How V8 Engines Establish New Benchmarks in High-Performance Vehicles?

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution

The evolution of V8 engines in high-performance vehicles has been a testament to automotive engineering prowess and the relentless pursuit of power and efficiency. From their inception in the early 20th century to their current state-of-the-art iterations, V8 engines have consistently pushed the boundaries of what's possible in vehicle performance.

The journey began with the Cadillac L-Head V8 in 1914, which set the stage for the V8 configuration's potential. This engine layout quickly gained popularity due to its compact design and smooth power delivery. As decades passed, manufacturers refined the V8 formula, introducing innovations such as overhead valves, higher compression ratios, and improved fuel delivery systems.

The 1950s and 1960s saw a significant leap in V8 development, particularly in American muscle cars. Iconic engines like the Chrysler HEMI and Chevrolet Small-Block V8 emerged, setting new standards for horsepower and torque. These engines not only dominated drag strips but also found their way into luxury vehicles, cementing the V8's reputation as a symbol of performance and prestige.

The oil crisis of the 1970s temporarily slowed V8 development, as manufacturers focused on fuel efficiency. However, this challenge led to innovations in engine management systems and fuel injection technology. The introduction of electronic fuel injection in the 1980s marked a turning point, allowing for more precise control over fuel delivery and ignition timing.

The 1990s and 2000s saw a resurgence in V8 performance, with advancements in materials science and computer-aided design enabling the creation of more powerful and efficient engines. Variable valve timing, direct injection, and forced induction became commonplace, allowing V8 engines to produce unprecedented levels of power while meeting increasingly stringent emissions regulations.

In recent years, the focus has shifted towards combining high performance with improved fuel economy and reduced emissions. This has led to the development of technologies such as cylinder deactivation, start-stop systems, and hybrid assistance. Modern V8 engines, such as those found in supercars and high-end sports sedans, now routinely produce over 600 horsepower while achieving fuel efficiency figures that would have been unthinkable just a decade ago.

The future of V8 engines continues to evolve, with manufacturers exploring new frontiers in materials, combustion processes, and electrification. While facing challenges from alternative powertrains, the V8 engine remains a benchmark for high-performance vehicles, continually adapting to meet the demands of power, efficiency, and environmental responsibility.

The journey began with the Cadillac L-Head V8 in 1914, which set the stage for the V8 configuration's potential. This engine layout quickly gained popularity due to its compact design and smooth power delivery. As decades passed, manufacturers refined the V8 formula, introducing innovations such as overhead valves, higher compression ratios, and improved fuel delivery systems.

The 1950s and 1960s saw a significant leap in V8 development, particularly in American muscle cars. Iconic engines like the Chrysler HEMI and Chevrolet Small-Block V8 emerged, setting new standards for horsepower and torque. These engines not only dominated drag strips but also found their way into luxury vehicles, cementing the V8's reputation as a symbol of performance and prestige.

The oil crisis of the 1970s temporarily slowed V8 development, as manufacturers focused on fuel efficiency. However, this challenge led to innovations in engine management systems and fuel injection technology. The introduction of electronic fuel injection in the 1980s marked a turning point, allowing for more precise control over fuel delivery and ignition timing.

The 1990s and 2000s saw a resurgence in V8 performance, with advancements in materials science and computer-aided design enabling the creation of more powerful and efficient engines. Variable valve timing, direct injection, and forced induction became commonplace, allowing V8 engines to produce unprecedented levels of power while meeting increasingly stringent emissions regulations.

In recent years, the focus has shifted towards combining high performance with improved fuel economy and reduced emissions. This has led to the development of technologies such as cylinder deactivation, start-stop systems, and hybrid assistance. Modern V8 engines, such as those found in supercars and high-end sports sedans, now routinely produce over 600 horsepower while achieving fuel efficiency figures that would have been unthinkable just a decade ago.

The future of V8 engines continues to evolve, with manufacturers exploring new frontiers in materials, combustion processes, and electrification. While facing challenges from alternative powertrains, the V8 engine remains a benchmark for high-performance vehicles, continually adapting to meet the demands of power, efficiency, and environmental responsibility.

Market Demand Analysis

The market demand for high-performance vehicles equipped with V8 engines continues to evolve, driven by a complex interplay of consumer preferences, technological advancements, and regulatory pressures. Despite the growing emphasis on fuel efficiency and environmental concerns, there remains a significant segment of automotive enthusiasts and luxury car buyers who prioritize power, performance, and the distinctive character of V8 engines.

In the luxury and sports car segments, V8-powered vehicles maintain a strong appeal. These engines are prized for their smooth power delivery, impressive torque, and the iconic sound that has become synonymous with high-performance driving. Market research indicates that consumers in this segment are willing to pay a premium for vehicles that offer exceptional acceleration, top speed, and overall driving experience, which V8 engines consistently deliver.

The racing and motorsport industry continues to be a key driver of demand for V8 engines. Many prestigious racing series, including Formula 1 and NASCAR, have historically used V8 configurations, creating a halo effect that influences consumer perceptions and desires in the broader automotive market. This connection between racing technology and road-going vehicles helps maintain the allure of V8-powered cars among enthusiasts and performance-oriented buyers.

However, the market is not without challenges. Stringent emissions regulations and increasing focus on fuel economy have put pressure on manufacturers to improve the efficiency of V8 engines. This has led to innovations such as cylinder deactivation, direct injection, and turbocharging, allowing V8 engines to meet stricter environmental standards while maintaining their performance characteristics. These advancements have helped sustain market demand by addressing some of the traditional criticisms of V8 engines.

The SUV and truck markets have emerged as significant growth areas for V8 engines. As consumers trend towards larger vehicles, there is a sustained demand for powerful engines capable of providing the necessary torque for towing and hauling. V8 engines in these applications offer a compelling balance of power and capability, meeting the needs of both recreational and commercial users.

Looking at market trends, while the overall automotive industry is shifting towards electrification, there remains a dedicated market for V8-powered vehicles. Luxury brands continue to offer V8 options in their flagship models, recognizing the engine's role in brand identity and customer expectations. Additionally, some manufacturers are exploring hybrid V8 powertrains, combining the traditional appeal of the V8 with improved efficiency and performance through electrification.

In conclusion, while facing challenges from environmental concerns and changing consumer preferences, the market for V8 engines in high-performance vehicles remains robust. The combination of technological advancements, enduring consumer appeal, and adaptability to new market segments suggests that V8 engines will continue to play a significant role in the high-performance vehicle market for the foreseeable future.

In the luxury and sports car segments, V8-powered vehicles maintain a strong appeal. These engines are prized for their smooth power delivery, impressive torque, and the iconic sound that has become synonymous with high-performance driving. Market research indicates that consumers in this segment are willing to pay a premium for vehicles that offer exceptional acceleration, top speed, and overall driving experience, which V8 engines consistently deliver.

The racing and motorsport industry continues to be a key driver of demand for V8 engines. Many prestigious racing series, including Formula 1 and NASCAR, have historically used V8 configurations, creating a halo effect that influences consumer perceptions and desires in the broader automotive market. This connection between racing technology and road-going vehicles helps maintain the allure of V8-powered cars among enthusiasts and performance-oriented buyers.

However, the market is not without challenges. Stringent emissions regulations and increasing focus on fuel economy have put pressure on manufacturers to improve the efficiency of V8 engines. This has led to innovations such as cylinder deactivation, direct injection, and turbocharging, allowing V8 engines to meet stricter environmental standards while maintaining their performance characteristics. These advancements have helped sustain market demand by addressing some of the traditional criticisms of V8 engines.

The SUV and truck markets have emerged as significant growth areas for V8 engines. As consumers trend towards larger vehicles, there is a sustained demand for powerful engines capable of providing the necessary torque for towing and hauling. V8 engines in these applications offer a compelling balance of power and capability, meeting the needs of both recreational and commercial users.

Looking at market trends, while the overall automotive industry is shifting towards electrification, there remains a dedicated market for V8-powered vehicles. Luxury brands continue to offer V8 options in their flagship models, recognizing the engine's role in brand identity and customer expectations. Additionally, some manufacturers are exploring hybrid V8 powertrains, combining the traditional appeal of the V8 with improved efficiency and performance through electrification.

In conclusion, while facing challenges from environmental concerns and changing consumer preferences, the market for V8 engines in high-performance vehicles remains robust. The combination of technological advancements, enduring consumer appeal, and adaptability to new market segments suggests that V8 engines will continue to play a significant role in the high-performance vehicle market for the foreseeable future.

Technical Challenges

The development of V8 engines for high-performance vehicles faces several significant technical challenges. One of the primary obstacles is achieving an optimal balance between power output and fuel efficiency. As environmental regulations become increasingly stringent, manufacturers must innovate to meet emission standards while maintaining the high performance expected from V8 engines.

Heat management presents another critical challenge. The intense heat generated by high-performance V8 engines can lead to reduced efficiency and potential component failure. Engineers must develop advanced cooling systems and utilize heat-resistant materials to ensure reliable operation under extreme conditions.

Weight reduction is a constant concern in the pursuit of improved performance. Traditional V8 engines are inherently heavy, which can negatively impact vehicle dynamics and fuel economy. Manufacturers are exploring the use of lightweight materials such as aluminum and carbon fiber composites to reduce engine weight without compromising structural integrity.

Vibration and noise control pose significant engineering challenges. The characteristic V8 sound is desirable to enthusiasts, but excessive noise and vibration can detract from overall vehicle refinement. Sophisticated engine mounts, sound dampening technologies, and precise balancing techniques are required to address these issues.

Durability and longevity remain crucial factors in V8 engine development. High-performance engines operate under extreme stress, necessitating robust designs and materials that can withstand prolonged high-load conditions. This challenge is particularly acute in racing applications where engines must deliver maximum power output while maintaining reliability.

The integration of advanced technologies such as direct fuel injection, variable valve timing, and cylinder deactivation systems adds complexity to V8 engine design. These technologies aim to improve efficiency and performance but require sophisticated control systems and precise calibration to function optimally.

Packaging constraints present another hurdle for V8 engine development. As vehicle designs prioritize aerodynamics and safety features, engine bay space becomes increasingly limited. Engineers must find innovative ways to package V8 engines efficiently while ensuring adequate cooling and serviceability.

Finally, the cost of development and production remains a significant challenge. High-performance V8 engines require extensive research, testing, and specialized manufacturing processes, which can drive up costs. Balancing performance improvements with economic viability is an ongoing challenge for manufacturers in this competitive segment.

Heat management presents another critical challenge. The intense heat generated by high-performance V8 engines can lead to reduced efficiency and potential component failure. Engineers must develop advanced cooling systems and utilize heat-resistant materials to ensure reliable operation under extreme conditions.

Weight reduction is a constant concern in the pursuit of improved performance. Traditional V8 engines are inherently heavy, which can negatively impact vehicle dynamics and fuel economy. Manufacturers are exploring the use of lightweight materials such as aluminum and carbon fiber composites to reduce engine weight without compromising structural integrity.

Vibration and noise control pose significant engineering challenges. The characteristic V8 sound is desirable to enthusiasts, but excessive noise and vibration can detract from overall vehicle refinement. Sophisticated engine mounts, sound dampening technologies, and precise balancing techniques are required to address these issues.

Durability and longevity remain crucial factors in V8 engine development. High-performance engines operate under extreme stress, necessitating robust designs and materials that can withstand prolonged high-load conditions. This challenge is particularly acute in racing applications where engines must deliver maximum power output while maintaining reliability.

The integration of advanced technologies such as direct fuel injection, variable valve timing, and cylinder deactivation systems adds complexity to V8 engine design. These technologies aim to improve efficiency and performance but require sophisticated control systems and precise calibration to function optimally.

Packaging constraints present another hurdle for V8 engine development. As vehicle designs prioritize aerodynamics and safety features, engine bay space becomes increasingly limited. Engineers must find innovative ways to package V8 engines efficiently while ensuring adequate cooling and serviceability.

Finally, the cost of development and production remains a significant challenge. High-performance V8 engines require extensive research, testing, and specialized manufacturing processes, which can drive up costs. Balancing performance improvements with economic viability is an ongoing challenge for manufacturers in this competitive segment.

Current V8 Solutions

01 Performance measurement and benchmarking systems

Systems and methods for measuring and benchmarking V8 engine performance, including data collection, analysis, and comparison against predefined standards or other engines. These systems help in evaluating various performance metrics and can be used for optimization and quality control.- Performance measurement and benchmarking systems: Systems and methods for measuring and benchmarking V8 engine performance, including data collection, analysis, and comparison against predefined standards or other engines. These systems help in evaluating various performance metrics and identifying areas for improvement.

- Engine simulation and modeling: Advanced simulation and modeling techniques for V8 engines, allowing for virtual testing and optimization of engine performance. These methods enable engineers to predict and analyze engine behavior under various conditions without physical prototyping.

- Real-time performance monitoring and diagnostics: Systems for real-time monitoring and diagnostics of V8 engine performance, utilizing sensors and data analytics to provide instant feedback on engine health and efficiency. These technologies enable proactive maintenance and performance optimization.

- Fuel efficiency and emissions optimization: Techniques and systems for optimizing V8 engine fuel efficiency and reducing emissions while maintaining performance. These innovations focus on balancing power output with environmental considerations through advanced engine management and design.

- Performance tuning and customization: Methods and systems for tuning and customizing V8 engine performance, including software-based adjustments and hardware modifications. These approaches allow for tailoring engine characteristics to specific requirements or preferences.

02 Engine simulation and modeling

Advanced simulation and modeling techniques for V8 engines, allowing for virtual testing and performance prediction. These methods can include computational fluid dynamics, thermodynamic modeling, and other simulation tools to assess engine behavior under various conditions without physical testing.Expand Specific Solutions03 Real-time performance monitoring and diagnostics

Systems for real-time monitoring of V8 engine performance, including onboard diagnostics and telemetry. These technologies allow for continuous assessment of engine health, early detection of potential issues, and performance optimization during operation.Expand Specific Solutions04 Fuel efficiency and emissions benchmarking

Methods and systems for benchmarking V8 engines' fuel efficiency and emissions performance. These approaches focus on optimizing the balance between power output and environmental impact, often utilizing advanced sensors and data analysis techniques.Expand Specific Solutions05 Comparative analysis and testing protocols

Standardized testing protocols and comparative analysis methods for V8 engines, ensuring consistent and reliable performance benchmarking across different models and manufacturers. These protocols may include specific test conditions, measurement techniques, and data interpretation guidelines.Expand Specific Solutions

Key Manufacturers

The V8 engine market in high-performance vehicles is in a mature stage, with established players and ongoing innovation. The global market size for V8 engines is substantial, driven by demand in luxury and sports car segments. Technologically, V8 engines are well-developed but continue to evolve, focusing on efficiency and performance improvements. Key players like GM Global Technology Operations, Ford Global Technologies, and BMW are at the forefront, investing heavily in R&D to enhance V8 capabilities. Other significant contributors include Toyota, Honda, and Hyundai, who are integrating advanced technologies to meet stringent emissions standards while maintaining power output. The competitive landscape is characterized by a balance between traditional automotive giants and emerging players pushing the boundaries of V8 engine technology.

GM Global Technology Operations LLC

Technical Solution: GM's V8 engine technology, particularly in their Small Block V8 series, has set new benchmarks in high-performance vehicles. Their latest LT2 6.2L V8 engine, used in the Corvette C8, delivers 495 horsepower and 470 lb-ft of torque[1]. This engine features advanced technologies such as Direct Fuel Injection, Active Fuel Management, and Variable Valve Timing, which contribute to improved performance and efficiency[2]. GM has also implemented a dry-sump oil system in their high-performance V8s, allowing for improved lubrication during high-G cornering and better overall engine reliability[3].

Strengths: High power output, advanced fuel management systems, and improved reliability. Weaknesses: Relatively high fuel consumption compared to smaller engines, and potential challenges in meeting stricter emission standards.

Bayerische Motoren Werke AG

Technical Solution: BMW's V8 engines, particularly the N63 and S63 series, have established new benchmarks in high-performance vehicles. The latest iteration, the S63B44T4 used in the M8 Competition, produces up to 617 horsepower[4]. BMW employs advanced technologies such as TwinPower Turbo, direct fuel injection, and VALVETRONIC variable valve timing[5]. The company has also implemented a "hot-V" configuration, placing the turbochargers between the cylinder banks for improved throttle response and compact packaging[6]. Additionally, BMW's V8 engines feature a cross-bank exhaust manifold, which optimizes exhaust gas flow and enhances engine efficiency.

Strengths: High power output, advanced turbocharging technology, and innovative engine layout. Weaknesses: Complexity of the engine design may lead to higher maintenance costs, and potential reliability issues in earlier versions.

Innovative Technologies

V8 engine

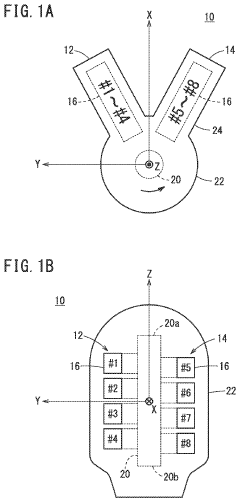

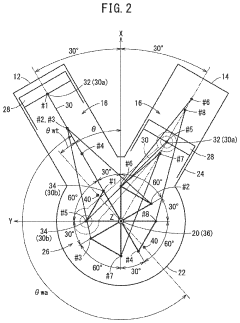

PatentActiveUS20230109196A1

Innovation

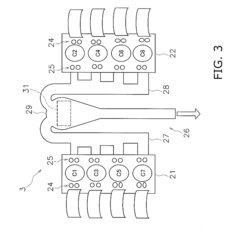

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized components by optimizing the arrangement of crank pins and connecting rods.

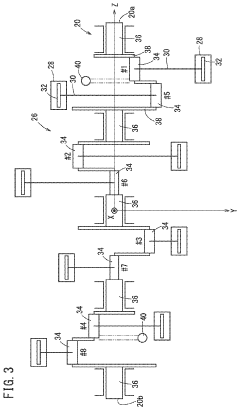

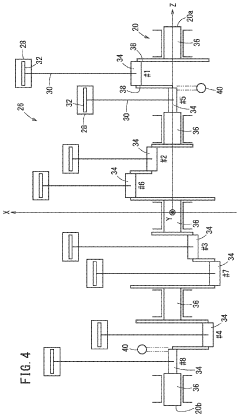

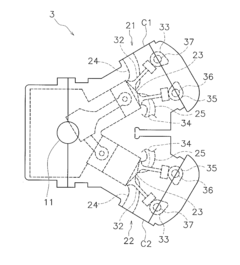

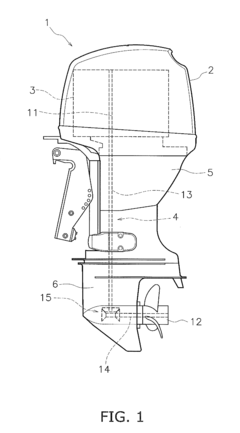

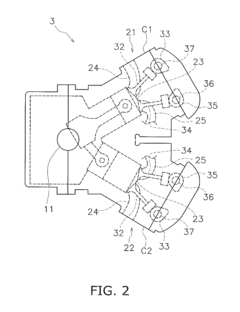

V8 engine and outboard motor

PatentActiveUS20160341097A1

Innovation

- A V8 engine design with a simple construction featuring aggregated exhaust pathways and adjustable exhaust cams, where the central angle of exhaust cams for each cylinder is optimized to minimize valve overlap and reduce exhaust interference, allowing for even firing intervals and improved exhaust gas management.

Emissions Regulations

Emissions regulations have become a critical factor in the development and deployment of high-performance V8 engines in modern vehicles. As governments worldwide implement increasingly stringent environmental standards, automakers are compelled to balance the pursuit of power with the need for cleaner emissions. These regulations have significantly influenced the design and engineering of V8 engines, driving innovations in fuel efficiency and exhaust treatment technologies.

In recent years, many countries have adopted more rigorous emissions standards, such as Euro 6 in Europe and Tier 3 in the United States. These standards set strict limits on various pollutants, including carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter. To meet these requirements, manufacturers have had to implement advanced technologies in their V8 engines, such as direct fuel injection, variable valve timing, and cylinder deactivation systems.

One of the most significant challenges for high-performance V8 engines is reducing CO2 emissions while maintaining power output. This has led to the widespread adoption of turbocharging and supercharging technologies, which allow for smaller displacement engines to produce comparable power to larger naturally aspirated units. Additionally, many manufacturers have incorporated start-stop systems and mild hybrid technologies to further reduce fuel consumption and emissions during urban driving conditions.

Exhaust after-treatment systems have also become more sophisticated to meet emissions regulations. Modern V8 engines often employ catalytic converters with higher precious metal content, particulate filters, and selective catalytic reduction (SCR) systems to reduce harmful emissions. These technologies work in tandem to convert pollutants into less harmful substances before they exit the exhaust system.

The impact of emissions regulations on V8 engines extends beyond the powertrain itself. Aerodynamics and weight reduction have become increasingly important factors in vehicle design, as they directly affect fuel efficiency and, consequently, emissions. Manufacturers are utilizing advanced materials such as carbon fiber and aluminum alloys to reduce vehicle weight, allowing V8-powered vehicles to achieve better fuel economy without sacrificing performance.

Despite these challenges, many automakers have successfully developed V8 engines that meet current emissions standards while still delivering impressive performance. However, the future of V8 engines in high-performance vehicles remains uncertain as regulations continue to tighten. Some manufacturers are exploring alternative technologies, such as high-output hybrid powertrains or fully electric performance vehicles, to meet future emissions targets while maintaining the level of performance expected from V8-powered vehicles.

In recent years, many countries have adopted more rigorous emissions standards, such as Euro 6 in Europe and Tier 3 in the United States. These standards set strict limits on various pollutants, including carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter. To meet these requirements, manufacturers have had to implement advanced technologies in their V8 engines, such as direct fuel injection, variable valve timing, and cylinder deactivation systems.

One of the most significant challenges for high-performance V8 engines is reducing CO2 emissions while maintaining power output. This has led to the widespread adoption of turbocharging and supercharging technologies, which allow for smaller displacement engines to produce comparable power to larger naturally aspirated units. Additionally, many manufacturers have incorporated start-stop systems and mild hybrid technologies to further reduce fuel consumption and emissions during urban driving conditions.

Exhaust after-treatment systems have also become more sophisticated to meet emissions regulations. Modern V8 engines often employ catalytic converters with higher precious metal content, particulate filters, and selective catalytic reduction (SCR) systems to reduce harmful emissions. These technologies work in tandem to convert pollutants into less harmful substances before they exit the exhaust system.

The impact of emissions regulations on V8 engines extends beyond the powertrain itself. Aerodynamics and weight reduction have become increasingly important factors in vehicle design, as they directly affect fuel efficiency and, consequently, emissions. Manufacturers are utilizing advanced materials such as carbon fiber and aluminum alloys to reduce vehicle weight, allowing V8-powered vehicles to achieve better fuel economy without sacrificing performance.

Despite these challenges, many automakers have successfully developed V8 engines that meet current emissions standards while still delivering impressive performance. However, the future of V8 engines in high-performance vehicles remains uncertain as regulations continue to tighten. Some manufacturers are exploring alternative technologies, such as high-output hybrid powertrains or fully electric performance vehicles, to meet future emissions targets while maintaining the level of performance expected from V8-powered vehicles.

Comparative Analysis

V8 engines have long been synonymous with high-performance vehicles, setting benchmarks that redefine automotive excellence. To understand how V8 engines establish new standards, a comparative analysis is essential. This analysis reveals the superiority of V8 engines in several key areas when compared to other engine configurations.

Firstly, power output is a critical factor where V8 engines excel. Compared to inline-four or V6 engines of similar displacement, V8s typically produce significantly more horsepower and torque. This power advantage is due to the V8's larger cylinder count and optimal firing order, which allows for more frequent power strokes and smoother power delivery.

In terms of acceleration, V8-powered vehicles consistently outperform their counterparts with fewer cylinders. The abundant low-end torque of V8 engines translates to quicker off-the-line acceleration and faster 0-60 mph times. This performance edge is particularly noticeable in heavier vehicles like luxury sedans and sports cars, where the V8's power helps overcome inertia more effectively.

Refinement is another area where V8 engines set new benchmarks. The inherent balance of the V8 configuration results in smoother operation and less vibration compared to many other engine layouts. This characteristic not only enhances driving comfort but also contributes to the overall perceived quality of high-performance vehicles.

When it comes to sound, V8 engines are in a league of their own. The distinctive V8 rumble is a hallmark of performance cars, creating an emotional connection with drivers and enthusiasts. This auditory experience is often cited as a key factor in the appeal of V8-powered vehicles, setting them apart from cars with less sonorous powerplants.

Durability and reliability are also areas where V8 engines often surpass expectations. Despite their high-performance nature, many V8 engines are engineered to withstand the rigors of sustained high-speed operation and frequent hard acceleration. This robustness is particularly evident in racing applications, where V8 engines have proven their mettle in grueling endurance events.

Fuel efficiency, traditionally a weakness of V8 engines, has seen significant improvements in recent years. Modern V8s incorporate advanced technologies such as direct injection, variable valve timing, and cylinder deactivation. These innovations allow V8-powered vehicles to achieve fuel economy figures that are increasingly competitive with smaller engines, especially in highway driving scenarios.

In conclusion, V8 engines continue to set new benchmarks in high-performance vehicles through their superior power output, acceleration, refinement, sound characteristics, durability, and improving efficiency. While other engine configurations have their merits, the V8 remains a pinnacle of automotive engineering, consistently pushing the boundaries of what's possible in high-performance applications.

Firstly, power output is a critical factor where V8 engines excel. Compared to inline-four or V6 engines of similar displacement, V8s typically produce significantly more horsepower and torque. This power advantage is due to the V8's larger cylinder count and optimal firing order, which allows for more frequent power strokes and smoother power delivery.

In terms of acceleration, V8-powered vehicles consistently outperform their counterparts with fewer cylinders. The abundant low-end torque of V8 engines translates to quicker off-the-line acceleration and faster 0-60 mph times. This performance edge is particularly noticeable in heavier vehicles like luxury sedans and sports cars, where the V8's power helps overcome inertia more effectively.

Refinement is another area where V8 engines set new benchmarks. The inherent balance of the V8 configuration results in smoother operation and less vibration compared to many other engine layouts. This characteristic not only enhances driving comfort but also contributes to the overall perceived quality of high-performance vehicles.

When it comes to sound, V8 engines are in a league of their own. The distinctive V8 rumble is a hallmark of performance cars, creating an emotional connection with drivers and enthusiasts. This auditory experience is often cited as a key factor in the appeal of V8-powered vehicles, setting them apart from cars with less sonorous powerplants.

Durability and reliability are also areas where V8 engines often surpass expectations. Despite their high-performance nature, many V8 engines are engineered to withstand the rigors of sustained high-speed operation and frequent hard acceleration. This robustness is particularly evident in racing applications, where V8 engines have proven their mettle in grueling endurance events.

Fuel efficiency, traditionally a weakness of V8 engines, has seen significant improvements in recent years. Modern V8s incorporate advanced technologies such as direct injection, variable valve timing, and cylinder deactivation. These innovations allow V8-powered vehicles to achieve fuel economy figures that are increasingly competitive with smaller engines, especially in highway driving scenarios.

In conclusion, V8 engines continue to set new benchmarks in high-performance vehicles through their superior power output, acceleration, refinement, sound characteristics, durability, and improving efficiency. While other engine configurations have their merits, the V8 remains a pinnacle of automotive engineering, consistently pushing the boundaries of what's possible in high-performance applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!