How V8 Engines Lead in Traction Control Innovations?

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Traction Control Evolution

The evolution of traction control in V8 engines represents a significant advancement in automotive technology, showcasing the continuous innovation in vehicle safety and performance. This progression can be traced through several key stages, each marking a leap forward in how V8-powered vehicles manage power delivery and maintain stability.

In the early days of V8 engines, traction control was non-existent, relying solely on the driver's skill to manage power output. The introduction of basic traction control systems in the 1970s marked the first step towards automated management of wheel spin. These early systems were primarily mechanical, using limited-slip differentials to distribute power between wheels.

The 1980s saw the integration of electronic sensors and computerized control units, enabling more sophisticated traction management. V8 engines, known for their high torque output, particularly benefited from these advancements. Systems could now detect wheel slip more accurately and respond faster by modulating engine power or applying individual wheel brakes.

The 1990s brought about a revolution with the introduction of integrated traction and stability control systems. V8 engines, often found in high-performance and luxury vehicles, were at the forefront of implementing these technologies. These systems not only managed traction but also helped prevent skidding and loss of control during cornering.

The turn of the millennium saw the advent of torque vectoring systems, particularly beneficial for V8-powered vehicles. This technology allowed for the dynamic distribution of power not just between axles but also between individual wheels, significantly enhancing cornering ability and overall vehicle dynamics.

Recent years have witnessed the integration of artificial intelligence and predictive algorithms into traction control systems. V8 engines, with their complex power delivery characteristics, have greatly benefited from these smart systems that can anticipate traction loss and preemptively adjust power distribution.

The latest frontier in V8 engine traction control involves the integration with hybrid and electric powertrains. This combination allows for instantaneous torque management through electric motors, complementing the traditional mechanical and hydraulic systems. Such setups provide unprecedented levels of traction control, especially in high-performance applications where V8 engines are commonly used.

Throughout this evolution, V8 engines have consistently been at the cutting edge of traction control innovations. Their high power output and prevalence in performance and luxury segments have made them ideal platforms for developing and refining these technologies, often setting the standard for the broader automotive industry.

In the early days of V8 engines, traction control was non-existent, relying solely on the driver's skill to manage power output. The introduction of basic traction control systems in the 1970s marked the first step towards automated management of wheel spin. These early systems were primarily mechanical, using limited-slip differentials to distribute power between wheels.

The 1980s saw the integration of electronic sensors and computerized control units, enabling more sophisticated traction management. V8 engines, known for their high torque output, particularly benefited from these advancements. Systems could now detect wheel slip more accurately and respond faster by modulating engine power or applying individual wheel brakes.

The 1990s brought about a revolution with the introduction of integrated traction and stability control systems. V8 engines, often found in high-performance and luxury vehicles, were at the forefront of implementing these technologies. These systems not only managed traction but also helped prevent skidding and loss of control during cornering.

The turn of the millennium saw the advent of torque vectoring systems, particularly beneficial for V8-powered vehicles. This technology allowed for the dynamic distribution of power not just between axles but also between individual wheels, significantly enhancing cornering ability and overall vehicle dynamics.

Recent years have witnessed the integration of artificial intelligence and predictive algorithms into traction control systems. V8 engines, with their complex power delivery characteristics, have greatly benefited from these smart systems that can anticipate traction loss and preemptively adjust power distribution.

The latest frontier in V8 engine traction control involves the integration with hybrid and electric powertrains. This combination allows for instantaneous torque management through electric motors, complementing the traditional mechanical and hydraulic systems. Such setups provide unprecedented levels of traction control, especially in high-performance applications where V8 engines are commonly used.

Throughout this evolution, V8 engines have consistently been at the cutting edge of traction control innovations. Their high power output and prevalence in performance and luxury segments have made them ideal platforms for developing and refining these technologies, often setting the standard for the broader automotive industry.

Market Demand Analysis

The market demand for V8 engines with advanced traction control innovations has been steadily growing, driven by the increasing consumer preference for high-performance vehicles and the automotive industry's focus on safety and driving dynamics. This demand is particularly strong in the luxury and sports car segments, where V8 engines are often synonymous with power and prestige.

In recent years, there has been a notable shift in consumer expectations regarding vehicle performance. Drivers are not only seeking raw power but also demanding sophisticated control systems that can harness that power effectively. This has led to a surge in demand for V8 engines equipped with cutting-edge traction control technologies, capable of delivering optimal performance under various driving conditions.

The market for V8 engines with advanced traction control is also being fueled by the growing popularity of performance SUVs and crossovers. These vehicles combine the power of V8 engines with the practicality of larger vehicles, creating a new niche that appeals to a broader range of consumers. As a result, manufacturers are investing heavily in developing traction control innovations specifically tailored for V8-powered SUVs.

Furthermore, the motorsport industry continues to be a significant driver of demand for V8 engines with advanced traction control. Racing teams and enthusiasts are constantly seeking the latest innovations to gain a competitive edge, which in turn influences consumer preferences in the broader automotive market.

The global market for V8 engines with traction control innovations is expected to show robust growth in the coming years. This growth is supported by the increasing disposable income in emerging markets, where luxury and high-performance vehicles are gaining popularity among affluent consumers.

However, the market is not without challenges. Stringent emissions regulations and the push towards electrification are putting pressure on manufacturers to improve the efficiency of V8 engines. This has led to increased investment in technologies that can enhance both performance and fuel economy, with traction control playing a crucial role in achieving this balance.

In response to these market dynamics, automotive manufacturers are focusing on developing integrated powertrain and chassis control systems that leverage the power of V8 engines while optimizing traction and stability. This holistic approach to vehicle dynamics is expected to drive further innovations in traction control technologies for V8 engines, meeting the evolving demands of consumers and regulatory bodies alike.

In recent years, there has been a notable shift in consumer expectations regarding vehicle performance. Drivers are not only seeking raw power but also demanding sophisticated control systems that can harness that power effectively. This has led to a surge in demand for V8 engines equipped with cutting-edge traction control technologies, capable of delivering optimal performance under various driving conditions.

The market for V8 engines with advanced traction control is also being fueled by the growing popularity of performance SUVs and crossovers. These vehicles combine the power of V8 engines with the practicality of larger vehicles, creating a new niche that appeals to a broader range of consumers. As a result, manufacturers are investing heavily in developing traction control innovations specifically tailored for V8-powered SUVs.

Furthermore, the motorsport industry continues to be a significant driver of demand for V8 engines with advanced traction control. Racing teams and enthusiasts are constantly seeking the latest innovations to gain a competitive edge, which in turn influences consumer preferences in the broader automotive market.

The global market for V8 engines with traction control innovations is expected to show robust growth in the coming years. This growth is supported by the increasing disposable income in emerging markets, where luxury and high-performance vehicles are gaining popularity among affluent consumers.

However, the market is not without challenges. Stringent emissions regulations and the push towards electrification are putting pressure on manufacturers to improve the efficiency of V8 engines. This has led to increased investment in technologies that can enhance both performance and fuel economy, with traction control playing a crucial role in achieving this balance.

In response to these market dynamics, automotive manufacturers are focusing on developing integrated powertrain and chassis control systems that leverage the power of V8 engines while optimizing traction and stability. This holistic approach to vehicle dynamics is expected to drive further innovations in traction control technologies for V8 engines, meeting the evolving demands of consumers and regulatory bodies alike.

Current Challenges in V8 Traction Control

Despite the advanced nature of V8 engines and their traction control systems, several challenges persist in achieving optimal performance and safety. One of the primary issues is the management of the immense power output characteristic of V8 engines. The high torque generated can easily overwhelm the tires, leading to loss of traction, especially during acceleration or cornering on low-friction surfaces.

Another significant challenge lies in the complexity of integrating traction control systems with the V8 engine's management system. The intricate interplay between engine power, throttle response, and wheel slip requires sophisticated algorithms and real-time data processing. This integration becomes even more challenging when considering the diverse driving conditions and varying surface types that vehicles may encounter.

The weight distribution in V8-powered vehicles presents an additional hurdle for traction control systems. The typically front-heavy nature of these vehicles can lead to uneven weight transfer during acceleration and braking, complicating the task of maintaining optimal traction across all wheels. This challenge is particularly pronounced in high-performance applications where weight reduction is a priority, potentially compromising the effectiveness of traction control systems.

Fuel efficiency concerns also pose a challenge for V8 traction control innovations. The inherent fuel consumption of V8 engines necessitates careful balancing between performance and efficiency. Traction control systems must be designed to optimize power delivery while minimizing unnecessary fuel usage, a task that becomes increasingly complex as environmental regulations tighten.

The thermal management of V8 engines and their associated traction control components represents another significant challenge. The heat generated by these powerful engines can affect the performance of sensors and electronic control units critical to traction control systems. Ensuring reliable operation across a wide range of temperatures and driving conditions requires advanced cooling solutions and heat-resistant materials.

Lastly, the cost and complexity of implementing cutting-edge traction control technologies in V8-powered vehicles present ongoing challenges. Advanced sensors, high-speed processors, and sophisticated software are necessary for state-of-the-art traction control systems, potentially increasing vehicle costs and complicating maintenance procedures. Balancing these technological advancements with market demands for affordability and reliability remains a persistent challenge for manufacturers and engineers in the automotive industry.

Another significant challenge lies in the complexity of integrating traction control systems with the V8 engine's management system. The intricate interplay between engine power, throttle response, and wheel slip requires sophisticated algorithms and real-time data processing. This integration becomes even more challenging when considering the diverse driving conditions and varying surface types that vehicles may encounter.

The weight distribution in V8-powered vehicles presents an additional hurdle for traction control systems. The typically front-heavy nature of these vehicles can lead to uneven weight transfer during acceleration and braking, complicating the task of maintaining optimal traction across all wheels. This challenge is particularly pronounced in high-performance applications where weight reduction is a priority, potentially compromising the effectiveness of traction control systems.

Fuel efficiency concerns also pose a challenge for V8 traction control innovations. The inherent fuel consumption of V8 engines necessitates careful balancing between performance and efficiency. Traction control systems must be designed to optimize power delivery while minimizing unnecessary fuel usage, a task that becomes increasingly complex as environmental regulations tighten.

The thermal management of V8 engines and their associated traction control components represents another significant challenge. The heat generated by these powerful engines can affect the performance of sensors and electronic control units critical to traction control systems. Ensuring reliable operation across a wide range of temperatures and driving conditions requires advanced cooling solutions and heat-resistant materials.

Lastly, the cost and complexity of implementing cutting-edge traction control technologies in V8-powered vehicles present ongoing challenges. Advanced sensors, high-speed processors, and sophisticated software are necessary for state-of-the-art traction control systems, potentially increasing vehicle costs and complicating maintenance procedures. Balancing these technological advancements with market demands for affordability and reliability remains a persistent challenge for manufacturers and engineers in the automotive industry.

Existing V8 Traction Control Solutions

01 V8 Engine Design and Configuration

V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for improved power output and balance compared to inline engines. The design can be optimized for various applications, including automotive and marine use, with considerations for factors such as displacement, compression ratio, and valve arrangement.- V8 Engine Design and Configuration: V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for improved power output and balance compared to inline engines. The design can be optimized for various applications, including automotive and marine use, with considerations for weight distribution and overall engine efficiency.

- Traction Control Systems for V8 Engines: Traction control systems for V8 engines are designed to prevent wheel slip and maintain vehicle stability. These systems typically involve sensors to monitor wheel speed and engine output, along with electronic control units that can modulate engine power or apply brakes to individual wheels as needed. Advanced systems may integrate with other vehicle dynamics controls for improved performance.

- Engine Management and Power Distribution: Engine management systems for V8 engines focus on optimizing power distribution and fuel efficiency. These systems can include variable valve timing, direct injection, and cylinder deactivation technologies. Advanced control algorithms adjust engine parameters in real-time to balance performance and traction requirements, especially in high-performance or off-road applications.

- Integration with Vehicle Dynamics Control: Traction control in V8-powered vehicles is often integrated with broader vehicle dynamics control systems. This integration allows for coordinated management of engine output, transmission behavior, and suspension settings. The combined system can provide enhanced stability and performance across various driving conditions, from high-speed cornering to low-traction surfaces.

- Specialized Traction Control for High-Performance V8 Applications: High-performance V8 engines, such as those used in sports cars or racing applications, require specialized traction control systems. These systems are designed to manage the high torque output of V8 engines while allowing for maximum performance. Features may include driver-selectable modes, launch control, and integration with active differentials to optimize power delivery to the wheels.

02 Traction Control Systems for V8 Engines

Traction control systems are implemented in vehicles with V8 engines to improve stability and handling. These systems typically monitor wheel spin and adjust engine power or apply brakes to individual wheels to maintain traction. Advanced traction control systems may integrate with other vehicle dynamics systems for enhanced performance and safety.Expand Specific Solutions03 Engine Management and Power Distribution

Engine management systems for V8 engines are designed to optimize power distribution and efficiency. These systems can include electronic throttle control, variable valve timing, and fuel injection management. Advanced systems may also incorporate adaptive algorithms to adjust engine performance based on driving conditions and traction requirements.Expand Specific Solutions04 Integration with Vehicle Dynamics Systems

V8 engine traction control is often integrated with broader vehicle dynamics systems. This integration can include stability control, anti-lock braking systems, and torque vectoring. The combined systems work together to enhance overall vehicle performance, handling, and safety, particularly in high-performance applications.Expand Specific Solutions05 Specialized Traction Control for High-Performance V8 Engines

High-performance V8 engines often require specialized traction control systems to manage their increased power output. These systems may include launch control features, adjustable traction settings, and integration with advanced differentials. Such systems are designed to optimize acceleration and handling in various driving conditions, from track use to everyday driving.Expand Specific Solutions

Key Players in V8 Engine Industry

The V8 engine traction control innovation landscape is characterized by intense competition among major automotive manufacturers in a mature market. Industry leaders like Hyundai, GM, Honda, BMW, and Toyota are investing heavily in advanced traction control systems for V8 engines, leveraging their extensive R&D capabilities and market presence. The global market for these technologies is substantial, driven by demand for high-performance vehicles and improved safety features. While the core technology is well-established, companies are focusing on incremental improvements and integration with emerging technologies like AI and electrification to maintain competitive edge and meet evolving consumer expectations.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed a sophisticated traction control system for their V8 engines, focusing on high-performance applications. Their system utilizes advanced sensors to monitor wheel slip and vehicle dynamics in real-time. The V8 engine's power is managed through a combination of throttle control, fuel injection adjustment, and spark timing modification to optimize traction. Hyundai's innovation includes a launch control feature specifically designed for V8 engines, allowing for maximum acceleration from a standing start while minimizing wheel spin[3]. The system also incorporates a variable torque split function, which can dynamically adjust power distribution between the front and rear axles based on driving conditions and driver input[4].

Strengths: High-performance focus, advanced launch control feature, and dynamic torque distribution. Weaknesses: May be less optimized for everyday driving conditions, and the system's complexity could lead to higher production costs.

GM Global Technology Operations LLC

Technical Solution: GM has innovated in V8 traction control with their Performance Traction Management (PTM) system, specifically designed for high-output V8 engines. This system integrates traction control with stability control and magnetic ride control for a comprehensive approach to vehicle dynamics. GM's V8 traction control uses advanced algorithms to predict and mitigate wheel slip before it occurs, utilizing the engine's torque characteristics for precise power delivery. The system features multiple modes, including a "race" mode that allows for more wheel slip to achieve faster lap times on track[5]. GM has also implemented a wet-weather traction control mode that adjusts the V8 engine's power delivery to maintain stability in slippery conditions[6].

Strengths: Comprehensive integration with other vehicle systems, predictive slip control, and specialized modes for various driving conditions. Weaknesses: The system's complexity may lead to higher costs and potential reliability concerns in the long term.

Core Innovations in V8 Traction Systems

Exhaust System for an Internal Combustion Engine

PatentActiveUS20100031905A1

Innovation

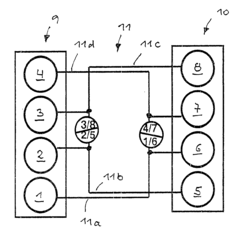

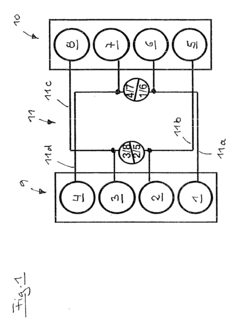

- The exhaust system is redesigned with two exhaust gas turbochargers and four exhaust lines, where each turbocharger is assigned to two cylinders with a 360° ignition interval and a 180° offset, allowing for prolonged intake valve opening and symmetrical air filling across all cylinders, using twin-scroll turbochargers arranged in the V between cylinder banks.

Control method and control device in a motor vehicle for shifting an automatic transmission

PatentWO2017025251A1

Innovation

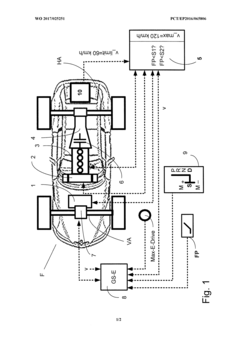

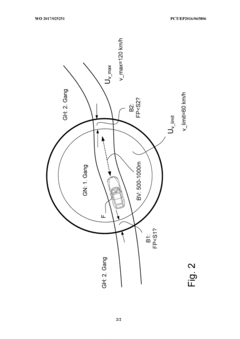

- A control method and device that uses electronic control units to analyze data from navigation systems and other sources to proactively shift gears based on look-ahead speed limits, maintaining lower gears in urban areas and shifting to higher gears when leaving such areas, ensuring optimal torque and acceleration performance.

Environmental Impact Assessment

The environmental impact of V8 engines and their traction control innovations is a complex and multifaceted issue. While these engines have traditionally been associated with high fuel consumption and increased emissions, recent advancements in traction control technology have led to some positive environmental outcomes.

V8 engines, known for their power and performance, have been a significant contributor to greenhouse gas emissions in the automotive sector. However, the integration of advanced traction control systems has resulted in more efficient power delivery and reduced fuel consumption. This optimization of power distribution has led to a decrease in overall emissions per kilometer traveled, particularly in challenging driving conditions where wheel spin and loss of traction were previously common.

The improved traction control systems in V8 engines have also contributed to reduced tire wear. By minimizing wheel spin and maintaining optimal grip, these innovations extend the lifespan of tires, reducing the frequency of replacements. This, in turn, decreases the environmental impact associated with tire production and disposal, which involves energy-intensive processes and the use of non-renewable resources.

Furthermore, the enhanced stability provided by advanced traction control systems has led to a reduction in accidents and off-road incidents involving V8-powered vehicles. This decrease in accidents not only improves safety but also reduces the environmental impact associated with vehicle repairs, replacements, and the disposal of damaged parts.

However, it is important to note that despite these improvements, V8 engines still consume more fuel compared to smaller, more efficient engine configurations. The production of V8 engines also requires more resources and energy compared to smaller engines, contributing to a larger carbon footprint in the manufacturing phase.

On a broader scale, the innovations in traction control for V8 engines have spurred research and development in vehicle dynamics and control systems. This has led to the creation of more advanced and efficient traction control technologies that are now being applied to a wide range of vehicles, including electric and hybrid models. The transfer of this technology to more environmentally friendly vehicle types has the potential to further reduce the overall environmental impact of the automotive industry.

In conclusion, while V8 engines continue to have a significant environmental impact, the innovations in traction control have led to some positive outcomes. These include improved fuel efficiency, reduced tire wear, and enhanced safety, all of which contribute to a reduction in the overall environmental footprint of V8-powered vehicles. However, the long-term sustainability of V8 engines remains a subject of debate in the context of global efforts to reduce carbon emissions and combat climate change.

V8 engines, known for their power and performance, have been a significant contributor to greenhouse gas emissions in the automotive sector. However, the integration of advanced traction control systems has resulted in more efficient power delivery and reduced fuel consumption. This optimization of power distribution has led to a decrease in overall emissions per kilometer traveled, particularly in challenging driving conditions where wheel spin and loss of traction were previously common.

The improved traction control systems in V8 engines have also contributed to reduced tire wear. By minimizing wheel spin and maintaining optimal grip, these innovations extend the lifespan of tires, reducing the frequency of replacements. This, in turn, decreases the environmental impact associated with tire production and disposal, which involves energy-intensive processes and the use of non-renewable resources.

Furthermore, the enhanced stability provided by advanced traction control systems has led to a reduction in accidents and off-road incidents involving V8-powered vehicles. This decrease in accidents not only improves safety but also reduces the environmental impact associated with vehicle repairs, replacements, and the disposal of damaged parts.

However, it is important to note that despite these improvements, V8 engines still consume more fuel compared to smaller, more efficient engine configurations. The production of V8 engines also requires more resources and energy compared to smaller engines, contributing to a larger carbon footprint in the manufacturing phase.

On a broader scale, the innovations in traction control for V8 engines have spurred research and development in vehicle dynamics and control systems. This has led to the creation of more advanced and efficient traction control technologies that are now being applied to a wide range of vehicles, including electric and hybrid models. The transfer of this technology to more environmentally friendly vehicle types has the potential to further reduce the overall environmental impact of the automotive industry.

In conclusion, while V8 engines continue to have a significant environmental impact, the innovations in traction control have led to some positive outcomes. These include improved fuel efficiency, reduced tire wear, and enhanced safety, all of which contribute to a reduction in the overall environmental footprint of V8-powered vehicles. However, the long-term sustainability of V8 engines remains a subject of debate in the context of global efforts to reduce carbon emissions and combat climate change.

Safety Regulations Compliance

V8 engines have played a significant role in advancing traction control innovations, particularly in the context of safety regulations compliance. As automotive safety standards have become increasingly stringent, manufacturers have been compelled to develop more sophisticated traction control systems to meet these requirements. V8 engines, with their inherent power and torque characteristics, have presented unique challenges and opportunities in this regard.

The implementation of traction control systems in V8-powered vehicles has been driven by the need to comply with various safety regulations, including those set by the National Highway Traffic Safety Administration (NHTSA) in the United States and the European New Car Assessment Programme (Euro NCAP) in Europe. These regulations often mandate specific performance criteria for vehicle stability and traction under various driving conditions.

One of the key areas where V8 engines have contributed to traction control innovations is in the development of advanced electronic stability control (ESC) systems. These systems are designed to detect and reduce loss of traction, particularly during cornering or on slippery surfaces. V8 engines, with their high power output, have necessitated the development of more responsive and precise ESC systems to ensure compliance with safety regulations.

Furthermore, the integration of traction control with engine management systems has been a crucial area of innovation for V8-powered vehicles. Manufacturers have developed sophisticated algorithms that can modulate engine power delivery in real-time, adjusting throttle response and fuel injection to optimize traction in various driving scenarios. This level of integration has been essential in meeting the stringent safety standards set by regulatory bodies.

Another aspect of safety regulation compliance addressed by V8 engine traction control innovations is the management of torque distribution in all-wheel-drive systems. Many high-performance V8 vehicles utilize advanced torque vectoring systems that can dynamically adjust power delivery to individual wheels, enhancing both safety and performance. These systems have been developed to ensure compliance with regulations regarding vehicle stability and handling characteristics.

The advent of electric and hybrid powertrains has also influenced traction control innovations in V8 engines. As regulations increasingly focus on emissions and fuel efficiency, manufacturers have developed hybrid V8 systems that incorporate electric motors for improved traction control. These systems not only enhance safety performance but also contribute to meeting stringent environmental regulations.

In conclusion, the evolution of traction control systems in V8 engines has been significantly influenced by the need to comply with ever-evolving safety regulations. This has led to a range of innovations that not only meet regulatory requirements but also enhance overall vehicle safety and performance, positioning V8 engines at the forefront of automotive safety technology.

The implementation of traction control systems in V8-powered vehicles has been driven by the need to comply with various safety regulations, including those set by the National Highway Traffic Safety Administration (NHTSA) in the United States and the European New Car Assessment Programme (Euro NCAP) in Europe. These regulations often mandate specific performance criteria for vehicle stability and traction under various driving conditions.

One of the key areas where V8 engines have contributed to traction control innovations is in the development of advanced electronic stability control (ESC) systems. These systems are designed to detect and reduce loss of traction, particularly during cornering or on slippery surfaces. V8 engines, with their high power output, have necessitated the development of more responsive and precise ESC systems to ensure compliance with safety regulations.

Furthermore, the integration of traction control with engine management systems has been a crucial area of innovation for V8-powered vehicles. Manufacturers have developed sophisticated algorithms that can modulate engine power delivery in real-time, adjusting throttle response and fuel injection to optimize traction in various driving scenarios. This level of integration has been essential in meeting the stringent safety standards set by regulatory bodies.

Another aspect of safety regulation compliance addressed by V8 engine traction control innovations is the management of torque distribution in all-wheel-drive systems. Many high-performance V8 vehicles utilize advanced torque vectoring systems that can dynamically adjust power delivery to individual wheels, enhancing both safety and performance. These systems have been developed to ensure compliance with regulations regarding vehicle stability and handling characteristics.

The advent of electric and hybrid powertrains has also influenced traction control innovations in V8 engines. As regulations increasingly focus on emissions and fuel efficiency, manufacturers have developed hybrid V8 systems that incorporate electric motors for improved traction control. These systems not only enhance safety performance but also contribute to meeting stringent environmental regulations.

In conclusion, the evolution of traction control systems in V8 engines has been significantly influenced by the need to comply with ever-evolving safety regulations. This has led to a range of innovations that not only meet regulatory requirements but also enhance overall vehicle safety and performance, positioning V8 engines at the forefront of automotive safety technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!