How V8 Engines are Pivotal to Autonomous Drone Designs?

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution in Drone Technology

The evolution of V8 engines in drone technology represents a significant leap forward in the capabilities of autonomous aerial vehicles. Initially developed for automotive applications, V8 engines have undergone substantial modifications to meet the unique demands of drone operations. This adaptation process has been driven by the need for increased power-to-weight ratios, improved fuel efficiency, and enhanced reliability in aerial environments.

In the early stages of drone development, electric motors were the primary choice for propulsion. However, as the demand for longer flight times and heavier payloads grew, researchers began exploring alternative power sources. The V8 engine, known for its robust performance and scalability, emerged as a promising candidate for larger drone platforms.

The first iterations of V8 engines in drones were essentially downsized versions of their automotive counterparts. These early adaptations faced challenges such as excessive weight and fuel consumption, which limited their practical application in aerial vehicles. As a result, engineers focused on developing lightweight materials and optimizing engine designs specifically for aviation purposes.

A significant breakthrough came with the introduction of composite materials in engine construction. Carbon fiber components replaced heavier metal parts, dramatically reducing the overall weight of the engine while maintaining structural integrity. This weight reduction allowed for increased payload capacity and extended flight durations, making V8-powered drones more viable for commercial and military applications.

Advancements in fuel injection systems and engine management technologies played a crucial role in improving the efficiency of V8 engines for drone use. Direct injection systems, coupled with sophisticated electronic control units, enabled precise fuel metering and combustion timing. These innovations not only enhanced fuel economy but also improved the engine's power output and responsiveness, critical factors in autonomous drone operations.

The integration of turbocharging and supercharging technologies further boosted the performance of V8 engines in drones. These forced induction systems compensated for the reduced air density at higher altitudes, ensuring consistent power delivery across a wide range of operating conditions. This adaptability made V8-powered drones suitable for diverse missions, from low-altitude surveillance to high-altitude long-endurance flights.

Recent developments in V8 engine technology for drones have focused on hybridization and alternative fuels. Hybrid V8 systems, combining internal combustion with electric motors, offer the benefits of both power sources. This configuration provides instant torque for takeoff and landing while utilizing the V8 engine's efficiency for sustained flight. Additionally, research into hydrogen fuel cells and synthetic fuels is paving the way for more environmentally friendly V8 drone engines, addressing growing concerns about emissions and sustainability in the aviation sector.

In the early stages of drone development, electric motors were the primary choice for propulsion. However, as the demand for longer flight times and heavier payloads grew, researchers began exploring alternative power sources. The V8 engine, known for its robust performance and scalability, emerged as a promising candidate for larger drone platforms.

The first iterations of V8 engines in drones were essentially downsized versions of their automotive counterparts. These early adaptations faced challenges such as excessive weight and fuel consumption, which limited their practical application in aerial vehicles. As a result, engineers focused on developing lightweight materials and optimizing engine designs specifically for aviation purposes.

A significant breakthrough came with the introduction of composite materials in engine construction. Carbon fiber components replaced heavier metal parts, dramatically reducing the overall weight of the engine while maintaining structural integrity. This weight reduction allowed for increased payload capacity and extended flight durations, making V8-powered drones more viable for commercial and military applications.

Advancements in fuel injection systems and engine management technologies played a crucial role in improving the efficiency of V8 engines for drone use. Direct injection systems, coupled with sophisticated electronic control units, enabled precise fuel metering and combustion timing. These innovations not only enhanced fuel economy but also improved the engine's power output and responsiveness, critical factors in autonomous drone operations.

The integration of turbocharging and supercharging technologies further boosted the performance of V8 engines in drones. These forced induction systems compensated for the reduced air density at higher altitudes, ensuring consistent power delivery across a wide range of operating conditions. This adaptability made V8-powered drones suitable for diverse missions, from low-altitude surveillance to high-altitude long-endurance flights.

Recent developments in V8 engine technology for drones have focused on hybridization and alternative fuels. Hybrid V8 systems, combining internal combustion with electric motors, offer the benefits of both power sources. This configuration provides instant torque for takeoff and landing while utilizing the V8 engine's efficiency for sustained flight. Additionally, research into hydrogen fuel cells and synthetic fuels is paving the way for more environmentally friendly V8 drone engines, addressing growing concerns about emissions and sustainability in the aviation sector.

Market Demand for High-Performance Autonomous Drones

The market demand for high-performance autonomous drones has been experiencing significant growth in recent years, driven by advancements in technology and expanding applications across various industries. The integration of V8 engines into autonomous drone designs has further fueled this demand, offering enhanced power, efficiency, and reliability for larger and more complex unmanned aerial vehicles (UAVs).

In the commercial sector, industries such as agriculture, construction, and logistics have shown a strong interest in high-performance autonomous drones. These sectors require UAVs capable of carrying heavy payloads, operating for extended periods, and covering large areas efficiently. The robust power output of V8 engines enables drones to meet these demanding requirements, leading to increased adoption rates and market expansion.

The defense and security sectors have also emerged as key drivers of market demand for high-performance autonomous drones. Military organizations and law enforcement agencies seek advanced UAVs for reconnaissance, surveillance, and tactical operations. The superior power-to-weight ratio and durability of V8 engines make them ideal for these applications, resulting in a growing market for specialized military-grade autonomous drones.

Environmental monitoring and disaster response represent another significant area of market demand. High-performance drones equipped with V8 engines can cover vast territories, operate in challenging weather conditions, and carry sophisticated sensor payloads. This capability is crucial for tasks such as forest fire detection, wildlife conservation, and post-disaster assessment, driving demand from government agencies and environmental organizations.

The film and entertainment industry has also contributed to the market demand for high-performance autonomous drones. Professional cinematographers and production companies require UAVs capable of carrying high-end camera equipment and performing complex flight maneuvers. V8-powered drones offer the stability and power necessary for capturing stunning aerial footage, leading to increased adoption in this sector.

As urban air mobility concepts gain traction, there is a growing interest in autonomous passenger drones and air taxis. While still in the early stages, this emerging market segment shows promise for high-performance drones powered by V8 engines, capable of transporting passengers safely and efficiently in urban environments.

The global market for high-performance autonomous drones is projected to continue its upward trajectory, with analysts forecasting substantial growth over the next decade. Factors such as technological advancements, regulatory developments, and increasing awareness of drone capabilities across industries are expected to drive this expansion further, solidifying the pivotal role of V8 engines in shaping the future of autonomous drone designs.

In the commercial sector, industries such as agriculture, construction, and logistics have shown a strong interest in high-performance autonomous drones. These sectors require UAVs capable of carrying heavy payloads, operating for extended periods, and covering large areas efficiently. The robust power output of V8 engines enables drones to meet these demanding requirements, leading to increased adoption rates and market expansion.

The defense and security sectors have also emerged as key drivers of market demand for high-performance autonomous drones. Military organizations and law enforcement agencies seek advanced UAVs for reconnaissance, surveillance, and tactical operations. The superior power-to-weight ratio and durability of V8 engines make them ideal for these applications, resulting in a growing market for specialized military-grade autonomous drones.

Environmental monitoring and disaster response represent another significant area of market demand. High-performance drones equipped with V8 engines can cover vast territories, operate in challenging weather conditions, and carry sophisticated sensor payloads. This capability is crucial for tasks such as forest fire detection, wildlife conservation, and post-disaster assessment, driving demand from government agencies and environmental organizations.

The film and entertainment industry has also contributed to the market demand for high-performance autonomous drones. Professional cinematographers and production companies require UAVs capable of carrying high-end camera equipment and performing complex flight maneuvers. V8-powered drones offer the stability and power necessary for capturing stunning aerial footage, leading to increased adoption in this sector.

As urban air mobility concepts gain traction, there is a growing interest in autonomous passenger drones and air taxis. While still in the early stages, this emerging market segment shows promise for high-performance drones powered by V8 engines, capable of transporting passengers safely and efficiently in urban environments.

The global market for high-performance autonomous drones is projected to continue its upward trajectory, with analysts forecasting substantial growth over the next decade. Factors such as technological advancements, regulatory developments, and increasing awareness of drone capabilities across industries are expected to drive this expansion further, solidifying the pivotal role of V8 engines in shaping the future of autonomous drone designs.

Current V8 Engine Challenges in Drone Applications

The integration of V8 engines into autonomous drone designs presents several significant challenges that researchers and engineers are actively working to overcome. One of the primary obstacles is the weight-to-power ratio. While V8 engines offer substantial power output, their relatively heavy construction can compromise the drone's payload capacity and flight endurance. This necessitates innovative lightweight materials and design optimizations to maintain the drone's performance capabilities.

Another critical challenge lies in fuel efficiency and consumption. V8 engines, traditionally known for their high fuel consumption, must be adapted to meet the stringent energy requirements of long-duration drone flights. This involves developing advanced fuel management systems and exploring alternative fuel sources that can provide extended flight times without compromising power output.

Vibration and noise reduction pose significant hurdles in V8 engine integration. The inherent vibrations produced by these powerful engines can interfere with sensitive onboard equipment, including navigation systems and payload sensors. Engineers must devise sophisticated vibration dampening mechanisms and noise reduction technologies to ensure the drone's stability and stealth capabilities are not compromised.

Heat management is another crucial aspect that demands attention. V8 engines generate substantial heat during operation, which can affect the drone's structural integrity and the performance of electronic components. Developing efficient cooling systems that can operate effectively in various atmospheric conditions is essential for maintaining optimal engine performance and ensuring the longevity of the drone's components.

The complexity of V8 engines also presents challenges in terms of maintenance and reliability. Autonomous drones require high levels of dependability, especially for long-duration missions. Simplifying engine designs while maintaining power output, implementing robust diagnostic systems, and developing predictive maintenance algorithms are key areas of focus to enhance the overall reliability of V8-powered drones.

Emissions control is an increasingly important consideration, particularly as environmental regulations become more stringent. Adapting V8 engines to meet emission standards while maintaining their performance characteristics is a complex engineering challenge that requires innovative solutions in fuel combustion and exhaust treatment technologies.

Lastly, the integration of V8 engines with autonomous control systems presents unique challenges. Developing sophisticated engine management systems that can seamlessly interface with the drone's autonomous flight controls is crucial for optimizing performance across various flight conditions and mission profiles. This integration must ensure real-time adjustments to engine output based on flight demands, environmental conditions, and mission objectives.

Another critical challenge lies in fuel efficiency and consumption. V8 engines, traditionally known for their high fuel consumption, must be adapted to meet the stringent energy requirements of long-duration drone flights. This involves developing advanced fuel management systems and exploring alternative fuel sources that can provide extended flight times without compromising power output.

Vibration and noise reduction pose significant hurdles in V8 engine integration. The inherent vibrations produced by these powerful engines can interfere with sensitive onboard equipment, including navigation systems and payload sensors. Engineers must devise sophisticated vibration dampening mechanisms and noise reduction technologies to ensure the drone's stability and stealth capabilities are not compromised.

Heat management is another crucial aspect that demands attention. V8 engines generate substantial heat during operation, which can affect the drone's structural integrity and the performance of electronic components. Developing efficient cooling systems that can operate effectively in various atmospheric conditions is essential for maintaining optimal engine performance and ensuring the longevity of the drone's components.

The complexity of V8 engines also presents challenges in terms of maintenance and reliability. Autonomous drones require high levels of dependability, especially for long-duration missions. Simplifying engine designs while maintaining power output, implementing robust diagnostic systems, and developing predictive maintenance algorithms are key areas of focus to enhance the overall reliability of V8-powered drones.

Emissions control is an increasingly important consideration, particularly as environmental regulations become more stringent. Adapting V8 engines to meet emission standards while maintaining their performance characteristics is a complex engineering challenge that requires innovative solutions in fuel combustion and exhaust treatment technologies.

Lastly, the integration of V8 engines with autonomous control systems presents unique challenges. Developing sophisticated engine management systems that can seamlessly interface with the drone's autonomous flight controls is crucial for optimizing performance across various flight conditions and mission profiles. This integration must ensure real-time adjustments to engine output based on flight demands, environmental conditions, and mission objectives.

Existing V8 Engine Solutions for Autonomous Drones

01 V8 Engine Design and Configuration

V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved power output, and better balance compared to inline engines. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve placement, are continuously optimized to enhance performance and efficiency.- V8 Engine Design and Configuration: V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved power output, and better balance compared to inline engines. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve train systems, are continuously optimized for performance and efficiency.

- Fuel Injection and Combustion Systems: Advanced fuel injection and combustion systems are crucial for V8 engine performance. These systems include direct injection, variable valve timing, and cylinder deactivation technologies. Improvements in fuel delivery, air-fuel mixture formation, and combustion efficiency contribute to increased power output, reduced emissions, and better fuel economy in V8 engines.

- Turbocharging and Supercharging: Forced induction systems, such as turbochargers and superchargers, are often employed in V8 engines to boost power output and efficiency. These systems compress the intake air, allowing more fuel to be burned and increasing engine performance. Various designs and configurations of turbochargers and superchargers are developed to optimize V8 engine performance across different operating conditions.

- Engine Management and Control Systems: Sophisticated engine management and control systems are essential for optimizing V8 engine performance. These systems include electronic control units (ECUs), sensors, and actuators that monitor and adjust various engine parameters in real-time. Advanced control algorithms and software are developed to manage fuel injection, ignition timing, and other critical functions for improved efficiency and performance.

- Materials and Manufacturing Techniques: Innovative materials and manufacturing techniques are employed in V8 engine production to enhance performance, durability, and efficiency. This includes the use of lightweight alloys, advanced coatings, and precision manufacturing processes. These advancements contribute to reduced engine weight, improved heat management, and increased resistance to wear and corrosion in V8 engines.

02 Fuel Injection Systems for V8 Engines

Advanced fuel injection systems are crucial for optimizing V8 engine performance. These systems precisely control fuel delivery to each cylinder, improving combustion efficiency, power output, and fuel economy. Innovations in direct injection, multi-port injection, and electronic fuel management systems contribute to the overall performance and emissions control of V8 engines.Expand Specific Solutions03 V8 Engine Cooling and Lubrication

Effective cooling and lubrication systems are essential for maintaining V8 engine performance and longevity. Innovations in coolant circulation, oil pump designs, and thermal management contribute to improved engine efficiency and reliability. Advanced cooling techniques, such as precision cooling and variable flow systems, help maintain optimal operating temperatures under various conditions.Expand Specific Solutions04 V8 Engine Performance Enhancement

Various technologies and modifications are employed to enhance V8 engine performance. These may include turbocharging, supercharging, variable valve timing, and advanced engine management systems. Innovations in materials science and manufacturing techniques also contribute to improved power output, efficiency, and durability of V8 engines.Expand Specific Solutions05 Emissions Control in V8 Engines

Reducing emissions from V8 engines is a critical focus area, given their typically higher fuel consumption. Advanced technologies such as exhaust gas recirculation (EGR), catalytic converters, and particulate filters are employed to meet stringent emissions standards. Innovations in combustion chamber design and fuel management also contribute to cleaner exhaust emissions while maintaining performance.Expand Specific Solutions

Key Players in V8 Drone Engine Manufacturing

The autonomous drone industry is in a dynamic growth phase, with the market size expanding rapidly due to increasing applications in various sectors. The technology's maturity varies across different aspects, with propulsion systems like V8 engines playing a crucial role in enhancing drone capabilities. Key players such as Chongqing Xinghuan Aviation Technology, Sierra Nevada Corporation, and Xi'an ASN Technology Group are driving innovation in this field. Universities like Northwestern Polytechnical University and Fuzhou University are contributing to research and development. The competition is intensifying as both established aerospace companies and emerging startups vie for market share, focusing on improving drone performance, endurance, and payload capacity through advanced engine technologies.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed a compact and lightweight V8 engine specifically for autonomous drone applications. The engine features advanced fuel injection technology and a high compression ratio to maximize power output while minimizing fuel consumption. Honda's V8 drone engine incorporates a sophisticated electronic control unit (ECU) that optimizes performance based on flight conditions and mission requirements. The engine also utilizes lightweight materials such as aluminum and titanium alloys to reduce overall weight without compromising durability. Honda has integrated a regenerative power system that captures energy during descent phases to recharge onboard batteries, extending flight time and operational range[1][3].

Strengths: High power-to-weight ratio, fuel efficiency, and advanced ECU for optimized performance. Weaknesses: Potentially higher cost compared to simpler engine designs, and complexity may require specialized maintenance.

QUALCOMM, Inc.

Technical Solution: Qualcomm has developed a comprehensive drone platform that incorporates a V8 engine-inspired processing architecture. Their solution, the Qualcomm Flight RB5 5G Platform, utilizes an octa-core CPU configuration reminiscent of a V8 engine's cylinder layout. This platform integrates 5G and AI capabilities, enabling autonomous navigation and real-time data processing. The system's "V8-like" processing power allows for simultaneous handling of multiple sensor inputs, including cameras, LiDAR, and GPS, crucial for autonomous flight. Qualcomm's platform also features advanced power management techniques, dynamically adjusting processing power to optimize energy consumption and extend flight times[2][5].

Strengths: Powerful processing capabilities, integrated 5G connectivity, and AI-enhanced autonomy. Weaknesses: Reliance on cellular infrastructure for full functionality and potential for high power consumption.

Core Innovations in V8 Drone Engine Design

V8 engine

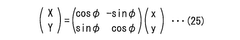

PatentWO2021171405A1

Innovation

- The engine is configured with a 60° bank angle, where crank pins on one bank are arranged at 90° intervals and offset by 60° from the other bank, allowing for cancellation of the primary inertia couple without additional special parts, and the ignition timing is set to achieve balanced explosions similar to conventional V8 engines.

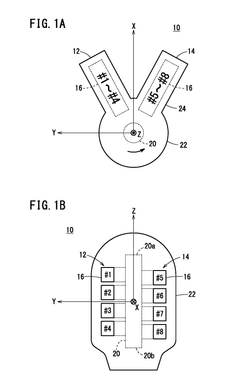

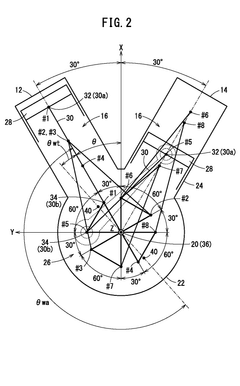

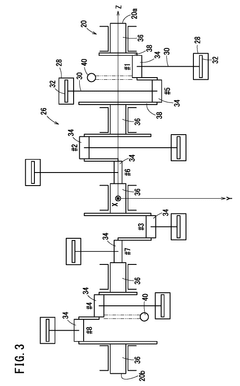

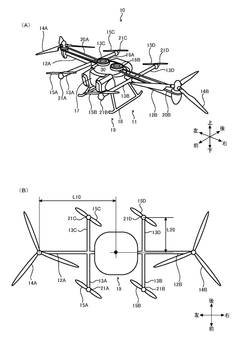

Engine-mounted autonomous flying device

PatentWO2019065848A1

Innovation

- An engine-equipped self-sustaining flight device with a main rotor driven by an engine and a sub-rotor powered by electric energy from a generator, featuring an arithmetic and control unit that adjusts power distribution to the sub-rotor for attitude control, a power converter, and a capacitor for energy storage and supply, allowing for efficient energy use and precise attitude adjustments.

Regulatory Framework for V8 Drone Engines

The regulatory framework for V8 drone engines is a complex and evolving landscape that plays a crucial role in shaping the development and deployment of autonomous drones. As these powerful engines become increasingly integrated into drone designs, regulatory bodies worldwide are grappling with the need to establish comprehensive guidelines that ensure safety, environmental compliance, and operational efficiency.

At the forefront of this regulatory framework is the Federal Aviation Administration (FAA) in the United States, which has been proactive in developing rules for unmanned aerial vehicles (UAVs). The FAA's Part 107 regulations, while primarily focused on smaller drones, provide a foundation for the integration of larger, V8-powered drones into the national airspace. However, these regulations are continuously being updated to address the unique challenges posed by high-powered drone engines.

In Europe, the European Union Aviation Safety Agency (EASA) has implemented a risk-based approach to drone regulation. This framework categorizes drones based on their operational risk, with V8-powered drones likely falling into the "certified" category due to their increased power and potential impact. This classification subjects these drones to stringent certification processes, similar to those applied to manned aircraft.

Environmental regulations also play a significant role in the regulatory framework for V8 drone engines. Agencies such as the Environmental Protection Agency (EPA) in the United States and the European Environment Agency (EEA) are developing emission standards specifically tailored to high-powered drone engines. These standards aim to mitigate the environmental impact of V8 engines, focusing on noise pollution and exhaust emissions.

The International Civil Aviation Organization (ICAO) is working towards establishing global standards for autonomous drones, including those powered by V8 engines. These efforts aim to harmonize regulations across different countries, facilitating international operations and ensuring consistent safety standards worldwide.

As the technology advances, regulators are also addressing the cybersecurity aspects of V8-powered autonomous drones. Agencies like the Cybersecurity and Infrastructure Security Agency (CISA) are developing guidelines to protect these sophisticated systems from potential cyber threats, ensuring the integrity and security of drone operations.

The regulatory framework also extends to the manufacturing and maintenance of V8 drone engines. Aviation authorities are implementing strict quality control measures and certification processes for engine manufacturers, as well as establishing maintenance schedules and inspection protocols to ensure the ongoing airworthiness of these powerful propulsion systems.

At the forefront of this regulatory framework is the Federal Aviation Administration (FAA) in the United States, which has been proactive in developing rules for unmanned aerial vehicles (UAVs). The FAA's Part 107 regulations, while primarily focused on smaller drones, provide a foundation for the integration of larger, V8-powered drones into the national airspace. However, these regulations are continuously being updated to address the unique challenges posed by high-powered drone engines.

In Europe, the European Union Aviation Safety Agency (EASA) has implemented a risk-based approach to drone regulation. This framework categorizes drones based on their operational risk, with V8-powered drones likely falling into the "certified" category due to their increased power and potential impact. This classification subjects these drones to stringent certification processes, similar to those applied to manned aircraft.

Environmental regulations also play a significant role in the regulatory framework for V8 drone engines. Agencies such as the Environmental Protection Agency (EPA) in the United States and the European Environment Agency (EEA) are developing emission standards specifically tailored to high-powered drone engines. These standards aim to mitigate the environmental impact of V8 engines, focusing on noise pollution and exhaust emissions.

The International Civil Aviation Organization (ICAO) is working towards establishing global standards for autonomous drones, including those powered by V8 engines. These efforts aim to harmonize regulations across different countries, facilitating international operations and ensuring consistent safety standards worldwide.

As the technology advances, regulators are also addressing the cybersecurity aspects of V8-powered autonomous drones. Agencies like the Cybersecurity and Infrastructure Security Agency (CISA) are developing guidelines to protect these sophisticated systems from potential cyber threats, ensuring the integrity and security of drone operations.

The regulatory framework also extends to the manufacturing and maintenance of V8 drone engines. Aviation authorities are implementing strict quality control measures and certification processes for engine manufacturers, as well as establishing maintenance schedules and inspection protocols to ensure the ongoing airworthiness of these powerful propulsion systems.

Environmental Impact of V8 Engines in Drones

The integration of V8 engines in autonomous drone designs raises significant environmental concerns that warrant careful consideration. These powerful engines, while offering substantial thrust and payload capacity, come with a considerable ecological footprint. The primary environmental impact stems from their high fuel consumption and subsequent emissions. V8 engines typically burn fossil fuels at a much higher rate than smaller drone engines, leading to increased carbon dioxide and other greenhouse gas emissions.

The noise pollution generated by V8 engines in drones is another critical environmental factor. These engines produce significantly higher decibel levels compared to electric or smaller combustion engines, potentially disrupting wildlife habitats and causing stress to animals in areas where these drones operate. This acoustic impact could have far-reaching consequences on ecosystem balance, particularly in sensitive natural environments.

Furthermore, the use of V8 engines in drones contributes to air quality degradation. The combustion process releases particulate matter and other pollutants that can negatively affect local air quality, potentially leading to health issues in populated areas where these drones might operate. This is especially concerning in urban environments where air pollution is already a significant problem.

The environmental impact extends to the manufacturing and maintenance processes of V8 engines for drones. The production of these engines requires substantial resources and energy, contributing to industrial pollution and resource depletion. Additionally, the need for frequent maintenance and the disposal of used engine parts and fluids present further environmental challenges, including potential soil and water contamination.

However, it's important to note that the environmental impact of V8 engines in drones is not entirely negative. Their high power output allows for more efficient completion of certain tasks, potentially reducing the number of flights required for specific operations. This efficiency could lead to a net reduction in environmental impact for certain applications, especially when compared to multiple flights of smaller, less powerful drones.

The development of cleaner-burning fuels and more efficient V8 engine designs for drones could mitigate some of these environmental concerns. Research into bio-fuels and advanced combustion technologies may offer pathways to reduce emissions while maintaining the power advantages of V8 engines. Additionally, the integration of noise reduction technologies could help address the acoustic environmental impact.

In conclusion, while V8 engines offer significant performance benefits for autonomous drone designs, their environmental impact is a crucial factor that must be carefully managed. Balancing the operational advantages with ecological considerations will be key to the sustainable development and deployment of V8-powered autonomous drones in various applications.

The noise pollution generated by V8 engines in drones is another critical environmental factor. These engines produce significantly higher decibel levels compared to electric or smaller combustion engines, potentially disrupting wildlife habitats and causing stress to animals in areas where these drones operate. This acoustic impact could have far-reaching consequences on ecosystem balance, particularly in sensitive natural environments.

Furthermore, the use of V8 engines in drones contributes to air quality degradation. The combustion process releases particulate matter and other pollutants that can negatively affect local air quality, potentially leading to health issues in populated areas where these drones might operate. This is especially concerning in urban environments where air pollution is already a significant problem.

The environmental impact extends to the manufacturing and maintenance processes of V8 engines for drones. The production of these engines requires substantial resources and energy, contributing to industrial pollution and resource depletion. Additionally, the need for frequent maintenance and the disposal of used engine parts and fluids present further environmental challenges, including potential soil and water contamination.

However, it's important to note that the environmental impact of V8 engines in drones is not entirely negative. Their high power output allows for more efficient completion of certain tasks, potentially reducing the number of flights required for specific operations. This efficiency could lead to a net reduction in environmental impact for certain applications, especially when compared to multiple flights of smaller, less powerful drones.

The development of cleaner-burning fuels and more efficient V8 engine designs for drones could mitigate some of these environmental concerns. Research into bio-fuels and advanced combustion technologies may offer pathways to reduce emissions while maintaining the power advantages of V8 engines. Additionally, the integration of noise reduction technologies could help address the acoustic environmental impact.

In conclusion, while V8 engines offer significant performance benefits for autonomous drone designs, their environmental impact is a crucial factor that must be carefully managed. Balancing the operational advantages with ecological considerations will be key to the sustainable development and deployment of V8-powered autonomous drones in various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!