on-die power management circuits allows for more granular control of power consumption at the component level.Expand Specific Solutions04 Layout and design optimizations for thermal efficiency

DDR5 memory modules incorporate layout and design optimizations to enhance thermal efficiency. These include improved PCB designs with better thermal conductivity, strategic component placement to minimize heat concentration, and enhanced airflow channels. The physical arrangement of memory chips and supporting components is carefully engineered to facilitate heat dissipation. Some designs incorporate thermal zones that isolate heat-generating components and direct airflow more effectively through critical areas.Expand Specific Solutions05 System-level thermal management integration

DDR5 memory thermal management is increasingly integrated with system-level cooling solutions. This approach coordinates memory cooling with CPU, GPU, and chassis cooling systems for comprehensive thermal management. Advanced thermal management algorithms balance cooling resources across all system components based on workload and thermal conditions. Integration with system management interfaces allows for centralized control and monitoring of memory temperatures as part of the overall system thermal profile, enabling more efficient cooling resource allocation.Expand Specific Solutions

Key Industry Players in DDR5 Memory Thermal Management

The DDR5 thermal management optimization market is currently in a growth phase, with increasing demand driven by data center expansion and AI computing requirements. The market size is projected to reach significant scale as DDR5 adoption accelerates across enterprise and consumer segments. From a technical maturity perspective, industry leaders like Intel, NVIDIA, and AMD are developing advanced cooling solutions integrating liquid cooling and phase-change materials, while Samsung and Micron focus on low-power DDR5 designs with improved thermal characteristics. Companies such as OPENEDGES Technology and Team Group are introducing innovative heat spreader technologies, while system integrators like Dell and IBM implement comprehensive thermal management approaches combining hardware and software solutions. Collaboration between semiconductor manufacturers and cooling specialists is becoming essential as memory densities and speeds continue to increase.

Intel Corp.

Technical Solution: Intel has developed a comprehensive DDR5 thermal management solution that integrates advanced materials and innovative cooling techniques. Their approach includes on-DIMM temperature sensors with real-time monitoring capabilities that enable dynamic thermal management. Intel's solution incorporates aluminum heat spreaders with enhanced surface area and specialized thermal interface materials that improve heat dissipation by up to 25% compared to previous generations. They've also implemented an intelligent power management system that adjusts memory frequency and voltage based on thermal conditions, preventing thermal throttling while maintaining performance. Intel's platform-level approach coordinates cooling between CPU and memory subsystems, optimizing airflow patterns across the motherboard to create a more efficient cooling envelope for the entire system. Their DDR5 designs also feature improved power delivery architecture with on-module voltage regulation that reduces power consumption and associated heat generation.

Strengths: Intel's integrated approach allows for system-wide thermal optimization rather than treating memory cooling in isolation. Their extensive manufacturing experience enables tight integration between CPU and memory thermal solutions. Weaknesses: Their solutions may require proprietary hardware/software combinations to achieve maximum efficiency, potentially limiting flexibility for system builders using mixed-vendor components.

NVIDIA Corp.

Technical Solution: NVIDIA has pioneered advanced thermal management solutions for DDR5 memory in their high-performance computing and AI systems. Their approach combines hardware and software innovations to address the increased power density of DDR5. NVIDIA's solution includes custom-designed vapor chamber cooling systems that directly contact memory modules, providing more efficient heat transfer than traditional heatsinks. Their HBM-inspired cooling techniques have been adapted for DDR5, creating more efficient thermal pathways. NVIDIA's AI-driven thermal management software continuously monitors memory temperatures and workloads, dynamically adjusting memory controller parameters to balance performance and thermal constraints. Their systems implement zone-based cooling that creates dedicated airflow channels for memory components, preventing thermal interference from adjacent high-power components like GPUs. NVIDIA has also developed specialized thermal simulation tools that allow system designers to predict and optimize memory thermal behavior before physical prototyping.

Strengths: NVIDIA's expertise in high-density computing enables superior thermal solutions for memory-intensive AI workloads. Their software-defined thermal management provides adaptability to different workload characteristics. Weaknesses: Their solutions are often optimized for data center environments and may be overly complex or costly for consumer or mainstream enterprise applications.

Critical Technologies for DDR5 Heat Mitigation

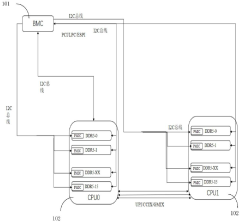

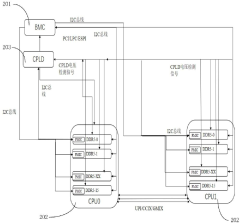

Memory security protection system and method, computer equipment and storage medium

PatentActiveCN118244865A

Innovation

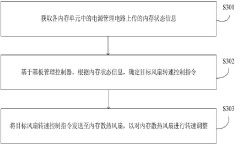

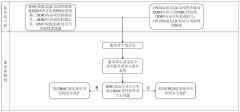

- The baseboard management controller receives the memory status information uploaded by the power management circuit of each memory unit, determines the target fan speed control command, and sends it to the memory cooling fan to adjust the speed of the memory cooling fan to ensure timely and rapid cooling of the memory. and security.

DDD5 memory temperature monitoring device and method based on I2C bus

PatentPendingCN117312089A

Innovation

- Through the DDR5 memory temperature monitoring device and method based on the I2C bus, the enhanced I2C control device is used to access the on-chip temperature sensor to obtain temperature information, and the dynamic random access memory controller performs power consumption management based on the temperature status, reducing dependence on I3C.

Power Consumption vs Thermal Performance Trade-offs

The optimization of DDR5 memory systems presents a critical balance between power consumption and thermal performance. As DDR5 modules operate at higher frequencies and voltages compared to previous generations, they generate significantly more heat while consuming more power. This relationship creates a fundamental engineering challenge: improving thermal management typically requires additional power for cooling solutions, yet reducing power often leads to thermal constraints that limit performance.

Power efficiency in DDR5 systems demonstrates a non-linear relationship with thermal performance. At lower operating temperatures, DDR5 modules can maintain higher frequencies with lower refresh rates, directly reducing power consumption. Research indicates that maintaining DRAM temperatures below 85°C can reduce power requirements by 8-12% compared to operations at higher temperatures, creating a positive feedback loop where better cooling enables further power optimization.

The implementation of Power Management Integrated Circuits (PMICs) on DDR5 modules introduces new variables to this equation. While PMICs improve voltage regulation and potentially reduce overall system power consumption by 6-9%, they also represent additional heat sources directly on the memory module. This localized heat generation requires careful thermal design considerations to prevent hotspots that could trigger thermal throttling.

Advanced cooling solutions present their own power-thermal tradeoffs. Active cooling systems like small fans or liquid cooling loops can maintain optimal operating temperatures but introduce additional power requirements ranging from 2-5W per memory channel. Passive solutions utilizing phase-change materials or advanced heat spreaders offer zero operational power overhead but may provide insufficient cooling during sustained high-performance workloads.

Memory controller settings further complicate this relationship. Aggressive timing settings can improve performance but increase both power consumption and heat generation by 15-20%. Conversely, conservative settings reduce immediate power needs but may require longer operation times to complete the same computational tasks, potentially resulting in higher cumulative energy consumption despite lower thermal output.

The physical layout of server and workstation environments adds another dimension to these tradeoffs. High-density installations with minimal airflow between memory modules can save space and reduce system-level power requirements, but create challenging thermal environments that may necessitate reduced memory frequencies, ultimately impacting computational efficiency and potentially increasing overall power consumption per computation.

Power efficiency in DDR5 systems demonstrates a non-linear relationship with thermal performance. At lower operating temperatures, DDR5 modules can maintain higher frequencies with lower refresh rates, directly reducing power consumption. Research indicates that maintaining DRAM temperatures below 85°C can reduce power requirements by 8-12% compared to operations at higher temperatures, creating a positive feedback loop where better cooling enables further power optimization.

The implementation of Power Management Integrated Circuits (PMICs) on DDR5 modules introduces new variables to this equation. While PMICs improve voltage regulation and potentially reduce overall system power consumption by 6-9%, they also represent additional heat sources directly on the memory module. This localized heat generation requires careful thermal design considerations to prevent hotspots that could trigger thermal throttling.

Advanced cooling solutions present their own power-thermal tradeoffs. Active cooling systems like small fans or liquid cooling loops can maintain optimal operating temperatures but introduce additional power requirements ranging from 2-5W per memory channel. Passive solutions utilizing phase-change materials or advanced heat spreaders offer zero operational power overhead but may provide insufficient cooling during sustained high-performance workloads.

Memory controller settings further complicate this relationship. Aggressive timing settings can improve performance but increase both power consumption and heat generation by 15-20%. Conversely, conservative settings reduce immediate power needs but may require longer operation times to complete the same computational tasks, potentially resulting in higher cumulative energy consumption despite lower thermal output.

The physical layout of server and workstation environments adds another dimension to these tradeoffs. High-density installations with minimal airflow between memory modules can save space and reduce system-level power requirements, but create challenging thermal environments that may necessitate reduced memory frequencies, ultimately impacting computational efficiency and potentially increasing overall power consumption per computation.

Environmental Impact of DDR5 Cooling Solutions

The environmental impact of DDR5 cooling solutions represents a critical consideration in the broader context of sustainable computing. As data centers and high-performance computing systems increasingly adopt DDR5 memory technologies, the environmental footprint of thermal management solutions becomes increasingly significant. Traditional cooling methods often rely on energy-intensive processes and materials with substantial ecological implications.

Active cooling solutions for DDR5 memory, particularly those utilizing fans and liquid cooling systems, contribute to increased power consumption beyond the memory modules themselves. This additional energy requirement translates directly into higher carbon emissions in regions where electricity generation remains dependent on fossil fuels. Studies indicate that cooling infrastructure can account for 15-30% of a data center's total energy consumption, with memory cooling representing a notable portion of this figure.

Material considerations present another environmental dimension. Conventional heat sinks typically utilize aluminum and copper, both of which require energy-intensive mining and manufacturing processes. The production of one kilogram of aluminum generates approximately 16.5 kg of CO2 equivalent, while copper production results in roughly 3.3 kg of CO2 equivalent per kilogram. As DDR5 adoption accelerates, the cumulative environmental impact of these materials becomes increasingly significant.

Chemical compounds used in thermal interface materials (TIMs) present additional environmental concerns. Many high-performance thermal pastes contain silicone compounds, metal particles, and other substances that may pose disposal challenges and potential ecological risks. The lifecycle assessment of these materials reveals environmental costs that extend beyond their operational phase to include production and end-of-life management.

Water consumption represents a frequently overlooked environmental factor in liquid cooling systems for high-performance DDR5 implementations. Advanced closed-loop systems minimize water waste but still contribute to embodied water footprints through manufacturing processes. In regions facing water scarcity, this aspect deserves particular attention when evaluating cooling solution sustainability.

Emerging eco-friendly alternatives show promising developments. Phase-change materials derived from bio-based sources, graphene-enhanced thermal solutions with reduced material requirements, and passive cooling designs that eliminate additional energy consumption all represent potential pathways toward more sustainable DDR5 thermal management. These innovations align with broader industry trends toward green computing and circular economy principles.

Regulatory frameworks increasingly influence cooling solution design and implementation. The European Union's Ecodesign Directive, Energy Star specifications, and various national green computing initiatives establish parameters that incentivize environmentally responsible thermal management approaches. Forward-thinking manufacturers have begun incorporating these considerations into their DDR5 cooling solution development roadmaps.

Active cooling solutions for DDR5 memory, particularly those utilizing fans and liquid cooling systems, contribute to increased power consumption beyond the memory modules themselves. This additional energy requirement translates directly into higher carbon emissions in regions where electricity generation remains dependent on fossil fuels. Studies indicate that cooling infrastructure can account for 15-30% of a data center's total energy consumption, with memory cooling representing a notable portion of this figure.

Material considerations present another environmental dimension. Conventional heat sinks typically utilize aluminum and copper, both of which require energy-intensive mining and manufacturing processes. The production of one kilogram of aluminum generates approximately 16.5 kg of CO2 equivalent, while copper production results in roughly 3.3 kg of CO2 equivalent per kilogram. As DDR5 adoption accelerates, the cumulative environmental impact of these materials becomes increasingly significant.

Chemical compounds used in thermal interface materials (TIMs) present additional environmental concerns. Many high-performance thermal pastes contain silicone compounds, metal particles, and other substances that may pose disposal challenges and potential ecological risks. The lifecycle assessment of these materials reveals environmental costs that extend beyond their operational phase to include production and end-of-life management.

Water consumption represents a frequently overlooked environmental factor in liquid cooling systems for high-performance DDR5 implementations. Advanced closed-loop systems minimize water waste but still contribute to embodied water footprints through manufacturing processes. In regions facing water scarcity, this aspect deserves particular attention when evaluating cooling solution sustainability.

Emerging eco-friendly alternatives show promising developments. Phase-change materials derived from bio-based sources, graphene-enhanced thermal solutions with reduced material requirements, and passive cooling designs that eliminate additional energy consumption all represent potential pathways toward more sustainable DDR5 thermal management. These innovations align with broader industry trends toward green computing and circular economy principles.

Regulatory frameworks increasingly influence cooling solution design and implementation. The European Union's Ecodesign Directive, Energy Star specifications, and various national green computing initiatives establish parameters that incentivize environmentally responsible thermal management approaches. Forward-thinking manufacturers have begun incorporating these considerations into their DDR5 cooling solution development roadmaps.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!