How V8 Engines Improve Road Grip: Technical Insights?

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution and Performance Goals

The V8 engine has undergone significant evolution since its inception, driven by the constant pursuit of enhanced performance and efficiency. Initially developed in the early 20th century, V8 engines quickly became synonymous with power and prestige in the automotive industry. The primary goal of V8 engine development has consistently been to maximize power output while improving fuel efficiency and reducing emissions.

In the early stages, V8 engines were primarily focused on raw power delivery, with little regard for fuel economy or environmental impact. However, as regulatory pressures increased and consumer preferences shifted, engine designers began to prioritize a more balanced approach. This led to the integration of advanced technologies such as variable valve timing, direct fuel injection, and cylinder deactivation, all aimed at optimizing performance across a broader range of operating conditions.

The evolution of V8 engines has also been closely tied to advancements in materials science and manufacturing techniques. The use of lightweight alloys and precision engineering has allowed for the creation of more compact and efficient V8 designs, capable of producing higher power outputs from smaller displacements. This trend towards "downsizing" has been a key focus in recent years, as manufacturers strive to meet increasingly stringent emissions standards without sacrificing the performance characteristics that V8 engines are known for.

One of the most significant performance goals in V8 engine development has been the improvement of low-end torque delivery. This focus on enhancing torque output at lower RPMs has direct implications for road grip and overall vehicle dynamics. By providing more usable power across a wider range of engine speeds, modern V8 engines contribute to improved traction and stability, particularly during acceleration and cornering maneuvers.

Another critical objective in V8 engine evolution has been the refinement of power delivery. Engineers have worked tirelessly to reduce vibration and harshness, resulting in smoother operation and enhanced drivability. This refinement not only improves the driving experience but also contributes to better road grip by minimizing unwanted forces that could destabilize the vehicle.

The integration of advanced electronic control systems has played a pivotal role in achieving these performance goals. Modern V8 engines utilize sophisticated engine management systems that continuously optimize fuel delivery, ignition timing, and valve operation based on real-time driving conditions. This level of precision control allows for rapid adjustments to engine output, which can be synchronized with traction control and stability systems to further enhance road grip and overall vehicle performance.

In the early stages, V8 engines were primarily focused on raw power delivery, with little regard for fuel economy or environmental impact. However, as regulatory pressures increased and consumer preferences shifted, engine designers began to prioritize a more balanced approach. This led to the integration of advanced technologies such as variable valve timing, direct fuel injection, and cylinder deactivation, all aimed at optimizing performance across a broader range of operating conditions.

The evolution of V8 engines has also been closely tied to advancements in materials science and manufacturing techniques. The use of lightweight alloys and precision engineering has allowed for the creation of more compact and efficient V8 designs, capable of producing higher power outputs from smaller displacements. This trend towards "downsizing" has been a key focus in recent years, as manufacturers strive to meet increasingly stringent emissions standards without sacrificing the performance characteristics that V8 engines are known for.

One of the most significant performance goals in V8 engine development has been the improvement of low-end torque delivery. This focus on enhancing torque output at lower RPMs has direct implications for road grip and overall vehicle dynamics. By providing more usable power across a wider range of engine speeds, modern V8 engines contribute to improved traction and stability, particularly during acceleration and cornering maneuvers.

Another critical objective in V8 engine evolution has been the refinement of power delivery. Engineers have worked tirelessly to reduce vibration and harshness, resulting in smoother operation and enhanced drivability. This refinement not only improves the driving experience but also contributes to better road grip by minimizing unwanted forces that could destabilize the vehicle.

The integration of advanced electronic control systems has played a pivotal role in achieving these performance goals. Modern V8 engines utilize sophisticated engine management systems that continuously optimize fuel delivery, ignition timing, and valve operation based on real-time driving conditions. This level of precision control allows for rapid adjustments to engine output, which can be synchronized with traction control and stability systems to further enhance road grip and overall vehicle performance.

Market Demand for High-Performance Vehicles

The market demand for high-performance vehicles, particularly those equipped with V8 engines, has shown remarkable resilience and growth in recent years. Despite increasing environmental concerns and stricter emissions regulations, consumers continue to seek out powerful, high-performance automobiles that offer superior road grip and driving dynamics.

This demand is primarily driven by automotive enthusiasts, luxury car buyers, and performance-oriented consumers who prioritize driving experience and vehicle capabilities over fuel efficiency. The allure of V8-powered vehicles lies in their ability to deliver exceptional acceleration, top speeds, and overall performance, which are highly valued in both everyday driving and track environments.

In the luxury and sports car segments, V8 engines remain a significant selling point. Manufacturers like Ferrari, Lamborghini, Mercedes-AMG, and BMW M continue to invest heavily in V8 technology, recognizing its importance in maintaining brand identity and meeting customer expectations. These high-end vehicles often serve as halo products, driving brand prestige and influencing sales across entire model ranges.

The motorsport industry also plays a crucial role in sustaining demand for V8-powered vehicles. Formula 1's use of V6 hybrid powertrains has not diminished the appeal of V8 engines in other racing series, such as NASCAR and Australian Supercars. This racing heritage translates to road cars, with manufacturers leveraging their motorsport expertise to develop advanced V8 engines for production vehicles.

Interestingly, the market has seen a trend towards downsized, turbocharged V8 engines that offer improved fuel efficiency without sacrificing performance. This evolution addresses some environmental concerns while maintaining the power output and character that V8 enthusiasts crave. Additionally, the integration of hybrid technology with V8 engines in hypercars and high-performance SUVs has opened new market segments, appealing to environmentally conscious buyers who still desire exceptional performance.

The global market for V8-powered vehicles, while niche, remains robust. North America continues to be a stronghold for V8 engines, particularly in pickup trucks and muscle cars. Europe and the Middle East show steady demand in the luxury and sports car segments, while emerging markets in Asia and South America present growth opportunities for high-performance vehicles.

Looking ahead, the market for V8-powered vehicles faces challenges from tightening emissions standards and the shift towards electrification. However, manufacturers are adapting by developing more efficient V8 engines and exploring hybrid powertrains. This evolution suggests that while the market may contract, there will likely remain a dedicated segment of consumers willing to pay a premium for the unique driving experience and road grip capabilities that V8 engines provide.

This demand is primarily driven by automotive enthusiasts, luxury car buyers, and performance-oriented consumers who prioritize driving experience and vehicle capabilities over fuel efficiency. The allure of V8-powered vehicles lies in their ability to deliver exceptional acceleration, top speeds, and overall performance, which are highly valued in both everyday driving and track environments.

In the luxury and sports car segments, V8 engines remain a significant selling point. Manufacturers like Ferrari, Lamborghini, Mercedes-AMG, and BMW M continue to invest heavily in V8 technology, recognizing its importance in maintaining brand identity and meeting customer expectations. These high-end vehicles often serve as halo products, driving brand prestige and influencing sales across entire model ranges.

The motorsport industry also plays a crucial role in sustaining demand for V8-powered vehicles. Formula 1's use of V6 hybrid powertrains has not diminished the appeal of V8 engines in other racing series, such as NASCAR and Australian Supercars. This racing heritage translates to road cars, with manufacturers leveraging their motorsport expertise to develop advanced V8 engines for production vehicles.

Interestingly, the market has seen a trend towards downsized, turbocharged V8 engines that offer improved fuel efficiency without sacrificing performance. This evolution addresses some environmental concerns while maintaining the power output and character that V8 enthusiasts crave. Additionally, the integration of hybrid technology with V8 engines in hypercars and high-performance SUVs has opened new market segments, appealing to environmentally conscious buyers who still desire exceptional performance.

The global market for V8-powered vehicles, while niche, remains robust. North America continues to be a stronghold for V8 engines, particularly in pickup trucks and muscle cars. Europe and the Middle East show steady demand in the luxury and sports car segments, while emerging markets in Asia and South America present growth opportunities for high-performance vehicles.

Looking ahead, the market for V8-powered vehicles faces challenges from tightening emissions standards and the shift towards electrification. However, manufacturers are adapting by developing more efficient V8 engines and exploring hybrid powertrains. This evolution suggests that while the market may contract, there will likely remain a dedicated segment of consumers willing to pay a premium for the unique driving experience and road grip capabilities that V8 engines provide.

Current V8 Technology and Traction Challenges

V8 engines have long been associated with high performance and power in the automotive industry. However, their contribution to road grip and traction has been a subject of ongoing technological development. Currently, V8 engines face several challenges in optimizing traction, particularly in high-performance vehicles where power transfer to the road surface is critical.

One of the primary challenges is managing the immense torque output of V8 engines, especially during acceleration. The sudden surge of power can overwhelm the tires, leading to wheel spin and reduced traction. This issue is particularly pronounced in rear-wheel-drive configurations, where the weight transfer during acceleration further reduces the load on the drive wheels.

To address these challenges, manufacturers have implemented various technologies. Traction control systems have become standard in V8-equipped vehicles, using sensors to detect wheel slip and modulate engine power or apply brakes to individual wheels. However, these systems can sometimes feel intrusive to drivers seeking a more engaging driving experience.

Advanced electronic differentials have also been developed to distribute torque more effectively between the wheels. Limited-slip differentials and torque vectoring systems help to maximize traction by directing power to the wheel with the most grip, improving cornering ability and stability.

Another area of focus has been weight distribution. Engineers have worked on optimizing the placement of V8 engines within the vehicle chassis to achieve better balance. Some manufacturers have adopted a front-mid-engine layout, positioning the V8 engine behind the front axle to improve weight distribution and, consequently, traction.

Suspension technology plays a crucial role in maximizing the traction potential of V8-powered vehicles. Adaptive suspension systems that can adjust damping rates in real-time help maintain optimal tire contact with the road surface, enhancing grip across various driving conditions.

Tire technology has also evolved to cope with the demands of V8 engines. High-performance tires with specialized compounds and tread patterns are designed to handle the power and heat generated by these engines, providing better grip and stability.

Despite these advancements, challenges remain. The ongoing push for increased power outputs in V8 engines continues to test the limits of current traction technologies. Additionally, the shift towards electrification and hybrid powertrains introduces new complexities in managing power delivery and traction in high-performance vehicles.

As environmental regulations tighten, V8 engine developers must also balance performance and traction improvements with fuel efficiency and emissions reduction. This has led to the exploration of technologies such as cylinder deactivation and variable valve timing, which can affect the engine's power delivery characteristics and, consequently, its impact on vehicle traction.

One of the primary challenges is managing the immense torque output of V8 engines, especially during acceleration. The sudden surge of power can overwhelm the tires, leading to wheel spin and reduced traction. This issue is particularly pronounced in rear-wheel-drive configurations, where the weight transfer during acceleration further reduces the load on the drive wheels.

To address these challenges, manufacturers have implemented various technologies. Traction control systems have become standard in V8-equipped vehicles, using sensors to detect wheel slip and modulate engine power or apply brakes to individual wheels. However, these systems can sometimes feel intrusive to drivers seeking a more engaging driving experience.

Advanced electronic differentials have also been developed to distribute torque more effectively between the wheels. Limited-slip differentials and torque vectoring systems help to maximize traction by directing power to the wheel with the most grip, improving cornering ability and stability.

Another area of focus has been weight distribution. Engineers have worked on optimizing the placement of V8 engines within the vehicle chassis to achieve better balance. Some manufacturers have adopted a front-mid-engine layout, positioning the V8 engine behind the front axle to improve weight distribution and, consequently, traction.

Suspension technology plays a crucial role in maximizing the traction potential of V8-powered vehicles. Adaptive suspension systems that can adjust damping rates in real-time help maintain optimal tire contact with the road surface, enhancing grip across various driving conditions.

Tire technology has also evolved to cope with the demands of V8 engines. High-performance tires with specialized compounds and tread patterns are designed to handle the power and heat generated by these engines, providing better grip and stability.

Despite these advancements, challenges remain. The ongoing push for increased power outputs in V8 engines continues to test the limits of current traction technologies. Additionally, the shift towards electrification and hybrid powertrains introduces new complexities in managing power delivery and traction in high-performance vehicles.

As environmental regulations tighten, V8 engine developers must also balance performance and traction improvements with fuel efficiency and emissions reduction. This has led to the exploration of technologies such as cylinder deactivation and variable valve timing, which can affect the engine's power delivery characteristics and, consequently, its impact on vehicle traction.

Existing V8 Road Grip Enhancement Solutions

01 V8 engine design improvements for enhanced road grip

Advancements in V8 engine design focus on improving power distribution and weight balance, which directly impacts road grip. These improvements include optimized cylinder configurations, advanced fuel injection systems, and integrated traction control mechanisms that work in harmony with the engine's power output to enhance overall vehicle stability and road grip.- V8 Engine Design for Improved Road Grip: V8 engines can be designed with specific features to enhance road grip. This includes optimizing weight distribution, lowering the center of gravity, and integrating advanced traction control systems. These design elements work together to improve the vehicle's stability and handling, particularly during acceleration and cornering.

- Suspension Systems for V8-Powered Vehicles: Specialized suspension systems can be developed for vehicles with V8 engines to maximize road grip. These systems may include adaptive dampers, active roll control, and advanced air suspension technologies. By continuously adjusting to road conditions and driving dynamics, these suspension systems help maintain optimal tire contact with the road surface.

- Tire Technology for High-Performance V8 Engines: Advanced tire technologies can be employed to enhance road grip for V8-powered vehicles. This includes developing specialized rubber compounds, tread patterns, and tire structures that can effectively manage the high torque output of V8 engines. These tires are designed to provide optimal traction in various driving conditions while handling the increased power and weight of V8 vehicles.

- Electronic Stability Control for V8 Engines: Sophisticated electronic stability control systems can be implemented in V8-powered vehicles to improve road grip. These systems use sensors to monitor vehicle dynamics and can selectively apply brakes or adjust engine power to maintain stability. Advanced algorithms tailored for V8 engine characteristics help optimize traction and handling in various driving scenarios.

- Aerodynamic Enhancements for V8 Vehicles: Aerodynamic features can be incorporated into V8-powered vehicles to increase downforce and improve road grip. This may include active aerodynamic elements, such as adjustable spoilers or diffusers, that can adapt to different speeds and driving conditions. These enhancements help press the vehicle onto the road, increasing traction and stability, especially at higher speeds.

02 Suspension and chassis integration with V8 engines

Integration of V8 engines with advanced suspension systems and chassis designs plays a crucial role in improving road grip. This includes adaptive suspension technologies, active damping systems, and intelligent weight distribution mechanisms that work in tandem with the engine's performance characteristics to optimize traction and handling across various driving conditions.Expand Specific Solutions03 Traction control systems for V8-powered vehicles

Specialized traction control systems designed for V8 engines help manage power delivery to the wheels, enhancing road grip. These systems incorporate advanced sensors, electronic control units, and torque vectoring technologies to monitor and adjust power distribution in real-time, ensuring optimal traction and stability, especially during high-performance driving scenarios.Expand Specific Solutions04 Aerodynamic enhancements for V8-equipped vehicles

Aerodynamic improvements specifically tailored for vehicles with V8 engines contribute to better road grip. These enhancements include active aerodynamic elements, underbody diffusers, and rear spoilers that work in conjunction with the engine's power output to increase downforce and improve overall vehicle stability at various speeds.Expand Specific Solutions05 Tire technology advancements for V8 performance

Development of specialized tire technologies for V8-powered vehicles focuses on maximizing road contact and grip. These advancements include compound formulations tailored to handle high torque outputs, tread patterns designed for optimal heat dissipation, and tire pressure monitoring systems that work in harmony with the engine's performance characteristics to ensure consistent grip across various driving conditions.Expand Specific Solutions

Major V8 Engine Manufacturers and Competitors

The V8 engine's impact on road grip represents a mature technology in the automotive industry, with a well-established market and significant player involvement. Major automotive manufacturers like Honda, Ford, BMW, and Mercedes-Benz have long incorporated V8 engines in their high-performance vehicles, contributing to a substantial market size. The technology's maturity is evident in the continuous refinements made by companies such as Continental AG, Robert Bosch GmbH, and Bridgestone Corp., focusing on enhancing traction control systems and tire technologies to complement V8 performance. While the industry is shifting towards electrification, V8 engines remain relevant in specific market segments, with ongoing research and development efforts by key players to improve efficiency and performance.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced V8 engine with a unique cylinder deactivation system that improves road grip by optimizing power delivery and weight distribution. The system selectively shuts off four cylinders during light load conditions, reducing fuel consumption and emissions. When full power is needed, all eight cylinders engage seamlessly. This technology is coupled with an intelligent all-wheel-drive system that continuously monitors road conditions and adjusts torque distribution to each wheel for maximum traction[1]. Ford's V8 engines also incorporate a flat-plane crankshaft design, which allows for higher revving and improved exhaust scavenging, resulting in better throttle response and enhanced cornering stability[2].

Strengths: Improved fuel efficiency, reduced emissions, and enhanced traction control. The system's ability to seamlessly switch between four and eight-cylinder operation provides both power and efficiency. Weaknesses: Increased complexity may lead to higher maintenance costs and potential reliability issues in the long term.

Bayerische Motoren Werke AG

Technical Solution: BMW's approach to improving road grip with V8 engines focuses on advanced engine management systems and integration with the vehicle's dynamic stability control. Their TwinPower Turbo V8 engines feature a cross-bank exhaust manifold that optimizes exhaust gas flow, reducing turbo lag and improving throttle response[3]. This is combined with BMW's xDrive intelligent all-wheel-drive system, which uses a multi-plate clutch to variably distribute drive torque between the front and rear axles. The system works in conjunction with Dynamic Stability Control (DSC) to predict and prevent traction loss before it occurs[4]. Additionally, BMW has implemented a water injection system in some high-performance V8 models, which cools the intake air, allowing for higher boost pressure and improved combustion efficiency, ultimately enhancing power delivery and traction[5].

Strengths: Excellent integration of engine management with vehicle dynamics systems, resulting in predictive traction control. The water injection system provides a unique advantage in high-performance scenarios. Weaknesses: The complexity of the systems may lead to higher production costs and potential reliability concerns in extreme conditions.

Key Innovations in V8 Traction Control Systems

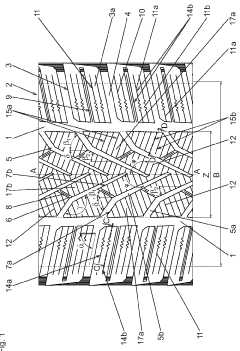

Vehicle tyre with a profiled tread

PatentInactiveEP1872974A3

Innovation

- Incorporating chamfered profile edge surfaces with increased surface roughness, specifically in the range of 10 to 500 μm, to enhance traction by increasing the contact surface area with the road, particularly through the use of V-shaped fine incisions and radial inward bending edges, which improve snow penetration and road grip.

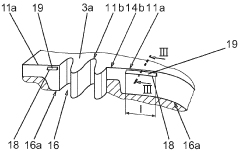

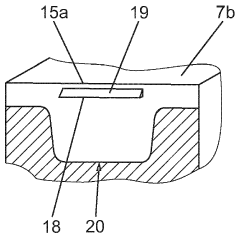

Pneumatic tyre for a vehicle

PatentWO2012072337A1

Innovation

- Incorporating additional gripping edges on the incision walls of tread blocks, positioned between 1 mm and 2 mm from the profile surface, which come into contact with the ground under deformation, increasing the edge effect and enhancing traction and braking on snow.

Environmental Impact of V8 Engine Technologies

The environmental impact of V8 engine technologies is a critical consideration in the automotive industry, particularly as global concerns about climate change and air pollution continue to grow. V8 engines, known for their power and performance, have traditionally been associated with high fuel consumption and increased emissions. However, recent technological advancements have aimed to mitigate these environmental concerns while maintaining the characteristic performance of V8 engines.

One of the primary environmental challenges posed by V8 engines is their higher fuel consumption compared to smaller engine configurations. This increased fuel usage directly correlates with higher carbon dioxide (CO2) emissions, a major contributor to global warming. To address this issue, manufacturers have implemented various fuel efficiency technologies, such as direct fuel injection, variable valve timing, and cylinder deactivation. These innovations have significantly reduced fuel consumption and, consequently, CO2 emissions in modern V8 engines.

Emissions control has been another focal point in improving the environmental profile of V8 engines. Stringent emissions standards worldwide have pushed manufacturers to develop advanced exhaust after-treatment systems. These include three-way catalytic converters, particulate filters, and selective catalytic reduction (SCR) systems, which effectively reduce harmful pollutants such as nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter.

The manufacturing process of V8 engines also has environmental implications. The production of larger, more complex engines typically requires more resources and energy compared to smaller engines. However, advancements in manufacturing techniques, such as improved casting processes and the use of lighter materials, have helped reduce the environmental footprint of V8 engine production.

Noise pollution is another environmental concern associated with V8 engines. Their characteristic sound, while appealing to enthusiasts, can contribute to urban noise pollution. To address this, manufacturers have developed sophisticated exhaust systems with active noise control, allowing for a balance between performance sound and environmental consideration.

Looking towards the future, the environmental impact of V8 engines is likely to be further mitigated through the integration of hybrid technologies. Hybrid V8 systems, which combine the power of a V8 engine with electric motors, offer a promising solution to reduce overall emissions while maintaining high performance levels. This approach allows for improved fuel efficiency in urban driving conditions and reduced emissions during low-speed operation.

In conclusion, while V8 engines have historically been associated with significant environmental impacts, ongoing technological advancements are continuously improving their ecological footprint. The challenge for manufacturers lies in balancing the performance characteristics that define V8 engines with the pressing need for environmental sustainability in the automotive industry.

One of the primary environmental challenges posed by V8 engines is their higher fuel consumption compared to smaller engine configurations. This increased fuel usage directly correlates with higher carbon dioxide (CO2) emissions, a major contributor to global warming. To address this issue, manufacturers have implemented various fuel efficiency technologies, such as direct fuel injection, variable valve timing, and cylinder deactivation. These innovations have significantly reduced fuel consumption and, consequently, CO2 emissions in modern V8 engines.

Emissions control has been another focal point in improving the environmental profile of V8 engines. Stringent emissions standards worldwide have pushed manufacturers to develop advanced exhaust after-treatment systems. These include three-way catalytic converters, particulate filters, and selective catalytic reduction (SCR) systems, which effectively reduce harmful pollutants such as nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter.

The manufacturing process of V8 engines also has environmental implications. The production of larger, more complex engines typically requires more resources and energy compared to smaller engines. However, advancements in manufacturing techniques, such as improved casting processes and the use of lighter materials, have helped reduce the environmental footprint of V8 engine production.

Noise pollution is another environmental concern associated with V8 engines. Their characteristic sound, while appealing to enthusiasts, can contribute to urban noise pollution. To address this, manufacturers have developed sophisticated exhaust systems with active noise control, allowing for a balance between performance sound and environmental consideration.

Looking towards the future, the environmental impact of V8 engines is likely to be further mitigated through the integration of hybrid technologies. Hybrid V8 systems, which combine the power of a V8 engine with electric motors, offer a promising solution to reduce overall emissions while maintaining high performance levels. This approach allows for improved fuel efficiency in urban driving conditions and reduced emissions during low-speed operation.

In conclusion, while V8 engines have historically been associated with significant environmental impacts, ongoing technological advancements are continuously improving their ecological footprint. The challenge for manufacturers lies in balancing the performance characteristics that define V8 engines with the pressing need for environmental sustainability in the automotive industry.

V8 Engine Integration with Vehicle Dynamics

The integration of V8 engines with vehicle dynamics plays a crucial role in enhancing road grip and overall performance. This synergy between powerful engine output and advanced chassis systems creates a harmonious balance that maximizes traction and handling capabilities.

V8 engines, known for their high power output and torque, provide the foundation for improved road grip. The engine's power delivery characteristics are carefully tuned to match the vehicle's suspension and tire capabilities. This optimization ensures that the power is transmitted to the wheels in a controlled manner, reducing wheel spin and enhancing traction.

Advanced electronic control systems play a vital role in managing the V8 engine's power output in relation to vehicle dynamics. These systems, such as traction control and stability control, continuously monitor wheel slip and vehicle behavior. They can instantly adjust engine power and torque distribution to maintain optimal grip in various driving conditions.

The integration of V8 engines with advanced drivetrain technologies further enhances road grip. All-wheel drive systems, for instance, can dynamically distribute power between the front and rear axles, as well as between individual wheels. This intelligent power distribution ensures maximum traction, especially during cornering or on low-friction surfaces.

Suspension systems in V8-powered vehicles are specifically designed to handle the engine's power output. Adaptive suspension systems can adjust damping rates in real-time, based on driving conditions and engine output. This dynamic adjustment helps maintain optimal tire contact with the road surface, enhancing grip and stability.

The weight distribution of V8 engines also contributes to improved road grip. Many high-performance vehicles with V8 engines are designed with a front-mid engine layout, placing the engine behind the front axle. This configuration helps achieve a more balanced weight distribution, improving overall vehicle dynamics and cornering abilities.

Aerodynamics play a significant role in the integration of V8 engines with vehicle dynamics. The high speeds achievable with V8 power necessitate careful aerodynamic design to generate downforce, which increases tire grip at higher speeds. Features such as active aerodynamic elements can adjust in real-time based on engine output and vehicle speed to optimize downforce and reduce lift.

In conclusion, the integration of V8 engines with vehicle dynamics is a complex interplay of power management, advanced control systems, and chassis design. This holistic approach ensures that the engine's power is effectively translated into superior road grip, resulting in enhanced performance, safety, and driving experience.

V8 engines, known for their high power output and torque, provide the foundation for improved road grip. The engine's power delivery characteristics are carefully tuned to match the vehicle's suspension and tire capabilities. This optimization ensures that the power is transmitted to the wheels in a controlled manner, reducing wheel spin and enhancing traction.

Advanced electronic control systems play a vital role in managing the V8 engine's power output in relation to vehicle dynamics. These systems, such as traction control and stability control, continuously monitor wheel slip and vehicle behavior. They can instantly adjust engine power and torque distribution to maintain optimal grip in various driving conditions.

The integration of V8 engines with advanced drivetrain technologies further enhances road grip. All-wheel drive systems, for instance, can dynamically distribute power between the front and rear axles, as well as between individual wheels. This intelligent power distribution ensures maximum traction, especially during cornering or on low-friction surfaces.

Suspension systems in V8-powered vehicles are specifically designed to handle the engine's power output. Adaptive suspension systems can adjust damping rates in real-time, based on driving conditions and engine output. This dynamic adjustment helps maintain optimal tire contact with the road surface, enhancing grip and stability.

The weight distribution of V8 engines also contributes to improved road grip. Many high-performance vehicles with V8 engines are designed with a front-mid engine layout, placing the engine behind the front axle. This configuration helps achieve a more balanced weight distribution, improving overall vehicle dynamics and cornering abilities.

Aerodynamics play a significant role in the integration of V8 engines with vehicle dynamics. The high speeds achievable with V8 power necessitate careful aerodynamic design to generate downforce, which increases tire grip at higher speeds. Features such as active aerodynamic elements can adjust in real-time based on engine output and vehicle speed to optimize downforce and reduce lift.

In conclusion, the integration of V8 engines with vehicle dynamics is a complex interplay of power management, advanced control systems, and chassis design. This holistic approach ensures that the engine's power is effectively translated into superior road grip, resulting in enhanced performance, safety, and driving experience.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!