How to Safely Handle Thermite Compositions?

JUN 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermite Composition Overview and Safety Objectives

Thermite compositions are highly energetic mixtures of metal powders and metal oxides that undergo an exothermic reduction-oxidation reaction when ignited. These compositions have been widely used in various applications, including welding, incendiary devices, and pyrotechnics, due to their ability to generate intense heat and molten metal. The primary components of thermite typically include aluminum powder as the reducing agent and iron oxide as the oxidizer, although other metal combinations can be used for specific purposes.

The development of thermite compositions dates back to the late 19th century, with significant advancements made during World War II for military applications. Since then, the technology has evolved to include a wide range of formulations tailored for specific industrial and scientific uses. The ongoing research in this field focuses on enhancing performance, improving safety, and expanding the range of applications.

Safety is paramount when handling thermite compositions due to their high reactivity and potential for uncontrolled reactions. The primary safety objectives in thermite handling include preventing accidental ignition, controlling the reaction rate, and mitigating the risks associated with the intense heat and molten metal produced during the reaction. These objectives are critical not only for protecting personnel but also for ensuring the reliability and effectiveness of thermite-based processes.

Key safety considerations involve proper storage, handling, and transportation of thermite materials. This includes maintaining strict control over environmental conditions such as temperature and humidity, as well as implementing robust containment measures to prevent contamination or unintended mixing of reactive components. Additionally, the development of specialized equipment and procedures for safe ignition and reaction control is essential for minimizing risks during intentional use.

The evolution of safety practices in thermite handling has been driven by a combination of regulatory requirements, industry standards, and ongoing research into reaction mechanisms and risk factors. Modern approaches emphasize the importance of comprehensive risk assessment, personnel training, and the implementation of engineered safety systems. These may include advanced fire suppression technologies, remote handling systems, and real-time monitoring of reaction parameters.

As the applications of thermite compositions continue to expand, particularly in advanced manufacturing and materials science, the focus on safety innovation remains critical. Current research trends include the development of inherently safer thermite formulations, such as those with reduced sensitivity to accidental ignition or improved control over reaction kinetics. Furthermore, the integration of smart materials and sensor technologies offers promising avenues for enhancing safety through real-time monitoring and adaptive control systems.

The development of thermite compositions dates back to the late 19th century, with significant advancements made during World War II for military applications. Since then, the technology has evolved to include a wide range of formulations tailored for specific industrial and scientific uses. The ongoing research in this field focuses on enhancing performance, improving safety, and expanding the range of applications.

Safety is paramount when handling thermite compositions due to their high reactivity and potential for uncontrolled reactions. The primary safety objectives in thermite handling include preventing accidental ignition, controlling the reaction rate, and mitigating the risks associated with the intense heat and molten metal produced during the reaction. These objectives are critical not only for protecting personnel but also for ensuring the reliability and effectiveness of thermite-based processes.

Key safety considerations involve proper storage, handling, and transportation of thermite materials. This includes maintaining strict control over environmental conditions such as temperature and humidity, as well as implementing robust containment measures to prevent contamination or unintended mixing of reactive components. Additionally, the development of specialized equipment and procedures for safe ignition and reaction control is essential for minimizing risks during intentional use.

The evolution of safety practices in thermite handling has been driven by a combination of regulatory requirements, industry standards, and ongoing research into reaction mechanisms and risk factors. Modern approaches emphasize the importance of comprehensive risk assessment, personnel training, and the implementation of engineered safety systems. These may include advanced fire suppression technologies, remote handling systems, and real-time monitoring of reaction parameters.

As the applications of thermite compositions continue to expand, particularly in advanced manufacturing and materials science, the focus on safety innovation remains critical. Current research trends include the development of inherently safer thermite formulations, such as those with reduced sensitivity to accidental ignition or improved control over reaction kinetics. Furthermore, the integration of smart materials and sensor technologies offers promising avenues for enhancing safety through real-time monitoring and adaptive control systems.

Industrial Applications and Market Demand

Thermite compositions have found significant applications across various industrial sectors, driving a robust market demand for these highly reactive materials. The primary industries utilizing thermite include metallurgy, welding, and pyrotechnics. In the metallurgical sector, thermite reactions are extensively used for metal purification processes and in the production of high-purity metals. The welding industry relies on thermite for rail welding, pipe welding, and underwater welding applications, particularly in remote or challenging environments where traditional welding methods are impractical.

The pyrotechnics industry employs thermite compositions in the manufacturing of fireworks, special effects for film and entertainment, and military applications such as incendiary devices. Additionally, thermite has gained traction in the aerospace and defense sectors for its potential use in self-destruct mechanisms and emergency destruction of sensitive equipment.

The global market for thermite compositions and related applications has been steadily growing, driven by increasing industrialization and infrastructure development projects worldwide. The rail industry, in particular, has been a significant contributor to this growth, with the expansion of rail networks in developing countries and the maintenance of existing rail systems in developed nations.

The demand for safer and more efficient thermite handling methods has also been on the rise, as industries seek to mitigate the risks associated with these highly reactive materials. This has led to the development of specialized equipment and safety protocols, creating a niche market for thermite handling solutions and safety gear.

Emerging applications in additive manufacturing and 3D printing technologies have opened new avenues for thermite compositions, potentially expanding the market further. Research into novel thermite formulations with enhanced properties and controlled reactivity is ongoing, driven by the need for more precise and tailored applications in advanced manufacturing processes.

However, the market for thermite compositions faces challenges related to safety concerns and regulatory restrictions. Stringent regulations governing the transportation, storage, and use of thermite materials have impacted market growth in some regions. Despite these challenges, the overall market outlook remains positive, with innovations in safety technologies and handling procedures expected to address regulatory concerns and drive further adoption across industries.

The pyrotechnics industry employs thermite compositions in the manufacturing of fireworks, special effects for film and entertainment, and military applications such as incendiary devices. Additionally, thermite has gained traction in the aerospace and defense sectors for its potential use in self-destruct mechanisms and emergency destruction of sensitive equipment.

The global market for thermite compositions and related applications has been steadily growing, driven by increasing industrialization and infrastructure development projects worldwide. The rail industry, in particular, has been a significant contributor to this growth, with the expansion of rail networks in developing countries and the maintenance of existing rail systems in developed nations.

The demand for safer and more efficient thermite handling methods has also been on the rise, as industries seek to mitigate the risks associated with these highly reactive materials. This has led to the development of specialized equipment and safety protocols, creating a niche market for thermite handling solutions and safety gear.

Emerging applications in additive manufacturing and 3D printing technologies have opened new avenues for thermite compositions, potentially expanding the market further. Research into novel thermite formulations with enhanced properties and controlled reactivity is ongoing, driven by the need for more precise and tailored applications in advanced manufacturing processes.

However, the market for thermite compositions faces challenges related to safety concerns and regulatory restrictions. Stringent regulations governing the transportation, storage, and use of thermite materials have impacted market growth in some regions. Despite these challenges, the overall market outlook remains positive, with innovations in safety technologies and handling procedures expected to address regulatory concerns and drive further adoption across industries.

Current Safety Challenges in Thermite Handling

Handling thermite compositions presents significant safety challenges due to their highly reactive nature and potential for extreme heat generation. One of the primary concerns is the risk of accidental ignition, which can occur through various means such as static electricity, friction, or exposure to heat sources. This risk is particularly high during storage, transportation, and preparation processes, necessitating stringent safety protocols and specialized handling equipment.

The extreme temperatures produced by thermite reactions pose severe burn hazards to personnel. Temperatures can reach up to 2500°C, capable of causing catastrophic injuries and damage to surrounding structures. Proper personal protective equipment (PPE) is essential, but current PPE technologies struggle to provide adequate protection against such intense heat, creating a significant safety gap.

Containment of thermite reactions is another critical challenge. Once ignited, thermite reactions are difficult to extinguish and can rapidly spread, potentially leading to large-scale fires or explosions. Traditional fire suppression methods are often ineffective, requiring specialized techniques and materials for containment. This challenge is compounded in industrial settings where large quantities of thermite may be present.

The production of toxic fumes and particulates during thermite reactions presents respiratory hazards. These byproducts can include metal oxides and other harmful substances, necessitating robust ventilation systems and respiratory protection. However, the effectiveness of current filtration technologies in completely mitigating these risks remains a concern.

Environmental contamination is an ongoing challenge in thermite handling. Improper disposal or accidental release can lead to soil and water pollution, with potential long-term ecological impacts. Developing safe disposal methods and containment strategies for thermite waste and residues is an area requiring further research and innovation.

The reactivity of thermite with water poses unique challenges, particularly in firefighting scenarios. Water can exacerbate thermite fires, potentially leading to violent reactions or explosions. This limitation complicates emergency response procedures and necessitates the development of alternative firefighting agents and techniques specifically designed for thermite-related incidents.

Lastly, the potential for thermite to be used in malicious activities presents security challenges. Strict access controls and inventory management are crucial to prevent unauthorized use or theft. However, balancing these security measures with operational efficiency remains a complex issue for many industries working with thermite compositions.

The extreme temperatures produced by thermite reactions pose severe burn hazards to personnel. Temperatures can reach up to 2500°C, capable of causing catastrophic injuries and damage to surrounding structures. Proper personal protective equipment (PPE) is essential, but current PPE technologies struggle to provide adequate protection against such intense heat, creating a significant safety gap.

Containment of thermite reactions is another critical challenge. Once ignited, thermite reactions are difficult to extinguish and can rapidly spread, potentially leading to large-scale fires or explosions. Traditional fire suppression methods are often ineffective, requiring specialized techniques and materials for containment. This challenge is compounded in industrial settings where large quantities of thermite may be present.

The production of toxic fumes and particulates during thermite reactions presents respiratory hazards. These byproducts can include metal oxides and other harmful substances, necessitating robust ventilation systems and respiratory protection. However, the effectiveness of current filtration technologies in completely mitigating these risks remains a concern.

Environmental contamination is an ongoing challenge in thermite handling. Improper disposal or accidental release can lead to soil and water pollution, with potential long-term ecological impacts. Developing safe disposal methods and containment strategies for thermite waste and residues is an area requiring further research and innovation.

The reactivity of thermite with water poses unique challenges, particularly in firefighting scenarios. Water can exacerbate thermite fires, potentially leading to violent reactions or explosions. This limitation complicates emergency response procedures and necessitates the development of alternative firefighting agents and techniques specifically designed for thermite-related incidents.

Lastly, the potential for thermite to be used in malicious activities presents security challenges. Strict access controls and inventory management are crucial to prevent unauthorized use or theft. However, balancing these security measures with operational efficiency remains a complex issue for many industries working with thermite compositions.

Existing Safety Measures and Handling Procedures

01 Composition of thermite mixtures

Thermite compositions typically consist of a metal oxide and a more reactive metal, often aluminum. The mixture can include additives to modify properties such as reaction rate, ignition temperature, or energy output. Common metal oxides used include iron oxide, copper oxide, or chromium oxide. The specific composition can be tailored for various applications, such as welding, incendiary devices, or pyrotechnics.- Composition of thermite mixtures: Thermite compositions typically consist of a metal oxide and a more reactive metal, often aluminum. The mixture can include additives to modify properties such as reaction rate, ignition temperature, or energy output. Common metal oxides used include iron oxide, copper oxide, or chromium oxide. The specific composition can be tailored for different applications, such as welding, incendiary devices, or pyrotechnics.

- Ignition methods for thermite reactions: Various methods can be employed to initiate thermite reactions. These may include electrical ignition systems, chemical igniters, or mechanical striking mechanisms. Some compositions incorporate materials that lower the ignition temperature or increase sensitivity to specific stimuli. The choice of ignition method often depends on the intended application and safety considerations.

- Applications of thermite reactions: Thermite reactions find use in diverse fields. They are employed in welding, particularly for joining railway tracks or large metal structures. In the military, thermite compositions are used in incendiary devices or for the destruction of sensitive equipment. Other applications include metal purification, emergency destruction of data storage devices, and as a heat source for certain chemical processes.

- Safety and control measures: Given the high temperatures and potential hazards associated with thermite reactions, various safety and control measures are implemented. These can include the use of containment vessels, remote ignition systems, and specialized handling procedures. Some compositions incorporate materials that help control the reaction rate or limit the spread of molten products. Proper storage, transportation, and disposal protocols are crucial for safe handling of thermite materials.

- Novel thermite formulations: Research continues to develop new thermite formulations with enhanced properties. These may include nanoparticle-based thermites for increased reactivity, environmentally friendly compositions, or formulations with specific energy outputs. Some novel approaches explore the use of alternative fuel materials or oxidizers to achieve desired characteristics such as lower toxicity, higher energy density, or improved stability.

02 Ignition methods for thermite reactions

Various methods can be employed to initiate thermite reactions. These may include electrical ignition systems, chemical initiators, or mechanical striking mechanisms. Some compositions incorporate materials that lower the ignition temperature or increase sensitivity to specific stimuli. The choice of ignition method often depends on the intended application and safety considerations.Expand Specific Solutions03 Applications in welding and metal joining

Thermite reactions are widely used in welding, particularly for joining railway tracks or large metal components. The exothermic reaction produces molten metal that can fuse separate pieces together. Specialized thermite compositions and ignition systems have been developed for specific welding applications, considering factors such as the metals being joined and the required joint strength.Expand Specific Solutions04 Use in military and demolition applications

Thermite compositions find use in military and demolition contexts due to their high heat output and ability to melt through metal. Applications include incendiary devices, breaching tools, and ordnance disposal. These compositions often incorporate additional components to enhance specific properties such as adhesion to targets or resistance to extinguishing efforts.Expand Specific Solutions05 Safety and storage considerations

Given the reactive nature of thermite compositions, special attention is paid to safety in handling, storage, and transportation. This may involve using stabilizing additives, developing specialized packaging, or implementing strict handling protocols. Some compositions are designed to be less sensitive to accidental ignition while maintaining their effectiveness for intended applications.Expand Specific Solutions

Key Players in Thermite Production and Research

The handling of thermite compositions presents a complex competitive landscape in the advanced materials and defense industries. The market is in a mature stage with established players like Lockheed Martin Corp. and Naval Research Laboratory leading research and development efforts. The global market size for thermite-related technologies is substantial, driven by applications in defense, aerospace, and industrial sectors. Technological maturity varies, with companies like Xi'an Modern Chemistry Research Institute and PLA Army Engineering University advancing state-of-the-art safety protocols. Battelle Memorial Institute and Fraunhofer-Gesellschaft eV contribute significant innovations in handling techniques, while emerging players like Anasphere, Inc. and Catator AB focus on niche applications, fostering a dynamic and competitive environment in thermite safety technology.

Lockheed Martin Corp.

Technical Solution: Lockheed Martin has developed advanced thermite compositions with enhanced safety features for military and aerospace applications. Their approach involves microencapsulation of thermite particles, which prevents accidental ignition and improves handling safety. The company also utilizes precise mixing techniques and specialized containment vessels to ensure uniform composition and prevent unintended reactions. Additionally, they have implemented remote ignition systems and advanced thermal management techniques to control the reaction process and minimize risks during deployment.

Strengths: Advanced safety features, precise composition control, and extensive experience in military applications. Weaknesses: High costs associated with advanced technologies and limited applicability outside specialized fields.

Naval Research Laboratory

Technical Solution: The Naval Research Laboratory has pioneered research in safe thermite handling, focusing on developing novel compositions with reduced sensitivity to accidental ignition. Their approach includes the use of nanostructured thermite materials that offer improved control over reaction rates and energy release. The lab has also developed specialized containment systems and handling protocols that minimize the risk of unintended reactions. Furthermore, they have conducted extensive research on the use of additives to modify the burning characteristics of thermite compositions, enhancing both safety and performance in naval applications.

Strengths: Cutting-edge research in nanostructured thermites and extensive safety protocols. Weaknesses: Research may be primarily focused on naval applications, potentially limiting broader commercial applications.

Innovative Safety Technologies for Thermite

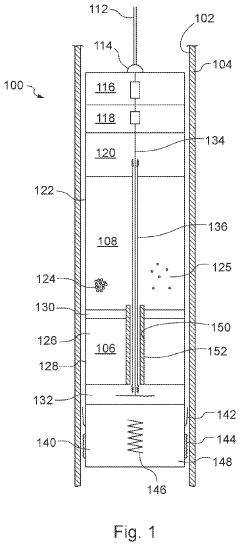

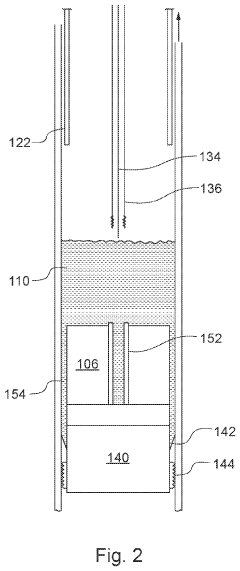

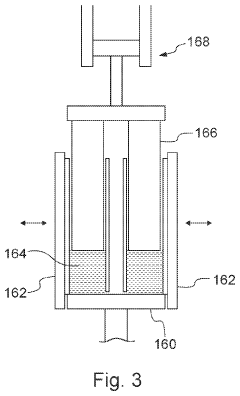

Downhole apparatus and method

PatentActiveUS20240011367A1

Innovation

- A downhole apparatus and method utilizing compressed thermite within a container, which reduces porosity and increases density, facilitating efficient heat transfer and reaction, and is combined with a low-melt-point alloy to form a solid plug, allowing for effective sealing without the need for binding agents and maintaining structural strength under pressure.

Low-sensitive fracturing composition with improved coefficient of deflagration transmission, igniting device for igniting at low energy, and blasting apparatus therewith

PatentWO2010101317A1

Innovation

- A composition with 35-45% metal oxide as an oxidizing agent, 8-12% metal powder as a reducing agent, and additional components like sodium percarbonate and a binder, combined with a low-energy ignition mechanism using a heating wire and high-temperature generator, to achieve uniform mixing and low-energy ignition, reducing hazardous substance use and improving handling stability.

Regulatory Framework for Pyrotechnic Materials

The regulatory framework for pyrotechnic materials, including thermite compositions, is a complex and critical aspect of ensuring safety in their handling and use. In the United States, the primary regulatory body overseeing pyrotechnic materials is the Bureau of Alcohol, Tobacco, Firearms and Explosives (ATF). The ATF enforces federal laws and regulations related to explosives, including thermite, under the authority of the Organized Crime Control Act of 1970 and the Safe Explosives Act of 2002.

These regulations establish strict guidelines for the manufacture, storage, transportation, and use of pyrotechnic materials. Manufacturers and users of thermite compositions must obtain appropriate licenses and permits from the ATF, which involve background checks and compliance inspections. The regulations also mandate specific storage requirements, including the use of approved magazines and maintaining certain distances from inhabited buildings and public highways.

The Occupational Safety and Health Administration (OSHA) also plays a crucial role in regulating workplace safety aspects related to thermite handling. OSHA standards require employers to provide proper training, personal protective equipment, and implement safety protocols for employees working with hazardous materials like thermite.

At the international level, the United Nations recommendations on the Transport of Dangerous Goods provide a framework for the safe transportation of pyrotechnic materials across borders. These recommendations are often adopted into national regulations, ensuring a degree of global consistency in handling practices.

Many countries have their own regulatory bodies and frameworks for pyrotechnic materials. For instance, in the European Union, the regulation of pyrotechnics falls under the Pyrotechnic Articles Directive (2013/29/EU), which sets harmonized rules for making pyrotechnic articles available on the EU market.

The regulatory landscape also includes industry standards and best practices developed by organizations such as the National Fire Protection Association (NFPA) in the United States. These standards often provide detailed guidelines on safe handling procedures, storage conditions, and emergency response protocols for pyrotechnic materials.

Compliance with these regulations and standards is essential not only for legal reasons but also for ensuring the safety of workers, the public, and the environment. Regular updates to these frameworks are necessary to address emerging safety concerns and technological advancements in pyrotechnic materials.

These regulations establish strict guidelines for the manufacture, storage, transportation, and use of pyrotechnic materials. Manufacturers and users of thermite compositions must obtain appropriate licenses and permits from the ATF, which involve background checks and compliance inspections. The regulations also mandate specific storage requirements, including the use of approved magazines and maintaining certain distances from inhabited buildings and public highways.

The Occupational Safety and Health Administration (OSHA) also plays a crucial role in regulating workplace safety aspects related to thermite handling. OSHA standards require employers to provide proper training, personal protective equipment, and implement safety protocols for employees working with hazardous materials like thermite.

At the international level, the United Nations recommendations on the Transport of Dangerous Goods provide a framework for the safe transportation of pyrotechnic materials across borders. These recommendations are often adopted into national regulations, ensuring a degree of global consistency in handling practices.

Many countries have their own regulatory bodies and frameworks for pyrotechnic materials. For instance, in the European Union, the regulation of pyrotechnics falls under the Pyrotechnic Articles Directive (2013/29/EU), which sets harmonized rules for making pyrotechnic articles available on the EU market.

The regulatory landscape also includes industry standards and best practices developed by organizations such as the National Fire Protection Association (NFPA) in the United States. These standards often provide detailed guidelines on safe handling procedures, storage conditions, and emergency response protocols for pyrotechnic materials.

Compliance with these regulations and standards is essential not only for legal reasons but also for ensuring the safety of workers, the public, and the environment. Regular updates to these frameworks are necessary to address emerging safety concerns and technological advancements in pyrotechnic materials.

Environmental Impact of Thermite Usage

The environmental impact of thermite usage is a critical consideration in the safe handling and application of these highly reactive compositions. Thermite reactions, known for their intense heat generation and ability to produce molten metal, can have significant consequences on the surrounding ecosystem if not properly managed.

One of the primary environmental concerns associated with thermite usage is the release of particulate matter and fumes. During the reaction, various metal oxides and other byproducts are produced, which can be dispersed into the air. These airborne particles may contribute to local air pollution and potentially affect air quality in the immediate vicinity. Prolonged exposure to these emissions could pose respiratory risks to both humans and wildlife in the area.

Soil contamination is another potential environmental issue arising from thermite reactions. The high temperatures generated during the process can lead to the formation of slag, a glassy byproduct that may contain heavy metals and other potentially harmful substances. If not properly contained and disposed of, this slag can leach into the soil, potentially affecting soil chemistry and microbial communities.

Water pollution is also a concern, particularly if thermite reactions occur near water bodies or if runoff from contaminated sites reaches aquatic ecosystems. The introduction of metal oxides and other reaction products into water systems can alter pH levels and introduce toxic elements, potentially harming aquatic life and disrupting local ecosystems.

The intense heat generated by thermite reactions can have localized impacts on vegetation and soil microorganisms. In cases where proper containment measures are not in place, the extreme temperatures can cause immediate damage to plant life and alter soil properties, potentially leading to long-term changes in local flora and fauna.

To mitigate these environmental impacts, several measures can be implemented. Proper containment systems should be employed to capture and control emissions and slag production. The use of protective barriers and specialized reaction vessels can help minimize the spread of byproducts. Additionally, conducting thermite reactions in controlled environments, such as industrial facilities with appropriate filtration and waste management systems, can significantly reduce environmental risks.

Post-reaction cleanup and proper disposal of byproducts are crucial steps in minimizing long-term environmental effects. This includes the careful collection and treatment of slag and other solid waste, as well as the implementation of soil and water remediation techniques if contamination occurs.

Ongoing environmental monitoring and assessment should be conducted in areas where thermite reactions are frequently performed. This can help identify any cumulative impacts and inform the development of more effective mitigation strategies. By adopting a proactive approach to environmental protection, the safe handling of thermite compositions can be achieved while minimizing ecological harm.

One of the primary environmental concerns associated with thermite usage is the release of particulate matter and fumes. During the reaction, various metal oxides and other byproducts are produced, which can be dispersed into the air. These airborne particles may contribute to local air pollution and potentially affect air quality in the immediate vicinity. Prolonged exposure to these emissions could pose respiratory risks to both humans and wildlife in the area.

Soil contamination is another potential environmental issue arising from thermite reactions. The high temperatures generated during the process can lead to the formation of slag, a glassy byproduct that may contain heavy metals and other potentially harmful substances. If not properly contained and disposed of, this slag can leach into the soil, potentially affecting soil chemistry and microbial communities.

Water pollution is also a concern, particularly if thermite reactions occur near water bodies or if runoff from contaminated sites reaches aquatic ecosystems. The introduction of metal oxides and other reaction products into water systems can alter pH levels and introduce toxic elements, potentially harming aquatic life and disrupting local ecosystems.

The intense heat generated by thermite reactions can have localized impacts on vegetation and soil microorganisms. In cases where proper containment measures are not in place, the extreme temperatures can cause immediate damage to plant life and alter soil properties, potentially leading to long-term changes in local flora and fauna.

To mitigate these environmental impacts, several measures can be implemented. Proper containment systems should be employed to capture and control emissions and slag production. The use of protective barriers and specialized reaction vessels can help minimize the spread of byproducts. Additionally, conducting thermite reactions in controlled environments, such as industrial facilities with appropriate filtration and waste management systems, can significantly reduce environmental risks.

Post-reaction cleanup and proper disposal of byproducts are crucial steps in minimizing long-term environmental effects. This includes the careful collection and treatment of slag and other solid waste, as well as the implementation of soil and water remediation techniques if contamination occurs.

Ongoing environmental monitoring and assessment should be conducted in areas where thermite reactions are frequently performed. This can help identify any cumulative impacts and inform the development of more effective mitigation strategies. By adopting a proactive approach to environmental protection, the safe handling of thermite compositions can be achieved while minimizing ecological harm.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!