How V8 Engines Enhance High-Speed Rail Capabilities?

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution in Rail

The evolution of V8 engines in rail transportation represents a significant leap in high-speed rail capabilities. Initially developed for automotive applications, V8 engines have undergone substantial modifications to meet the unique demands of rail systems. This adaptation process has been driven by the need for increased power, improved efficiency, and enhanced reliability in high-speed rail operations.

The journey of V8 engines in rail began with their introduction in diesel locomotives during the mid-20th century. These early adaptations focused on increasing power output and durability to handle the continuous operation required in rail transport. As high-speed rail technology advanced, so did the requirements for V8 engines, leading to a series of innovations and refinements.

One of the key evolutionary steps was the development of turbocharged V8 engines specifically designed for rail applications. This advancement significantly boosted power output while maintaining fuel efficiency, a crucial factor in long-distance rail operations. The integration of electronic fuel injection systems further enhanced engine performance and reduced emissions, aligning with increasingly stringent environmental regulations.

Another critical development in V8 engine evolution for rail was the implementation of advanced cooling systems. These systems were designed to manage the intense heat generated during high-speed operations, ensuring optimal engine performance and longevity. Coupled with this, improvements in materials technology led to the use of lighter, more durable components, contributing to overall weight reduction and improved energy efficiency.

The integration of sophisticated engine management systems marked a pivotal point in V8 engine evolution for rail. These systems enabled real-time monitoring and adjustment of engine parameters, optimizing performance across various operating conditions. This level of control not only enhanced efficiency but also significantly improved the reliability and maintenance predictability of rail engines.

Recent advancements have focused on hybridization, combining V8 engines with electric propulsion systems. This hybrid approach leverages the power and reliability of V8 engines while capitalizing on the efficiency and environmental benefits of electric technology. Such innovations are paving the way for more sustainable high-speed rail solutions without compromising on performance.

The ongoing evolution of V8 engines in rail continues to push the boundaries of high-speed capabilities. Current research is exploring the potential of alternative fuels and advanced combustion technologies to further enhance efficiency and reduce environmental impact. These developments underscore the enduring relevance of V8 engines in the rail sector and their critical role in shaping the future of high-speed rail transportation.

The journey of V8 engines in rail began with their introduction in diesel locomotives during the mid-20th century. These early adaptations focused on increasing power output and durability to handle the continuous operation required in rail transport. As high-speed rail technology advanced, so did the requirements for V8 engines, leading to a series of innovations and refinements.

One of the key evolutionary steps was the development of turbocharged V8 engines specifically designed for rail applications. This advancement significantly boosted power output while maintaining fuel efficiency, a crucial factor in long-distance rail operations. The integration of electronic fuel injection systems further enhanced engine performance and reduced emissions, aligning with increasingly stringent environmental regulations.

Another critical development in V8 engine evolution for rail was the implementation of advanced cooling systems. These systems were designed to manage the intense heat generated during high-speed operations, ensuring optimal engine performance and longevity. Coupled with this, improvements in materials technology led to the use of lighter, more durable components, contributing to overall weight reduction and improved energy efficiency.

The integration of sophisticated engine management systems marked a pivotal point in V8 engine evolution for rail. These systems enabled real-time monitoring and adjustment of engine parameters, optimizing performance across various operating conditions. This level of control not only enhanced efficiency but also significantly improved the reliability and maintenance predictability of rail engines.

Recent advancements have focused on hybridization, combining V8 engines with electric propulsion systems. This hybrid approach leverages the power and reliability of V8 engines while capitalizing on the efficiency and environmental benefits of electric technology. Such innovations are paving the way for more sustainable high-speed rail solutions without compromising on performance.

The ongoing evolution of V8 engines in rail continues to push the boundaries of high-speed capabilities. Current research is exploring the potential of alternative fuels and advanced combustion technologies to further enhance efficiency and reduce environmental impact. These developments underscore the enduring relevance of V8 engines in the rail sector and their critical role in shaping the future of high-speed rail transportation.

High-Speed Rail Market Trends

The high-speed rail market has experienced significant growth in recent years, driven by increasing demand for efficient and sustainable transportation solutions. This trend is expected to continue, with the global high-speed rail market projected to expand at a compound annual growth rate of 5.5% from 2021 to 2026. The Asia-Pacific region, particularly China, remains the largest market for high-speed rail, accounting for over 60% of the global market share.

Europe follows as the second-largest market, with countries like France, Germany, and Spain leading the way in high-speed rail infrastructure development. The North American market, while currently smaller, is showing signs of growth, with several high-speed rail projects in various stages of planning and development.

One of the key drivers of market growth is the increasing focus on sustainable transportation solutions. High-speed rail offers a more environmentally friendly alternative to air and road travel, with significantly lower carbon emissions per passenger kilometer. This aligns well with global efforts to reduce greenhouse gas emissions and combat climate change.

Technological advancements are also playing a crucial role in shaping market trends. The integration of advanced propulsion systems, such as V8 engines, is enhancing the capabilities of high-speed trains, allowing for increased speed, improved energy efficiency, and reduced maintenance requirements. This trend towards more powerful and efficient engines is expected to continue, driving further innovation in the sector.

Government initiatives and investments are another significant factor influencing market growth. Many countries are allocating substantial funds to develop and expand their high-speed rail networks as part of broader infrastructure development plans. These investments not only stimulate economic growth but also improve connectivity between urban centers, fostering regional development.

The COVID-19 pandemic has had a mixed impact on the high-speed rail market. While it initially led to a decrease in ridership and delayed some projects, the long-term outlook remains positive. As economies recover, there is an increased emphasis on infrastructure development as a means of economic stimulus, which is likely to benefit the high-speed rail sector.

Looking ahead, emerging technologies such as maglev (magnetic levitation) trains are expected to shape the future of high-speed rail. While currently limited in deployment, maglev technology offers the potential for even higher speeds and improved energy efficiency, potentially revolutionizing long-distance travel.

Europe follows as the second-largest market, with countries like France, Germany, and Spain leading the way in high-speed rail infrastructure development. The North American market, while currently smaller, is showing signs of growth, with several high-speed rail projects in various stages of planning and development.

One of the key drivers of market growth is the increasing focus on sustainable transportation solutions. High-speed rail offers a more environmentally friendly alternative to air and road travel, with significantly lower carbon emissions per passenger kilometer. This aligns well with global efforts to reduce greenhouse gas emissions and combat climate change.

Technological advancements are also playing a crucial role in shaping market trends. The integration of advanced propulsion systems, such as V8 engines, is enhancing the capabilities of high-speed trains, allowing for increased speed, improved energy efficiency, and reduced maintenance requirements. This trend towards more powerful and efficient engines is expected to continue, driving further innovation in the sector.

Government initiatives and investments are another significant factor influencing market growth. Many countries are allocating substantial funds to develop and expand their high-speed rail networks as part of broader infrastructure development plans. These investments not only stimulate economic growth but also improve connectivity between urban centers, fostering regional development.

The COVID-19 pandemic has had a mixed impact on the high-speed rail market. While it initially led to a decrease in ridership and delayed some projects, the long-term outlook remains positive. As economies recover, there is an increased emphasis on infrastructure development as a means of economic stimulus, which is likely to benefit the high-speed rail sector.

Looking ahead, emerging technologies such as maglev (magnetic levitation) trains are expected to shape the future of high-speed rail. While currently limited in deployment, maglev technology offers the potential for even higher speeds and improved energy efficiency, potentially revolutionizing long-distance travel.

V8 Engine Challenges in HSR

The integration of V8 engines in high-speed rail (HSR) systems presents several significant challenges that must be addressed to ensure optimal performance and safety. One of the primary obstacles is the adaptation of V8 engines, traditionally designed for automotive applications, to the unique demands of rail transportation. The high-speed and long-duration operation required in HSR systems places unprecedented stress on engine components, necessitating extensive redesign and reinforcement.

Thermal management emerges as a critical challenge in V8 engine implementation for HSR. The sustained high-power output generates substantial heat, which must be efficiently dissipated to prevent engine damage and maintain performance. This issue is compounded by the limited space available in rail carriages for cooling systems, requiring innovative solutions for heat exchange and airflow management.

Vibration and noise control present another significant hurdle. The powerful V8 engines produce considerable vibrations that can affect passenger comfort and potentially compromise structural integrity over time. Engineers must develop advanced isolation systems and damping technologies to mitigate these effects, ensuring a smooth and quiet ride for passengers while maintaining the robustness of the rail infrastructure.

Fuel efficiency and emissions reduction pose ongoing challenges in V8 engine adaptation for HSR. The need for sustained high-speed operation conflicts with environmental concerns and operational cost considerations. Developing strategies to optimize fuel consumption while meeting stringent emissions standards requires a delicate balance of performance tuning and the integration of cutting-edge emission control technologies.

Reliability and maintenance considerations are paramount in HSR applications. V8 engines must be engineered to withstand the rigors of continuous operation over extended periods, with minimal downtime for maintenance. This necessitates the development of robust components, advanced lubrication systems, and predictive maintenance protocols to ensure consistent performance and reduce the risk of unexpected failures.

Weight reduction and space optimization present additional challenges in integrating V8 engines into HSR systems. The power-to-weight ratio is crucial for achieving and maintaining high speeds, requiring innovative materials and design approaches to minimize engine weight without compromising strength or durability. Furthermore, the compact packaging of engine systems within the limited confines of rail vehicles demands creative engineering solutions.

Lastly, the integration of V8 engines with electric propulsion systems in hybrid HSR configurations introduces complex control and power management challenges. Developing sophisticated algorithms for seamless power transition and optimal energy utilization between combustion and electric systems is essential for maximizing efficiency and performance across various operating conditions.

Thermal management emerges as a critical challenge in V8 engine implementation for HSR. The sustained high-power output generates substantial heat, which must be efficiently dissipated to prevent engine damage and maintain performance. This issue is compounded by the limited space available in rail carriages for cooling systems, requiring innovative solutions for heat exchange and airflow management.

Vibration and noise control present another significant hurdle. The powerful V8 engines produce considerable vibrations that can affect passenger comfort and potentially compromise structural integrity over time. Engineers must develop advanced isolation systems and damping technologies to mitigate these effects, ensuring a smooth and quiet ride for passengers while maintaining the robustness of the rail infrastructure.

Fuel efficiency and emissions reduction pose ongoing challenges in V8 engine adaptation for HSR. The need for sustained high-speed operation conflicts with environmental concerns and operational cost considerations. Developing strategies to optimize fuel consumption while meeting stringent emissions standards requires a delicate balance of performance tuning and the integration of cutting-edge emission control technologies.

Reliability and maintenance considerations are paramount in HSR applications. V8 engines must be engineered to withstand the rigors of continuous operation over extended periods, with minimal downtime for maintenance. This necessitates the development of robust components, advanced lubrication systems, and predictive maintenance protocols to ensure consistent performance and reduce the risk of unexpected failures.

Weight reduction and space optimization present additional challenges in integrating V8 engines into HSR systems. The power-to-weight ratio is crucial for achieving and maintaining high speeds, requiring innovative materials and design approaches to minimize engine weight without compromising strength or durability. Furthermore, the compact packaging of engine systems within the limited confines of rail vehicles demands creative engineering solutions.

Lastly, the integration of V8 engines with electric propulsion systems in hybrid HSR configurations introduces complex control and power management challenges. Developing sophisticated algorithms for seamless power transition and optimal energy utilization between combustion and electric systems is essential for maximizing efficiency and performance across various operating conditions.

V8 Engine HSR Applications

01 Performance optimization of V8 engines

V8 engines are optimized for high performance through various techniques, including improved fuel injection systems, advanced valve timing mechanisms, and enhanced combustion chamber designs. These optimizations result in increased power output, better fuel efficiency, and reduced emissions.- V8 Engine Performance Optimization: Various techniques are employed to enhance V8 engine performance, including improved combustion efficiency, advanced fuel injection systems, and optimized valve timing. These innovations aim to increase power output, reduce fuel consumption, and minimize emissions, making V8 engines more competitive in modern automotive applications.

- V8 Engine Noise and Vibration Reduction: Advancements in V8 engine design focus on reducing noise and vibration levels. This includes the development of improved engine mounts, balancing techniques, and acoustic insulation materials. These enhancements contribute to a smoother and quieter driving experience while maintaining the characteristic V8 sound.

- V8 Engine Cylinder Deactivation Technology: Cylinder deactivation systems are implemented in V8 engines to improve fuel efficiency during low-load conditions. This technology allows the engine to operate on fewer cylinders when full power is not required, resulting in reduced fuel consumption and emissions without compromising performance when needed.

- V8 Engine Turbocharging and Supercharging: Forced induction technologies, such as turbocharging and supercharging, are applied to V8 engines to significantly boost power output and torque. These systems allow for smaller displacement engines to achieve higher performance levels, contributing to improved fuel efficiency and reduced emissions while maintaining the desirable V8 characteristics.

- V8 Engine Cooling and Thermal Management: Advanced cooling systems and thermal management techniques are developed for V8 engines to optimize operating temperatures and enhance overall efficiency. These innovations include improved coolant circulation, heat dissipation methods, and intelligent temperature control systems, contributing to increased engine longevity and performance.

02 Cylinder deactivation technology

V8 engines can incorporate cylinder deactivation technology, which allows the engine to operate on fewer cylinders during low-load conditions. This capability improves fuel economy without sacrificing the power available when all cylinders are active.Expand Specific Solutions03 Variable valve timing and lift

Advanced V8 engines utilize variable valve timing and lift systems to optimize engine performance across different operating conditions. This technology allows for better control of air intake and exhaust, resulting in improved power delivery, fuel efficiency, and emissions control.Expand Specific Solutions04 Turbocharging and supercharging

V8 engines can be equipped with turbochargers or superchargers to increase power output and torque. These forced induction systems compress the intake air, allowing for more efficient combustion and significantly boosting engine performance.Expand Specific Solutions05 Integration of hybrid technology

Modern V8 engines can be integrated with hybrid electric systems to enhance performance and fuel efficiency. This combination allows for electric assist during acceleration, regenerative braking, and the ability to operate in electric-only mode for short distances.Expand Specific Solutions

Key HSR Engine Manufacturers

The high-speed rail industry is in a mature growth phase, with a global market size expected to reach $75 billion by 2025. The technology for V8 engines in high-speed rail is advancing rapidly, with key players like China State Railway Group, CRRC, and Siemens leading innovation. These companies are focusing on improving efficiency, reducing emissions, and increasing speed capabilities. The competitive landscape is characterized by a mix of established rail manufacturers and new entrants from the automotive sector, such as Hyundai and Honda, bringing expertise in engine technology. Universities like Southwest Jiaotong and Zhejiang are contributing to R&D efforts, fostering industry-academia collaborations to drive technological advancements in high-speed rail propulsion systems.

China State Railway Group Co., Ltd.

Technical Solution: China State Railway Group Co., Ltd. has been at the forefront of high-speed rail development, incorporating advanced V8 engine technology to enhance rail capabilities. Their approach involves integrating V8 engines as auxiliary power units (APUs) in high-speed trains, providing supplementary power for critical systems. These V8 engines are optimized for high efficiency and low emissions, utilizing advanced fuel injection systems and turbocharging technology. The company has implemented a hybrid power system where V8 engines work in conjunction with electric traction motors, allowing for improved acceleration and energy recovery during braking[1]. This system enables trains to maintain high speeds over extended distances, even in areas with limited electrification[2].

Strengths: Improved power distribution, enhanced acceleration, and extended range. Weaknesses: Increased complexity of the power system and potential maintenance challenges.

CRRC Qingdao Sifang Co., Ltd.

Technical Solution: CRRC Qingdao Sifang Co., Ltd. has developed a novel approach to integrating V8 engines in high-speed rail systems. Their technology focuses on using compact, lightweight V8 engines as part of a distributed power system throughout the train. This configuration allows for better weight distribution and improved traction, especially during acceleration and on steep gradients. The company has implemented advanced thermal management systems to optimize engine performance in the high-speed rail environment. Additionally, they have developed a smart power management system that dynamically adjusts the power output of the V8 engines based on real-time operational demands, enhancing overall energy efficiency[3]. CRRC Qingdao Sifang's V8 engines are also designed with advanced noise reduction technologies to minimize vibration and sound pollution, crucial for passenger comfort in high-speed rail travel[4].

Strengths: Improved weight distribution, enhanced traction, and adaptive power management. Weaknesses: Potential increase in overall train weight and complexity of the power distribution system.

V8 HSR Engine Innovations

V8 engine

PatentWO2021171405A1

Innovation

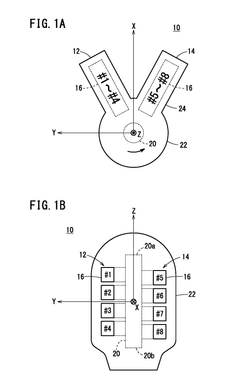

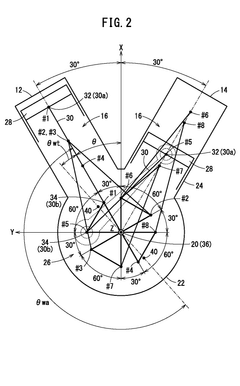

- The engine is configured with a 60° bank angle, where crank pins on one bank are arranged at 90° intervals and offset by 60° from the other bank, allowing for cancellation of the primary inertia couple without additional special parts, and the ignition timing is set to achieve balanced explosions similar to conventional V8 engines.

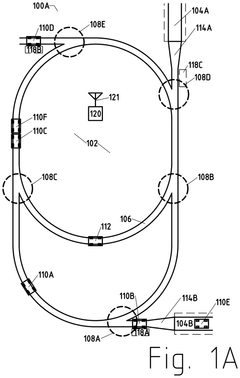

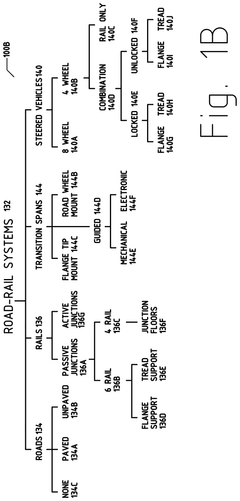

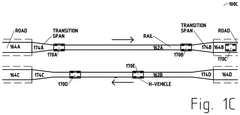

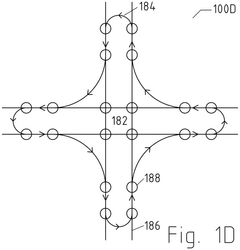

Road to Rail Hybrid Vehicles Using a Transition Span and Passive Junctions

PatentActiveUS20250135814A1

Innovation

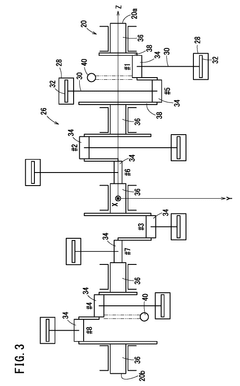

- The development of a road-rail transportation system using hybrid (H-) vehicles equipped with eight wheels, including retractable or combination wheels, that can seamlessly transition between road and rail travel using passive junctions and transition spans, allowing for automatic operation and improved traction and braking.

Environmental Impact of V8 HSR

The implementation of V8 engines in high-speed rail (HSR) systems presents a complex environmental impact profile that requires careful consideration. While these powerful engines offer significant performance enhancements, their environmental footprint must be thoroughly evaluated to ensure sustainable development in the transportation sector.

V8 engines in HSR contribute to increased energy consumption due to their higher power output. This translates to a potentially larger carbon footprint compared to traditional rail systems, particularly if the energy source is not renewable. However, the improved speed and efficiency of V8-powered HSR can lead to reduced travel times and increased passenger capacity, potentially offsetting some of the environmental costs by reducing the need for alternative, more polluting forms of transportation.

Air quality is another crucial factor to consider. V8 engines, especially those using diesel fuel, emit particulate matter and nitrogen oxides, which can contribute to local air pollution. This impact is particularly significant in urban areas and along rail corridors. However, advancements in engine technology and the use of cleaner fuels can mitigate these effects to some extent.

Noise pollution is a notable concern with V8-powered HSR systems. The high-performance engines generate significant noise levels, which can have detrimental effects on wildlife habitats and human communities along rail routes. Implementing sound barriers and developing quieter engine technologies are essential strategies to address this issue.

Land use and habitat fragmentation are additional environmental considerations. While HSR systems generally require less land than equivalent highway infrastructure, the construction of new rail lines for V8-powered trains may still lead to habitat disruption and biodiversity loss. Careful route planning and the implementation of wildlife corridors can help minimize these impacts.

On the positive side, V8-powered HSR systems can contribute to overall transportation efficiency. By providing a fast and reliable alternative to air and road travel, they can help reduce overall transportation-related emissions on a broader scale. This is particularly true when the electricity powering the rail system is derived from renewable sources.

Water resource management is another aspect to consider. The maintenance and operation of V8 engines in HSR systems may require significant water usage for cooling and cleaning purposes. Implementing water-efficient practices and recycling systems can help mitigate this impact.

In conclusion, while V8 engines offer substantial performance benefits for high-speed rail, their environmental impact is multifaceted. Balancing the advantages of improved transportation efficiency against the potential negative effects on air quality, noise levels, and resource consumption is crucial. Ongoing research and development in engine technology, coupled with sustainable operational practices, will be key to maximizing the benefits of V8-powered HSR while minimizing its environmental footprint.

V8 engines in HSR contribute to increased energy consumption due to their higher power output. This translates to a potentially larger carbon footprint compared to traditional rail systems, particularly if the energy source is not renewable. However, the improved speed and efficiency of V8-powered HSR can lead to reduced travel times and increased passenger capacity, potentially offsetting some of the environmental costs by reducing the need for alternative, more polluting forms of transportation.

Air quality is another crucial factor to consider. V8 engines, especially those using diesel fuel, emit particulate matter and nitrogen oxides, which can contribute to local air pollution. This impact is particularly significant in urban areas and along rail corridors. However, advancements in engine technology and the use of cleaner fuels can mitigate these effects to some extent.

Noise pollution is a notable concern with V8-powered HSR systems. The high-performance engines generate significant noise levels, which can have detrimental effects on wildlife habitats and human communities along rail routes. Implementing sound barriers and developing quieter engine technologies are essential strategies to address this issue.

Land use and habitat fragmentation are additional environmental considerations. While HSR systems generally require less land than equivalent highway infrastructure, the construction of new rail lines for V8-powered trains may still lead to habitat disruption and biodiversity loss. Careful route planning and the implementation of wildlife corridors can help minimize these impacts.

On the positive side, V8-powered HSR systems can contribute to overall transportation efficiency. By providing a fast and reliable alternative to air and road travel, they can help reduce overall transportation-related emissions on a broader scale. This is particularly true when the electricity powering the rail system is derived from renewable sources.

Water resource management is another aspect to consider. The maintenance and operation of V8 engines in HSR systems may require significant water usage for cooling and cleaning purposes. Implementing water-efficient practices and recycling systems can help mitigate this impact.

In conclusion, while V8 engines offer substantial performance benefits for high-speed rail, their environmental impact is multifaceted. Balancing the advantages of improved transportation efficiency against the potential negative effects on air quality, noise levels, and resource consumption is crucial. Ongoing research and development in engine technology, coupled with sustainable operational practices, will be key to maximizing the benefits of V8-powered HSR while minimizing its environmental footprint.

Safety Regulations for HSR Engines

Safety regulations for high-speed rail (HSR) engines, particularly those utilizing V8 configurations, are paramount to ensure the secure operation of these advanced transportation systems. These regulations encompass a wide range of aspects, from design and manufacturing to maintenance and operational protocols.

One of the primary safety considerations for HSR V8 engines is the structural integrity of the engine components. Regulations mandate the use of high-quality, heat-resistant materials capable of withstanding the extreme temperatures and pressures generated during high-speed operation. Stringent testing procedures are required to verify the durability and reliability of these components under various operating conditions.

Vibration control is another critical aspect addressed by safety regulations. V8 engines in HSR applications must adhere to strict vibration limits to prevent structural fatigue and ensure passenger comfort. Advanced vibration dampening systems and precise balancing techniques are typically mandated to minimize potentially harmful oscillations.

Fuel system safety is of utmost importance in HSR V8 engines. Regulations often specify the use of advanced fuel injection systems with multiple redundancies to prevent fuel leaks or combustion irregularities. Additionally, fire suppression systems are required to be integrated into the engine compartment, capable of rapidly detecting and extinguishing any potential fires.

Emissions control is a significant focus of HSR engine safety regulations. V8 engines must comply with stringent emissions standards, often necessitating the implementation of advanced catalytic converters and exhaust gas recirculation systems. These measures not only reduce environmental impact but also minimize the risk of harmful exhaust gases entering passenger compartments.

Noise reduction is another key area addressed by safety regulations. HSR V8 engines must operate within specified noise limits to protect both passengers and surrounding communities. This often requires the use of sophisticated sound insulation materials and muffler systems designed specifically for high-speed applications.

Maintenance and inspection protocols form a crucial part of HSR engine safety regulations. Regular, comprehensive inspections are mandated to detect any signs of wear, fatigue, or potential failure. These inspections often utilize advanced non-destructive testing methods, such as ultrasonic and magnetic particle inspections, to ensure the ongoing integrity of critical engine components.

Emergency shutdown systems are a vital safety feature required by regulations. HSR V8 engines must be equipped with multiple, redundant systems capable of rapidly shutting down the engine in the event of a critical malfunction. These systems are typically designed to operate independently of the main engine control unit to ensure reliability in all scenarios.

In conclusion, safety regulations for HSR V8 engines are comprehensive and multifaceted, addressing every aspect of engine design, operation, and maintenance. These regulations are continually evolving to incorporate new technologies and insights, ensuring that high-speed rail remains one of the safest forms of transportation available.

One of the primary safety considerations for HSR V8 engines is the structural integrity of the engine components. Regulations mandate the use of high-quality, heat-resistant materials capable of withstanding the extreme temperatures and pressures generated during high-speed operation. Stringent testing procedures are required to verify the durability and reliability of these components under various operating conditions.

Vibration control is another critical aspect addressed by safety regulations. V8 engines in HSR applications must adhere to strict vibration limits to prevent structural fatigue and ensure passenger comfort. Advanced vibration dampening systems and precise balancing techniques are typically mandated to minimize potentially harmful oscillations.

Fuel system safety is of utmost importance in HSR V8 engines. Regulations often specify the use of advanced fuel injection systems with multiple redundancies to prevent fuel leaks or combustion irregularities. Additionally, fire suppression systems are required to be integrated into the engine compartment, capable of rapidly detecting and extinguishing any potential fires.

Emissions control is a significant focus of HSR engine safety regulations. V8 engines must comply with stringent emissions standards, often necessitating the implementation of advanced catalytic converters and exhaust gas recirculation systems. These measures not only reduce environmental impact but also minimize the risk of harmful exhaust gases entering passenger compartments.

Noise reduction is another key area addressed by safety regulations. HSR V8 engines must operate within specified noise limits to protect both passengers and surrounding communities. This often requires the use of sophisticated sound insulation materials and muffler systems designed specifically for high-speed applications.

Maintenance and inspection protocols form a crucial part of HSR engine safety regulations. Regular, comprehensive inspections are mandated to detect any signs of wear, fatigue, or potential failure. These inspections often utilize advanced non-destructive testing methods, such as ultrasonic and magnetic particle inspections, to ensure the ongoing integrity of critical engine components.

Emergency shutdown systems are a vital safety feature required by regulations. HSR V8 engines must be equipped with multiple, redundant systems capable of rapidly shutting down the engine in the event of a critical malfunction. These systems are typically designed to operate independently of the main engine control unit to ensure reliability in all scenarios.

In conclusion, safety regulations for HSR V8 engines are comprehensive and multifaceted, addressing every aspect of engine design, operation, and maintenance. These regulations are continually evolving to incorporate new technologies and insights, ensuring that high-speed rail remains one of the safest forms of transportation available.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!