How V8 Engines Influence Global Emissions Policies?

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution

The evolution of V8 engines has been a significant factor in shaping global emissions policies over the past several decades. Initially developed in the early 20th century, V8 engines quickly became synonymous with power and performance in the automotive industry. Their popularity soared in the 1950s and 1960s, particularly in American muscle cars and luxury vehicles.

As environmental concerns grew in the 1970s, the first major emissions regulations were introduced, forcing manufacturers to adapt V8 engines to meet new standards. This led to the development of technologies such as catalytic converters and fuel injection systems, which improved efficiency and reduced harmful emissions.

The 1980s and 1990s saw further advancements in V8 engine technology, with the introduction of electronic engine management systems and variable valve timing. These innovations allowed for better control over the combustion process, resulting in improved fuel economy and reduced emissions while maintaining performance.

In the early 2000s, the focus on climate change intensified, leading to stricter emissions standards worldwide. This prompted automakers to invest heavily in research and development to make V8 engines more environmentally friendly. Technologies such as cylinder deactivation, direct fuel injection, and turbocharging were widely adopted to improve efficiency and reduce CO2 emissions.

The late 2000s and early 2010s marked a turning point in V8 engine evolution, as many manufacturers began to downsize their engines or shift towards alternative powertrains. However, advancements in materials and manufacturing techniques allowed some automakers to continue producing high-performance V8 engines that could meet increasingly stringent emissions regulations.

Recent years have seen the emergence of hybrid and electric V8 powertrains, combining traditional internal combustion technology with electric motors to further reduce emissions while maintaining the characteristic power and sound of V8 engines. This trend reflects the automotive industry's efforts to balance performance with environmental responsibility.

The ongoing evolution of V8 engines has played a crucial role in driving global emissions policies. As these engines have become more efficient and less polluting, policymakers have responded by setting increasingly ambitious targets for vehicle emissions. This cycle of technological advancement and regulatory tightening has been a key factor in the overall reduction of automotive emissions worldwide.

As environmental concerns grew in the 1970s, the first major emissions regulations were introduced, forcing manufacturers to adapt V8 engines to meet new standards. This led to the development of technologies such as catalytic converters and fuel injection systems, which improved efficiency and reduced harmful emissions.

The 1980s and 1990s saw further advancements in V8 engine technology, with the introduction of electronic engine management systems and variable valve timing. These innovations allowed for better control over the combustion process, resulting in improved fuel economy and reduced emissions while maintaining performance.

In the early 2000s, the focus on climate change intensified, leading to stricter emissions standards worldwide. This prompted automakers to invest heavily in research and development to make V8 engines more environmentally friendly. Technologies such as cylinder deactivation, direct fuel injection, and turbocharging were widely adopted to improve efficiency and reduce CO2 emissions.

The late 2000s and early 2010s marked a turning point in V8 engine evolution, as many manufacturers began to downsize their engines or shift towards alternative powertrains. However, advancements in materials and manufacturing techniques allowed some automakers to continue producing high-performance V8 engines that could meet increasingly stringent emissions regulations.

Recent years have seen the emergence of hybrid and electric V8 powertrains, combining traditional internal combustion technology with electric motors to further reduce emissions while maintaining the characteristic power and sound of V8 engines. This trend reflects the automotive industry's efforts to balance performance with environmental responsibility.

The ongoing evolution of V8 engines has played a crucial role in driving global emissions policies. As these engines have become more efficient and less polluting, policymakers have responded by setting increasingly ambitious targets for vehicle emissions. This cycle of technological advancement and regulatory tightening has been a key factor in the overall reduction of automotive emissions worldwide.

Global Emissions Market

The global emissions market has become a critical arena for addressing climate change and environmental concerns. V8 engines, known for their power and performance, have played a significant role in shaping emissions policies worldwide. These engines, typically found in high-performance vehicles and larger trucks, have been a focal point for regulators due to their higher fuel consumption and emission levels compared to smaller engine configurations.

The market for emissions control technologies and solutions has expanded rapidly in response to stringent regulations targeting V8 engines. This growth has been driven by the need for automotive manufacturers to comply with increasingly strict emission standards while maintaining the performance characteristics that V8 engines are known for. As a result, the global emissions market has seen a surge in demand for advanced catalytic converters, particulate filters, and exhaust gas recirculation systems specifically designed for V8 engines.

Emissions trading schemes and carbon markets have also been influenced by the presence of V8 engines in the global vehicle fleet. These market-based mechanisms often include specific provisions or weightings for high-emission vehicles, creating economic incentives for manufacturers to improve the efficiency of their V8 engines or transition to alternative powertrains. This has led to the development of a secondary market for emissions credits, where companies can trade allowances based on their fleet's overall emissions performance.

The influence of V8 engines on global emissions policies has also spurred innovation in the automotive sector. Manufacturers have invested heavily in research and development to create more efficient V8 engines, including the integration of cylinder deactivation technology, direct injection systems, and turbocharging. These advancements have not only helped meet emissions targets but have also created new opportunities in the emissions control technology market.

Furthermore, the global emissions market has seen a shift in focus towards lifecycle emissions assessments, partly driven by the debate surrounding V8 engines. This holistic approach considers not only tailpipe emissions but also the environmental impact of vehicle production and end-of-life disposal. As a result, new market segments have emerged, focusing on sustainable manufacturing processes and materials for V8 engines and their components.

The presence of V8 engines in the market has also influenced the development of alternative fuel technologies. As policymakers seek to reduce emissions from high-performance vehicles, there has been increased investment in biofuels, synthetic fuels, and hydrogen technologies compatible with V8 engine architectures. This has created new opportunities within the global emissions market, fostering collaboration between traditional automotive suppliers and emerging clean energy companies.

The market for emissions control technologies and solutions has expanded rapidly in response to stringent regulations targeting V8 engines. This growth has been driven by the need for automotive manufacturers to comply with increasingly strict emission standards while maintaining the performance characteristics that V8 engines are known for. As a result, the global emissions market has seen a surge in demand for advanced catalytic converters, particulate filters, and exhaust gas recirculation systems specifically designed for V8 engines.

Emissions trading schemes and carbon markets have also been influenced by the presence of V8 engines in the global vehicle fleet. These market-based mechanisms often include specific provisions or weightings for high-emission vehicles, creating economic incentives for manufacturers to improve the efficiency of their V8 engines or transition to alternative powertrains. This has led to the development of a secondary market for emissions credits, where companies can trade allowances based on their fleet's overall emissions performance.

The influence of V8 engines on global emissions policies has also spurred innovation in the automotive sector. Manufacturers have invested heavily in research and development to create more efficient V8 engines, including the integration of cylinder deactivation technology, direct injection systems, and turbocharging. These advancements have not only helped meet emissions targets but have also created new opportunities in the emissions control technology market.

Furthermore, the global emissions market has seen a shift in focus towards lifecycle emissions assessments, partly driven by the debate surrounding V8 engines. This holistic approach considers not only tailpipe emissions but also the environmental impact of vehicle production and end-of-life disposal. As a result, new market segments have emerged, focusing on sustainable manufacturing processes and materials for V8 engines and their components.

The presence of V8 engines in the market has also influenced the development of alternative fuel technologies. As policymakers seek to reduce emissions from high-performance vehicles, there has been increased investment in biofuels, synthetic fuels, and hydrogen technologies compatible with V8 engine architectures. This has created new opportunities within the global emissions market, fostering collaboration between traditional automotive suppliers and emerging clean energy companies.

V8 Tech Challenges

V8 engines, known for their power and performance, face significant challenges in the context of global emissions policies. The primary hurdle is meeting increasingly stringent emissions standards while maintaining the performance characteristics that define these engines. Many countries and regions have implemented or are planning to implement stricter regulations on vehicle emissions, particularly targeting carbon dioxide (CO2) and nitrogen oxides (NOx).

One of the main technical challenges is improving fuel efficiency without compromising power output. V8 engines typically consume more fuel than smaller engines, making it difficult to meet fuel economy standards. Engineers are exploring various technologies such as direct injection, variable valve timing, and cylinder deactivation to address this issue. However, integrating these technologies while preserving the distinctive V8 sound and feel presents a complex engineering task.

Another significant challenge is reducing NOx emissions. V8 engines, especially in high-performance applications, tend to produce higher levels of NOx due to their higher combustion temperatures. Advanced exhaust after-treatment systems, such as selective catalytic reduction (SCR) and lean NOx traps, are being developed and refined to tackle this problem. However, these systems add complexity, weight, and cost to the vehicle.

The transition to electrification poses a unique challenge for V8 engines. As the automotive industry moves towards hybrid and electric powertrains, manufacturers must find ways to integrate electric motors with V8 engines effectively. This hybridization process requires sophisticated control systems to manage power distribution between the combustion engine and electric motor, adding another layer of complexity to V8 engine design.

Weight reduction is another critical area of focus. V8 engines are inherently heavier than smaller engines, which impacts overall vehicle efficiency. Engineers are exploring the use of lightweight materials and innovative design techniques to reduce engine weight without compromising durability or performance.

Lastly, the challenge of balancing performance with emissions compliance extends to the entire vehicle design. Aerodynamics, transmission efficiency, and overall vehicle weight all play crucial roles in meeting emissions targets. This holistic approach requires close collaboration between engine designers and other vehicle engineering teams, adding to the complexity of V8 engine development in the context of global emissions policies.

One of the main technical challenges is improving fuel efficiency without compromising power output. V8 engines typically consume more fuel than smaller engines, making it difficult to meet fuel economy standards. Engineers are exploring various technologies such as direct injection, variable valve timing, and cylinder deactivation to address this issue. However, integrating these technologies while preserving the distinctive V8 sound and feel presents a complex engineering task.

Another significant challenge is reducing NOx emissions. V8 engines, especially in high-performance applications, tend to produce higher levels of NOx due to their higher combustion temperatures. Advanced exhaust after-treatment systems, such as selective catalytic reduction (SCR) and lean NOx traps, are being developed and refined to tackle this problem. However, these systems add complexity, weight, and cost to the vehicle.

The transition to electrification poses a unique challenge for V8 engines. As the automotive industry moves towards hybrid and electric powertrains, manufacturers must find ways to integrate electric motors with V8 engines effectively. This hybridization process requires sophisticated control systems to manage power distribution between the combustion engine and electric motor, adding another layer of complexity to V8 engine design.

Weight reduction is another critical area of focus. V8 engines are inherently heavier than smaller engines, which impacts overall vehicle efficiency. Engineers are exploring the use of lightweight materials and innovative design techniques to reduce engine weight without compromising durability or performance.

Lastly, the challenge of balancing performance with emissions compliance extends to the entire vehicle design. Aerodynamics, transmission efficiency, and overall vehicle weight all play crucial roles in meeting emissions targets. This holistic approach requires close collaboration between engine designers and other vehicle engineering teams, adding to the complexity of V8 engine development in the context of global emissions policies.

V8 Emission Solutions

01 Emission control systems for V8 engines

Various emission control systems are developed for V8 engines to reduce harmful exhaust emissions. These systems may include catalytic converters, exhaust gas recirculation (EGR) systems, and advanced fuel injection technologies. The goal is to meet increasingly stringent emission standards while maintaining engine performance.- Emission control systems for V8 engines: Various emission control systems are developed for V8 engines to reduce harmful exhaust emissions. These systems may include catalytic converters, exhaust gas recirculation (EGR) systems, and advanced fuel injection technologies. The goal is to meet increasingly stringent emission standards while maintaining engine performance.

- Fuel efficiency improvements in V8 engines: Techniques are implemented to improve fuel efficiency in V8 engines, which in turn helps reduce emissions. These may include cylinder deactivation, variable valve timing, and advanced combustion strategies. By optimizing fuel consumption, these methods contribute to lower overall emissions from V8 engines.

- Exhaust aftertreatment technologies: Aftertreatment technologies are developed to treat exhaust gases from V8 engines before they are released into the atmosphere. These may include selective catalytic reduction (SCR) systems, diesel particulate filters (DPF), and oxidation catalysts. These technologies aim to reduce nitrogen oxides, particulate matter, and other pollutants in the exhaust.

- Engine management and control systems: Advanced engine management and control systems are implemented in V8 engines to optimize performance and emissions. These systems may use sensors, electronic control units (ECUs), and sophisticated algorithms to monitor and adjust engine parameters in real-time, ensuring optimal combustion and minimizing emissions across various operating conditions.

- Alternative fuel and hybrid technologies for V8 engines: Research is conducted on incorporating alternative fuel capabilities and hybrid technologies into V8 engines to reduce emissions. This may include adapting V8 engines to run on biofuels, developing hybrid V8 powertrains, or integrating electric assistance to reduce the overall carbon footprint of vehicles equipped with V8 engines.

02 Fuel efficiency improvements in V8 engines

Techniques are implemented to improve fuel efficiency in V8 engines, which in turn helps reduce emissions. These may include cylinder deactivation, variable valve timing, and advanced combustion strategies. By optimizing fuel consumption, these methods contribute to lower overall emissions from V8 engines.Expand Specific Solutions03 Alternative fuel systems for V8 engines

Research and development efforts focus on adapting V8 engines to use alternative fuels or hybrid systems. This includes modifications to enable the use of biofuels, natural gas, or the integration of electric powertrains. These adaptations aim to reduce reliance on traditional fossil fuels and lower emissions.Expand Specific Solutions04 Exhaust aftertreatment technologies

Advanced exhaust aftertreatment technologies are developed specifically for V8 engines. These may include selective catalytic reduction (SCR) systems, diesel particulate filters (DPF), and advanced oxidation catalysts. These technologies are designed to treat exhaust gases and reduce harmful emissions before they are released into the atmosphere.Expand Specific Solutions05 Engine management and control systems

Sophisticated engine management and control systems are implemented in V8 engines to optimize performance and emissions. These systems use advanced sensors, real-time monitoring, and adaptive algorithms to fine-tune engine operation. By precisely controlling factors such as fuel injection timing and air-fuel ratios, these systems help minimize emissions across various operating conditions.Expand Specific Solutions

Key Automotive Players

The global V8 engine market is in a mature stage, with established players and a stable demand. However, the industry is undergoing a transformation due to increasing environmental concerns and emissions regulations. The market size remains significant, driven by the automotive and marine sectors. Technologically, V8 engines are well-developed, but innovations focus on improving efficiency and reducing emissions. Key players like BMW, Honda, and Yamaha are investing in advanced technologies to meet stricter emissions standards. Research institutions such as Southwest Research Institute and universities like South China University of Technology are contributing to advancements in V8 engine technology, particularly in areas of emissions reduction and alternative fuels.

Bayerische Motoren Werke AG

Technical Solution: BMW has developed advanced V8 engines with TwinPower Turbo technology, incorporating high-precision direct fuel injection, Valvetronic variable valve timing, and Double-VANOS camshaft control [1]. These innovations have resulted in a 25% reduction in fuel consumption and CO2 emissions compared to previous generations [2]. BMW's V8 engines also feature a cross-bank exhaust manifold and optimized cooling system, further enhancing efficiency and performance [3]. The company has implemented a 48V mild-hybrid system in some V8 models, which can provide an additional 11 hp boost while reducing fuel consumption by up to 0.3 l/100 km [4].

Strengths: Advanced technology integration, significant emissions reduction, and improved fuel efficiency. Weaknesses: Higher production costs and complexity in manufacturing and maintenance.

Honda Motor Co., Ltd.

Technical Solution: Honda has focused on improving V8 engine efficiency through its Earth Dreams Technology initiative. Their V8 engines incorporate direct injection, variable cylinder management (VCM), and i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) systems [5]. The VCM system allows the engine to operate on three or four cylinders during light load conditions, significantly reducing fuel consumption and emissions [6]. Honda has also implemented a two-stage Variable Cylinder Management system in some V8 models, which can deactivate up to half of the cylinders for improved efficiency [7]. Additionally, Honda's V8 engines feature advanced thermal management systems and low-friction technologies to further enhance fuel economy and reduce emissions.

Strengths: Innovative cylinder deactivation technology, improved fuel efficiency in various driving conditions. Weaknesses: Limited V8 engine offerings compared to some competitors, potential complexity in VCM system maintenance.

V8 Efficiency Patents

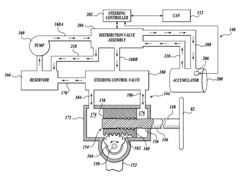

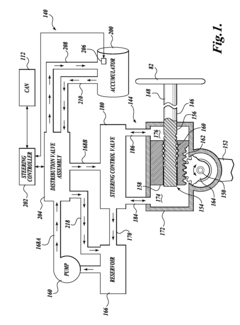

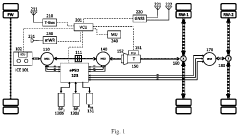

Steering systems and methods for hybrid vehicles

PatentInactiveUS20100056326A1

Innovation

- A system comprising a fuel-powered engine with an engine-on and engine-off condition, a hydraulic accumulator for storing pressure, a hydraulic motor, and a fluid pump that supplies hydraulic fluid to the motor and accumulator, along with a controlling component that monitors pressure and prevents engine shutdown if the accumulator pressure falls below a threshold, ensuring continuous power steering functionality.

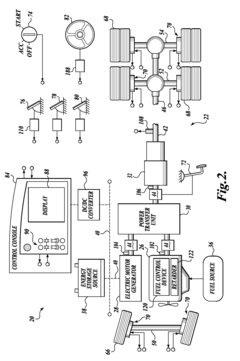

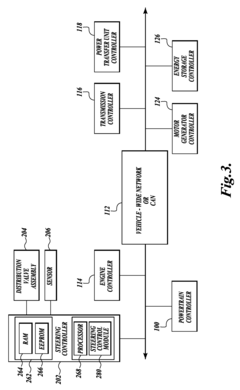

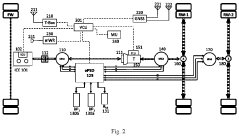

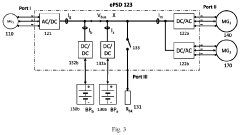

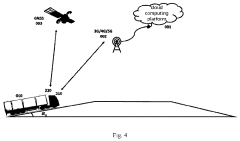

Heavy truck fuel-saving robot device and control method

PatentInactiveUS20220176965A1

Innovation

- The development of an Automated-Connected-Electrified (ACE) heavy duty truck with a double-motor and single-clutch mixed hybrid powertrain, integrating 100-kilowatt-class power electronic three-port network, Global Navigation Satellite System, 3D electronic navigation map, Internet of Things, and artificial intelligence to optimize energy management and reduce fuel consumption.

Policy Impact Analysis

The influence of V8 engines on global emissions policies has been profound and far-reaching. These powerful engines, known for their high performance and fuel consumption, have become a focal point in the ongoing debate about vehicle emissions and their impact on climate change. As governments worldwide grapple with the challenge of reducing greenhouse gas emissions, V8 engines have emerged as a symbol of the tension between automotive performance and environmental responsibility.

In response to the environmental concerns associated with V8 engines, many countries have implemented stringent emissions standards and fuel efficiency regulations. These policies have forced automakers to invest heavily in technologies that can improve the efficiency of V8 engines or develop alternative powertrains. The Corporate Average Fuel Economy (CAFE) standards in the United States, for example, have put pressure on manufacturers to balance their high-performance V8 offerings with more fuel-efficient models in their lineup.

The European Union has taken an even more aggressive stance, with plans to phase out internal combustion engines, including V8s, by 2035. This policy has accelerated the development of electric and hybrid technologies, as automakers scramble to adapt their product lines to meet future regulations. The impact of these policies extends beyond the automotive industry, influencing energy production, infrastructure development, and even urban planning.

In emerging markets, the policy response to V8 engines has been mixed. While some countries are following the lead of developed nations in implementing stricter emissions standards, others are more focused on economic growth and have been slower to adopt restrictive policies. This disparity in global policy approaches has created challenges for automakers attempting to develop global platforms and marketing strategies.

The influence of V8 engines on emissions policies has also sparked a broader debate about the role of personal transportation in addressing climate change. Policymakers are increasingly considering not just the emissions of individual vehicles, but also the overall impact of transportation systems on the environment. This has led to the development of policies that promote public transportation, car-sharing, and alternative modes of transport.

As technology advances, the policy landscape continues to evolve. The development of more efficient V8 engines, as well as hybrid and electric powertrains that can match V8 performance, is reshaping the conversation around emissions policies. Governments are now faced with the challenge of balancing environmental goals with consumer preferences and economic considerations, leading to a complex and dynamic policy environment that continues to be influenced by the legacy of the V8 engine.

In response to the environmental concerns associated with V8 engines, many countries have implemented stringent emissions standards and fuel efficiency regulations. These policies have forced automakers to invest heavily in technologies that can improve the efficiency of V8 engines or develop alternative powertrains. The Corporate Average Fuel Economy (CAFE) standards in the United States, for example, have put pressure on manufacturers to balance their high-performance V8 offerings with more fuel-efficient models in their lineup.

The European Union has taken an even more aggressive stance, with plans to phase out internal combustion engines, including V8s, by 2035. This policy has accelerated the development of electric and hybrid technologies, as automakers scramble to adapt their product lines to meet future regulations. The impact of these policies extends beyond the automotive industry, influencing energy production, infrastructure development, and even urban planning.

In emerging markets, the policy response to V8 engines has been mixed. While some countries are following the lead of developed nations in implementing stricter emissions standards, others are more focused on economic growth and have been slower to adopt restrictive policies. This disparity in global policy approaches has created challenges for automakers attempting to develop global platforms and marketing strategies.

The influence of V8 engines on emissions policies has also sparked a broader debate about the role of personal transportation in addressing climate change. Policymakers are increasingly considering not just the emissions of individual vehicles, but also the overall impact of transportation systems on the environment. This has led to the development of policies that promote public transportation, car-sharing, and alternative modes of transport.

As technology advances, the policy landscape continues to evolve. The development of more efficient V8 engines, as well as hybrid and electric powertrains that can match V8 performance, is reshaping the conversation around emissions policies. Governments are now faced with the challenge of balancing environmental goals with consumer preferences and economic considerations, leading to a complex and dynamic policy environment that continues to be influenced by the legacy of the V8 engine.

Sustainable V8 Design

The pursuit of sustainable V8 engine design represents a critical intersection between automotive engineering and environmental responsibility. As global emissions policies become increasingly stringent, manufacturers are compelled to innovate and adapt their high-performance engines to meet these challenges.

One key area of focus in sustainable V8 design is the implementation of advanced fuel injection systems. Direct injection technology, coupled with precise electronic control units, allows for more efficient fuel atomization and combustion. This results in improved fuel economy and reduced emissions without sacrificing the power output that V8 enthusiasts crave.

Cylinder deactivation is another pivotal technology in sustainable V8 design. This system allows the engine to operate on fewer cylinders during low-load conditions, significantly reducing fuel consumption and emissions during highway cruising or city driving. When full power is needed, all cylinders can be reactivated seamlessly, providing the characteristic V8 performance.

Lightweight materials play a crucial role in enhancing V8 efficiency. The use of aluminum alloys, carbon fiber, and even magnesium in engine components reduces overall weight, leading to improved power-to-weight ratios and decreased fuel consumption. These materials also contribute to better heat dissipation, allowing for more efficient thermal management.

Turbocharging and supercharging technologies are being refined to work in harmony with V8 engines, enabling manufacturers to downsize displacement while maintaining or even increasing power output. This approach, often referred to as "downspeeding," allows engines to operate at lower RPMs, reducing friction losses and improving overall efficiency.

Advanced exhaust gas recirculation (EGR) systems are being integrated into V8 designs to further reduce emissions. By recirculating a portion of the exhaust gases back into the combustion chamber, these systems lower combustion temperatures, reducing the formation of nitrogen oxides (NOx) – a major pollutant targeted by emissions regulations.

Hybrid technologies are increasingly being incorporated into V8 powertrains. Mild hybrid systems, utilizing 48-volt electrical architectures, can provide power assist during acceleration and enable more efficient start-stop functionality. More advanced hybrid systems can even allow for short periods of all-electric operation in urban environments.

The integration of artificial intelligence and machine learning algorithms in engine management systems is pushing the boundaries of V8 efficiency. These systems can continuously optimize engine performance based on driving conditions, driver behavior, and even predictive data from navigation systems, ensuring the engine operates at peak efficiency at all times.

As manufacturers continue to invest in sustainable V8 design, we can expect to see further innovations in areas such as variable compression ratios, advanced thermal management systems, and the use of sustainable biofuels. These developments will be crucial in ensuring that V8 engines can continue to thrive in an increasingly environmentally conscious automotive landscape.

One key area of focus in sustainable V8 design is the implementation of advanced fuel injection systems. Direct injection technology, coupled with precise electronic control units, allows for more efficient fuel atomization and combustion. This results in improved fuel economy and reduced emissions without sacrificing the power output that V8 enthusiasts crave.

Cylinder deactivation is another pivotal technology in sustainable V8 design. This system allows the engine to operate on fewer cylinders during low-load conditions, significantly reducing fuel consumption and emissions during highway cruising or city driving. When full power is needed, all cylinders can be reactivated seamlessly, providing the characteristic V8 performance.

Lightweight materials play a crucial role in enhancing V8 efficiency. The use of aluminum alloys, carbon fiber, and even magnesium in engine components reduces overall weight, leading to improved power-to-weight ratios and decreased fuel consumption. These materials also contribute to better heat dissipation, allowing for more efficient thermal management.

Turbocharging and supercharging technologies are being refined to work in harmony with V8 engines, enabling manufacturers to downsize displacement while maintaining or even increasing power output. This approach, often referred to as "downspeeding," allows engines to operate at lower RPMs, reducing friction losses and improving overall efficiency.

Advanced exhaust gas recirculation (EGR) systems are being integrated into V8 designs to further reduce emissions. By recirculating a portion of the exhaust gases back into the combustion chamber, these systems lower combustion temperatures, reducing the formation of nitrogen oxides (NOx) – a major pollutant targeted by emissions regulations.

Hybrid technologies are increasingly being incorporated into V8 powertrains. Mild hybrid systems, utilizing 48-volt electrical architectures, can provide power assist during acceleration and enable more efficient start-stop functionality. More advanced hybrid systems can even allow for short periods of all-electric operation in urban environments.

The integration of artificial intelligence and machine learning algorithms in engine management systems is pushing the boundaries of V8 efficiency. These systems can continuously optimize engine performance based on driving conditions, driver behavior, and even predictive data from navigation systems, ensuring the engine operates at peak efficiency at all times.

As manufacturers continue to invest in sustainable V8 design, we can expect to see further innovations in areas such as variable compression ratios, advanced thermal management systems, and the use of sustainable biofuels. These developments will be crucial in ensuring that V8 engines can continue to thrive in an increasingly environmentally conscious automotive landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!