How V8 Engines Shape Electro-Mechanical Integration Strategies?

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution

The evolution of V8 engines has been a significant driver in shaping electro-mechanical integration strategies within the automotive industry. This powerful engine configuration, characterized by its V-shaped cylinder arrangement, has undergone substantial transformations since its inception in the early 20th century.

Initially, V8 engines were primarily mechanical systems with limited electronic components. The focus was on improving power output and efficiency through mechanical innovations such as overhead valves and higher compression ratios. However, as automotive technology advanced, the integration of electronic systems became increasingly crucial in enhancing engine performance and meeting stringent emissions standards.

The 1970s marked a turning point in V8 engine evolution with the introduction of electronic fuel injection systems. This development necessitated the integration of sensors, actuators, and electronic control units (ECUs) into the engine design. The shift from carburetors to fuel injection systems not only improved fuel efficiency but also laid the groundwork for more sophisticated electro-mechanical integration strategies.

In the 1980s and 1990s, the advent of computerized engine management systems further accelerated the integration of electronics into V8 engines. These systems allowed for precise control of fuel delivery, ignition timing, and emissions control devices. The increased complexity of engine control algorithms demanded more powerful ECUs and a more extensive network of sensors throughout the engine.

The turn of the millennium saw a dramatic increase in the sophistication of electro-mechanical systems in V8 engines. Variable valve timing, cylinder deactivation, and direct fuel injection technologies were introduced, all requiring intricate coordination between mechanical components and electronic control systems. These advancements not only improved performance and efficiency but also necessitated more complex integration strategies to ensure seamless operation.

Recent years have witnessed a paradigm shift in V8 engine design with the rise of hybrid and electrification technologies. Modern V8 engines often incorporate electric motors, regenerative braking systems, and advanced battery management systems. This hybridization has led to unprecedented levels of electro-mechanical integration, where the line between traditional mechanical systems and electrical components has become increasingly blurred.

The evolution of V8 engines has thus driven a continuous refinement of electro-mechanical integration strategies. From simple mechanical systems to highly sophisticated electro-mechanical powertrains, V8 engines have been at the forefront of automotive innovation. This evolution has not only improved engine performance and efficiency but has also paved the way for the development of advanced driver assistance systems and autonomous driving technologies, further emphasizing the critical role of electro-mechanical integration in modern vehicle design.

Initially, V8 engines were primarily mechanical systems with limited electronic components. The focus was on improving power output and efficiency through mechanical innovations such as overhead valves and higher compression ratios. However, as automotive technology advanced, the integration of electronic systems became increasingly crucial in enhancing engine performance and meeting stringent emissions standards.

The 1970s marked a turning point in V8 engine evolution with the introduction of electronic fuel injection systems. This development necessitated the integration of sensors, actuators, and electronic control units (ECUs) into the engine design. The shift from carburetors to fuel injection systems not only improved fuel efficiency but also laid the groundwork for more sophisticated electro-mechanical integration strategies.

In the 1980s and 1990s, the advent of computerized engine management systems further accelerated the integration of electronics into V8 engines. These systems allowed for precise control of fuel delivery, ignition timing, and emissions control devices. The increased complexity of engine control algorithms demanded more powerful ECUs and a more extensive network of sensors throughout the engine.

The turn of the millennium saw a dramatic increase in the sophistication of electro-mechanical systems in V8 engines. Variable valve timing, cylinder deactivation, and direct fuel injection technologies were introduced, all requiring intricate coordination between mechanical components and electronic control systems. These advancements not only improved performance and efficiency but also necessitated more complex integration strategies to ensure seamless operation.

Recent years have witnessed a paradigm shift in V8 engine design with the rise of hybrid and electrification technologies. Modern V8 engines often incorporate electric motors, regenerative braking systems, and advanced battery management systems. This hybridization has led to unprecedented levels of electro-mechanical integration, where the line between traditional mechanical systems and electrical components has become increasingly blurred.

The evolution of V8 engines has thus driven a continuous refinement of electro-mechanical integration strategies. From simple mechanical systems to highly sophisticated electro-mechanical powertrains, V8 engines have been at the forefront of automotive innovation. This evolution has not only improved engine performance and efficiency but has also paved the way for the development of advanced driver assistance systems and autonomous driving technologies, further emphasizing the critical role of electro-mechanical integration in modern vehicle design.

Market Demand Analysis

The market demand for V8 engines in electro-mechanical integration strategies has been evolving rapidly in recent years. This shift is driven by the automotive industry's push towards more efficient and powerful vehicles, as well as the increasing need for advanced integration between mechanical and electrical systems.

In the luxury and high-performance vehicle segments, V8 engines continue to be in high demand. These engines are prized for their smooth power delivery, distinctive sound, and ability to provide rapid acceleration. However, the market is witnessing a transformation as manufacturers seek to balance performance with fuel efficiency and emissions regulations.

The integration of V8 engines with electric powertrains has emerged as a significant trend. This hybrid approach allows automakers to maintain the appeal of V8 power while improving overall vehicle efficiency. As a result, the market for electro-mechanical integration solutions specifically tailored for V8 engines has expanded considerably.

Performance-oriented SUVs and trucks represent another growing segment where V8 engines play a crucial role. These vehicles require sophisticated integration strategies to manage power distribution, traction control, and overall vehicle dynamics. The demand for advanced electro-mechanical systems in this sector has led to increased investment in research and development.

In the motorsports industry, V8 engines remain a staple in various racing categories. The need for precise control and optimization of these engines has driven innovation in electro-mechanical integration, with technologies often trickling down to consumer vehicles.

The commercial vehicle sector, particularly in heavy-duty trucks and specialized equipment, continues to rely on V8 engines for their power and durability. In this market, the focus is on integrating V8 engines with advanced electronic control systems to improve fuel efficiency, reduce emissions, and enhance overall performance.

As environmental regulations become more stringent, the market is seeing a rise in demand for electro-mechanical solutions that can help V8 engines meet these standards. This includes advanced engine management systems, variable valve timing, and cylinder deactivation technologies, all of which require sophisticated integration strategies.

The aftermarket and performance tuning sectors also contribute significantly to the demand for V8-specific electro-mechanical integration solutions. Enthusiasts and tuning companies seek advanced control systems and integration strategies to maximize the potential of V8 engines in modified vehicles.

Overall, while the automotive industry is gradually shifting towards electrification, the market demand for V8 engines and associated electro-mechanical integration strategies remains strong in specific segments. This demand is driving innovation in powertrain technology, control systems, and vehicle architecture, shaping the future of high-performance and luxury vehicles.

In the luxury and high-performance vehicle segments, V8 engines continue to be in high demand. These engines are prized for their smooth power delivery, distinctive sound, and ability to provide rapid acceleration. However, the market is witnessing a transformation as manufacturers seek to balance performance with fuel efficiency and emissions regulations.

The integration of V8 engines with electric powertrains has emerged as a significant trend. This hybrid approach allows automakers to maintain the appeal of V8 power while improving overall vehicle efficiency. As a result, the market for electro-mechanical integration solutions specifically tailored for V8 engines has expanded considerably.

Performance-oriented SUVs and trucks represent another growing segment where V8 engines play a crucial role. These vehicles require sophisticated integration strategies to manage power distribution, traction control, and overall vehicle dynamics. The demand for advanced electro-mechanical systems in this sector has led to increased investment in research and development.

In the motorsports industry, V8 engines remain a staple in various racing categories. The need for precise control and optimization of these engines has driven innovation in electro-mechanical integration, with technologies often trickling down to consumer vehicles.

The commercial vehicle sector, particularly in heavy-duty trucks and specialized equipment, continues to rely on V8 engines for their power and durability. In this market, the focus is on integrating V8 engines with advanced electronic control systems to improve fuel efficiency, reduce emissions, and enhance overall performance.

As environmental regulations become more stringent, the market is seeing a rise in demand for electro-mechanical solutions that can help V8 engines meet these standards. This includes advanced engine management systems, variable valve timing, and cylinder deactivation technologies, all of which require sophisticated integration strategies.

The aftermarket and performance tuning sectors also contribute significantly to the demand for V8-specific electro-mechanical integration solutions. Enthusiasts and tuning companies seek advanced control systems and integration strategies to maximize the potential of V8 engines in modified vehicles.

Overall, while the automotive industry is gradually shifting towards electrification, the market demand for V8 engines and associated electro-mechanical integration strategies remains strong in specific segments. This demand is driving innovation in powertrain technology, control systems, and vehicle architecture, shaping the future of high-performance and luxury vehicles.

Technical Challenges

The integration of V8 engines into electro-mechanical systems presents several significant technical challenges that require innovative solutions. One of the primary obstacles is the management of heat generated by these powerful engines. V8 engines produce substantial thermal energy, which can adversely affect the performance and longevity of surrounding electronic components. Engineers must develop advanced cooling systems and thermal management strategies to maintain optimal operating temperatures for both the engine and the integrated electronic systems.

Another critical challenge lies in the vibration and noise produced by V8 engines. These high-performance powerplants generate considerable mechanical vibrations that can disrupt the functioning of sensitive electronic equipment. Implementing effective vibration isolation techniques and developing robust mounting systems are essential to ensure the reliability and accuracy of integrated electro-mechanical components.

The complexity of controlling V8 engines in conjunction with electronic systems poses a significant hurdle. Sophisticated engine management systems must be developed to optimize performance, fuel efficiency, and emissions while seamlessly interfacing with other vehicle systems. This requires advanced algorithms and real-time processing capabilities to handle the intricate interplay between mechanical and electronic components.

Weight distribution and packaging constraints present additional challenges in V8 engine integration. The substantial size and weight of these engines can impact vehicle dynamics and space utilization. Engineers must find innovative ways to balance the vehicle's weight distribution while accommodating the engine and necessary electronic components within limited space.

Electromagnetic interference (EMI) is another critical issue that arises when integrating V8 engines with electronic systems. The engine's ignition system and other electrical components can generate electromagnetic noise that may disrupt the functioning of sensitive electronic equipment. Implementing effective EMI shielding and developing robust electronic designs are crucial to ensure system reliability and performance.

Lastly, the integration of V8 engines with emerging technologies such as hybrid powertrains and autonomous driving systems presents new challenges. Engineers must develop strategies to seamlessly blend the traditional mechanical power of V8 engines with electric motors and advanced driver assistance systems. This requires a holistic approach to system design, considering factors such as power management, control algorithms, and system redundancy to ensure optimal performance and safety.

Another critical challenge lies in the vibration and noise produced by V8 engines. These high-performance powerplants generate considerable mechanical vibrations that can disrupt the functioning of sensitive electronic equipment. Implementing effective vibration isolation techniques and developing robust mounting systems are essential to ensure the reliability and accuracy of integrated electro-mechanical components.

The complexity of controlling V8 engines in conjunction with electronic systems poses a significant hurdle. Sophisticated engine management systems must be developed to optimize performance, fuel efficiency, and emissions while seamlessly interfacing with other vehicle systems. This requires advanced algorithms and real-time processing capabilities to handle the intricate interplay between mechanical and electronic components.

Weight distribution and packaging constraints present additional challenges in V8 engine integration. The substantial size and weight of these engines can impact vehicle dynamics and space utilization. Engineers must find innovative ways to balance the vehicle's weight distribution while accommodating the engine and necessary electronic components within limited space.

Electromagnetic interference (EMI) is another critical issue that arises when integrating V8 engines with electronic systems. The engine's ignition system and other electrical components can generate electromagnetic noise that may disrupt the functioning of sensitive electronic equipment. Implementing effective EMI shielding and developing robust electronic designs are crucial to ensure system reliability and performance.

Lastly, the integration of V8 engines with emerging technologies such as hybrid powertrains and autonomous driving systems presents new challenges. Engineers must develop strategies to seamlessly blend the traditional mechanical power of V8 engines with electric motors and advanced driver assistance systems. This requires a holistic approach to system design, considering factors such as power management, control algorithms, and system redundancy to ensure optimal performance and safety.

Current Solutions

01 Electro-mechanical integration in V8 engines

The integration of electronic and mechanical components in V8 engines to improve performance, efficiency, and control. This includes the incorporation of sensors, actuators, and electronic control units to optimize engine operation and enhance overall vehicle performance.- Electro-mechanical integration in V8 engines: Integration of electronic control systems with mechanical components in V8 engines to enhance performance, efficiency, and emissions control. This includes the incorporation of sensors, actuators, and electronic control units to optimize engine operation and power delivery.

- Advanced fuel injection systems for V8 engines: Development of sophisticated fuel injection systems tailored for V8 engines, incorporating electronic control and high-precision injectors. These systems improve fuel atomization, combustion efficiency, and power output while reducing emissions.

- Electro-mechanical valve actuation in V8 engines: Implementation of electro-mechanical valve actuation systems in V8 engines to replace traditional camshaft-driven valves. This technology allows for more precise control of valve timing and lift, resulting in improved engine performance and fuel efficiency across various operating conditions.

- Integration of electric motors in V8 hybrid powertrains: Incorporation of electric motors into V8 engine powertrains to create hybrid systems. This integration involves complex electro-mechanical coupling mechanisms and control strategies to seamlessly blend power from both the internal combustion engine and electric motor(s) for improved efficiency and performance.

- Electro-mechanical thermal management systems: Development of advanced thermal management systems for V8 engines using electro-mechanical components. These systems employ electronically controlled pumps, valves, and fans to optimize engine temperature across various operating conditions, improving efficiency and reducing emissions.

02 Advanced control systems for V8 engines

Implementation of sophisticated control systems specifically designed for V8 engines, utilizing advanced algorithms and real-time data processing to manage engine parameters such as fuel injection, ignition timing, and valve timing. These systems aim to improve engine efficiency, reduce emissions, and enhance overall performance.Expand Specific Solutions03 Electro-mechanical valve actuation in V8 engines

Development of electro-mechanical valve actuation systems for V8 engines, replacing traditional camshaft-driven valves with electronically controlled actuators. This technology allows for more precise control of valve timing and lift, potentially improving engine efficiency and performance across a wide range of operating conditions.Expand Specific Solutions04 Integration of electric motors in V8 hybrid powertrains

Incorporation of electric motors into V8 engine powertrains to create hybrid systems, combining the power of internal combustion engines with the efficiency of electric propulsion. This integration involves complex electro-mechanical systems to manage power distribution, energy recovery, and seamless transitions between power sources.Expand Specific Solutions05 Electro-mechanical thermal management in V8 engines

Implementation of advanced thermal management systems in V8 engines using electro-mechanical components. These systems may include electronically controlled coolant pumps, smart thermostats, and active cooling systems to optimize engine temperature across various operating conditions, potentially improving efficiency and reducing emissions.Expand Specific Solutions

Key Industry Players

The V8 engine integration landscape is in a mature phase, with established players like BMW, Toyota, and GM dominating the market. The global V8 engine market size is substantial, driven by demand in high-performance and luxury vehicles. Technologically, V8 engines are well-developed, with companies like Honda, Nissan, and Ford continuously refining their designs for improved efficiency and power output. However, the industry is facing challenges from electrification trends, prompting companies such as Mercedes-Benz and Yamaha to explore hybrid V8 solutions, balancing traditional performance with emerging environmental concerns.

GM Global Technology Operations LLC

Technical Solution: GM's approach to V8 engine electro-mechanical integration focuses on advanced cylinder deactivation systems. Their Dynamic Fuel Management (DFM) technology allows the engine to operate on anywhere from two to eight cylinders, depending on demand[1]. This system uses solenoids to control oil flow to the valve lifters, enabling or disabling specific cylinders as needed. GM has also integrated this technology with their eAssist mild-hybrid system, which adds a small electric motor to assist the V8 engine during acceleration and enable start-stop functionality[2]. This combination allows for improved fuel efficiency without sacrificing the power and performance associated with V8 engines.

Strengths: Improved fuel efficiency, maintained performance, seamless integration with hybrid systems. Weaknesses: Increased complexity, potential reliability concerns with more moving parts.

Honda Motor Co., Ltd.

Technical Solution: Honda's approach to V8 electro-mechanical integration is exemplified in their Variable Cylinder Management (VCM) system. This technology allows the engine to run on three, four, or all six cylinders based on driving conditions[3]. While primarily used in V6 engines, Honda has applied similar principles to their limited V8 offerings. The system uses active engine mounts and noise cancellation technology to ensure smooth operation when switching between cylinder modes. Honda has also explored integrating their i-MMD (Intelligent Multi-Mode Drive) hybrid system with larger engines, potentially including V8s, to further improve efficiency and performance[4].

Strengths: Smooth operation, improved fuel efficiency, noise reduction technology. Weaknesses: Limited experience with V8 engines, potential complexity in full integration with hybrid systems.

Core Technologies

V8 engine

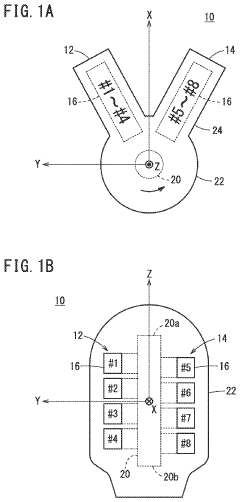

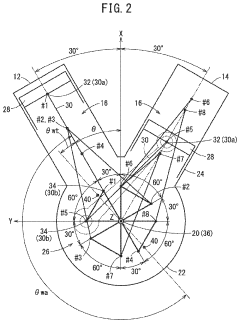

PatentActiveUS11821359B2

Innovation

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized parts by optimizing the arrangement of crank pins and connecting rods.

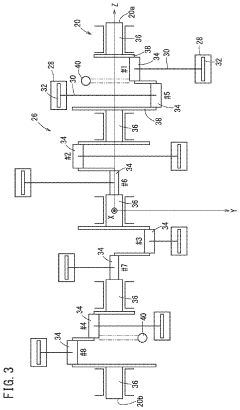

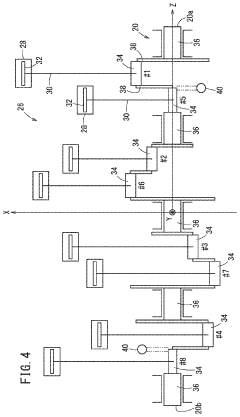

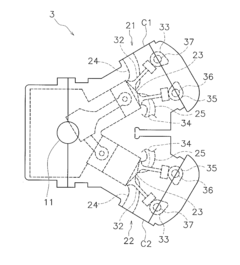

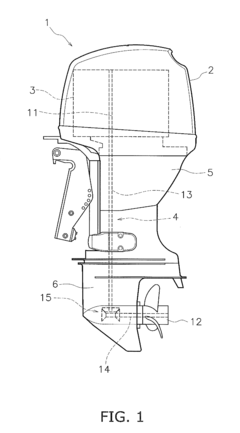

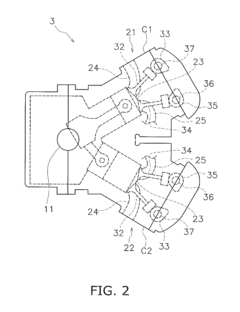

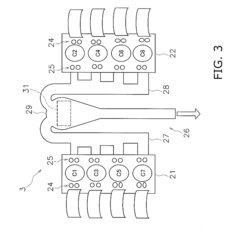

V8 engine and outboard motor

PatentActiveUS20160341097A1

Innovation

- A V8 engine design with a simple construction featuring aggregated exhaust pathways and adjustable exhaust cams, where the central angle of exhaust cams for each cylinder is optimized to minimize valve overlap and reduce exhaust interference, allowing for even firing intervals and improved exhaust gas management.

Emissions Regulations

Emissions regulations have become a critical factor in shaping the development and integration strategies of V8 engines in modern vehicles. As governments worldwide implement increasingly stringent emissions standards, manufacturers are compelled to adapt their V8 engine designs to meet these requirements while maintaining performance and efficiency.

The evolution of emissions regulations has led to significant changes in V8 engine technology. Early regulations focused primarily on reducing carbon monoxide and hydrocarbon emissions. However, as understanding of environmental impacts grew, regulations expanded to include nitrogen oxides, particulate matter, and greenhouse gases. This progression has driven the adoption of advanced technologies such as direct fuel injection, variable valve timing, and cylinder deactivation in V8 engines.

One of the most impactful emissions regulations for V8 engines has been the Corporate Average Fuel Economy (CAFE) standards in the United States. These standards have pushed manufacturers to improve fuel efficiency across their vehicle lineups, including those equipped with V8 engines. As a result, electro-mechanical integration strategies have become increasingly important in optimizing V8 engine performance while reducing fuel consumption and emissions.

The European Union's Euro emissions standards have also played a significant role in shaping V8 engine development. The progression from Euro 1 to Euro 6 has seen a dramatic reduction in allowable emissions levels, particularly for diesel engines. This has led to the integration of advanced aftertreatment systems, such as selective catalytic reduction (SCR) and diesel particulate filters (DPF), in V8 diesel engines.

China's emissions regulations, which closely follow European standards, have further influenced global V8 engine strategies. As the world's largest automotive market, China's stringent emissions requirements have compelled manufacturers to develop V8 engines that can meet these standards while still appealing to luxury and performance vehicle segments.

The impact of emissions regulations on V8 engines extends beyond just the engine itself. Electro-mechanical integration strategies now encompass the entire powertrain, including transmission systems, hybrid technologies, and even vehicle aerodynamics. This holistic approach is necessary to meet the complex demands of modern emissions standards while preserving the power and character that V8 engines are known for.

Looking ahead, upcoming regulations such as Euro 7 and the next phase of CAFE standards will continue to challenge V8 engine manufacturers. These future standards are expected to further tighten emissions limits and fuel efficiency requirements, potentially accelerating the shift towards electrification and alternative powertrain technologies. As a result, the role of electro-mechanical integration in V8 engines will become even more crucial in balancing performance, efficiency, and regulatory compliance.

The evolution of emissions regulations has led to significant changes in V8 engine technology. Early regulations focused primarily on reducing carbon monoxide and hydrocarbon emissions. However, as understanding of environmental impacts grew, regulations expanded to include nitrogen oxides, particulate matter, and greenhouse gases. This progression has driven the adoption of advanced technologies such as direct fuel injection, variable valve timing, and cylinder deactivation in V8 engines.

One of the most impactful emissions regulations for V8 engines has been the Corporate Average Fuel Economy (CAFE) standards in the United States. These standards have pushed manufacturers to improve fuel efficiency across their vehicle lineups, including those equipped with V8 engines. As a result, electro-mechanical integration strategies have become increasingly important in optimizing V8 engine performance while reducing fuel consumption and emissions.

The European Union's Euro emissions standards have also played a significant role in shaping V8 engine development. The progression from Euro 1 to Euro 6 has seen a dramatic reduction in allowable emissions levels, particularly for diesel engines. This has led to the integration of advanced aftertreatment systems, such as selective catalytic reduction (SCR) and diesel particulate filters (DPF), in V8 diesel engines.

China's emissions regulations, which closely follow European standards, have further influenced global V8 engine strategies. As the world's largest automotive market, China's stringent emissions requirements have compelled manufacturers to develop V8 engines that can meet these standards while still appealing to luxury and performance vehicle segments.

The impact of emissions regulations on V8 engines extends beyond just the engine itself. Electro-mechanical integration strategies now encompass the entire powertrain, including transmission systems, hybrid technologies, and even vehicle aerodynamics. This holistic approach is necessary to meet the complex demands of modern emissions standards while preserving the power and character that V8 engines are known for.

Looking ahead, upcoming regulations such as Euro 7 and the next phase of CAFE standards will continue to challenge V8 engine manufacturers. These future standards are expected to further tighten emissions limits and fuel efficiency requirements, potentially accelerating the shift towards electrification and alternative powertrain technologies. As a result, the role of electro-mechanical integration in V8 engines will become even more crucial in balancing performance, efficiency, and regulatory compliance.

Performance Metrics

Performance metrics play a crucial role in evaluating the effectiveness of electro-mechanical integration strategies in V8 engines. These metrics provide quantitative and qualitative measures to assess the overall performance, efficiency, and reliability of the integrated system.

One of the primary performance metrics for V8 engines is power output, typically measured in horsepower or kilowatts. This metric directly reflects the engine's ability to convert fuel energy into mechanical energy. In the context of electro-mechanical integration, power output is often optimized through advanced electronic control systems and precise mechanical components.

Fuel efficiency is another critical metric, usually expressed in miles per gallon or liters per 100 kilometers. As environmental concerns and fuel costs continue to rise, improving fuel efficiency has become a key focus in V8 engine development. Electro-mechanical integration strategies often target this metric by implementing sophisticated fuel injection systems and engine management algorithms.

Torque output and its distribution across the engine's RPM range are essential performance indicators. These metrics influence the vehicle's acceleration, towing capacity, and overall drivability. Advanced electro-mechanical systems can optimize torque delivery through variable valve timing and lift mechanisms, as well as intelligent turbocharging solutions.

Emissions performance is an increasingly important metric, particularly in light of stringent environmental regulations. This includes measurements of carbon dioxide, nitrogen oxides, and particulate matter. Electro-mechanical integration plays a vital role in minimizing emissions through precise air-fuel mixture control and advanced exhaust aftertreatment systems.

Reliability and durability metrics are crucial for assessing the long-term performance of V8 engines. These include mean time between failures (MTBF), component wear rates, and overall engine lifespan. Electro-mechanical integration strategies often focus on improving these metrics through enhanced monitoring systems, predictive maintenance algorithms, and robust design practices.

Noise, vibration, and harshness (NVH) characteristics are important performance metrics that directly impact user experience. These metrics evaluate the engine's smoothness of operation and perceived quality. Electro-mechanical integration strategies often target NVH improvements through active engine mounts, variable exhaust systems, and advanced combustion control algorithms.

Response time and throttle sensitivity are critical metrics for assessing the engine's dynamic performance. These metrics evaluate how quickly the engine responds to driver inputs and changes in operating conditions. Electro-mechanical integration strategies often focus on optimizing these aspects through advanced electronic throttle control systems and rapid-response sensors.

In conclusion, these performance metrics serve as key indicators for evaluating and guiding the development of electro-mechanical integration strategies in V8 engines. By focusing on these metrics, engineers can create more efficient, powerful, and environmentally friendly engines that meet the evolving demands of the automotive industry.

One of the primary performance metrics for V8 engines is power output, typically measured in horsepower or kilowatts. This metric directly reflects the engine's ability to convert fuel energy into mechanical energy. In the context of electro-mechanical integration, power output is often optimized through advanced electronic control systems and precise mechanical components.

Fuel efficiency is another critical metric, usually expressed in miles per gallon or liters per 100 kilometers. As environmental concerns and fuel costs continue to rise, improving fuel efficiency has become a key focus in V8 engine development. Electro-mechanical integration strategies often target this metric by implementing sophisticated fuel injection systems and engine management algorithms.

Torque output and its distribution across the engine's RPM range are essential performance indicators. These metrics influence the vehicle's acceleration, towing capacity, and overall drivability. Advanced electro-mechanical systems can optimize torque delivery through variable valve timing and lift mechanisms, as well as intelligent turbocharging solutions.

Emissions performance is an increasingly important metric, particularly in light of stringent environmental regulations. This includes measurements of carbon dioxide, nitrogen oxides, and particulate matter. Electro-mechanical integration plays a vital role in minimizing emissions through precise air-fuel mixture control and advanced exhaust aftertreatment systems.

Reliability and durability metrics are crucial for assessing the long-term performance of V8 engines. These include mean time between failures (MTBF), component wear rates, and overall engine lifespan. Electro-mechanical integration strategies often focus on improving these metrics through enhanced monitoring systems, predictive maintenance algorithms, and robust design practices.

Noise, vibration, and harshness (NVH) characteristics are important performance metrics that directly impact user experience. These metrics evaluate the engine's smoothness of operation and perceived quality. Electro-mechanical integration strategies often target NVH improvements through active engine mounts, variable exhaust systems, and advanced combustion control algorithms.

Response time and throttle sensitivity are critical metrics for assessing the engine's dynamic performance. These metrics evaluate how quickly the engine responds to driver inputs and changes in operating conditions. Electro-mechanical integration strategies often focus on optimizing these aspects through advanced electronic throttle control systems and rapid-response sensors.

In conclusion, these performance metrics serve as key indicators for evaluating and guiding the development of electro-mechanical integration strategies in V8 engines. By focusing on these metrics, engineers can create more efficient, powerful, and environmentally friendly engines that meet the evolving demands of the automotive industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!