How V8 Engines Balance Performance and Sustainability?

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution

The evolution of V8 engines represents a fascinating journey of technological advancement, balancing the pursuit of performance with the growing demand for sustainability. This evolution can be traced back to the early 20th century when the first V8 engine was introduced, marking a significant leap in automotive engineering.

In the initial stages, V8 engines were primarily focused on raw power and performance. The 1930s and 1940s saw the widespread adoption of V8 engines in American automobiles, with manufacturers like Ford and Chevrolet leading the charge. These early V8s were characterized by their large displacement and high fuel consumption, prioritizing power output over efficiency.

The 1960s and 1970s marked a turning point in V8 engine development. The muscle car era pushed the boundaries of V8 performance, with engines reaching new heights in horsepower and torque. However, this period also coincided with growing concerns about fuel efficiency and environmental impact, leading to the introduction of emission control systems and a shift towards smaller, more efficient designs.

The oil crises of the 1970s further accelerated the need for more fuel-efficient V8 engines. This led to innovations such as electronic fuel injection, variable valve timing, and cylinder deactivation technologies. These advancements allowed V8 engines to maintain their performance characteristics while significantly improving fuel economy and reducing emissions.

The late 20th and early 21st centuries saw a renewed focus on balancing performance and sustainability. Advanced materials and manufacturing techniques enabled the creation of lighter, more compact V8 engines. The introduction of direct injection, turbocharging, and supercharging allowed smaller displacement V8s to produce power comparable to their larger predecessors while consuming less fuel.

In recent years, the evolution of V8 engines has been heavily influenced by stringent emissions regulations and the push for greater sustainability. This has led to the development of hybrid V8 systems, combining traditional internal combustion with electric power. These hybrid V8s offer a compromise between high performance and improved fuel efficiency, representing a new frontier in engine technology.

The latest advancements in V8 engine technology focus on further optimizing combustion processes, reducing friction losses, and integrating smart engine management systems. These innovations aim to extract maximum performance while minimizing environmental impact, showcasing the ongoing efforts to balance power and sustainability in V8 engine design.

In the initial stages, V8 engines were primarily focused on raw power and performance. The 1930s and 1940s saw the widespread adoption of V8 engines in American automobiles, with manufacturers like Ford and Chevrolet leading the charge. These early V8s were characterized by their large displacement and high fuel consumption, prioritizing power output over efficiency.

The 1960s and 1970s marked a turning point in V8 engine development. The muscle car era pushed the boundaries of V8 performance, with engines reaching new heights in horsepower and torque. However, this period also coincided with growing concerns about fuel efficiency and environmental impact, leading to the introduction of emission control systems and a shift towards smaller, more efficient designs.

The oil crises of the 1970s further accelerated the need for more fuel-efficient V8 engines. This led to innovations such as electronic fuel injection, variable valve timing, and cylinder deactivation technologies. These advancements allowed V8 engines to maintain their performance characteristics while significantly improving fuel economy and reducing emissions.

The late 20th and early 21st centuries saw a renewed focus on balancing performance and sustainability. Advanced materials and manufacturing techniques enabled the creation of lighter, more compact V8 engines. The introduction of direct injection, turbocharging, and supercharging allowed smaller displacement V8s to produce power comparable to their larger predecessors while consuming less fuel.

In recent years, the evolution of V8 engines has been heavily influenced by stringent emissions regulations and the push for greater sustainability. This has led to the development of hybrid V8 systems, combining traditional internal combustion with electric power. These hybrid V8s offer a compromise between high performance and improved fuel efficiency, representing a new frontier in engine technology.

The latest advancements in V8 engine technology focus on further optimizing combustion processes, reducing friction losses, and integrating smart engine management systems. These innovations aim to extract maximum performance while minimizing environmental impact, showcasing the ongoing efforts to balance power and sustainability in V8 engine design.

Market Demand Analysis

The market demand for V8 engines that balance performance and sustainability has been steadily growing in recent years. This trend is driven by increasing environmental concerns, stricter emissions regulations, and consumer preferences for more fuel-efficient vehicles without compromising power and performance.

In the automotive sector, there is a significant demand for V8 engines in luxury vehicles, sports cars, and high-performance SUVs. These segments continue to value the power and prestige associated with V8 engines. However, manufacturers are under pressure to improve fuel efficiency and reduce emissions to meet regulatory standards and consumer expectations.

The commercial vehicle market, particularly in heavy-duty trucks and construction equipment, also shows a strong demand for V8 engines that can deliver high torque and power while meeting increasingly stringent emissions standards. This sector requires engines that can maintain performance under heavy loads and harsh conditions while minimizing environmental impact.

Marine and aviation industries represent another significant market for V8 engines. In these sectors, the balance between performance and sustainability is crucial, as operators seek to reduce fuel consumption and emissions without compromising on power and reliability.

The racing industry continues to be a key driver of innovation in V8 engine technology. While performance remains paramount in this sector, there is growing emphasis on developing more sustainable racing engines, which often translates to advancements that can be applied to consumer vehicles.

Market analysis indicates that consumers are increasingly willing to pay a premium for vehicles that offer both high performance and improved fuel efficiency. This trend is particularly evident in the luxury and performance vehicle segments, where buyers expect cutting-edge technology that addresses both power and environmental concerns.

The global market for V8 engines is projected to grow, albeit at a slower rate compared to previous decades. This growth is primarily driven by emerging markets where demand for luxury and high-performance vehicles is increasing. However, in mature markets, there is a shift towards downsized engines and alternative powertrains, which is partially offset by the demand for more efficient and sustainable V8 options.

Manufacturers are responding to these market demands by investing heavily in research and development to create V8 engines that incorporate advanced technologies such as cylinder deactivation, direct injection, and mild hybrid systems. These innovations aim to significantly improve fuel efficiency and reduce emissions while maintaining the power and character that V8 engines are known for.

In the automotive sector, there is a significant demand for V8 engines in luxury vehicles, sports cars, and high-performance SUVs. These segments continue to value the power and prestige associated with V8 engines. However, manufacturers are under pressure to improve fuel efficiency and reduce emissions to meet regulatory standards and consumer expectations.

The commercial vehicle market, particularly in heavy-duty trucks and construction equipment, also shows a strong demand for V8 engines that can deliver high torque and power while meeting increasingly stringent emissions standards. This sector requires engines that can maintain performance under heavy loads and harsh conditions while minimizing environmental impact.

Marine and aviation industries represent another significant market for V8 engines. In these sectors, the balance between performance and sustainability is crucial, as operators seek to reduce fuel consumption and emissions without compromising on power and reliability.

The racing industry continues to be a key driver of innovation in V8 engine technology. While performance remains paramount in this sector, there is growing emphasis on developing more sustainable racing engines, which often translates to advancements that can be applied to consumer vehicles.

Market analysis indicates that consumers are increasingly willing to pay a premium for vehicles that offer both high performance and improved fuel efficiency. This trend is particularly evident in the luxury and performance vehicle segments, where buyers expect cutting-edge technology that addresses both power and environmental concerns.

The global market for V8 engines is projected to grow, albeit at a slower rate compared to previous decades. This growth is primarily driven by emerging markets where demand for luxury and high-performance vehicles is increasing. However, in mature markets, there is a shift towards downsized engines and alternative powertrains, which is partially offset by the demand for more efficient and sustainable V8 options.

Manufacturers are responding to these market demands by investing heavily in research and development to create V8 engines that incorporate advanced technologies such as cylinder deactivation, direct injection, and mild hybrid systems. These innovations aim to significantly improve fuel efficiency and reduce emissions while maintaining the power and character that V8 engines are known for.

Technical Challenges

V8 engines face several technical challenges in balancing performance and sustainability. One of the primary issues is the trade-off between power output and fuel efficiency. As manufacturers strive to meet increasingly stringent emissions regulations, they must find ways to maintain or improve engine performance while reducing fuel consumption and emissions.

The complexity of modern V8 engines presents another significant challenge. Advanced technologies such as direct fuel injection, variable valve timing, and turbocharging are employed to enhance performance and efficiency. However, these systems add complexity to the engine design, potentially increasing manufacturing costs and maintenance requirements.

Thermal management is a critical concern in V8 engines, particularly in high-performance applications. The need to dissipate heat effectively while maintaining optimal operating temperatures can be challenging, especially when pushing the limits of power output. This challenge is further compounded by the trend towards downsizing engines, which can lead to increased thermal stress on components.

Material selection and weight reduction pose additional challenges. Engineers must balance the use of lightweight materials to improve fuel efficiency with the need for durability and longevity. Advanced materials such as high-strength alloys and composites offer potential solutions but often come with increased costs and manufacturing complexities.

The integration of hybrid and electrification technologies into V8 powertrains presents both opportunities and challenges. While these systems can significantly improve fuel efficiency and reduce emissions, they add complexity to the overall powertrain design and require careful integration to maintain the characteristic performance and sound of V8 engines.

Emissions control remains a persistent challenge for V8 engines. Meeting increasingly stringent regulations while maintaining performance requires sophisticated aftertreatment systems and engine management strategies. The need to reduce particulate matter, NOx, and CO2 emissions often conflicts with the goal of maximizing power output.

Durability and reliability are crucial factors in V8 engine design, particularly in high-performance applications. Engineers must ensure that components can withstand the stresses of increased power output and thermal loads while maintaining longevity and reliability. This challenge is particularly acute in forced induction systems, where increased pressures and temperatures can accelerate wear and fatigue.

Finally, the development of sustainable fuels and their compatibility with V8 engines presents both opportunities and challenges. While alternative fuels such as biofuels and synthetic fuels offer potential pathways to reduce carbon emissions, they may require modifications to engine design and fuel systems to ensure optimal performance and longevity.

The complexity of modern V8 engines presents another significant challenge. Advanced technologies such as direct fuel injection, variable valve timing, and turbocharging are employed to enhance performance and efficiency. However, these systems add complexity to the engine design, potentially increasing manufacturing costs and maintenance requirements.

Thermal management is a critical concern in V8 engines, particularly in high-performance applications. The need to dissipate heat effectively while maintaining optimal operating temperatures can be challenging, especially when pushing the limits of power output. This challenge is further compounded by the trend towards downsizing engines, which can lead to increased thermal stress on components.

Material selection and weight reduction pose additional challenges. Engineers must balance the use of lightweight materials to improve fuel efficiency with the need for durability and longevity. Advanced materials such as high-strength alloys and composites offer potential solutions but often come with increased costs and manufacturing complexities.

The integration of hybrid and electrification technologies into V8 powertrains presents both opportunities and challenges. While these systems can significantly improve fuel efficiency and reduce emissions, they add complexity to the overall powertrain design and require careful integration to maintain the characteristic performance and sound of V8 engines.

Emissions control remains a persistent challenge for V8 engines. Meeting increasingly stringent regulations while maintaining performance requires sophisticated aftertreatment systems and engine management strategies. The need to reduce particulate matter, NOx, and CO2 emissions often conflicts with the goal of maximizing power output.

Durability and reliability are crucial factors in V8 engine design, particularly in high-performance applications. Engineers must ensure that components can withstand the stresses of increased power output and thermal loads while maintaining longevity and reliability. This challenge is particularly acute in forced induction systems, where increased pressures and temperatures can accelerate wear and fatigue.

Finally, the development of sustainable fuels and their compatibility with V8 engines presents both opportunities and challenges. While alternative fuels such as biofuels and synthetic fuels offer potential pathways to reduce carbon emissions, they may require modifications to engine design and fuel systems to ensure optimal performance and longevity.

Current Solutions

01 Engine Control Systems for V8 Performance

Advanced control systems are being developed to optimize V8 engine performance. These systems utilize sophisticated algorithms and sensors to manage fuel injection, ignition timing, and valve operation. By precisely controlling these parameters, the engine's power output and efficiency can be significantly improved while reducing emissions.- Advanced engine control systems: Modern V8 engines utilize sophisticated control systems to optimize performance and fuel efficiency. These systems incorporate real-time monitoring and adjustment of various engine parameters, including fuel injection, ignition timing, and valve timing. By precisely controlling these factors, the engine can achieve improved power output while maintaining or reducing fuel consumption.

- Sustainable fuel technologies: To enhance sustainability, V8 engines are being adapted to use alternative fuels or fuel blends. This includes the development of engines capable of running on biofuels, hydrogen, or synthetic fuels. These advancements aim to reduce the carbon footprint of V8 engines while maintaining their characteristic performance.

- Lightweight materials and design: The use of lightweight materials such as aluminum alloys and carbon fiber composites in V8 engine construction helps to reduce overall vehicle weight. This, combined with innovative design techniques, leads to improved power-to-weight ratios and enhanced fuel efficiency without compromising performance or durability.

- Hybrid and electrification integration: To meet stringent emissions standards and improve overall efficiency, V8 engines are being integrated with hybrid and electric technologies. This includes the development of mild hybrid systems, plug-in hybrid powertrains, and even fully electric assist systems that complement the V8 engine's performance while reducing fuel consumption and emissions.

- Advanced thermal management: Innovative thermal management systems are being developed to optimize V8 engine performance and efficiency. These systems include advanced cooling technologies, heat recovery systems, and thermal barrier coatings. By managing heat more effectively, these advancements contribute to improved engine efficiency, reduced emissions, and enhanced overall performance.

02 Sustainable Fuel Technologies for V8 Engines

Research is focused on adapting V8 engines to use more sustainable fuel sources. This includes the development of biofuel compatibility, hydrogen fuel systems, and synthetic fuel technologies. These advancements aim to reduce the environmental impact of V8 engines while maintaining their characteristic power and performance.Expand Specific Solutions03 Thermal Management and Energy Recovery

Innovative thermal management systems are being integrated into V8 engines to improve overall efficiency. These systems include advanced cooling techniques and waste heat recovery mechanisms. By effectively managing heat and recovering otherwise wasted energy, the engine's fuel efficiency and performance can be enhanced while reducing its environmental footprint.Expand Specific Solutions04 Lightweight Materials and Design Optimization

The use of lightweight materials and optimized design techniques is improving V8 engine sustainability. Advanced alloys, composites, and innovative manufacturing processes are being employed to reduce engine weight while maintaining strength and durability. These improvements lead to better fuel efficiency and reduced emissions without compromising performance.Expand Specific Solutions05 Hybrid and Electric Integration with V8 Engines

Integration of hybrid and electric technologies with V8 engines is being explored to enhance sustainability. This includes the development of mild hybrid systems, plug-in hybrid configurations, and electric assist technologies specifically designed for V8 engines. These innovations aim to combine the power of V8 engines with the efficiency benefits of electrification.Expand Specific Solutions

Key Industry Players

The V8 engine market is in a mature stage, with established players like BMW, Honda, Toyota, and Ford dominating the landscape. The global V8 engine market size is estimated to be in the billions, driven by demand in high-performance vehicles and luxury segments. Technologically, V8 engines are well-developed, but face challenges in balancing performance with sustainability. Companies like Mercedes-Benz and GM are investing in innovative solutions to improve fuel efficiency and reduce emissions, while maintaining power output. The industry is gradually shifting towards electrification, with hybrid V8 systems emerging as a transitional technology. This evolution is pushing traditional V8 manufacturers to adapt their strategies and invest in sustainable powertrain technologies.

Bayerische Motoren Werke AG

Technical Solution: BMW's approach to balancing performance and sustainability in V8 engines involves a combination of advanced technologies. Their latest V8 engines feature TwinPower Turbo technology, which includes twin-scroll turbochargers, high-precision direct injection, and VALVETRONIC fully variable valve control[13]. BMW has implemented a cross-bank exhaust manifold to improve turbocharger response and efficiency[14]. The company also utilizes a cylinder deactivation system that can shut down four cylinders under light load conditions, improving fuel economy by up to 15%[15]. BMW has integrated a 48V mild hybrid system in some V8 models, which includes an electric motor that can provide additional power and enable extended start-stop functionality[16]. Additionally, BMW has focused on reducing internal friction and improving thermal management to enhance overall engine efficiency[17].

Strengths: Advanced turbocharging technology, efficient cylinder deactivation, and mild hybrid integration for improved performance and efficiency. Weaknesses: Increased complexity may lead to higher production and maintenance costs, potential long-term reliability concerns with advanced technologies.

Honda Motor Co., Ltd.

Technical Solution: Honda's approach to balancing performance and sustainability in V8 engines focuses on their i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) technology. This system optimizes valve timing and lift for both low and high RPM operations, improving both fuel efficiency and power output[18]. Honda has also implemented direct injection and a high compression ratio in their V8 engines to enhance thermal efficiency[19]. While Honda doesn't widely use V8 engines in their current lineup, their racing division has developed a twin-turbocharged V8 engine for IndyCar racing that incorporates advanced fuel efficiency measures and meets strict emissions regulations[20]. This racing technology often trickles down to their production engines. Additionally, Honda has been exploring the use of variable displacement technology and start-stop systems to further improve fuel economy in their larger engines[21].

Strengths: Advanced valve control technology, high thermal efficiency, and racing-derived innovations. Weaknesses: Limited current production of V8 engines may result in less real-world data on long-term sustainability in consumer vehicles.

Core Innovations

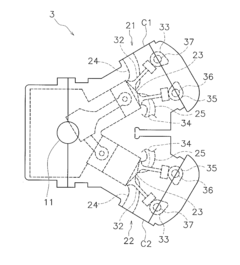

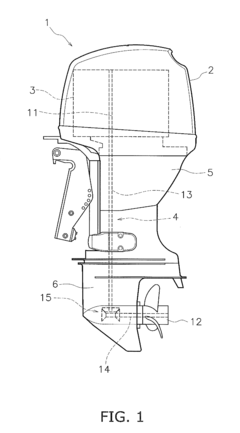

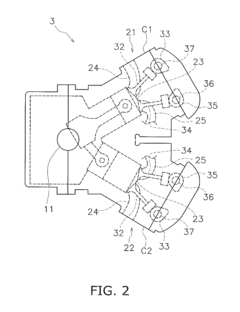

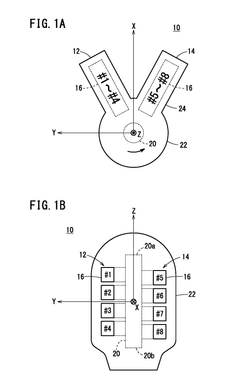

V8 engine and outboard motor

PatentActiveUS20160341097A1

Innovation

- A V8 engine design with a simple construction featuring aggregated exhaust pathways and adjustable exhaust cams, where the central angle of exhaust cams for each cylinder is optimized to minimize valve overlap and reduce exhaust interference, allowing for even firing intervals and improved exhaust gas management.

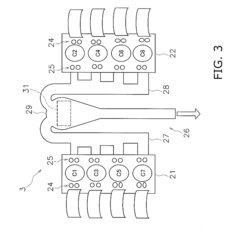

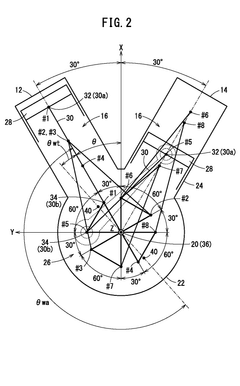

V8 engine

PatentWO2021171405A1

Innovation

- The engine is configured with a 60° bank angle, where crank pins on one bank are arranged at 90° intervals and offset by 60° from the other bank, allowing for cancellation of the primary inertia couple without additional special parts, and the ignition timing is set to achieve balanced explosions similar to conventional V8 engines.

Emissions Regulations

Emissions regulations have become increasingly stringent in recent years, significantly impacting the development and performance of V8 engines. These regulations aim to reduce harmful emissions and improve air quality, forcing manufacturers to adapt their engine designs to meet new standards while maintaining performance levels.

The most prominent emissions regulations affecting V8 engines include the European Union's Euro standards, the United States Environmental Protection Agency's (EPA) Tier 3 standards, and California Air Resources Board (CARB) regulations. These standards set limits on various pollutants, including carbon monoxide (CO), nitrogen oxides (NOx), particulate matter (PM), and hydrocarbons (HC).

To comply with these regulations, V8 engine manufacturers have implemented various technologies and strategies. One key approach is the use of advanced fuel injection systems, such as direct injection, which allows for more precise control of fuel delivery and combustion. This technology helps reduce emissions while improving fuel efficiency and performance.

Another crucial development is the widespread adoption of exhaust gas recirculation (EGR) systems. EGR reduces NOx emissions by recirculating a portion of the exhaust gases back into the combustion chamber, lowering peak combustion temperatures. While this can slightly reduce engine power, careful calibration helps minimize performance losses.

Catalytic converters have also undergone significant improvements to meet stricter emissions standards. Modern V8 engines often employ three-way catalytic converters, which simultaneously reduce CO, HC, and NOx emissions. Some manufacturers have even introduced close-coupled catalysts, positioned closer to the engine for faster light-off and improved efficiency.

The integration of variable valve timing (VVT) and lift systems has further enhanced V8 engines' ability to balance performance and emissions compliance. These systems allow for optimized engine breathing across different operating conditions, improving both power output and emissions control.

In recent years, cylinder deactivation technology has gained popularity in V8 engines. This system allows the engine to shut down a portion of its cylinders during light-load conditions, reducing fuel consumption and emissions without significantly compromising performance when full power is needed.

As emissions regulations continue to evolve, V8 engine manufacturers are exploring more advanced technologies. These include mild hybrid systems, which can provide electric assist and enable more aggressive start-stop functionality, further reducing emissions in urban driving scenarios.

The challenge for V8 engine designers lies in balancing these emissions-reducing technologies with the power and character that enthusiasts expect from these engines. As regulations become more stringent, manufacturers must continue to innovate to ensure that V8 engines remain viable in an increasingly environmentally conscious automotive landscape.

The most prominent emissions regulations affecting V8 engines include the European Union's Euro standards, the United States Environmental Protection Agency's (EPA) Tier 3 standards, and California Air Resources Board (CARB) regulations. These standards set limits on various pollutants, including carbon monoxide (CO), nitrogen oxides (NOx), particulate matter (PM), and hydrocarbons (HC).

To comply with these regulations, V8 engine manufacturers have implemented various technologies and strategies. One key approach is the use of advanced fuel injection systems, such as direct injection, which allows for more precise control of fuel delivery and combustion. This technology helps reduce emissions while improving fuel efficiency and performance.

Another crucial development is the widespread adoption of exhaust gas recirculation (EGR) systems. EGR reduces NOx emissions by recirculating a portion of the exhaust gases back into the combustion chamber, lowering peak combustion temperatures. While this can slightly reduce engine power, careful calibration helps minimize performance losses.

Catalytic converters have also undergone significant improvements to meet stricter emissions standards. Modern V8 engines often employ three-way catalytic converters, which simultaneously reduce CO, HC, and NOx emissions. Some manufacturers have even introduced close-coupled catalysts, positioned closer to the engine for faster light-off and improved efficiency.

The integration of variable valve timing (VVT) and lift systems has further enhanced V8 engines' ability to balance performance and emissions compliance. These systems allow for optimized engine breathing across different operating conditions, improving both power output and emissions control.

In recent years, cylinder deactivation technology has gained popularity in V8 engines. This system allows the engine to shut down a portion of its cylinders during light-load conditions, reducing fuel consumption and emissions without significantly compromising performance when full power is needed.

As emissions regulations continue to evolve, V8 engine manufacturers are exploring more advanced technologies. These include mild hybrid systems, which can provide electric assist and enable more aggressive start-stop functionality, further reducing emissions in urban driving scenarios.

The challenge for V8 engine designers lies in balancing these emissions-reducing technologies with the power and character that enthusiasts expect from these engines. As regulations become more stringent, manufacturers must continue to innovate to ensure that V8 engines remain viable in an increasingly environmentally conscious automotive landscape.

Alternative Fuels

Alternative fuels play a crucial role in balancing performance and sustainability in V8 engines. As environmental concerns grow, manufacturers are exploring various options to reduce emissions while maintaining the power and performance associated with V8 engines.

One promising alternative fuel is hydrogen. When used in a V8 engine, hydrogen produces zero carbon emissions, making it an environmentally friendly option. However, challenges remain in hydrogen production, storage, and distribution infrastructure. Despite these hurdles, several automotive companies are investing in hydrogen-powered V8 engines for high-performance vehicles.

Biofuels, particularly advanced biofuels derived from non-food sources, offer another sustainable alternative for V8 engines. These fuels can be produced from agricultural waste, algae, or other renewable sources. When blended with traditional gasoline or used as a standalone fuel, biofuels can significantly reduce carbon emissions while maintaining engine performance.

Synthetic fuels, also known as e-fuels, are gaining attention as a potential solution for V8 engines. These laboratory-created fuels are designed to mimic the properties of traditional fossil fuels but with a lower carbon footprint. Synthetic fuels can be tailored to meet specific engine requirements, potentially enhancing performance while reducing emissions.

Natural gas, particularly in the form of compressed natural gas (CNG) or liquefied natural gas (LNG), is another alternative fuel option for V8 engines. While not carbon-neutral, natural gas produces fewer emissions compared to traditional gasoline or diesel. Some manufacturers have developed V8 engines capable of running on natural gas, offering a balance between performance and reduced environmental impact.

Ethanol, a renewable fuel derived from plant materials, has been used in V8 engines for years. High-ethanol blends, such as E85, can provide increased power output in properly tuned engines while reducing greenhouse gas emissions. However, ethanol's lower energy density compared to gasoline can impact fuel efficiency and range.

As the automotive industry continues to evolve, research into alternative fuels for V8 engines is ongoing. Manufacturers are exploring combinations of these alternative fuels, as well as hybrid systems that incorporate electric power alongside alternative fuels. These innovations aim to preserve the performance characteristics of V8 engines while meeting increasingly stringent environmental regulations and consumer demands for sustainability.

One promising alternative fuel is hydrogen. When used in a V8 engine, hydrogen produces zero carbon emissions, making it an environmentally friendly option. However, challenges remain in hydrogen production, storage, and distribution infrastructure. Despite these hurdles, several automotive companies are investing in hydrogen-powered V8 engines for high-performance vehicles.

Biofuels, particularly advanced biofuels derived from non-food sources, offer another sustainable alternative for V8 engines. These fuels can be produced from agricultural waste, algae, or other renewable sources. When blended with traditional gasoline or used as a standalone fuel, biofuels can significantly reduce carbon emissions while maintaining engine performance.

Synthetic fuels, also known as e-fuels, are gaining attention as a potential solution for V8 engines. These laboratory-created fuels are designed to mimic the properties of traditional fossil fuels but with a lower carbon footprint. Synthetic fuels can be tailored to meet specific engine requirements, potentially enhancing performance while reducing emissions.

Natural gas, particularly in the form of compressed natural gas (CNG) or liquefied natural gas (LNG), is another alternative fuel option for V8 engines. While not carbon-neutral, natural gas produces fewer emissions compared to traditional gasoline or diesel. Some manufacturers have developed V8 engines capable of running on natural gas, offering a balance between performance and reduced environmental impact.

Ethanol, a renewable fuel derived from plant materials, has been used in V8 engines for years. High-ethanol blends, such as E85, can provide increased power output in properly tuned engines while reducing greenhouse gas emissions. However, ethanol's lower energy density compared to gasoline can impact fuel efficiency and range.

As the automotive industry continues to evolve, research into alternative fuels for V8 engines is ongoing. Manufacturers are exploring combinations of these alternative fuels, as well as hybrid systems that incorporate electric power alongside alternative fuels. These innovations aim to preserve the performance characteristics of V8 engines while meeting increasingly stringent environmental regulations and consumer demands for sustainability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!