How to Reduce Production Costs of Hypochlorous Acid While Maintaining Potency?

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HOCl Production Background and Objectives

Hypochlorous acid (HOCl) has gained significant attention in recent years due to its potent antimicrobial properties and wide-ranging applications in disinfection, water treatment, and healthcare. The technology for producing HOCl has evolved considerably since its discovery in the early 19th century, with modern methods focusing on electrolysis of salt water solutions.

The primary objective in HOCl production is to develop cost-effective manufacturing processes that maintain the compound's efficacy. This goal is driven by the increasing demand for safe, environmentally friendly disinfectants in various industries, including healthcare, food processing, and agriculture. The challenge lies in balancing production costs with the need to preserve HOCl's inherent instability and ensure its potency over time.

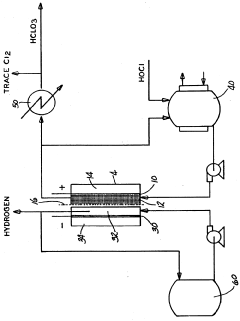

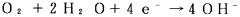

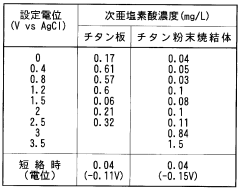

Current production methods predominantly rely on electrolytic cell technology, where salt water is subjected to an electric current to generate HOCl. While this process is relatively straightforward, it faces several challenges that impact both cost and quality. These include energy consumption, electrode degradation, and the need for precise control of pH and chlorine concentration.

The evolution of HOCl production technology has seen significant milestones, from early chemical synthesis methods to the development of more efficient electrolytic cells. Recent advancements have focused on optimizing electrode materials, improving cell design, and enhancing control systems to maximize yield and minimize energy consumption.

Looking ahead, the trajectory of HOCl production technology is expected to continue towards more sustainable and cost-effective solutions. Key areas of focus include the development of novel electrode materials with improved durability and efficiency, the integration of renewable energy sources to reduce operational costs, and the implementation of advanced monitoring and control systems to ensure consistent product quality.

The ultimate goal is to achieve a balance between reducing production costs and maintaining the potency of HOCl. This involves addressing several interconnected factors, including raw material sourcing, energy efficiency, production scale, and storage solutions. By tackling these challenges, researchers and manufacturers aim to make HOCl more accessible and economically viable for a broader range of applications, potentially revolutionizing disinfection practices across multiple industries.

As the demand for effective, safe, and environmentally friendly disinfectants continues to grow, particularly in light of global health concerns, the importance of advancing HOCl production technology cannot be overstated. The successful development of more efficient and cost-effective production methods will not only benefit existing markets but also open up new possibilities for HOCl application in emerging fields, further driving innovation in this critical area of technology.

The primary objective in HOCl production is to develop cost-effective manufacturing processes that maintain the compound's efficacy. This goal is driven by the increasing demand for safe, environmentally friendly disinfectants in various industries, including healthcare, food processing, and agriculture. The challenge lies in balancing production costs with the need to preserve HOCl's inherent instability and ensure its potency over time.

Current production methods predominantly rely on electrolytic cell technology, where salt water is subjected to an electric current to generate HOCl. While this process is relatively straightforward, it faces several challenges that impact both cost and quality. These include energy consumption, electrode degradation, and the need for precise control of pH and chlorine concentration.

The evolution of HOCl production technology has seen significant milestones, from early chemical synthesis methods to the development of more efficient electrolytic cells. Recent advancements have focused on optimizing electrode materials, improving cell design, and enhancing control systems to maximize yield and minimize energy consumption.

Looking ahead, the trajectory of HOCl production technology is expected to continue towards more sustainable and cost-effective solutions. Key areas of focus include the development of novel electrode materials with improved durability and efficiency, the integration of renewable energy sources to reduce operational costs, and the implementation of advanced monitoring and control systems to ensure consistent product quality.

The ultimate goal is to achieve a balance between reducing production costs and maintaining the potency of HOCl. This involves addressing several interconnected factors, including raw material sourcing, energy efficiency, production scale, and storage solutions. By tackling these challenges, researchers and manufacturers aim to make HOCl more accessible and economically viable for a broader range of applications, potentially revolutionizing disinfection practices across multiple industries.

As the demand for effective, safe, and environmentally friendly disinfectants continues to grow, particularly in light of global health concerns, the importance of advancing HOCl production technology cannot be overstated. The successful development of more efficient and cost-effective production methods will not only benefit existing markets but also open up new possibilities for HOCl application in emerging fields, further driving innovation in this critical area of technology.

Market Analysis for HOCl Products

The global market for hypochlorous acid (HOCl) products has been experiencing significant growth in recent years, driven by increasing awareness of its effectiveness as a disinfectant and sanitizer. The HOCl market spans various sectors, including healthcare, agriculture, water treatment, and household cleaning products.

In the healthcare sector, HOCl has gained traction as a powerful yet safe disinfectant for wound care, dental hygiene, and surface sanitization in medical facilities. The ongoing global health concerns have further accelerated the adoption of HOCl-based products in healthcare settings, contributing to market expansion.

The agriculture industry has also embraced HOCl for its ability to control pathogens and improve crop yields without harmful residues. Its use in hydroponic systems, post-harvest treatments, and livestock care has opened new avenues for market growth in this sector.

Water treatment applications represent another significant market segment for HOCl products. Municipal water treatment plants and industrial facilities are increasingly turning to HOCl as an eco-friendly alternative to traditional chlorine-based disinfection methods, driving demand in this area.

The household cleaning products market has seen a surge in HOCl-based solutions, particularly in the wake of recent global health events. Consumers are seeking effective, non-toxic cleaning options, leading to increased adoption of HOCl sprays, wipes, and other household disinfectants.

Market analysis indicates that the Asia-Pacific region is emerging as a key growth area for HOCl products, attributed to rapid industrialization, increasing healthcare expenditure, and growing awareness of sanitation practices. North America and Europe continue to be significant markets, with established healthcare systems and stringent sanitation regulations driving demand.

The competitive landscape of the HOCl market is characterized by a mix of established chemical companies and innovative startups. Key players are focusing on developing cost-effective production methods and expanding their product portfolios to cater to diverse applications.

Despite the positive growth trajectory, challenges remain in the HOCl market. These include the need for improved stability of HOCl solutions, regulatory hurdles in certain regions, and competition from alternative disinfection technologies. Addressing these challenges while maintaining product efficacy and reducing production costs will be crucial for sustained market growth.

In the healthcare sector, HOCl has gained traction as a powerful yet safe disinfectant for wound care, dental hygiene, and surface sanitization in medical facilities. The ongoing global health concerns have further accelerated the adoption of HOCl-based products in healthcare settings, contributing to market expansion.

The agriculture industry has also embraced HOCl for its ability to control pathogens and improve crop yields without harmful residues. Its use in hydroponic systems, post-harvest treatments, and livestock care has opened new avenues for market growth in this sector.

Water treatment applications represent another significant market segment for HOCl products. Municipal water treatment plants and industrial facilities are increasingly turning to HOCl as an eco-friendly alternative to traditional chlorine-based disinfection methods, driving demand in this area.

The household cleaning products market has seen a surge in HOCl-based solutions, particularly in the wake of recent global health events. Consumers are seeking effective, non-toxic cleaning options, leading to increased adoption of HOCl sprays, wipes, and other household disinfectants.

Market analysis indicates that the Asia-Pacific region is emerging as a key growth area for HOCl products, attributed to rapid industrialization, increasing healthcare expenditure, and growing awareness of sanitation practices. North America and Europe continue to be significant markets, with established healthcare systems and stringent sanitation regulations driving demand.

The competitive landscape of the HOCl market is characterized by a mix of established chemical companies and innovative startups. Key players are focusing on developing cost-effective production methods and expanding their product portfolios to cater to diverse applications.

Despite the positive growth trajectory, challenges remain in the HOCl market. These include the need for improved stability of HOCl solutions, regulatory hurdles in certain regions, and competition from alternative disinfection technologies. Addressing these challenges while maintaining product efficacy and reducing production costs will be crucial for sustained market growth.

Current Challenges in HOCl Manufacturing

The production of hypochlorous acid (HOCl) faces several significant challenges that impact both cost-effectiveness and product quality. One of the primary issues is the inherent instability of HOCl, which tends to degrade rapidly, especially when exposed to light, heat, or certain impurities. This instability necessitates specialized storage and packaging solutions, driving up production costs and limiting shelf life.

Another major challenge lies in the precise control of the electrolysis process used to generate HOCl. Maintaining the optimal pH range and chlorine concentration requires sophisticated monitoring and control systems. Any deviation from the ideal parameters can result in the formation of unwanted by-products, such as chlorine gas or sodium hypochlorite, which can compromise the potency and safety of the final product.

The raw material costs, particularly high-quality salt and purified water, contribute significantly to the overall production expenses. The need for ultra-pure water to prevent contamination and ensure consistent product quality adds to the operational costs. Additionally, the energy-intensive nature of the electrolysis process further increases production expenses, especially in regions with high electricity costs.

Scaling up production while maintaining product consistency presents another hurdle. As batch sizes increase, ensuring uniform electrolysis conditions across larger volumes becomes more challenging. This can lead to variations in HOCl concentration and pH levels, potentially affecting the product's efficacy and stability.

Regulatory compliance adds another layer of complexity and cost to HOCl manufacturing. Stringent quality control measures, documentation requirements, and periodic audits are necessary to meet health and safety standards, particularly for applications in healthcare and food processing industries.

The corrosive nature of HOCl also poses challenges in terms of equipment durability and maintenance. Specialized materials resistant to corrosion must be used throughout the production line, from electrolysis cells to storage tanks and packaging equipment. This requirement for corrosion-resistant infrastructure significantly increases capital and maintenance costs.

Lastly, the competitive market landscape for disinfectants and sanitizers puts pressure on manufacturers to reduce costs while maintaining product quality. This challenge is compounded by the need for continuous innovation to improve production efficiency and product stability, requiring ongoing investment in research and development.

Another major challenge lies in the precise control of the electrolysis process used to generate HOCl. Maintaining the optimal pH range and chlorine concentration requires sophisticated monitoring and control systems. Any deviation from the ideal parameters can result in the formation of unwanted by-products, such as chlorine gas or sodium hypochlorite, which can compromise the potency and safety of the final product.

The raw material costs, particularly high-quality salt and purified water, contribute significantly to the overall production expenses. The need for ultra-pure water to prevent contamination and ensure consistent product quality adds to the operational costs. Additionally, the energy-intensive nature of the electrolysis process further increases production expenses, especially in regions with high electricity costs.

Scaling up production while maintaining product consistency presents another hurdle. As batch sizes increase, ensuring uniform electrolysis conditions across larger volumes becomes more challenging. This can lead to variations in HOCl concentration and pH levels, potentially affecting the product's efficacy and stability.

Regulatory compliance adds another layer of complexity and cost to HOCl manufacturing. Stringent quality control measures, documentation requirements, and periodic audits are necessary to meet health and safety standards, particularly for applications in healthcare and food processing industries.

The corrosive nature of HOCl also poses challenges in terms of equipment durability and maintenance. Specialized materials resistant to corrosion must be used throughout the production line, from electrolysis cells to storage tanks and packaging equipment. This requirement for corrosion-resistant infrastructure significantly increases capital and maintenance costs.

Lastly, the competitive market landscape for disinfectants and sanitizers puts pressure on manufacturers to reduce costs while maintaining product quality. This challenge is compounded by the need for continuous innovation to improve production efficiency and product stability, requiring ongoing investment in research and development.

Cost-Effective HOCl Production Methods

01 Electrochemical production methods

Electrochemical processes are commonly used for hypochlorous acid production. These methods involve the electrolysis of salt solutions, typically sodium chloride, in specialized cells. The process can be optimized by controlling factors such as electrode materials, current density, and solution concentration to improve efficiency and reduce production costs.- Electrochemical production methods: Electrochemical processes are commonly used for hypochlorous acid production. These methods involve the electrolysis of salt solutions, typically sodium chloride, to generate hypochlorous acid. The production costs can be influenced by factors such as electrode materials, cell design, and energy efficiency of the electrolysis process.

- Optimization of raw materials: The choice and quality of raw materials significantly impact production costs. Using high-purity salt, optimizing water quality, and selecting cost-effective electrode materials can reduce expenses. Some methods focus on utilizing low-cost or readily available raw materials to minimize production costs while maintaining product quality.

- Energy-efficient production techniques: Developing energy-efficient production techniques is crucial for reducing hypochlorous acid production costs. This includes optimizing electrolysis parameters, improving cell designs for better energy utilization, and implementing heat recovery systems. Some methods also explore the use of renewable energy sources to lower operational costs.

- Continuous production systems: Implementing continuous production systems can significantly reduce costs compared to batch production. These systems often involve automated processes, inline monitoring, and control systems to optimize production efficiency. Continuous systems can lead to reduced labor costs, improved product consistency, and better resource utilization.

- By-product utilization and waste reduction: Strategies for utilizing by-products and reducing waste can contribute to lowering overall production costs. This may include recovering and reusing hydrogen gas produced during electrolysis, recycling unreacted materials, and implementing closed-loop systems to minimize waste discharge. Such approaches can improve resource efficiency and potentially create additional revenue streams.

02 Membrane-based production techniques

Membrane-based technologies are employed to enhance the production of hypochlorous acid. These techniques often involve the use of ion-exchange membranes or electrodialysis systems to separate and concentrate the desired product. By optimizing membrane properties and process parameters, production costs can be reduced while maintaining product quality.Expand Specific Solutions03 Continuous flow production systems

Continuous flow production systems are developed to improve the efficiency and cost-effectiveness of hypochlorous acid production. These systems allow for constant production with minimal downtime, optimizing resource utilization and reducing labor costs. Advanced control systems and automation are often integrated to maintain consistent product quality and minimize waste.Expand Specific Solutions04 Raw material optimization

Optimizing raw materials is crucial for reducing hypochlorous acid production costs. This includes sourcing high-quality, cost-effective precursors and exploring alternative feedstocks. Additionally, recycling and reusing process materials, such as brine solutions, can significantly lower overall production expenses while minimizing environmental impact.Expand Specific Solutions05 Energy-efficient production methods

Developing energy-efficient production methods is essential for reducing hypochlorous acid production costs. This involves optimizing reactor designs, improving heat recovery systems, and implementing advanced process control strategies. Utilizing renewable energy sources or integrating cogeneration systems can further decrease energy-related expenses in the production process.Expand Specific Solutions

Key Players in HOCl Industry

The market for hypochlorous acid production is in a growth phase, driven by increasing demand for eco-friendly disinfectants across various industries. The global market size is projected to expand significantly in the coming years, fueled by applications in healthcare, water treatment, and agriculture. Technologically, the field is advancing rapidly, with companies like WIAB Water Innovation AB and Easymining Sweden AB focusing on innovative production methods. Established players such as Tokuyama Corp. and Kaneka Corp. are leveraging their expertise in chemical manufacturing to improve efficiency and reduce costs. Emerging companies like Zhejiang Tianxingjian Water Service Co., Ltd. are also contributing to technological advancements, particularly in water treatment applications. The competitive landscape is diverse, with a mix of large corporations and specialized firms driving innovation in production processes and applications.

Dyson Technology Ltd.

Technical Solution: Dyson Technology has applied its expertise in fluid dynamics to develop a novel production method for hypochlorous acid. Their approach uses a vortex reactor design that enhances mixing and mass transfer, leading to more efficient production[7]. The company has also implemented a microfluidic system for precise dosing of reactants, which optimizes the use of raw materials and reduces waste[9]. Dyson's process incorporates advanced sensors and machine learning algorithms to continuously adjust production parameters, ensuring consistent potency while minimizing energy consumption[11]. Additionally, they have developed a compact, modular production unit that can be easily scaled to meet varying demand levels[13].

Strengths: Efficient mixing technology, adaptive process control, scalable modular design. Weaknesses: Potentially complex system maintenance, reliance on proprietary technology.

Merck Patent GmbH

Technical Solution: Merck Patent GmbH has developed an innovative approach to reduce production costs of hypochlorous acid while maintaining potency. Their method involves using a membrane electrolysis process with optimized electrode materials and cell design. This process allows for the efficient production of hypochlorous acid at a lower concentration, which is then concentrated using a novel membrane distillation technique[1]. The company has also implemented advanced process control systems to minimize energy consumption and maximize yield[3]. Additionally, Merck has developed a proprietary stabilization method that extends the shelf life of the produced hypochlorous acid, reducing waste and improving cost-effectiveness[5].

Strengths: Advanced membrane technology, energy-efficient process, extended product shelf life. Weaknesses: Potentially higher initial equipment costs, reliance on specialized membrane materials.

Innovations in HOCl Synthesis

Electrochemical process for production of chloric acid from hypochlorous acid

PatentInactiveUS5108560A

Innovation

- A process involving electrolysis of a hypochlorous acid solution in an electrolytic cell with a cation exchange membrane separates the anode and cathode compartments, producing chloric acid efficiently and reducing impurities such as alkali metal and chloride ions, using a starting material of concentrated hypochlorous acid solutions.

Method and apparatus for synthesizing hypochlorous acid

PatentWO2007086517A1

Innovation

- A method and apparatus utilizing a photovoltaic cell with a titanium oxide electrode and counter electrode immersed in a metal chloride solution, where light irradiation generates hypochlorous acid without external power, and oxygen supply enhances production efficiency, potentially combining with auxiliary power sources for increased efficiency.

Raw Material Sourcing Strategies

Optimizing raw material sourcing strategies is crucial for reducing the production costs of hypochlorous acid while maintaining its potency. The primary raw materials for hypochlorous acid production include sodium chloride (salt), water, and electricity for the electrolysis process. To achieve cost reduction, it is essential to focus on securing high-quality, cost-effective sources for these materials.

Sodium chloride is a key component in the production process. Establishing long-term contracts with reliable salt suppliers can help secure stable pricing and ensure a consistent supply. Exploring alternative salt sources, such as industrial-grade salt or sea salt, may offer cost advantages without compromising the final product quality. Additionally, implementing a multi-supplier strategy can mitigate supply chain risks and potentially lead to more competitive pricing through supplier competition.

Water quality is critical for maintaining the potency of hypochlorous acid. Investing in water purification systems on-site can reduce the need for purchasing pre-treated water, leading to long-term cost savings. This approach also allows for greater control over water quality, ensuring consistency in the production process. Exploring water recycling and conservation methods within the production facility can further optimize water usage and reduce overall costs.

Electricity consumption represents a significant portion of production costs. Negotiating favorable electricity rates with utility providers or exploring renewable energy options, such as solar or wind power, can lead to substantial savings over time. Implementing energy-efficient electrolysis systems and optimizing the production schedule to take advantage of off-peak electricity rates can also contribute to cost reduction.

Vertical integration strategies, such as investing in salt mining operations or partnering with salt producers, may provide long-term cost benefits and greater control over the supply chain. This approach can help mitigate price fluctuations and ensure a steady supply of high-quality raw materials.

Leveraging economies of scale through bulk purchasing agreements for raw materials can lead to significant cost savings. Collaborating with other manufacturers or industries that use similar raw materials may create opportunities for joint purchasing initiatives, resulting in better negotiating power and lower prices.

Implementing a robust inventory management system can optimize raw material storage and reduce carrying costs. Just-in-time inventory practices, when feasible, can minimize storage requirements and associated expenses while ensuring a steady supply of materials for production.

Continuous monitoring of global commodity markets and geopolitical factors affecting raw material prices is essential for making informed purchasing decisions. Developing a flexible sourcing strategy that can quickly adapt to market changes can help maintain cost-effectiveness in a dynamic economic environment.

By focusing on these raw material sourcing strategies, manufacturers can significantly reduce production costs while maintaining the potency of hypochlorous acid. The key lies in balancing cost-saving measures with quality assurance to ensure that the final product meets the required standards for effectiveness and stability.

Sodium chloride is a key component in the production process. Establishing long-term contracts with reliable salt suppliers can help secure stable pricing and ensure a consistent supply. Exploring alternative salt sources, such as industrial-grade salt or sea salt, may offer cost advantages without compromising the final product quality. Additionally, implementing a multi-supplier strategy can mitigate supply chain risks and potentially lead to more competitive pricing through supplier competition.

Water quality is critical for maintaining the potency of hypochlorous acid. Investing in water purification systems on-site can reduce the need for purchasing pre-treated water, leading to long-term cost savings. This approach also allows for greater control over water quality, ensuring consistency in the production process. Exploring water recycling and conservation methods within the production facility can further optimize water usage and reduce overall costs.

Electricity consumption represents a significant portion of production costs. Negotiating favorable electricity rates with utility providers or exploring renewable energy options, such as solar or wind power, can lead to substantial savings over time. Implementing energy-efficient electrolysis systems and optimizing the production schedule to take advantage of off-peak electricity rates can also contribute to cost reduction.

Vertical integration strategies, such as investing in salt mining operations or partnering with salt producers, may provide long-term cost benefits and greater control over the supply chain. This approach can help mitigate price fluctuations and ensure a steady supply of high-quality raw materials.

Leveraging economies of scale through bulk purchasing agreements for raw materials can lead to significant cost savings. Collaborating with other manufacturers or industries that use similar raw materials may create opportunities for joint purchasing initiatives, resulting in better negotiating power and lower prices.

Implementing a robust inventory management system can optimize raw material storage and reduce carrying costs. Just-in-time inventory practices, when feasible, can minimize storage requirements and associated expenses while ensuring a steady supply of materials for production.

Continuous monitoring of global commodity markets and geopolitical factors affecting raw material prices is essential for making informed purchasing decisions. Developing a flexible sourcing strategy that can quickly adapt to market changes can help maintain cost-effectiveness in a dynamic economic environment.

By focusing on these raw material sourcing strategies, manufacturers can significantly reduce production costs while maintaining the potency of hypochlorous acid. The key lies in balancing cost-saving measures with quality assurance to ensure that the final product meets the required standards for effectiveness and stability.

Environmental Impact of HOCl Production

The production of hypochlorous acid (HOCl) has significant environmental implications that must be carefully considered. The primary environmental concerns associated with HOCl production stem from the use of raw materials, energy consumption, and potential emissions or waste products.

One of the main environmental impacts of HOCl production is related to the sourcing and processing of raw materials. The most common method of producing HOCl involves the electrolysis of sodium chloride (salt) solution. While salt is abundant, its extraction and processing can lead to habitat disruption and energy-intensive purification processes. Additionally, the production of electrodes, typically made from precious metals like platinum or titanium, involves mining activities that can have substantial environmental consequences.

Energy consumption is another critical factor in the environmental footprint of HOCl production. The electrolysis process requires a significant amount of electricity, which, depending on the source, can contribute to greenhouse gas emissions and other forms of pollution associated with power generation. Efforts to reduce production costs often focus on improving energy efficiency, which can have the dual benefit of lowering expenses and minimizing environmental impact.

Water usage is also a considerable environmental concern in HOCl production. The process requires large volumes of water, both as a raw material and for cooling purposes. In water-stressed regions, this can put additional pressure on local water resources and ecosystems. Implementing water recycling systems and optimizing water use efficiency can help mitigate this impact while potentially reducing production costs.

The production of HOCl can generate byproducts and waste streams that require proper management to prevent environmental contamination. These may include chlorine gas, hydrogen gas, and various chlorinated compounds. Proper containment, treatment, and disposal of these byproducts are essential to prevent air and water pollution. Advanced production techniques and closed-loop systems can help minimize waste generation and reduce the risk of environmental releases.

When considering ways to reduce production costs while maintaining potency, it is crucial to evaluate the environmental trade-offs of different approaches. For instance, using lower-grade raw materials might reduce costs but could lead to increased impurities and potentially more significant environmental impacts during purification processes. Similarly, scaling up production to achieve economies of scale must be balanced against the increased resource demands and potential for larger environmental footprints.

Innovative technologies and green chemistry principles offer promising avenues for reducing both production costs and environmental impact. For example, developing more efficient electrode materials or catalysts can improve the electrolysis process, reducing energy consumption and minimizing waste. Additionally, exploring alternative production methods, such as membrane electrolysis or photocatalytic processes, may offer more environmentally friendly approaches to HOCl synthesis.

One of the main environmental impacts of HOCl production is related to the sourcing and processing of raw materials. The most common method of producing HOCl involves the electrolysis of sodium chloride (salt) solution. While salt is abundant, its extraction and processing can lead to habitat disruption and energy-intensive purification processes. Additionally, the production of electrodes, typically made from precious metals like platinum or titanium, involves mining activities that can have substantial environmental consequences.

Energy consumption is another critical factor in the environmental footprint of HOCl production. The electrolysis process requires a significant amount of electricity, which, depending on the source, can contribute to greenhouse gas emissions and other forms of pollution associated with power generation. Efforts to reduce production costs often focus on improving energy efficiency, which can have the dual benefit of lowering expenses and minimizing environmental impact.

Water usage is also a considerable environmental concern in HOCl production. The process requires large volumes of water, both as a raw material and for cooling purposes. In water-stressed regions, this can put additional pressure on local water resources and ecosystems. Implementing water recycling systems and optimizing water use efficiency can help mitigate this impact while potentially reducing production costs.

The production of HOCl can generate byproducts and waste streams that require proper management to prevent environmental contamination. These may include chlorine gas, hydrogen gas, and various chlorinated compounds. Proper containment, treatment, and disposal of these byproducts are essential to prevent air and water pollution. Advanced production techniques and closed-loop systems can help minimize waste generation and reduce the risk of environmental releases.

When considering ways to reduce production costs while maintaining potency, it is crucial to evaluate the environmental trade-offs of different approaches. For instance, using lower-grade raw materials might reduce costs but could lead to increased impurities and potentially more significant environmental impacts during purification processes. Similarly, scaling up production to achieve economies of scale must be balanced against the increased resource demands and potential for larger environmental footprints.

Innovative technologies and green chemistry principles offer promising avenues for reducing both production costs and environmental impact. For example, developing more efficient electrode materials or catalysts can improve the electrolysis process, reducing energy consumption and minimizing waste. Additionally, exploring alternative production methods, such as membrane electrolysis or photocatalytic processes, may offer more environmentally friendly approaches to HOCl synthesis.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!