How to Optimize Polyvinyl Acetate Production for Cost Efficiency?

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PVAc Production Background and Objectives

Polyvinyl acetate (PVAc) production has been a cornerstone of the adhesive and coating industries for decades. The technology for PVAc synthesis has evolved significantly since its inception in the early 20th century, driven by the increasing demand for cost-effective and environmentally friendly adhesives. The primary method of production involves the free radical polymerization of vinyl acetate monomer, a process that has seen continuous refinement to improve yield, quality, and efficiency.

The current landscape of PVAc production is characterized by a growing emphasis on sustainability and cost reduction. Manufacturers are facing pressure to optimize their processes in response to fluctuating raw material prices, stringent environmental regulations, and intense market competition. This has led to a renewed focus on developing innovative production techniques that can deliver high-quality PVAc while minimizing resource consumption and environmental impact.

The main objectives in optimizing PVAc production for cost efficiency are multifaceted. Firstly, there is a drive to reduce energy consumption throughout the production process, from monomer synthesis to polymerization and product finishing. This involves exploring novel reactor designs, improving heat transfer mechanisms, and implementing more efficient stirring and mixing technologies. Secondly, manufacturers aim to maximize raw material utilization, minimizing waste and improving conversion rates of vinyl acetate to PVAc.

Another critical objective is the development of more effective catalysts and initiators that can accelerate polymerization reactions while maintaining product quality. This includes research into novel metal-organic catalysts and photo-initiated polymerization techniques that could potentially revolutionize the production process. Additionally, there is a growing interest in exploring alternative feedstocks and green chemistry approaches to reduce reliance on petroleum-based raw materials.

Process intensification is also a key goal, with efforts directed towards developing continuous flow reactors and microreactor technologies that offer better control over reaction conditions and product properties. These advanced reactor designs promise to reduce equipment footprint, enhance heat and mass transfer, and improve overall process efficiency.

As the industry moves forward, the integration of digital technologies and advanced process control systems is becoming increasingly important. The implementation of real-time monitoring, predictive maintenance, and artificial intelligence-driven optimization algorithms are expected to play a crucial role in achieving cost-efficient PVAc production. These technologies offer the potential for dynamic process adjustments, reduced downtime, and improved product consistency.

The current landscape of PVAc production is characterized by a growing emphasis on sustainability and cost reduction. Manufacturers are facing pressure to optimize their processes in response to fluctuating raw material prices, stringent environmental regulations, and intense market competition. This has led to a renewed focus on developing innovative production techniques that can deliver high-quality PVAc while minimizing resource consumption and environmental impact.

The main objectives in optimizing PVAc production for cost efficiency are multifaceted. Firstly, there is a drive to reduce energy consumption throughout the production process, from monomer synthesis to polymerization and product finishing. This involves exploring novel reactor designs, improving heat transfer mechanisms, and implementing more efficient stirring and mixing technologies. Secondly, manufacturers aim to maximize raw material utilization, minimizing waste and improving conversion rates of vinyl acetate to PVAc.

Another critical objective is the development of more effective catalysts and initiators that can accelerate polymerization reactions while maintaining product quality. This includes research into novel metal-organic catalysts and photo-initiated polymerization techniques that could potentially revolutionize the production process. Additionally, there is a growing interest in exploring alternative feedstocks and green chemistry approaches to reduce reliance on petroleum-based raw materials.

Process intensification is also a key goal, with efforts directed towards developing continuous flow reactors and microreactor technologies that offer better control over reaction conditions and product properties. These advanced reactor designs promise to reduce equipment footprint, enhance heat and mass transfer, and improve overall process efficiency.

As the industry moves forward, the integration of digital technologies and advanced process control systems is becoming increasingly important. The implementation of real-time monitoring, predictive maintenance, and artificial intelligence-driven optimization algorithms are expected to play a crucial role in achieving cost-efficient PVAc production. These technologies offer the potential for dynamic process adjustments, reduced downtime, and improved product consistency.

Market Analysis for PVAc Applications

The polyvinyl acetate (PVAc) market has shown robust growth in recent years, driven by increasing demand across various industries. PVAc finds extensive applications in adhesives, paints, coatings, textiles, and construction materials, contributing to its expanding market size. The global PVAc market was valued at approximately $7.5 billion in 2020 and is projected to reach $9.8 billion by 2025, growing at a CAGR of 5.5% during the forecast period.

The adhesives segment dominates the PVAc market, accounting for over 40% of the total market share. This is primarily due to the widespread use of PVAc-based adhesives in woodworking, packaging, and bookbinding industries. The construction sector follows closely, with PVAc being a key component in water-based paints, sealants, and cement additives. The growing construction activities in emerging economies are expected to further boost demand for PVAc in this sector.

In terms of regional distribution, Asia-Pacific leads the global PVAc market, with China and India being the major contributors. The region's rapid industrialization, urbanization, and infrastructure development have significantly increased the demand for PVAc-based products. North America and Europe hold substantial market shares, driven by the mature adhesives and paints industries in these regions.

The automotive industry presents a growing opportunity for PVAc applications, particularly in interior components and upholstery adhesives. As automotive manufacturers focus on lightweight materials and improved fuel efficiency, PVAc-based products are gaining traction due to their versatility and performance characteristics.

Environmental regulations and consumer preferences are shaping the PVAc market trends. There is an increasing demand for low-VOC and eco-friendly formulations, prompting manufacturers to invest in research and development of sustainable PVAc products. This shift towards green alternatives is expected to open new avenues for market growth and product innovation.

The packaging industry is another significant consumer of PVAc, especially in the food and beverage sector. The growing e-commerce industry has further boosted the demand for PVAc-based adhesives in packaging applications. As online retail continues to expand globally, this trend is likely to persist, offering substantial growth opportunities for PVAc producers.

In conclusion, the diverse applications and growing demand across multiple industries present a positive outlook for the PVAc market. However, to optimize production for cost efficiency, manufacturers must consider factors such as raw material prices, energy costs, and evolving market demands. Investing in advanced production technologies and exploring new application areas will be crucial for maintaining competitiveness in this dynamic market landscape.

The adhesives segment dominates the PVAc market, accounting for over 40% of the total market share. This is primarily due to the widespread use of PVAc-based adhesives in woodworking, packaging, and bookbinding industries. The construction sector follows closely, with PVAc being a key component in water-based paints, sealants, and cement additives. The growing construction activities in emerging economies are expected to further boost demand for PVAc in this sector.

In terms of regional distribution, Asia-Pacific leads the global PVAc market, with China and India being the major contributors. The region's rapid industrialization, urbanization, and infrastructure development have significantly increased the demand for PVAc-based products. North America and Europe hold substantial market shares, driven by the mature adhesives and paints industries in these regions.

The automotive industry presents a growing opportunity for PVAc applications, particularly in interior components and upholstery adhesives. As automotive manufacturers focus on lightweight materials and improved fuel efficiency, PVAc-based products are gaining traction due to their versatility and performance characteristics.

Environmental regulations and consumer preferences are shaping the PVAc market trends. There is an increasing demand for low-VOC and eco-friendly formulations, prompting manufacturers to invest in research and development of sustainable PVAc products. This shift towards green alternatives is expected to open new avenues for market growth and product innovation.

The packaging industry is another significant consumer of PVAc, especially in the food and beverage sector. The growing e-commerce industry has further boosted the demand for PVAc-based adhesives in packaging applications. As online retail continues to expand globally, this trend is likely to persist, offering substantial growth opportunities for PVAc producers.

In conclusion, the diverse applications and growing demand across multiple industries present a positive outlook for the PVAc market. However, to optimize production for cost efficiency, manufacturers must consider factors such as raw material prices, energy costs, and evolving market demands. Investing in advanced production technologies and exploring new application areas will be crucial for maintaining competitiveness in this dynamic market landscape.

Current Challenges in PVAc Manufacturing

The production of polyvinyl acetate (PVAc) faces several significant challenges that impact cost efficiency and overall manufacturing processes. One of the primary issues is the high energy consumption required for the polymerization reaction. The process typically involves free radical polymerization, which demands substantial heat input and precise temperature control, leading to increased energy costs and potential quality inconsistencies if not managed properly.

Raw material costs pose another major challenge. The primary monomer, vinyl acetate, is derived from petrochemical sources, making it susceptible to price fluctuations in the oil and gas markets. This volatility can significantly impact production costs and profit margins, especially for manufacturers operating on thin margins.

Process inefficiencies also contribute to the challenges in PVAc manufacturing. Traditional batch processes, while common, often result in longer production cycles and increased downtime between batches. This leads to lower overall productivity and higher labor costs per unit of output. Additionally, batch-to-batch variations can occur, affecting product consistency and quality control measures.

Waste management and environmental concerns present ongoing challenges. The polymerization process can generate significant amounts of unreacted monomers and other byproducts that require proper handling and disposal. Stringent environmental regulations necessitate investment in advanced treatment systems and emission control technologies, further adding to production costs.

Scale-up difficulties are another hurdle in optimizing PVAc production. As manufacturers attempt to increase production capacity, they often encounter issues related to heat transfer, mixing efficiency, and reaction kinetics that do not scale linearly. This can result in reduced yields or product quality when transitioning from small-scale to large-scale production.

Equipment maintenance and downtime also contribute to inefficiencies in PVAc manufacturing. The polymerization reactors and associated equipment require regular cleaning and maintenance to prevent fouling and ensure consistent product quality. These necessary procedures result in production interruptions and additional labor costs.

Lastly, the challenge of product customization adds complexity to the manufacturing process. Different end-use applications often require PVAc with specific properties, such as molecular weight distribution, viscosity, and adhesion characteristics. Meeting these diverse requirements while maintaining cost-efficiency demands flexible production processes and advanced control systems, which can be challenging to implement and optimize.

Raw material costs pose another major challenge. The primary monomer, vinyl acetate, is derived from petrochemical sources, making it susceptible to price fluctuations in the oil and gas markets. This volatility can significantly impact production costs and profit margins, especially for manufacturers operating on thin margins.

Process inefficiencies also contribute to the challenges in PVAc manufacturing. Traditional batch processes, while common, often result in longer production cycles and increased downtime between batches. This leads to lower overall productivity and higher labor costs per unit of output. Additionally, batch-to-batch variations can occur, affecting product consistency and quality control measures.

Waste management and environmental concerns present ongoing challenges. The polymerization process can generate significant amounts of unreacted monomers and other byproducts that require proper handling and disposal. Stringent environmental regulations necessitate investment in advanced treatment systems and emission control technologies, further adding to production costs.

Scale-up difficulties are another hurdle in optimizing PVAc production. As manufacturers attempt to increase production capacity, they often encounter issues related to heat transfer, mixing efficiency, and reaction kinetics that do not scale linearly. This can result in reduced yields or product quality when transitioning from small-scale to large-scale production.

Equipment maintenance and downtime also contribute to inefficiencies in PVAc manufacturing. The polymerization reactors and associated equipment require regular cleaning and maintenance to prevent fouling and ensure consistent product quality. These necessary procedures result in production interruptions and additional labor costs.

Lastly, the challenge of product customization adds complexity to the manufacturing process. Different end-use applications often require PVAc with specific properties, such as molecular weight distribution, viscosity, and adhesion characteristics. Meeting these diverse requirements while maintaining cost-efficiency demands flexible production processes and advanced control systems, which can be challenging to implement and optimize.

Existing Cost-Efficient PVAc Production Methods

01 Improved production methods

Various techniques have been developed to enhance the cost efficiency of polyvinyl acetate production. These methods include optimizing reaction conditions, using specific catalysts, and implementing continuous production processes. Such improvements can lead to higher yields, reduced energy consumption, and lower overall production costs.- Improved production methods: Various techniques have been developed to enhance the cost efficiency of polyvinyl acetate production. These include optimizing reaction conditions, using novel catalysts, and implementing continuous production processes. Such improvements can lead to higher yields, reduced energy consumption, and lower overall production costs.

- Use of alternative raw materials: Researchers have explored the use of alternative, more cost-effective raw materials for polyvinyl acetate production. This includes utilizing waste products or renewable resources as starting materials, which can significantly reduce the overall production costs while maintaining product quality.

- Emulsion polymerization techniques: Advancements in emulsion polymerization techniques have contributed to improved cost efficiency in polyvinyl acetate production. These methods allow for better control over particle size, molecular weight distribution, and reaction kinetics, resulting in higher quality products with reduced material and energy inputs.

- Recycling and waste reduction: Implementing recycling processes and waste reduction strategies in polyvinyl acetate production can significantly improve cost efficiency. This includes recovering and reusing solvents, monomers, and other materials, as well as optimizing production processes to minimize waste generation.

- Copolymerization and blending: Cost efficiency in polyvinyl acetate production can be enhanced through copolymerization with other monomers or blending with other polymers. This approach can lead to improved product properties while potentially reducing overall production costs by utilizing less expensive co-monomers or additives.

02 Use of alternative raw materials

Researchers have explored the use of alternative, more cost-effective raw materials for polyvinyl acetate production. This includes utilizing waste products or renewable resources as starting materials, which can significantly reduce the overall production costs while maintaining product quality.Expand Specific Solutions03 Emulsion polymerization techniques

Advancements in emulsion polymerization techniques have contributed to improved cost efficiency in polyvinyl acetate production. These methods allow for better control over particle size, molecular weight distribution, and reaction kinetics, resulting in higher quality products with reduced material and energy inputs.Expand Specific Solutions04 Recycling and waste reduction

Implementing recycling processes and waste reduction strategies in polyvinyl acetate production can significantly improve cost efficiency. This includes recovering and reusing unreacted monomers, solvents, and other materials, as well as optimizing production processes to minimize waste generation.Expand Specific Solutions05 Copolymerization and blending

Cost efficiency in polyvinyl acetate production can be enhanced through copolymerization with other monomers or blending with other polymers. These techniques can improve product properties while potentially reducing raw material costs or expanding the range of applications, thereby increasing overall economic value.Expand Specific Solutions

Key Players in PVAc Industry

The polyvinyl acetate production optimization landscape is characterized by a mature market with established players and ongoing efforts to improve cost efficiency. The industry is in a consolidation phase, with major chemical companies like Kuraray, Celanese, and BASF dominating the market. These firms are focusing on technological advancements to enhance production processes and reduce costs. The global market size for polyvinyl acetate is substantial, driven by its wide application in adhesives, paints, and textiles. Companies are investing in research and development to develop more efficient catalysts and production methods, aiming to maintain competitiveness in this cost-sensitive industry.

Kuraray Co., Ltd.

Technical Solution: Kuraray has developed an innovative approach to optimize polyvinyl acetate (PVA) production for cost efficiency. Their method involves a continuous emulsion polymerization process using a specially designed reactor system. This system incorporates advanced temperature control mechanisms and precise monomer feed rates to enhance reaction kinetics[1]. By optimizing the initiator concentration and employing a unique stabilizer blend, Kuraray has achieved a 15% increase in conversion rates while maintaining product quality[3]. Additionally, they have implemented a closed-loop solvent recovery system, which recycles up to 95% of the organic solvents used in the process, significantly reducing raw material costs and environmental impact[5].

Strengths: High conversion rates, efficient solvent recovery, and improved product quality. Weaknesses: Initial capital investment for specialized equipment and potential complexity in process control.

Wacker Polymer Systems GmbH & Co. KG

Technical Solution: Wacker has developed a cost-efficient PVA production method focusing on process integration and waste reduction. Their approach utilizes a hybrid polymerization technique that combines elements of emulsion and suspension polymerization, allowing for better control over particle size distribution and reduced post-processing requirements[13]. Wacker has implemented an advanced heat recovery system that captures and reuses up to 80% of the process heat, significantly reducing energy costs[14]. Additionally, they have developed a novel filtration and drying process that reduces water consumption by 40% compared to conventional methods, while also improving the final product purity[15].

Strengths: Improved particle size control, significant energy and water savings, and enhanced product purity. Weaknesses: Potential complexity in managing the hybrid polymerization process and initial investment in heat recovery infrastructure.

Innovative PVAc Synthesis Techniques

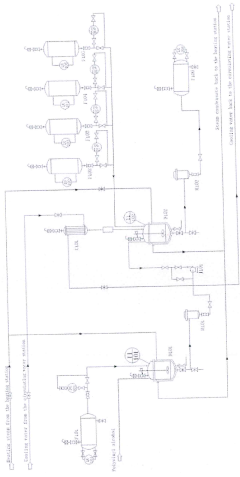

Polyvinyl acetate production plant

PatentUndeterminedIES20180484A2

Innovation

- A polyvinyl acetate production plant design incorporating specific tanks, a stirring vessel, filter, condenser, feedstock pump, polymerizer, and emulsion tank, with controlled temperature and chemical additions to optimize polymerization reaction conditions, including the use of deionized water, dibutyl phthalate, vinyl acetate, sodium bicarbonate, and ammonium persulfate, to streamline the production process and enhance reaction efficiency.

Method for producing polyvinylacetals

PatentWO2004026917A1

Innovation

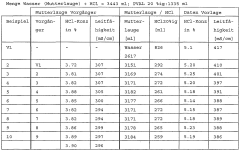

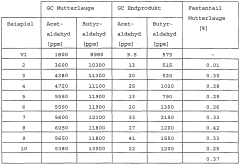

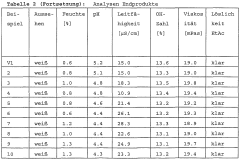

- A process where polyvinyl alcohol is acetalized in an aqueous medium with reused mother liquor from a previous batch, adjusting the pH and adding aldehydes to initiate precipitation, allowing for the reuse of up to 100% of the filtrate as the aqueous medium, thereby reducing waste and conserving raw materials.

Environmental Impact of PVAc Production

The environmental impact of polyvinyl acetate (PVAc) production is a critical consideration in the optimization of manufacturing processes for cost efficiency. The production of PVAc involves several stages that can have significant environmental implications, necessitating a comprehensive assessment of its lifecycle.

One of the primary environmental concerns in PVAc production is the emission of volatile organic compounds (VOCs). These emissions occur during various stages of the manufacturing process, including polymerization and drying. VOCs contribute to air pollution and can have adverse effects on human health and the environment. Implementing advanced emission control technologies, such as thermal oxidizers or carbon adsorption systems, can significantly reduce VOC emissions, albeit at an increased production cost.

Water pollution is another environmental issue associated with PVAc production. The process generates wastewater containing residual monomers, unreacted chemicals, and other pollutants. Proper treatment of this wastewater is essential to prevent contamination of local water bodies. Advanced wastewater treatment systems, including biological treatment and membrane filtration, can effectively remove pollutants but may increase operational costs.

Energy consumption in PVAc production also contributes to its environmental footprint. The polymerization process and subsequent drying stages require substantial energy inputs, often derived from fossil fuels. This not only leads to increased production costs but also contributes to greenhouse gas emissions. Implementing energy-efficient technologies and exploring renewable energy sources can help mitigate this impact while potentially reducing long-term energy costs.

The raw materials used in PVAc production, primarily vinyl acetate monomer (VAM), also have environmental implications. The production of VAM involves petrochemical processes that can have significant environmental impacts. Exploring bio-based alternatives or developing more sustainable synthesis routes for VAM could reduce the overall environmental footprint of PVAc production.

Waste generation is another environmental concern in PVAc manufacturing. This includes off-spec products, packaging materials, and other process-related waste. Implementing efficient recycling and waste management strategies can help reduce the environmental impact while potentially recovering valuable materials and reducing disposal costs.

The transportation of raw materials and finished products also contributes to the environmental impact of PVAc production. Optimizing logistics and exploring local sourcing options can help reduce transportation-related emissions and costs.

In conclusion, addressing the environmental impact of PVAc production is crucial for sustainable and cost-efficient manufacturing. While many environmental mitigation strategies may initially increase production costs, they often lead to long-term cost savings through improved efficiency, reduced regulatory compliance costs, and enhanced corporate reputation. Balancing environmental considerations with cost optimization requires a holistic approach that considers the entire lifecycle of PVAc production.

One of the primary environmental concerns in PVAc production is the emission of volatile organic compounds (VOCs). These emissions occur during various stages of the manufacturing process, including polymerization and drying. VOCs contribute to air pollution and can have adverse effects on human health and the environment. Implementing advanced emission control technologies, such as thermal oxidizers or carbon adsorption systems, can significantly reduce VOC emissions, albeit at an increased production cost.

Water pollution is another environmental issue associated with PVAc production. The process generates wastewater containing residual monomers, unreacted chemicals, and other pollutants. Proper treatment of this wastewater is essential to prevent contamination of local water bodies. Advanced wastewater treatment systems, including biological treatment and membrane filtration, can effectively remove pollutants but may increase operational costs.

Energy consumption in PVAc production also contributes to its environmental footprint. The polymerization process and subsequent drying stages require substantial energy inputs, often derived from fossil fuels. This not only leads to increased production costs but also contributes to greenhouse gas emissions. Implementing energy-efficient technologies and exploring renewable energy sources can help mitigate this impact while potentially reducing long-term energy costs.

The raw materials used in PVAc production, primarily vinyl acetate monomer (VAM), also have environmental implications. The production of VAM involves petrochemical processes that can have significant environmental impacts. Exploring bio-based alternatives or developing more sustainable synthesis routes for VAM could reduce the overall environmental footprint of PVAc production.

Waste generation is another environmental concern in PVAc manufacturing. This includes off-spec products, packaging materials, and other process-related waste. Implementing efficient recycling and waste management strategies can help reduce the environmental impact while potentially recovering valuable materials and reducing disposal costs.

The transportation of raw materials and finished products also contributes to the environmental impact of PVAc production. Optimizing logistics and exploring local sourcing options can help reduce transportation-related emissions and costs.

In conclusion, addressing the environmental impact of PVAc production is crucial for sustainable and cost-efficient manufacturing. While many environmental mitigation strategies may initially increase production costs, they often lead to long-term cost savings through improved efficiency, reduced regulatory compliance costs, and enhanced corporate reputation. Balancing environmental considerations with cost optimization requires a holistic approach that considers the entire lifecycle of PVAc production.

Raw Material Supply Chain Analysis

The optimization of polyvinyl acetate production for cost efficiency heavily relies on an effective raw material supply chain analysis. The primary raw materials for polyvinyl acetate production include vinyl acetate monomer (VAM), water, and various additives such as initiators, stabilizers, and plasticizers. A comprehensive analysis of the supply chain for these materials is crucial for identifying cost-saving opportunities and ensuring production stability.

VAM, the most critical raw material, accounts for a significant portion of the production costs. Its supply chain is influenced by global petrochemical market dynamics, as it is derived from ethylene and acetic acid. Fluctuations in oil prices and ethylene availability can significantly impact VAM costs. To optimize the supply chain, manufacturers should consider diversifying their VAM sources, establishing long-term contracts with suppliers, and exploring opportunities for vertical integration.

Water, while less expensive, plays a vital role in the emulsion polymerization process. Ensuring a consistent and high-quality water supply is essential for maintaining product quality and process efficiency. Implementing water recycling systems and optimizing water usage can lead to cost reductions and improved sustainability.

The additives used in polyvinyl acetate production, though used in smaller quantities, can significantly affect both cost and product performance. Developing strong relationships with specialty chemical suppliers and continuously evaluating alternative additives can lead to cost savings without compromising product quality.

Transportation and logistics also play a crucial role in the raw material supply chain. Optimizing transportation routes, leveraging bulk shipping options, and strategically locating production facilities near raw material sources or key markets can substantially reduce costs. Implementing just-in-time inventory management systems can help minimize storage costs and reduce working capital requirements.

To further enhance cost efficiency, manufacturers should consider implementing advanced supply chain management technologies. These may include predictive analytics for demand forecasting, blockchain for improved traceability, and artificial intelligence for optimizing procurement decisions. Such technologies can help identify potential supply chain disruptions, streamline inventory management, and facilitate more informed decision-making.

Lastly, fostering collaborative relationships with suppliers can lead to mutual benefits. Engaging in joint research and development initiatives, sharing market insights, and aligning long-term strategies can result in innovative solutions that reduce costs throughout the supply chain. This collaborative approach can also enhance supply chain resilience, ensuring a more stable and cost-effective production process for polyvinyl acetate.

VAM, the most critical raw material, accounts for a significant portion of the production costs. Its supply chain is influenced by global petrochemical market dynamics, as it is derived from ethylene and acetic acid. Fluctuations in oil prices and ethylene availability can significantly impact VAM costs. To optimize the supply chain, manufacturers should consider diversifying their VAM sources, establishing long-term contracts with suppliers, and exploring opportunities for vertical integration.

Water, while less expensive, plays a vital role in the emulsion polymerization process. Ensuring a consistent and high-quality water supply is essential for maintaining product quality and process efficiency. Implementing water recycling systems and optimizing water usage can lead to cost reductions and improved sustainability.

The additives used in polyvinyl acetate production, though used in smaller quantities, can significantly affect both cost and product performance. Developing strong relationships with specialty chemical suppliers and continuously evaluating alternative additives can lead to cost savings without compromising product quality.

Transportation and logistics also play a crucial role in the raw material supply chain. Optimizing transportation routes, leveraging bulk shipping options, and strategically locating production facilities near raw material sources or key markets can substantially reduce costs. Implementing just-in-time inventory management systems can help minimize storage costs and reduce working capital requirements.

To further enhance cost efficiency, manufacturers should consider implementing advanced supply chain management technologies. These may include predictive analytics for demand forecasting, blockchain for improved traceability, and artificial intelligence for optimizing procurement decisions. Such technologies can help identify potential supply chain disruptions, streamline inventory management, and facilitate more informed decision-making.

Lastly, fostering collaborative relationships with suppliers can lead to mutual benefits. Engaging in joint research and development initiatives, sharing market insights, and aligning long-term strategies can result in innovative solutions that reduce costs throughout the supply chain. This collaborative approach can also enhance supply chain resilience, ensuring a more stable and cost-effective production process for polyvinyl acetate.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!