How V8 Engines Influence Fuel Economy: Proven Insights?

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution and Efficiency Goals

The V8 engine has undergone significant evolution since its inception, with a primary focus on improving fuel economy while maintaining performance. Initially designed for high-power applications, V8 engines have faced increasing pressure to become more efficient due to stricter emissions regulations and consumer demand for better fuel economy.

In the early stages of V8 development, the emphasis was primarily on power output and durability. However, as environmental concerns grew and fuel prices increased, manufacturers began to shift their focus towards efficiency. This transition marked the beginning of a new era in V8 engine design, where the goal became to achieve a balance between performance and fuel economy.

One of the key milestones in V8 engine evolution was the introduction of variable displacement technology, also known as cylinder deactivation. This innovation allowed engines to operate on fewer cylinders during low-load conditions, significantly reducing fuel consumption without compromising power when needed. The development of this technology represented a major step forward in addressing the inherent inefficiency of V8 engines during light-load operation.

Another crucial advancement in V8 efficiency was the widespread adoption of direct fuel injection. This technology improved fuel atomization and allowed for more precise control over the combustion process, resulting in better fuel economy and reduced emissions. Combined with advanced engine management systems, direct injection enabled V8 engines to operate more efficiently across a wider range of driving conditions.

The integration of turbocharging and supercharging technologies into V8 engines has also played a significant role in improving efficiency. These forced induction systems allow for smaller displacement engines to produce comparable power to larger naturally aspirated units, while consuming less fuel under normal driving conditions. This downsizing trend has become increasingly prevalent in the automotive industry as a means to meet stringent fuel economy standards.

Recent developments in V8 engine technology have focused on further refining combustion processes and reducing internal friction. Advanced materials and manufacturing techniques have allowed for tighter tolerances and lighter components, contributing to overall efficiency gains. Additionally, the implementation of start-stop systems and mild hybrid technologies has helped to reduce fuel consumption in urban driving scenarios.

Looking forward, the goals for V8 engine efficiency continue to evolve. Manufacturers are exploring new avenues such as homogeneous charge compression ignition (HCCI) and advanced thermal management systems to extract even greater efficiency from the V8 configuration. The challenge remains to preserve the characteristic power and sound of V8 engines while meeting increasingly stringent environmental regulations and consumer expectations for fuel economy.

In the early stages of V8 development, the emphasis was primarily on power output and durability. However, as environmental concerns grew and fuel prices increased, manufacturers began to shift their focus towards efficiency. This transition marked the beginning of a new era in V8 engine design, where the goal became to achieve a balance between performance and fuel economy.

One of the key milestones in V8 engine evolution was the introduction of variable displacement technology, also known as cylinder deactivation. This innovation allowed engines to operate on fewer cylinders during low-load conditions, significantly reducing fuel consumption without compromising power when needed. The development of this technology represented a major step forward in addressing the inherent inefficiency of V8 engines during light-load operation.

Another crucial advancement in V8 efficiency was the widespread adoption of direct fuel injection. This technology improved fuel atomization and allowed for more precise control over the combustion process, resulting in better fuel economy and reduced emissions. Combined with advanced engine management systems, direct injection enabled V8 engines to operate more efficiently across a wider range of driving conditions.

The integration of turbocharging and supercharging technologies into V8 engines has also played a significant role in improving efficiency. These forced induction systems allow for smaller displacement engines to produce comparable power to larger naturally aspirated units, while consuming less fuel under normal driving conditions. This downsizing trend has become increasingly prevalent in the automotive industry as a means to meet stringent fuel economy standards.

Recent developments in V8 engine technology have focused on further refining combustion processes and reducing internal friction. Advanced materials and manufacturing techniques have allowed for tighter tolerances and lighter components, contributing to overall efficiency gains. Additionally, the implementation of start-stop systems and mild hybrid technologies has helped to reduce fuel consumption in urban driving scenarios.

Looking forward, the goals for V8 engine efficiency continue to evolve. Manufacturers are exploring new avenues such as homogeneous charge compression ignition (HCCI) and advanced thermal management systems to extract even greater efficiency from the V8 configuration. The challenge remains to preserve the characteristic power and sound of V8 engines while meeting increasingly stringent environmental regulations and consumer expectations for fuel economy.

Market Demand for Fuel-Efficient V8 Vehicles

The market demand for fuel-efficient V8 vehicles has been evolving significantly in recent years, driven by a complex interplay of consumer preferences, regulatory pressures, and technological advancements. Despite the general trend towards smaller, more efficient engines, there remains a substantial market segment that values the power and performance characteristics of V8 engines while also seeking improved fuel economy.

In the luxury and high-performance vehicle sectors, V8 engines continue to be a sought-after feature. Consumers in these segments often prioritize performance and brand prestige, but are increasingly conscious of fuel efficiency. This has led to a growing demand for V8-powered vehicles that can deliver both power and improved fuel economy, particularly in markets where fuel prices are high or environmental regulations are stringent.

The pickup truck market, especially in North America, represents another significant area of demand for fuel-efficient V8 engines. Many consumers require the towing capacity and payload capabilities that V8 engines provide but are also sensitive to fuel costs, especially for commercial and fleet applications. This has spurred manufacturers to invest heavily in developing more efficient V8 engines for their truck lineups.

Sports car enthusiasts constitute another key market segment. While some sports car manufacturers have moved towards smaller, turbocharged engines, there remains a dedicated consumer base that prefers the distinctive sound and power delivery of V8 engines. These consumers are willing to pay a premium for V8-powered sports cars that offer improved fuel efficiency without compromising on performance.

The demand for fuel-efficient V8 vehicles is also influenced by regional factors. In markets with less stringent emissions regulations or lower fuel prices, such as certain Middle Eastern countries, large V8-powered vehicles continue to be popular. However, even in these markets, there is a growing awareness of fuel efficiency, driven by global environmental concerns and the desire for reduced operating costs.

Manufacturers have responded to this market demand by implementing various technologies to improve V8 engine efficiency. These include cylinder deactivation, direct injection, variable valve timing, and the integration of hybrid systems. The success of these technologies in improving fuel economy while maintaining V8 performance characteristics has helped sustain and, in some cases, grow the market for V8-powered vehicles.

Looking ahead, the market for fuel-efficient V8 vehicles is expected to remain significant, albeit with potential shifts in focus. As electrification technologies advance, there may be increased demand for hybrid V8 powertrains that offer even greater improvements in fuel economy. Additionally, the development of synthetic fuels could provide a pathway for V8 engines to remain relevant in an increasingly carbon-conscious market.

In the luxury and high-performance vehicle sectors, V8 engines continue to be a sought-after feature. Consumers in these segments often prioritize performance and brand prestige, but are increasingly conscious of fuel efficiency. This has led to a growing demand for V8-powered vehicles that can deliver both power and improved fuel economy, particularly in markets where fuel prices are high or environmental regulations are stringent.

The pickup truck market, especially in North America, represents another significant area of demand for fuel-efficient V8 engines. Many consumers require the towing capacity and payload capabilities that V8 engines provide but are also sensitive to fuel costs, especially for commercial and fleet applications. This has spurred manufacturers to invest heavily in developing more efficient V8 engines for their truck lineups.

Sports car enthusiasts constitute another key market segment. While some sports car manufacturers have moved towards smaller, turbocharged engines, there remains a dedicated consumer base that prefers the distinctive sound and power delivery of V8 engines. These consumers are willing to pay a premium for V8-powered sports cars that offer improved fuel efficiency without compromising on performance.

The demand for fuel-efficient V8 vehicles is also influenced by regional factors. In markets with less stringent emissions regulations or lower fuel prices, such as certain Middle Eastern countries, large V8-powered vehicles continue to be popular. However, even in these markets, there is a growing awareness of fuel efficiency, driven by global environmental concerns and the desire for reduced operating costs.

Manufacturers have responded to this market demand by implementing various technologies to improve V8 engine efficiency. These include cylinder deactivation, direct injection, variable valve timing, and the integration of hybrid systems. The success of these technologies in improving fuel economy while maintaining V8 performance characteristics has helped sustain and, in some cases, grow the market for V8-powered vehicles.

Looking ahead, the market for fuel-efficient V8 vehicles is expected to remain significant, albeit with potential shifts in focus. As electrification technologies advance, there may be increased demand for hybrid V8 powertrains that offer even greater improvements in fuel economy. Additionally, the development of synthetic fuels could provide a pathway for V8 engines to remain relevant in an increasingly carbon-conscious market.

Current V8 Technology and Fuel Economy Challenges

V8 engines, known for their power and performance, have long been a staple in high-performance vehicles and larger automobiles. However, in recent years, these engines have faced significant challenges in meeting increasingly stringent fuel economy standards and environmental regulations. The current state of V8 technology reflects a delicate balance between maintaining the performance characteristics that consumers desire and improving fuel efficiency to meet regulatory requirements.

One of the primary challenges facing V8 engines is their inherently higher fuel consumption compared to smaller, more efficient engine configurations. This is due to their larger displacement and increased number of cylinders, which typically result in greater fuel usage, especially during acceleration and high-speed operation. To address this, manufacturers have implemented various technologies to enhance fuel economy without significantly compromising performance.

Cylinder deactivation, also known as variable displacement, has emerged as a key technology in improving V8 fuel efficiency. This system allows the engine to shut down a set of cylinders during light load conditions, effectively operating as a smaller, more efficient engine. When additional power is needed, all cylinders are reactivated seamlessly. While this technology has shown promising results in reducing fuel consumption, it adds complexity to engine design and control systems.

Direct fuel injection is another critical advancement in V8 technology aimed at improving fuel economy. By precisely controlling the timing and amount of fuel injected directly into the combustion chamber, this system optimizes fuel usage and enhances combustion efficiency. Combined with advanced engine management systems, direct injection can significantly reduce fuel consumption, particularly in partial load conditions.

Turbocharging and supercharging have also been widely adopted in modern V8 engines to improve efficiency while maintaining or even enhancing performance. These forced induction systems allow for engine downsizing, where smaller displacement V8s can produce power equivalent to larger naturally aspirated engines, resulting in improved fuel economy under normal driving conditions.

Despite these advancements, V8 engines still face challenges in meeting future fuel economy standards. The push towards electrification and hybrid powertrains poses a significant threat to traditional V8 configurations. Manufacturers are exploring mild hybrid systems and start-stop technology to further enhance fuel efficiency, but these solutions often add weight and complexity to the vehicle.

The integration of lightweight materials in engine construction, such as aluminum and composite components, has helped reduce overall engine weight, contributing to improved fuel economy. However, the cost of these materials and the complexity of manufacturing processes present ongoing challenges for widespread adoption.

As emission regulations continue to tighten globally, V8 engines face increasing pressure to reduce not only fuel consumption but also harmful emissions. Advanced exhaust after-treatment systems and precise engine control strategies are being developed to meet these standards, but they often come at the cost of increased complexity and potential reliability concerns.

One of the primary challenges facing V8 engines is their inherently higher fuel consumption compared to smaller, more efficient engine configurations. This is due to their larger displacement and increased number of cylinders, which typically result in greater fuel usage, especially during acceleration and high-speed operation. To address this, manufacturers have implemented various technologies to enhance fuel economy without significantly compromising performance.

Cylinder deactivation, also known as variable displacement, has emerged as a key technology in improving V8 fuel efficiency. This system allows the engine to shut down a set of cylinders during light load conditions, effectively operating as a smaller, more efficient engine. When additional power is needed, all cylinders are reactivated seamlessly. While this technology has shown promising results in reducing fuel consumption, it adds complexity to engine design and control systems.

Direct fuel injection is another critical advancement in V8 technology aimed at improving fuel economy. By precisely controlling the timing and amount of fuel injected directly into the combustion chamber, this system optimizes fuel usage and enhances combustion efficiency. Combined with advanced engine management systems, direct injection can significantly reduce fuel consumption, particularly in partial load conditions.

Turbocharging and supercharging have also been widely adopted in modern V8 engines to improve efficiency while maintaining or even enhancing performance. These forced induction systems allow for engine downsizing, where smaller displacement V8s can produce power equivalent to larger naturally aspirated engines, resulting in improved fuel economy under normal driving conditions.

Despite these advancements, V8 engines still face challenges in meeting future fuel economy standards. The push towards electrification and hybrid powertrains poses a significant threat to traditional V8 configurations. Manufacturers are exploring mild hybrid systems and start-stop technology to further enhance fuel efficiency, but these solutions often add weight and complexity to the vehicle.

The integration of lightweight materials in engine construction, such as aluminum and composite components, has helped reduce overall engine weight, contributing to improved fuel economy. However, the cost of these materials and the complexity of manufacturing processes present ongoing challenges for widespread adoption.

As emission regulations continue to tighten globally, V8 engines face increasing pressure to reduce not only fuel consumption but also harmful emissions. Advanced exhaust after-treatment systems and precise engine control strategies are being developed to meet these standards, but they often come at the cost of increased complexity and potential reliability concerns.

Existing V8 Fuel Economy Solutions

01 Fuel efficiency optimization in V8 engines

Various methods are employed to improve fuel economy in V8 engines, including advanced engine management systems, variable valve timing, and cylinder deactivation technologies. These techniques help optimize fuel consumption while maintaining performance.- Fuel injection and combustion optimization: Improving fuel economy in V8 engines through advanced fuel injection systems and optimized combustion processes. This includes precise fuel metering, improved atomization, and better air-fuel mixture control to enhance efficiency and reduce fuel consumption.

- Engine management and control systems: Utilizing sophisticated engine management and control systems to monitor and adjust various parameters in real-time. These systems can optimize fuel delivery, ignition timing, and other factors to maximize fuel efficiency while maintaining performance in V8 engines.

- Cylinder deactivation technology: Implementing cylinder deactivation or variable displacement technology in V8 engines. This allows the engine to operate on fewer cylinders during low-load conditions, significantly reducing fuel consumption without compromising power when needed.

- Lightweight materials and design optimization: Employing lightweight materials and optimized engine designs to reduce overall weight and improve fuel efficiency. This includes the use of advanced alloys, composite materials, and innovative structural designs to minimize energy loss and enhance performance.

- Alternative fuel and hybrid technologies: Integrating alternative fuel capabilities or hybrid technologies with V8 engines to improve fuel economy. This may include adapting V8 engines to run on biofuels, implementing start-stop systems, or combining electric motors with the V8 engine for a hybrid powertrain.

02 Monitoring and analysis of V8 engine performance

Systems and methods for monitoring and analyzing V8 engine performance to improve fuel economy. This includes real-time data collection, diagnostic tools, and predictive maintenance techniques to ensure optimal engine efficiency.Expand Specific Solutions03 Alternative fuel solutions for V8 engines

Research and development of alternative fuel solutions for V8 engines to enhance fuel economy. This includes the use of biofuels, hydrogen, and other renewable energy sources to reduce reliance on traditional fossil fuels.Expand Specific Solutions04 Aerodynamic improvements for vehicles with V8 engines

Implementing aerodynamic enhancements to vehicles equipped with V8 engines to reduce drag and improve overall fuel efficiency. This includes modifications to body design, underbody panels, and active aerodynamic systems.Expand Specific Solutions05 Weight reduction strategies for V8-powered vehicles

Developing and implementing weight reduction strategies for vehicles with V8 engines to improve fuel economy. This includes the use of lightweight materials, component redesign, and overall vehicle architecture optimization.Expand Specific Solutions

Key Players in V8 Engine Manufacturing

The V8 engine market is in a mature phase, with established players like Ford, GM, Toyota, and Honda dominating the landscape. The global V8 engine market size is estimated to be in the billions, driven by demand in high-performance vehicles and luxury segments. Technologically, V8 engines have reached a high level of sophistication, with companies like Ford Global Technologies and GM Global Technology Operations leading innovation in fuel efficiency. Other players such as Delphi Technology and ExxonMobil Chemical Patents are contributing to advancements in engine components and fuel formulations, respectively, to further improve V8 engine performance and economy.

Ford Global Technologies LLC

Technical Solution: Ford has developed advanced V8 engine technologies to improve fuel economy while maintaining performance. Their EcoBoost V8 engines utilize direct fuel injection, turbocharging, and variable valve timing to optimize combustion efficiency. Ford's latest 5.0L Coyote V8 engine incorporates plasma transferred wire arc (PTWA) cylinder liner technology, reducing friction and improving thermal management[1]. They have also implemented cylinder deactivation systems, allowing the engine to operate on four cylinders during light load conditions, significantly reducing fuel consumption[2]. Ford's dual-fuel injection system combines port and direct injection to enhance fuel atomization and combustion efficiency across various operating conditions[3].

Strengths: Advanced technologies like EcoBoost and cylinder deactivation improve fuel efficiency. Weaknesses: Complexity of systems may increase maintenance costs and potential reliability issues.

GM Global Technology Operations LLC

Technical Solution: GM has developed Dynamic Fuel Management (DFM) for their V8 engines, an advanced cylinder deactivation system that can operate on as few as two cylinders to maximize fuel efficiency[4]. Their latest V8 engines feature direct injection, variable valve timing, and Active Fuel Management, which can shut off four cylinders during light load conditions. GM has also implemented a stop-start system in their V8 engines, automatically shutting off the engine when the vehicle comes to a stop and restarting it when the brake is released[5]. Additionally, GM's V8 engines utilize advanced materials and coatings to reduce friction and improve thermal efficiency, contributing to better fuel economy[6].

Strengths: Dynamic Fuel Management offers flexible cylinder deactivation for improved efficiency. Weaknesses: Increased system complexity may lead to higher production costs.

Core Innovations in V8 Fuel Efficiency

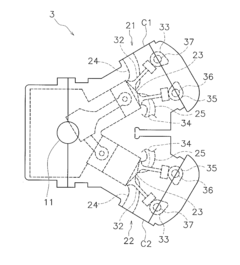

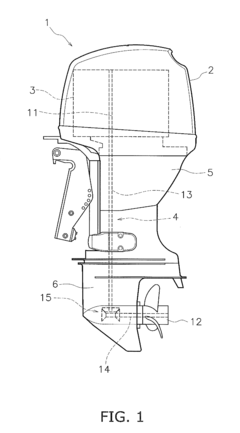

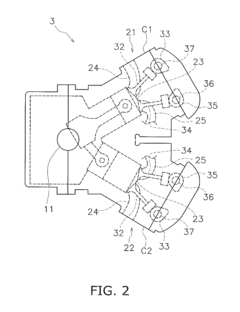

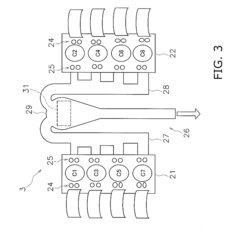

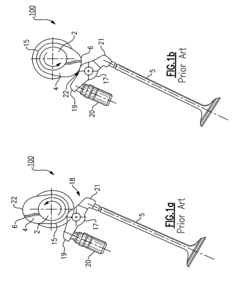

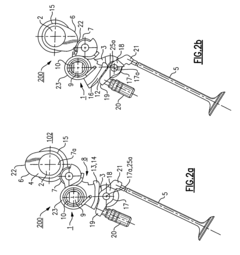

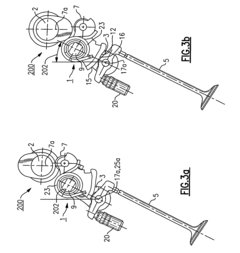

V8 engine and outboard motor

PatentActiveUS20160341097A1

Innovation

- A V8 engine design with a simple construction featuring aggregated exhaust pathways and adjustable exhaust cams, where the central angle of exhaust cams for each cylinder is optimized to minimize valve overlap and reduce exhaust interference, allowing for even firing intervals and improved exhaust gas management.

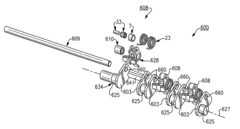

System for variable valvetrain actuation

PatentInactiveUS7409934B2

Innovation

- A simplified VVA system using a single rotary actuator per bank of valves, with a hardened steel rocker subassembly and a one-piece control shaft that varies valve lift, duration, and phasing without being mounted on the engine camshaft, utilizing needle roller bearings and a worm gear drive for precise control.

Environmental Regulations Impact on V8 Engines

Environmental regulations have significantly impacted the development and use of V8 engines, particularly in relation to fuel economy and emissions standards. Over the past few decades, governments worldwide have implemented increasingly stringent regulations to reduce greenhouse gas emissions and improve air quality. These regulations have forced automakers to adapt their V8 engine designs or, in some cases, phase them out entirely.

In the United States, the Corporate Average Fuel Economy (CAFE) standards have been a driving force behind improvements in V8 engine efficiency. These standards require automakers to achieve specific fleet-wide fuel economy targets, which has led to the development of more fuel-efficient V8 engines. Technologies such as variable valve timing, direct fuel injection, and cylinder deactivation have been implemented to improve the fuel economy of V8 engines while maintaining their performance characteristics.

The European Union has also introduced strict emissions standards, including the Euro 6 regulations, which have made it increasingly challenging for V8 engines to comply. These regulations have led to the widespread adoption of turbocharging and downsizing strategies, where smaller displacement engines are used to achieve similar power outputs with improved fuel efficiency.

China, the world's largest automotive market, has implemented its own set of fuel economy and emissions standards. These regulations have prompted automakers to focus on developing more efficient powertrains, including hybrid and electric vehicles, which has indirectly affected the market share of V8 engines in the country.

The impact of environmental regulations on V8 engines has not been limited to passenger vehicles. Commercial vehicles and heavy-duty trucks have also been subject to increasingly stringent emissions standards, such as the EPA's Heavy-Duty Engine and Vehicle Standards in the United States. These regulations have led to the development of more efficient V8 diesel engines and the adoption of alternative powertrains in some applications.

As a result of these regulations, many automakers have invested heavily in research and development to improve the efficiency of V8 engines. This has led to innovations such as start-stop systems, advanced thermal management, and the integration of mild hybrid technologies. However, despite these advancements, the long-term viability of V8 engines in many markets remains uncertain as regulations continue to tighten.

The shift towards electrification, driven in part by environmental regulations, has also had a significant impact on the future of V8 engines. Many countries have announced plans to phase out internal combustion engines entirely in the coming decades, which will likely accelerate the decline of V8 engines in mainstream vehicles. However, in certain niche markets, such as high-performance sports cars and luxury vehicles, V8 engines may continue to play a role, albeit with increasingly sophisticated technologies to meet regulatory requirements.

In the United States, the Corporate Average Fuel Economy (CAFE) standards have been a driving force behind improvements in V8 engine efficiency. These standards require automakers to achieve specific fleet-wide fuel economy targets, which has led to the development of more fuel-efficient V8 engines. Technologies such as variable valve timing, direct fuel injection, and cylinder deactivation have been implemented to improve the fuel economy of V8 engines while maintaining their performance characteristics.

The European Union has also introduced strict emissions standards, including the Euro 6 regulations, which have made it increasingly challenging for V8 engines to comply. These regulations have led to the widespread adoption of turbocharging and downsizing strategies, where smaller displacement engines are used to achieve similar power outputs with improved fuel efficiency.

China, the world's largest automotive market, has implemented its own set of fuel economy and emissions standards. These regulations have prompted automakers to focus on developing more efficient powertrains, including hybrid and electric vehicles, which has indirectly affected the market share of V8 engines in the country.

The impact of environmental regulations on V8 engines has not been limited to passenger vehicles. Commercial vehicles and heavy-duty trucks have also been subject to increasingly stringent emissions standards, such as the EPA's Heavy-Duty Engine and Vehicle Standards in the United States. These regulations have led to the development of more efficient V8 diesel engines and the adoption of alternative powertrains in some applications.

As a result of these regulations, many automakers have invested heavily in research and development to improve the efficiency of V8 engines. This has led to innovations such as start-stop systems, advanced thermal management, and the integration of mild hybrid technologies. However, despite these advancements, the long-term viability of V8 engines in many markets remains uncertain as regulations continue to tighten.

The shift towards electrification, driven in part by environmental regulations, has also had a significant impact on the future of V8 engines. Many countries have announced plans to phase out internal combustion engines entirely in the coming decades, which will likely accelerate the decline of V8 engines in mainstream vehicles. However, in certain niche markets, such as high-performance sports cars and luxury vehicles, V8 engines may continue to play a role, albeit with increasingly sophisticated technologies to meet regulatory requirements.

V8 vs Alternative Powertrains Comparison

When comparing V8 engines to alternative powertrains, it's essential to consider various factors that influence fuel economy and overall performance. V8 engines, known for their power and smooth operation, have long been a staple in high-performance vehicles and larger trucks. However, as fuel efficiency and environmental concerns have become increasingly important, alternative powertrains have gained significant traction in the automotive industry.

One of the primary alternatives to V8 engines is the turbocharged four-cylinder engine. These smaller displacement engines can often match or exceed the power output of V8s while consuming less fuel. The use of turbocharging allows for more efficient combustion and better overall fuel economy, especially in city driving conditions where V8 engines tend to be less efficient.

Hybrid powertrains represent another significant alternative to V8 engines. By combining a gasoline engine with electric motors, hybrid systems can dramatically improve fuel efficiency, particularly in urban environments. The ability to operate on electric power alone for short distances and the energy recovery through regenerative braking contribute to their superior fuel economy compared to traditional V8 engines.

Electric powertrains have emerged as a revolutionary alternative, offering zero direct emissions and potentially lower operating costs. While they may not match the long-range capabilities of V8 engines without recharging, electric vehicles (EVs) provide instant torque and smooth acceleration, often surpassing V8 engines in terms of immediate performance.

Diesel engines, although less common in passenger vehicles, offer another alternative to V8 gasoline engines. Diesel powertrains typically provide better fuel economy and higher torque at lower RPMs, making them suitable for heavy-duty applications where V8 engines are often used.

When evaluating these alternatives against V8 engines, it's crucial to consider factors such as power output, torque delivery, fuel efficiency, emissions, and overall driving experience. While V8 engines excel in raw power and characteristic sound, alternative powertrains often provide better fuel economy and lower emissions, aligning more closely with current environmental regulations and consumer preferences for efficiency.

The choice between a V8 engine and alternative powertrains ultimately depends on the specific application, user requirements, and priorities regarding performance, efficiency, and environmental impact. As technology advances, the gap in performance between V8 engines and their alternatives continues to narrow, offering consumers a wider range of options to suit their needs.

One of the primary alternatives to V8 engines is the turbocharged four-cylinder engine. These smaller displacement engines can often match or exceed the power output of V8s while consuming less fuel. The use of turbocharging allows for more efficient combustion and better overall fuel economy, especially in city driving conditions where V8 engines tend to be less efficient.

Hybrid powertrains represent another significant alternative to V8 engines. By combining a gasoline engine with electric motors, hybrid systems can dramatically improve fuel efficiency, particularly in urban environments. The ability to operate on electric power alone for short distances and the energy recovery through regenerative braking contribute to their superior fuel economy compared to traditional V8 engines.

Electric powertrains have emerged as a revolutionary alternative, offering zero direct emissions and potentially lower operating costs. While they may not match the long-range capabilities of V8 engines without recharging, electric vehicles (EVs) provide instant torque and smooth acceleration, often surpassing V8 engines in terms of immediate performance.

Diesel engines, although less common in passenger vehicles, offer another alternative to V8 gasoline engines. Diesel powertrains typically provide better fuel economy and higher torque at lower RPMs, making them suitable for heavy-duty applications where V8 engines are often used.

When evaluating these alternatives against V8 engines, it's crucial to consider factors such as power output, torque delivery, fuel efficiency, emissions, and overall driving experience. While V8 engines excel in raw power and characteristic sound, alternative powertrains often provide better fuel economy and lower emissions, aligning more closely with current environmental regulations and consumer preferences for efficiency.

The choice between a V8 engine and alternative powertrains ultimately depends on the specific application, user requirements, and priorities regarding performance, efficiency, and environmental impact. As technology advances, the gap in performance between V8 engines and their alternatives continues to narrow, offering consumers a wider range of options to suit their needs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!