How to Use Thermite for Hazardous Material Neutralization?

JUN 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermite Neutralization Background and Objectives

Thermite, a pyrotechnic composition of metal powder fuel and metal oxide, has been utilized in various industrial applications for decades. Its ability to generate intense heat through an exothermic reaction has made it a subject of interest in hazardous material neutralization. The primary objective of this research is to explore the potential of thermite reactions in safely and effectively neutralizing dangerous substances, particularly in scenarios where conventional methods may be inadequate or pose additional risks.

The development of thermite-based neutralization techniques stems from the need for more efficient and versatile methods to handle hazardous materials. Traditional approaches often involve chemical treatments, incineration, or containment, each with its own limitations. Thermite reactions offer a unique advantage due to their ability to produce extremely high temperatures rapidly, potentially destroying or rendering harmless a wide range of toxic, radioactive, or otherwise dangerous substances.

One of the key goals in this field is to optimize thermite compositions for specific types of hazardous materials. This involves tailoring the metal fuel and oxide components to achieve the desired reaction temperature and duration while minimizing unwanted byproducts. Researchers aim to develop formulations that can effectively neutralize materials ranging from chemical warfare agents to industrial pollutants, addressing a broad spectrum of environmental and safety concerns.

Another critical objective is to design safe and controlled delivery systems for thermite-based neutralization. This includes developing mechanisms for precise ignition, containment of the reaction, and management of the resulting heat and byproducts. The challenge lies in harnessing the power of thermite reactions while ensuring they can be deployed safely in various environments, from laboratory settings to field operations.

Furthermore, the research seeks to understand and mitigate any potential environmental impacts of thermite-based neutralization. This involves studying the reaction products, their interactions with the environment, and developing methods to capture or neutralize any harmful emissions. The ultimate aim is to create a neutralization process that is not only effective against the target hazardous material but also environmentally responsible.

As the field progresses, there is a growing focus on integrating thermite neutralization techniques with other technologies. This includes exploring combinations with robotics for remote deployment in high-risk areas, or with advanced sensing and analysis systems for real-time monitoring of neutralization effectiveness. Such integrations could significantly enhance the safety and efficiency of hazardous material management operations.

The development of thermite-based neutralization techniques stems from the need for more efficient and versatile methods to handle hazardous materials. Traditional approaches often involve chemical treatments, incineration, or containment, each with its own limitations. Thermite reactions offer a unique advantage due to their ability to produce extremely high temperatures rapidly, potentially destroying or rendering harmless a wide range of toxic, radioactive, or otherwise dangerous substances.

One of the key goals in this field is to optimize thermite compositions for specific types of hazardous materials. This involves tailoring the metal fuel and oxide components to achieve the desired reaction temperature and duration while minimizing unwanted byproducts. Researchers aim to develop formulations that can effectively neutralize materials ranging from chemical warfare agents to industrial pollutants, addressing a broad spectrum of environmental and safety concerns.

Another critical objective is to design safe and controlled delivery systems for thermite-based neutralization. This includes developing mechanisms for precise ignition, containment of the reaction, and management of the resulting heat and byproducts. The challenge lies in harnessing the power of thermite reactions while ensuring they can be deployed safely in various environments, from laboratory settings to field operations.

Furthermore, the research seeks to understand and mitigate any potential environmental impacts of thermite-based neutralization. This involves studying the reaction products, their interactions with the environment, and developing methods to capture or neutralize any harmful emissions. The ultimate aim is to create a neutralization process that is not only effective against the target hazardous material but also environmentally responsible.

As the field progresses, there is a growing focus on integrating thermite neutralization techniques with other technologies. This includes exploring combinations with robotics for remote deployment in high-risk areas, or with advanced sensing and analysis systems for real-time monitoring of neutralization effectiveness. Such integrations could significantly enhance the safety and efficiency of hazardous material management operations.

Market Analysis for Hazardous Material Disposal

The global market for hazardous material disposal has been experiencing steady growth, driven by increasing industrial activities, stringent environmental regulations, and growing awareness of the importance of proper waste management. The market size was valued at approximately $28 billion in 2020 and is projected to reach $36 billion by 2025, with a compound annual growth rate (CAGR) of 5.2%.

The demand for hazardous material disposal services is primarily fueled by industries such as chemical manufacturing, oil and gas, pharmaceuticals, and electronics. These sectors generate significant amounts of hazardous waste that require specialized treatment and disposal methods. The market is also influenced by the implementation of strict environmental regulations across various countries, which mandate proper handling and disposal of hazardous materials.

North America and Europe currently dominate the market, accounting for over 60% of the global share. This is attributed to well-established regulatory frameworks and advanced waste management infrastructure in these regions. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing environmental concerns in countries like China and India.

The market is characterized by the presence of both large multinational corporations and regional players. Key market players include Clean Harbors, Veolia, Suez, and Stericycle, who offer a wide range of hazardous waste management services. These companies are continuously investing in research and development to improve their disposal technologies and expand their service offerings.

Emerging trends in the hazardous material disposal market include the adoption of advanced technologies such as plasma gasification, supercritical water oxidation, and chemical neutralization. These technologies offer more efficient and environmentally friendly methods of waste treatment compared to traditional incineration or landfill disposal.

The use of thermite for hazardous material neutralization represents a niche but growing segment within the broader hazardous waste disposal market. Thermite reactions offer advantages such as high-temperature decomposition of toxic substances and the ability to treat a wide range of hazardous materials. However, the market for thermite-based neutralization is still relatively small compared to other disposal methods, primarily due to safety concerns and the specialized nature of the technology.

The demand for hazardous material disposal services is primarily fueled by industries such as chemical manufacturing, oil and gas, pharmaceuticals, and electronics. These sectors generate significant amounts of hazardous waste that require specialized treatment and disposal methods. The market is also influenced by the implementation of strict environmental regulations across various countries, which mandate proper handling and disposal of hazardous materials.

North America and Europe currently dominate the market, accounting for over 60% of the global share. This is attributed to well-established regulatory frameworks and advanced waste management infrastructure in these regions. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing environmental concerns in countries like China and India.

The market is characterized by the presence of both large multinational corporations and regional players. Key market players include Clean Harbors, Veolia, Suez, and Stericycle, who offer a wide range of hazardous waste management services. These companies are continuously investing in research and development to improve their disposal technologies and expand their service offerings.

Emerging trends in the hazardous material disposal market include the adoption of advanced technologies such as plasma gasification, supercritical water oxidation, and chemical neutralization. These technologies offer more efficient and environmentally friendly methods of waste treatment compared to traditional incineration or landfill disposal.

The use of thermite for hazardous material neutralization represents a niche but growing segment within the broader hazardous waste disposal market. Thermite reactions offer advantages such as high-temperature decomposition of toxic substances and the ability to treat a wide range of hazardous materials. However, the market for thermite-based neutralization is still relatively small compared to other disposal methods, primarily due to safety concerns and the specialized nature of the technology.

Current Challenges in Thermite-Based Neutralization

Despite the promising potential of thermite-based neutralization for hazardous materials, several significant challenges currently hinder its widespread adoption and effectiveness. One of the primary concerns is the control and containment of the intense heat generated during the thermite reaction. The extremely high temperatures produced can pose safety risks to operators and potentially damage surrounding infrastructure or equipment.

Another challenge lies in the precise mixing and application of thermite compounds. The effectiveness of neutralization heavily depends on achieving the correct ratio of reactants and ensuring uniform distribution across the hazardous material. Inconsistencies in mixing or application can lead to incomplete neutralization or unpredictable reactions, compromising the overall efficacy of the process.

The reactivity of thermite with different types of hazardous materials presents an additional hurdle. While thermite reactions are highly effective against certain substances, they may be less suitable or even counterproductive for others. Developing a comprehensive understanding of the compatibility and reaction dynamics between thermite and various hazardous materials is crucial for safe and effective neutralization.

Environmental concerns also play a significant role in the challenges faced by thermite-based neutralization. The byproducts of thermite reactions, including metal oxides and other compounds, may have environmental impacts that need to be carefully managed and mitigated. Ensuring that the neutralization process does not create secondary environmental hazards is a critical consideration.

Scalability and cost-effectiveness represent further challenges in the implementation of thermite-based neutralization techniques. While the method may be suitable for small-scale applications, scaling up to handle large volumes of hazardous materials efficiently and economically remains a significant hurdle. The cost of materials, specialized equipment, and trained personnel can limit the widespread adoption of this technology.

Regulatory compliance and safety standards pose additional challenges. The use of thermite for hazardous material neutralization must adhere to strict safety protocols and regulatory requirements. Developing standardized procedures and obtaining necessary approvals from relevant authorities can be a complex and time-consuming process, potentially slowing down the adoption of this technology in practical applications.

Another challenge lies in the precise mixing and application of thermite compounds. The effectiveness of neutralization heavily depends on achieving the correct ratio of reactants and ensuring uniform distribution across the hazardous material. Inconsistencies in mixing or application can lead to incomplete neutralization or unpredictable reactions, compromising the overall efficacy of the process.

The reactivity of thermite with different types of hazardous materials presents an additional hurdle. While thermite reactions are highly effective against certain substances, they may be less suitable or even counterproductive for others. Developing a comprehensive understanding of the compatibility and reaction dynamics between thermite and various hazardous materials is crucial for safe and effective neutralization.

Environmental concerns also play a significant role in the challenges faced by thermite-based neutralization. The byproducts of thermite reactions, including metal oxides and other compounds, may have environmental impacts that need to be carefully managed and mitigated. Ensuring that the neutralization process does not create secondary environmental hazards is a critical consideration.

Scalability and cost-effectiveness represent further challenges in the implementation of thermite-based neutralization techniques. While the method may be suitable for small-scale applications, scaling up to handle large volumes of hazardous materials efficiently and economically remains a significant hurdle. The cost of materials, specialized equipment, and trained personnel can limit the widespread adoption of this technology.

Regulatory compliance and safety standards pose additional challenges. The use of thermite for hazardous material neutralization must adhere to strict safety protocols and regulatory requirements. Developing standardized procedures and obtaining necessary approvals from relevant authorities can be a complex and time-consuming process, potentially slowing down the adoption of this technology in practical applications.

Existing Thermite Neutralization Methodologies

01 Thermite composition for neutralization

Specialized thermite compositions are developed for neutralization purposes. These compositions are designed to generate high temperatures and molten metal products upon ignition, which can be used to neutralize hazardous materials or render explosive devices inert. The compositions may include various metal oxides and reducing agents tailored for specific neutralization applications.- Thermite neutralization using water-based solutions: This method involves using water-based solutions to neutralize thermite reactions. The solutions may contain additives that enhance their effectiveness in suppressing the thermite reaction. This approach is particularly useful for safely handling and disposing of thermite materials.

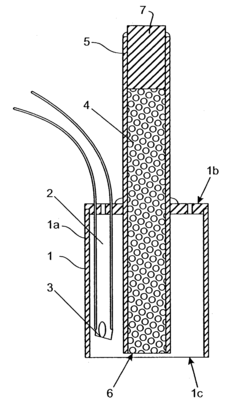

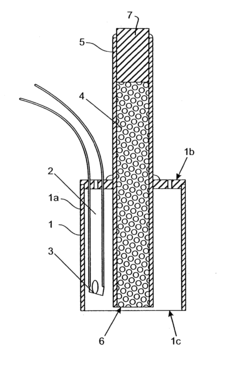

- Containment and controlled detonation of thermite: This technique focuses on containing thermite materials in specially designed vessels or chambers, allowing for controlled detonation or neutralization. The containment systems are engineered to withstand the high temperatures and pressures associated with thermite reactions, ensuring safe disposal.

- Chemical neutralization of thermite components: This approach involves using specific chemical agents to react with and neutralize the components of thermite mixtures. The chemical agents are selected to render the thermite inert or less reactive, preventing unintended ignition or explosion.

- Thermal management and heat dissipation techniques: These methods focus on managing the heat generated during thermite reactions. Techniques may include the use of heat-absorbing materials, cooling systems, or specialized coatings to dissipate heat and prevent the propagation of thermite reactions.

- Remote handling and robotic neutralization systems: This approach involves the use of remote-controlled or robotic systems for handling and neutralizing thermite materials. These systems are designed to minimize human exposure to the hazardous materials and allow for safe manipulation and disposal of thermite in various environments.

02 Containment and delivery systems

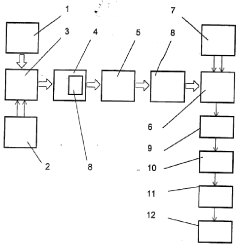

Innovative containment and delivery systems are developed for safe storage, transport, and deployment of thermite neutralization agents. These systems may include specialized containers, ignition mechanisms, and deployment methods to ensure controlled and effective neutralization processes while minimizing risks to operators and the environment.Expand Specific Solutions03 Remote activation and control

Advanced remote activation and control systems are implemented for thermite neutralization operations. These systems allow for safe initiation and monitoring of the neutralization process from a distance, reducing risks to personnel. They may include wireless communication, sensors, and automated control mechanisms to ensure precise and timely neutralization.Expand Specific Solutions04 Integration with robotic systems

Thermite neutralization techniques are integrated with robotic systems for enhanced safety and efficiency. Robotic platforms are designed to carry, deploy, and monitor thermite neutralization agents in hazardous environments, allowing for remote operation and reducing human exposure to dangerous situations.Expand Specific Solutions05 Environmental considerations and cleanup

Methods are developed to address environmental concerns and facilitate cleanup after thermite neutralization operations. These may include techniques for containing and treating byproducts, minimizing collateral damage, and restoring affected areas. Environmentally friendly thermite compositions and neutralization processes are also explored to reduce long-term environmental impact.Expand Specific Solutions

Key Players in Hazardous Material Disposal Industry

The hazardous material neutralization using thermite technology is in a growth phase, with increasing market size due to rising environmental concerns and industrial safety regulations. The global market for hazardous waste management is projected to expand significantly in the coming years. Technologically, the field is moderately mature, with ongoing research and development efforts. Key players like China Petroleum & Chemical Corp., Lockheed Martin Corp., and Naval Research Laboratory are actively advancing the technology. Companies such as SINOPEC Beijing Research Institute of Chemical Industry and Chemical Materials Research Institute of China Academy of Engineering Physics are contributing to innovations in thermite-based neutralization methods. The competitive landscape is diverse, including both established chemical companies and specialized research institutions, indicating a dynamic and evolving sector.

Leidos, Inc.

Technical Solution: Leidos has developed a thermite-based hazardous material neutralization system that utilizes a controlled exothermic reaction to rapidly decompose and neutralize chemical warfare agents and other toxic materials. The system employs a specially formulated thermite mixture that can be safely initiated and contained, allowing for the complete destruction of hazardous substances through high-temperature oxidation. This approach enables on-site treatment of dangerous materials, reducing the risks associated with transportation and storage.

Strengths: Rapid and complete neutralization of hazardous materials, on-site treatment capability, reduced transportation risks. Weaknesses: High heat generation requires careful containment, potential for unintended reactions with certain materials.

Lockheed Martin Corp.

Technical Solution: Lockheed Martin has engineered an advanced thermite-based neutralization technology for hazardous materials, particularly focused on chemical and biological agents. Their system incorporates precision-controlled thermite reactions within a specially designed containment vessel. The technology uses a computer-controlled ignition sequence and carefully calibrated thermite compositions to achieve optimal neutralization temperatures for specific hazardous substances. Additionally, they have integrated filtration and scrubbing systems to capture and treat any potentially harmful byproducts of the neutralization process.

Strengths: Precise control over neutralization process, versatility in treating various hazardous materials, integrated safety features. Weaknesses: Complex system requiring specialized training to operate, potentially high cost for implementation.

Innovative Thermite Formulations for Neutralization

Method and apparatus for mine and unexploded ordnance neutralization

PatentInactiveUS20040059176A1

Innovation

- A method involving a charge of a compound that reacts with a high heat-release rate, generating intense exothermic reactions to disrupt and combust the casing of UXO, allowing for controlled burnout of the explosive content, potentially enhanced with an oxidizer to ensure complete consumption of the explosive before detonation.

Method for thermochemically neutrolising highly toxic agents

PatentInactiveIN4667DELNP2006A

Innovation

- Multistage treatment process involving thermochemical decomposition, additional oxidation, and chemical reagent addition for complete neutralization.

- Acceleration of gas flow containing neutralizing agent to supersonic speed, followed by transformation to subsonic flow in shock waves.

- Versatile method applicable to various toxic agents in different physical states (liquid, powder, gas).

Environmental Impact Assessment

The use of thermite for hazardous material neutralization presents significant environmental considerations that must be carefully assessed. The high-temperature reaction of thermite produces intense heat and molten metal, which can have both immediate and long-term impacts on the surrounding ecosystem. In the short term, the extreme temperatures generated during the thermite reaction can cause localized soil sterilization, destroying microorganisms and altering soil chemistry. This may lead to temporary disruption of local plant and animal habitats in the immediate vicinity of the neutralization site.

Air quality is another critical concern, as the thermite reaction releases various gases and particulate matter. These emissions may include metal oxides, carbon dioxide, and potentially toxic fumes depending on the composition of the hazardous materials being neutralized. Proper containment and filtration systems are essential to mitigate the release of harmful substances into the atmosphere, which could otherwise contribute to air pollution and pose risks to human health and wildlife.

Water resources in the area may also be affected by thermite-based neutralization processes. Runoff from the reaction site could potentially contaminate nearby water bodies with metal residues and altered pH levels. This necessitates the implementation of robust containment measures and post-neutralization site remediation to prevent long-term impacts on aquatic ecosystems and groundwater quality.

The disposal of reaction byproducts presents another environmental challenge. The slag produced by thermite reactions may contain heavy metals and other hazardous substances, requiring careful handling and disposal in accordance with environmental regulations. Proper characterization and management of these byproducts are crucial to prevent secondary contamination of soil and water resources.

Long-term ecological effects must also be considered. While thermite neutralization can effectively destroy certain hazardous materials, it may alter the physical and chemical properties of the treated area. This could lead to changes in local vegetation patterns, soil fertility, and habitat suitability for various species. Monitoring programs should be established to assess and mitigate any long-term ecological shifts resulting from the neutralization process.

Energy consumption and carbon footprint associated with thermite production and deployment should be factored into the overall environmental impact assessment. While the neutralization process itself may be relatively quick, the upstream environmental costs of manufacturing and transporting thermite materials must be weighed against alternative hazardous material treatment methods.

In conclusion, while thermite-based neutralization offers an effective means of addressing certain hazardous materials, its environmental impacts require thorough evaluation and mitigation strategies. A comprehensive environmental management plan, including pre-treatment site assessment, emission control measures, post-treatment monitoring, and ecosystem restoration efforts, is essential to minimize the ecological footprint of this neutralization technique.

Air quality is another critical concern, as the thermite reaction releases various gases and particulate matter. These emissions may include metal oxides, carbon dioxide, and potentially toxic fumes depending on the composition of the hazardous materials being neutralized. Proper containment and filtration systems are essential to mitigate the release of harmful substances into the atmosphere, which could otherwise contribute to air pollution and pose risks to human health and wildlife.

Water resources in the area may also be affected by thermite-based neutralization processes. Runoff from the reaction site could potentially contaminate nearby water bodies with metal residues and altered pH levels. This necessitates the implementation of robust containment measures and post-neutralization site remediation to prevent long-term impacts on aquatic ecosystems and groundwater quality.

The disposal of reaction byproducts presents another environmental challenge. The slag produced by thermite reactions may contain heavy metals and other hazardous substances, requiring careful handling and disposal in accordance with environmental regulations. Proper characterization and management of these byproducts are crucial to prevent secondary contamination of soil and water resources.

Long-term ecological effects must also be considered. While thermite neutralization can effectively destroy certain hazardous materials, it may alter the physical and chemical properties of the treated area. This could lead to changes in local vegetation patterns, soil fertility, and habitat suitability for various species. Monitoring programs should be established to assess and mitigate any long-term ecological shifts resulting from the neutralization process.

Energy consumption and carbon footprint associated with thermite production and deployment should be factored into the overall environmental impact assessment. While the neutralization process itself may be relatively quick, the upstream environmental costs of manufacturing and transporting thermite materials must be weighed against alternative hazardous material treatment methods.

In conclusion, while thermite-based neutralization offers an effective means of addressing certain hazardous materials, its environmental impacts require thorough evaluation and mitigation strategies. A comprehensive environmental management plan, including pre-treatment site assessment, emission control measures, post-treatment monitoring, and ecosystem restoration efforts, is essential to minimize the ecological footprint of this neutralization technique.

Safety Protocols and Regulatory Compliance

The use of thermite for hazardous material neutralization requires strict adherence to safety protocols and regulatory compliance. Given the highly exothermic nature of thermite reactions, comprehensive safety measures are essential to protect personnel, equipment, and the environment. Personal protective equipment (PPE) is mandatory, including fire-resistant suits, face shields, and respiratory protection. Operators must undergo specialized training in thermite handling and emergency procedures.

Regulatory compliance is a critical aspect of thermite use in hazardous material neutralization. Operators must adhere to local, state, and federal regulations governing the storage, transportation, and use of thermite and other reactive materials. This includes obtaining necessary permits and licenses, as well as maintaining detailed records of thermite usage and disposal. Environmental impact assessments may be required, particularly when conducting neutralization operations in sensitive areas.

Safety protocols for thermite-based neutralization operations typically involve establishing a controlled perimeter around the reaction site. This includes designating hot, warm, and cold zones to manage access and minimize potential exposure. Emergency response plans must be in place, including provisions for fire suppression, spill containment, and medical assistance. Regular safety drills and equipment inspections are essential to maintain operational readiness.

The storage and handling of thermite require specific safety considerations. Thermite must be stored in dry, cool conditions, away from potential ignition sources and incompatible materials. Proper labeling and inventory management are crucial to prevent accidental misuse. When preparing for a neutralization operation, precise measurements and mixing procedures must be followed to ensure the correct thermite composition for the specific hazardous material being treated.

During the neutralization process, continuous monitoring of reaction parameters is necessary to ensure safety and efficacy. This may include temperature readings, gas detection, and visual inspection of the reaction site. Remote ignition systems and robotic deployment mechanisms can be employed to minimize human exposure to potential hazards. Post-reaction procedures must address the safe disposal of reaction products and any residual materials.

Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) provide guidelines and standards relevant to thermite use in hazardous material neutralization. Compliance with these regulations often requires detailed documentation, including risk assessments, standard operating procedures, and incident reporting protocols. Regular audits and inspections by regulatory agencies may be conducted to ensure ongoing compliance and safety.

Regulatory compliance is a critical aspect of thermite use in hazardous material neutralization. Operators must adhere to local, state, and federal regulations governing the storage, transportation, and use of thermite and other reactive materials. This includes obtaining necessary permits and licenses, as well as maintaining detailed records of thermite usage and disposal. Environmental impact assessments may be required, particularly when conducting neutralization operations in sensitive areas.

Safety protocols for thermite-based neutralization operations typically involve establishing a controlled perimeter around the reaction site. This includes designating hot, warm, and cold zones to manage access and minimize potential exposure. Emergency response plans must be in place, including provisions for fire suppression, spill containment, and medical assistance. Regular safety drills and equipment inspections are essential to maintain operational readiness.

The storage and handling of thermite require specific safety considerations. Thermite must be stored in dry, cool conditions, away from potential ignition sources and incompatible materials. Proper labeling and inventory management are crucial to prevent accidental misuse. When preparing for a neutralization operation, precise measurements and mixing procedures must be followed to ensure the correct thermite composition for the specific hazardous material being treated.

During the neutralization process, continuous monitoring of reaction parameters is necessary to ensure safety and efficacy. This may include temperature readings, gas detection, and visual inspection of the reaction site. Remote ignition systems and robotic deployment mechanisms can be employed to minimize human exposure to potential hazards. Post-reaction procedures must address the safe disposal of reaction products and any residual materials.

Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) provide guidelines and standards relevant to thermite use in hazardous material neutralization. Compliance with these regulations often requires detailed documentation, including risk assessments, standard operating procedures, and incident reporting protocols. Regular audits and inspections by regulatory agencies may be conducted to ensure ongoing compliance and safety.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!