How V8 Engines Shape Regulations for Automotive Emissions?

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution and Emission Goals

The evolution of V8 engines has been closely intertwined with the development of automotive emission regulations. Since their inception in the early 20th century, V8 engines have been prized for their power, smoothness, and distinctive sound. However, as environmental concerns grew, these engines became a focal point for emission reduction efforts.

In the 1960s and 1970s, the first major emission regulations were introduced in the United States, targeting pollutants such as carbon monoxide, hydrocarbons, and nitrogen oxides. This marked the beginning of a significant shift in V8 engine design and technology. Manufacturers were compelled to develop new solutions to meet these standards while maintaining performance.

The 1980s and 1990s saw the widespread adoption of electronic fuel injection and catalytic converters in V8 engines. These technologies allowed for more precise fuel management and reduced harmful emissions. Concurrently, emission goals became increasingly stringent, pushing engineers to innovate further.

The turn of the millennium brought about a new era of emission regulations, with a focus on reducing carbon dioxide emissions and improving fuel efficiency. This led to the development of technologies such as variable valve timing, cylinder deactivation, and direct fuel injection for V8 engines. These advancements allowed V8s to remain competitive in an increasingly environmentally conscious market.

In recent years, the push for even lower emissions has led to the integration of hybrid technologies with V8 engines. This combination allows for improved fuel efficiency and reduced emissions while maintaining the power and character that V8 enthusiasts appreciate. Some manufacturers have also explored the use of alternative fuels in V8 engines to meet stricter emission targets.

Looking forward, the future of V8 engines is closely tied to evolving emission goals. As regulations continue to tighten, particularly regarding greenhouse gas emissions, V8 engines face significant challenges. Manufacturers are exploring advanced technologies such as 48-volt mild hybrid systems, e-turbos, and even full electrification to keep V8 engines relevant in an increasingly eco-conscious automotive landscape.

The ongoing evolution of V8 engines in response to emission regulations demonstrates the automotive industry's ability to adapt and innovate. While the long-term viability of V8 engines in a zero-emission future remains uncertain, their journey thus far showcases the intricate relationship between technological advancement and environmental responsibility in the automotive sector.

In the 1960s and 1970s, the first major emission regulations were introduced in the United States, targeting pollutants such as carbon monoxide, hydrocarbons, and nitrogen oxides. This marked the beginning of a significant shift in V8 engine design and technology. Manufacturers were compelled to develop new solutions to meet these standards while maintaining performance.

The 1980s and 1990s saw the widespread adoption of electronic fuel injection and catalytic converters in V8 engines. These technologies allowed for more precise fuel management and reduced harmful emissions. Concurrently, emission goals became increasingly stringent, pushing engineers to innovate further.

The turn of the millennium brought about a new era of emission regulations, with a focus on reducing carbon dioxide emissions and improving fuel efficiency. This led to the development of technologies such as variable valve timing, cylinder deactivation, and direct fuel injection for V8 engines. These advancements allowed V8s to remain competitive in an increasingly environmentally conscious market.

In recent years, the push for even lower emissions has led to the integration of hybrid technologies with V8 engines. This combination allows for improved fuel efficiency and reduced emissions while maintaining the power and character that V8 enthusiasts appreciate. Some manufacturers have also explored the use of alternative fuels in V8 engines to meet stricter emission targets.

Looking forward, the future of V8 engines is closely tied to evolving emission goals. As regulations continue to tighten, particularly regarding greenhouse gas emissions, V8 engines face significant challenges. Manufacturers are exploring advanced technologies such as 48-volt mild hybrid systems, e-turbos, and even full electrification to keep V8 engines relevant in an increasingly eco-conscious automotive landscape.

The ongoing evolution of V8 engines in response to emission regulations demonstrates the automotive industry's ability to adapt and innovate. While the long-term viability of V8 engines in a zero-emission future remains uncertain, their journey thus far showcases the intricate relationship between technological advancement and environmental responsibility in the automotive sector.

Market Demand for High-Performance Engines

The market demand for high-performance engines, particularly V8 engines, has been a significant driver in the automotive industry for decades. Despite increasing environmental concerns and stricter emissions regulations, there remains a strong consumer appetite for powerful, high-displacement engines. This demand is primarily fueled by enthusiasts, luxury car buyers, and performance vehicle segments.

In the luxury and sports car markets, V8 engines continue to be a symbol of prestige and performance. Brands like Mercedes-AMG, BMW M, Audi RS, and Jaguar Land Rover still offer V8 options in their high-end models, catering to customers who prioritize power and driving experience over fuel efficiency. The North American market, in particular, shows a persistent demand for V8-powered vehicles, especially in the pickup truck and muscle car segments.

However, the market landscape is evolving. While there is still a core group of consumers who desire V8 engines, overall market trends are shifting towards more fuel-efficient and environmentally friendly options. This shift is driven by a combination of factors, including rising fuel costs, increasing environmental awareness, and tightening government regulations on emissions and fuel economy.

Manufacturers are responding to these changing market dynamics by developing advanced technologies to improve the efficiency of V8 engines. These include cylinder deactivation, direct injection, and turbocharging, which allow V8 engines to deliver high performance while reducing fuel consumption and emissions. Some automakers are also exploring hybrid V8 powertrains as a way to meet both performance demands and regulatory requirements.

The commercial vehicle sector, particularly heavy-duty trucks and construction equipment, continues to show strong demand for V8 engines due to their power and torque characteristics. In these applications, V8 engines often provide the best balance of performance, durability, and efficiency for demanding tasks.

Looking ahead, the market for V8 engines is likely to become more niche but will not disappear entirely. As electric vehicles gain market share and emissions regulations become stricter, V8 engines may increasingly be reserved for specialized applications, limited edition models, and high-end performance vehicles. This trend is already visible in the strategies of some automakers who are reducing their V8 offerings in mainstream models while maintaining them in their most premium and performance-oriented products.

In conclusion, while the overall automotive market is trending towards electrification and smaller, more efficient engines, there remains a significant, albeit potentially shrinking, demand for high-performance V8 engines. The challenge for manufacturers will be to continue meeting this demand while also complying with increasingly stringent emissions regulations and shifting consumer preferences.

In the luxury and sports car markets, V8 engines continue to be a symbol of prestige and performance. Brands like Mercedes-AMG, BMW M, Audi RS, and Jaguar Land Rover still offer V8 options in their high-end models, catering to customers who prioritize power and driving experience over fuel efficiency. The North American market, in particular, shows a persistent demand for V8-powered vehicles, especially in the pickup truck and muscle car segments.

However, the market landscape is evolving. While there is still a core group of consumers who desire V8 engines, overall market trends are shifting towards more fuel-efficient and environmentally friendly options. This shift is driven by a combination of factors, including rising fuel costs, increasing environmental awareness, and tightening government regulations on emissions and fuel economy.

Manufacturers are responding to these changing market dynamics by developing advanced technologies to improve the efficiency of V8 engines. These include cylinder deactivation, direct injection, and turbocharging, which allow V8 engines to deliver high performance while reducing fuel consumption and emissions. Some automakers are also exploring hybrid V8 powertrains as a way to meet both performance demands and regulatory requirements.

The commercial vehicle sector, particularly heavy-duty trucks and construction equipment, continues to show strong demand for V8 engines due to their power and torque characteristics. In these applications, V8 engines often provide the best balance of performance, durability, and efficiency for demanding tasks.

Looking ahead, the market for V8 engines is likely to become more niche but will not disappear entirely. As electric vehicles gain market share and emissions regulations become stricter, V8 engines may increasingly be reserved for specialized applications, limited edition models, and high-end performance vehicles. This trend is already visible in the strategies of some automakers who are reducing their V8 offerings in mainstream models while maintaining them in their most premium and performance-oriented products.

In conclusion, while the overall automotive market is trending towards electrification and smaller, more efficient engines, there remains a significant, albeit potentially shrinking, demand for high-performance V8 engines. The challenge for manufacturers will be to continue meeting this demand while also complying with increasingly stringent emissions regulations and shifting consumer preferences.

Current V8 Emission Challenges

V8 engines, known for their power and performance, face significant challenges in meeting increasingly stringent emission regulations. The primary issue lies in their inherent design, which typically results in higher fuel consumption and, consequently, increased emissions compared to smaller engines. This presents a complex problem for automotive manufacturers striving to balance performance with environmental responsibility.

One of the main challenges is reducing carbon dioxide (CO2) emissions. V8 engines, due to their larger displacement and higher fuel consumption, naturally produce more CO2 than their smaller counterparts. This is particularly problematic in regions with strict CO2 emission targets, such as the European Union, where fleet-wide emission standards are becoming increasingly difficult to meet with V8-powered vehicles in the lineup.

Nitrogen oxides (NOx) emissions pose another significant challenge for V8 engines. The high combustion temperatures typical of these powerful engines tend to produce elevated levels of NOx, which contributes to air pollution and the formation of smog. Addressing this issue often requires sophisticated aftertreatment systems, adding complexity and cost to the vehicle.

Particulate matter (PM) emissions, especially in direct-injection gasoline V8 engines, have also come under scrutiny. These engines can produce fine particles that are harmful to human health, necessitating the implementation of gasoline particulate filters (GPFs) similar to those used in diesel engines.

The challenge of cold-start emissions is particularly pronounced in V8 engines. During the first few minutes of operation, before the catalytic converter reaches its optimal operating temperature, emissions are significantly higher. This "cold-start" period contributes disproportionately to overall emissions, making it a key area of focus for improvement.

Fuel efficiency remains a persistent challenge for V8 engines. While technologies like cylinder deactivation and variable valve timing have improved efficiency, V8 engines still struggle to match the fuel economy of smaller, turbocharged engines. This efficiency gap translates directly into higher CO2 emissions, making it increasingly difficult to justify V8 engines in markets with strict fuel economy standards.

The implementation of real-world driving emissions (RDE) tests has further complicated the emission compliance landscape for V8 engines. These tests, which measure emissions during actual on-road driving conditions, often reveal higher emission levels than those recorded in laboratory settings. This discrepancy has forced manufacturers to develop more robust emission control strategies that perform consistently across a wide range of driving conditions.

Addressing these challenges while maintaining the performance characteristics that V8 engines are known for requires significant engineering efforts and technological innovations. As emission regulations continue to tighten globally, the future of V8 engines in mainstream vehicles remains uncertain, with manufacturers exploring various strategies to ensure compliance or considering alternative powertrain options.

One of the main challenges is reducing carbon dioxide (CO2) emissions. V8 engines, due to their larger displacement and higher fuel consumption, naturally produce more CO2 than their smaller counterparts. This is particularly problematic in regions with strict CO2 emission targets, such as the European Union, where fleet-wide emission standards are becoming increasingly difficult to meet with V8-powered vehicles in the lineup.

Nitrogen oxides (NOx) emissions pose another significant challenge for V8 engines. The high combustion temperatures typical of these powerful engines tend to produce elevated levels of NOx, which contributes to air pollution and the formation of smog. Addressing this issue often requires sophisticated aftertreatment systems, adding complexity and cost to the vehicle.

Particulate matter (PM) emissions, especially in direct-injection gasoline V8 engines, have also come under scrutiny. These engines can produce fine particles that are harmful to human health, necessitating the implementation of gasoline particulate filters (GPFs) similar to those used in diesel engines.

The challenge of cold-start emissions is particularly pronounced in V8 engines. During the first few minutes of operation, before the catalytic converter reaches its optimal operating temperature, emissions are significantly higher. This "cold-start" period contributes disproportionately to overall emissions, making it a key area of focus for improvement.

Fuel efficiency remains a persistent challenge for V8 engines. While technologies like cylinder deactivation and variable valve timing have improved efficiency, V8 engines still struggle to match the fuel economy of smaller, turbocharged engines. This efficiency gap translates directly into higher CO2 emissions, making it increasingly difficult to justify V8 engines in markets with strict fuel economy standards.

The implementation of real-world driving emissions (RDE) tests has further complicated the emission compliance landscape for V8 engines. These tests, which measure emissions during actual on-road driving conditions, often reveal higher emission levels than those recorded in laboratory settings. This discrepancy has forced manufacturers to develop more robust emission control strategies that perform consistently across a wide range of driving conditions.

Addressing these challenges while maintaining the performance characteristics that V8 engines are known for requires significant engineering efforts and technological innovations. As emission regulations continue to tighten globally, the future of V8 engines in mainstream vehicles remains uncertain, with manufacturers exploring various strategies to ensure compliance or considering alternative powertrain options.

Existing V8 Emission Control Solutions

01 Emission control systems for V8 engines

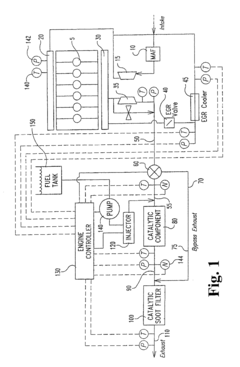

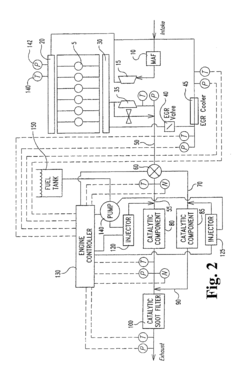

Various emission control systems are developed for V8 engines to reduce harmful exhaust emissions. These systems may include catalytic converters, exhaust gas recirculation (EGR) systems, and advanced fuel injection technologies. The goal is to meet increasingly stringent emission standards while maintaining engine performance.- Emission control systems for V8 engines: Various emission control systems are developed for V8 engines to reduce harmful exhaust emissions. These systems may include catalytic converters, exhaust gas recirculation (EGR) systems, and advanced fuel injection technologies. The goal is to meet increasingly stringent emission standards while maintaining engine performance.

- Fuel efficiency improvements in V8 engines: Techniques are implemented to improve fuel efficiency in V8 engines, which in turn helps reduce emissions. These may include cylinder deactivation, variable valve timing, and advanced combustion strategies. By optimizing fuel consumption, these methods contribute to lower overall emissions from V8 engines.

- Alternative fuel systems for V8 engines: Research and development efforts focus on adapting V8 engines to use alternative fuels or hybrid systems. This includes modifications to enable the use of biofuels, natural gas, or the integration of electric powertrains. These adaptations aim to reduce reliance on traditional fossil fuels and lower emissions.

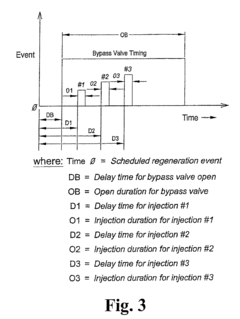

- Exhaust aftertreatment technologies: Advanced exhaust aftertreatment technologies are developed specifically for V8 engines to further reduce emissions. These may include selective catalytic reduction (SCR) systems, diesel particulate filters (DPF), and advanced oxidation catalysts. These technologies target specific pollutants in the exhaust stream to minimize environmental impact.

- Engine management and control systems: Sophisticated engine management and control systems are implemented in V8 engines to optimize performance and emissions. These systems use advanced sensors, real-time monitoring, and adaptive algorithms to fine-tune engine operation under various conditions, ensuring optimal combustion and minimizing emissions.

02 Fuel efficiency improvements in V8 engines

Techniques are implemented to improve fuel efficiency in V8 engines, which in turn helps reduce emissions. These may include cylinder deactivation, variable valve timing, and advanced combustion strategies. By optimizing fuel consumption, these methods contribute to lower overall emissions from V8 engines.Expand Specific Solutions03 Alternative fuel adaptations for V8 engines

V8 engines are modified to run on alternative fuels such as natural gas, biofuels, or hydrogen. These adaptations aim to reduce carbon emissions and dependence on fossil fuels. The modifications may involve changes to fuel delivery systems, engine management, and combustion chamber design.Expand Specific Solutions04 Exhaust aftertreatment technologies

Advanced exhaust aftertreatment technologies are developed for V8 engines to further reduce emissions. These may include selective catalytic reduction (SCR) systems, diesel particulate filters (DPF), and advanced oxidation catalysts. These technologies target specific pollutants in the exhaust stream to meet stringent emission regulations.Expand Specific Solutions05 Engine design optimizations for emission reduction

Fundamental design changes are made to V8 engines to inherently reduce emissions. These may include modifications to combustion chamber geometry, piston design, and valve configurations. The aim is to optimize the combustion process, leading to more complete fuel burning and reduced formation of pollutants.Expand Specific Solutions

Key V8 Engine Manufacturers

The V8 engine emissions regulation landscape is characterized by a mature market with established players and evolving technological standards. The industry is in a transitional phase, moving towards stricter emissions controls and alternative powertrains. Major companies like Cummins, GM, and Caterpillar are investing heavily in R&D to meet increasingly stringent regulations. The market size is substantial, driven by ongoing demand in automotive, marine, and industrial sectors. Technological maturity varies, with traditional V8 engines being well-established, but innovations in emissions reduction and efficiency are rapidly advancing. Companies such as Delphi Technology and BorgWarner are at the forefront of developing advanced emission control systems, while others like Hyundai and Ford are exploring hybrid and electric alternatives to complement their V8 offerings.

Cummins, Inc.

Technical Solution: Cummins has developed a range of technologies for V8 engines to meet emissions regulations in various markets. Their XPI (Extreme High-Pressure Injection) fuel system allows for multiple injection events per cycle, optimizing combustion and reducing emissions[8]. Cummins has also implemented advanced aftertreatment systems, including Diesel Particulate Filters (DPF) and Selective Catalytic Reduction (SCR), to meet stringent NOx and particulate matter regulations[9]. The company's V8 engines feature variable geometry turbochargers and cooled EGR systems to balance performance and emissions across a wide operating range. Cummins has invested in engine control software that uses predictive models to optimize fuel injection and air handling in real-time, further reducing emissions[10].

Strengths: Advanced fuel injection systems, comprehensive aftertreatment solutions, and sophisticated engine control software. Weaknesses: Focus on diesel V8 engines may be challenged by the shift towards electrification in some markets.

GM Global Technology Operations LLC

Technical Solution: GM has developed advanced V8 engine technologies to meet stringent emissions regulations while maintaining performance. Their Dynamic Fuel Management system allows the engine to operate on two to eight cylinders, depending on demand, significantly reducing fuel consumption and emissions[1]. GM's V8 engines also incorporate direct injection, variable valve timing, and advanced catalytic converters to minimize pollutants. The company has invested in cylinder deactivation technology, which can improve fuel efficiency by up to 15% in certain driving conditions[2]. GM's latest V8 engines are designed to be compatible with renewable fuels, including E85 ethanol blends, to further reduce carbon emissions[3].

Strengths: Advanced fuel management systems, compatibility with renewable fuels, and significant improvements in fuel efficiency. Weaknesses: Complexity of systems may lead to higher maintenance costs, and the continued focus on V8 engines may conflict with stricter future emissions standards.

Innovative V8 Emission Reduction Technologies

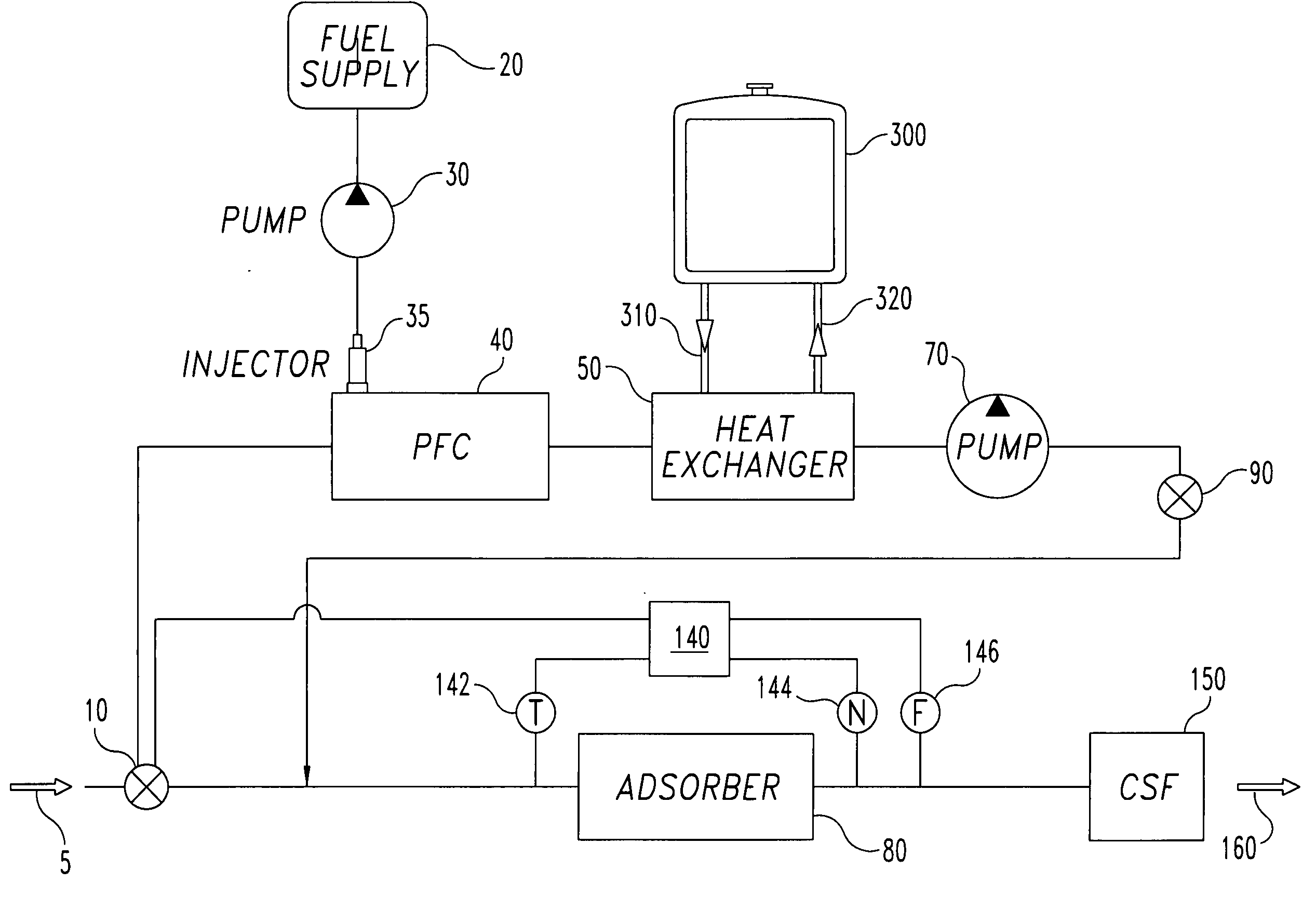

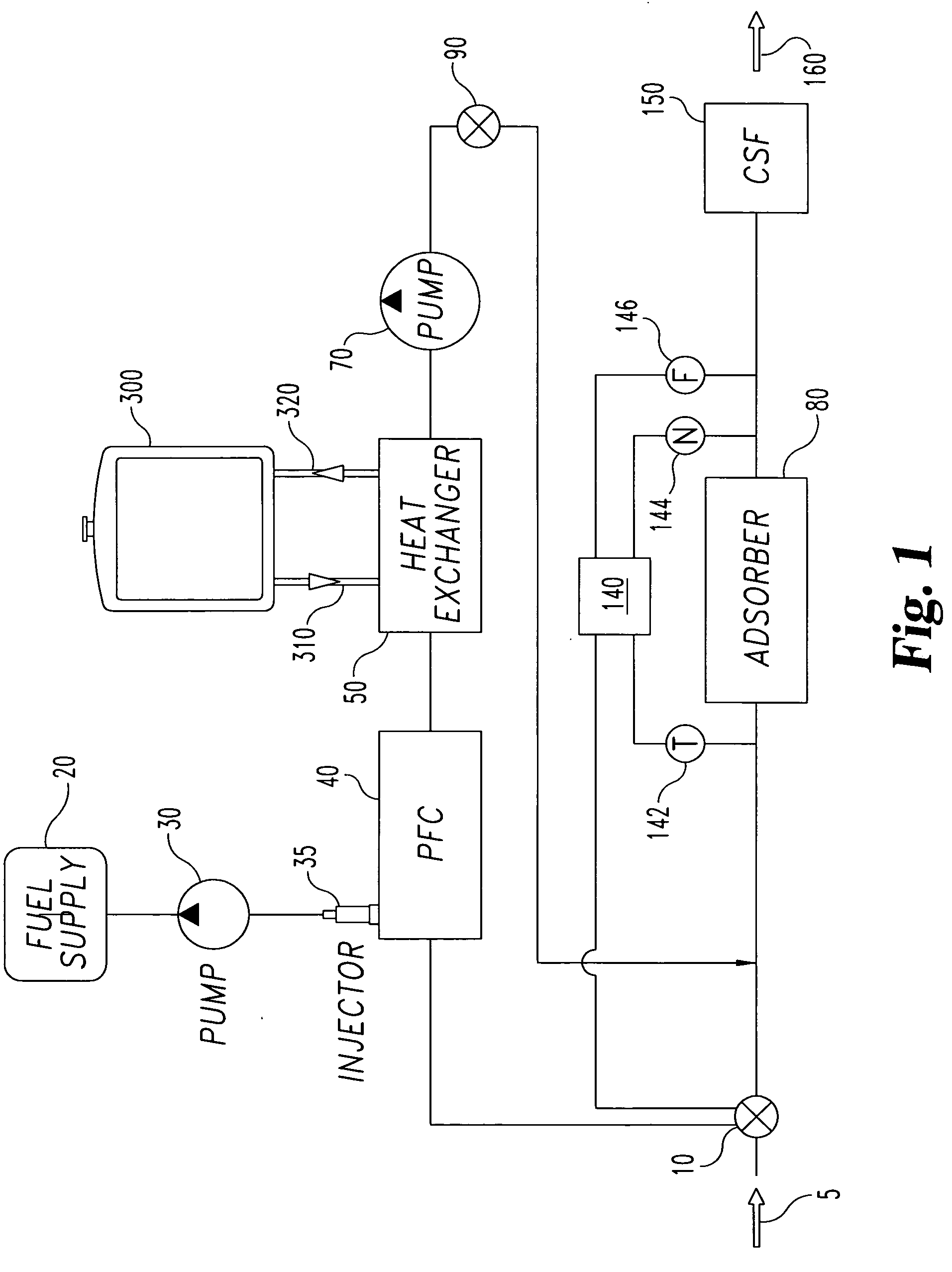

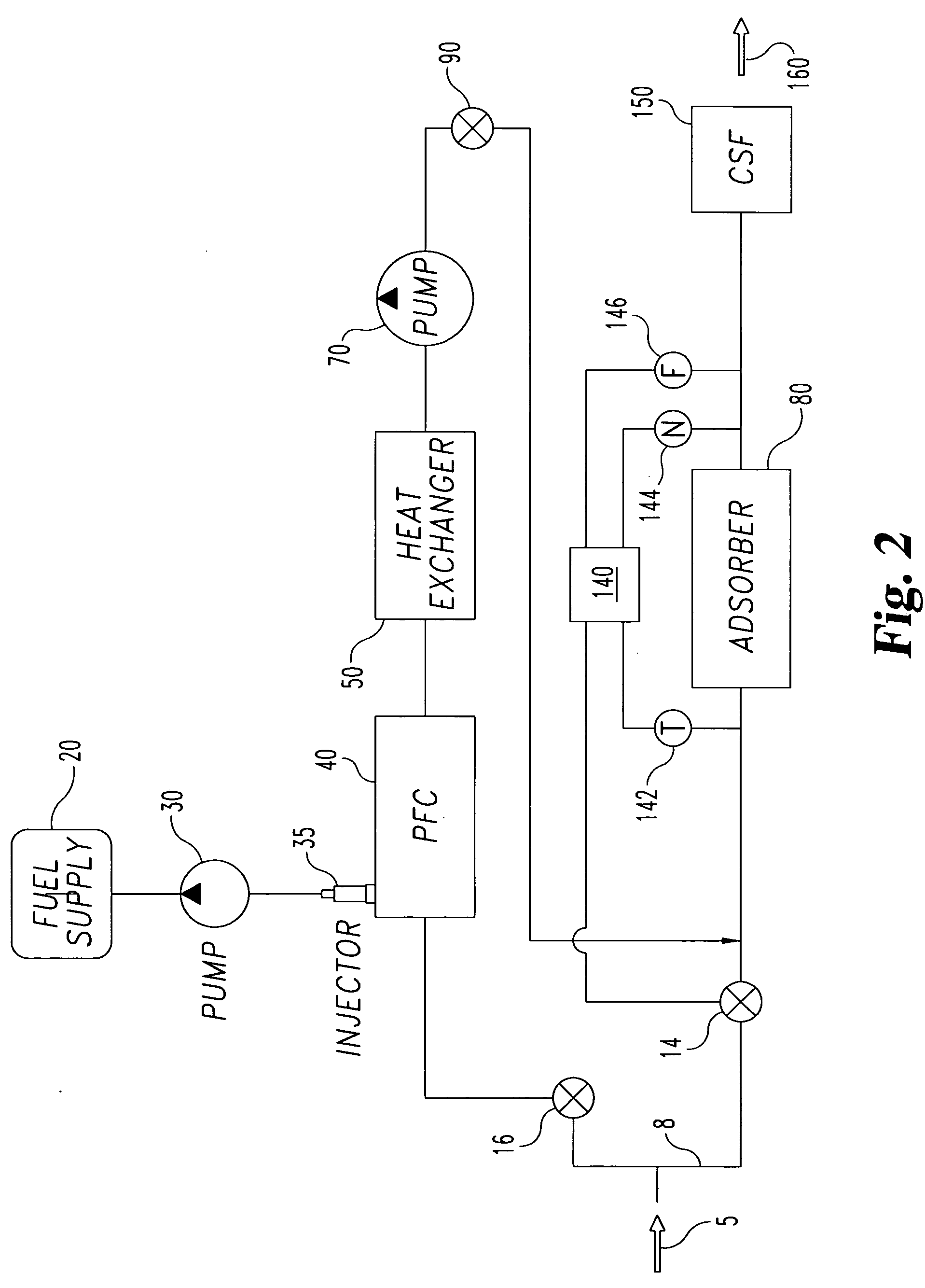

Plasma fuel converter NOx adsorber system for exhaust aftertreatment

PatentInactiveUS20050178107A1

Innovation

- A plasma fuel converter (PFC) system is used upstream of NOx adsorbers to regenerate NOx adsorbents, utilizing a slip-stream of engine exhaust, injected fuel, and electrical current to produce reductants like CO and H2, which are stored and delivered as needed to NOx adsorbers and other aftertreatment components, allowing for continuous or intermittent operation without a dedicated water supply and minimizing fuel consumption.

Reductant injection rate shaping method for regeneration of aftertreatment systems

PatentActiveUS20100043399A1

Innovation

- A method involving the controlled introduction of reductants into the exhaust gas aftertreatment system in discrete portions, with pauses between each portion and reduced exhaust gas flow to create rich conditions, minimizing the amount of reductant required and reducing unreacted reductant passage, utilizing a dedicated reductant injection system and closed or open control systems to optimize regeneration efficiency.

Global Automotive Emission Regulations

Global automotive emission regulations have evolved significantly over the past few decades, driven by increasing concerns about air pollution and climate change. These regulations vary across different regions but generally aim to reduce harmful emissions from vehicles, particularly those equipped with V8 engines.

In the United States, the Environmental Protection Agency (EPA) sets federal standards for vehicle emissions. The Clean Air Act of 1970 established the foundation for these regulations, which have become increasingly stringent over time. The Corporate Average Fuel Economy (CAFE) standards, introduced in 1975, further incentivize manufacturers to produce more fuel-efficient vehicles, indirectly impacting emissions from V8 engines.

The European Union has implemented a series of Euro emission standards, starting with Euro 1 in 1992 and progressing to the current Euro 6 standard. These regulations set limits on various pollutants, including carbon monoxide, nitrogen oxides, and particulate matter. The EU's approach has been particularly challenging for V8 engines, which typically produce higher emissions than smaller engines.

In China, the world's largest automotive market, emission standards have rapidly evolved to address severe air pollution issues. The country has adopted standards similar to Euro norms, with major cities often implementing stricter regulations ahead of national rollouts. This has led to significant challenges for manufacturers of V8-powered vehicles in the Chinese market.

Japan, known for its stringent environmental policies, has implemented its own set of emission regulations. The Japanese government has focused on promoting fuel-efficient vehicles through tax incentives and strict emission limits, which has indirectly affected the viability of V8 engines in the Japanese market.

Emerging markets, such as India and Brazil, have also been adopting more stringent emission norms, often following European standards with a time lag. This global trend towards stricter regulations has forced automakers to invest heavily in technologies to reduce emissions from V8 engines or to shift towards smaller, more efficient powertrains.

The impact of these regulations on V8 engines has been profound. Manufacturers have had to implement various technologies, such as direct injection, variable valve timing, and cylinder deactivation, to meet emission standards while maintaining performance. In some cases, automakers have opted to downsize their engines or switch to forced induction to achieve better efficiency and lower emissions.

In the United States, the Environmental Protection Agency (EPA) sets federal standards for vehicle emissions. The Clean Air Act of 1970 established the foundation for these regulations, which have become increasingly stringent over time. The Corporate Average Fuel Economy (CAFE) standards, introduced in 1975, further incentivize manufacturers to produce more fuel-efficient vehicles, indirectly impacting emissions from V8 engines.

The European Union has implemented a series of Euro emission standards, starting with Euro 1 in 1992 and progressing to the current Euro 6 standard. These regulations set limits on various pollutants, including carbon monoxide, nitrogen oxides, and particulate matter. The EU's approach has been particularly challenging for V8 engines, which typically produce higher emissions than smaller engines.

In China, the world's largest automotive market, emission standards have rapidly evolved to address severe air pollution issues. The country has adopted standards similar to Euro norms, with major cities often implementing stricter regulations ahead of national rollouts. This has led to significant challenges for manufacturers of V8-powered vehicles in the Chinese market.

Japan, known for its stringent environmental policies, has implemented its own set of emission regulations. The Japanese government has focused on promoting fuel-efficient vehicles through tax incentives and strict emission limits, which has indirectly affected the viability of V8 engines in the Japanese market.

Emerging markets, such as India and Brazil, have also been adopting more stringent emission norms, often following European standards with a time lag. This global trend towards stricter regulations has forced automakers to invest heavily in technologies to reduce emissions from V8 engines or to shift towards smaller, more efficient powertrains.

The impact of these regulations on V8 engines has been profound. Manufacturers have had to implement various technologies, such as direct injection, variable valve timing, and cylinder deactivation, to meet emission standards while maintaining performance. In some cases, automakers have opted to downsize their engines or switch to forced induction to achieve better efficiency and lower emissions.

V8 Engine Sustainability Initiatives

V8 engine manufacturers are increasingly focusing on sustainability initiatives to address environmental concerns and meet stringent emissions regulations. These initiatives encompass a wide range of strategies aimed at reducing the environmental impact of V8 engines while maintaining their performance characteristics.

One key area of focus is the development of advanced fuel injection systems. Direct injection technology, for instance, has been widely adopted to improve fuel efficiency and reduce emissions. By precisely controlling the amount and timing of fuel delivery, these systems optimize combustion processes, resulting in lower fuel consumption and reduced pollutant formation.

Engine management systems have also undergone significant improvements. Modern V8 engines utilize sophisticated electronic control units (ECUs) that continuously monitor and adjust various engine parameters in real-time. These systems optimize air-fuel ratios, ignition timing, and valve timing to maximize efficiency and minimize emissions across different operating conditions.

Lightweight materials and advanced manufacturing techniques play a crucial role in V8 engine sustainability efforts. The use of aluminum alloys, composite materials, and high-strength steels has led to significant weight reductions in engine components. This not only improves fuel efficiency but also reduces the overall environmental impact of vehicle production and operation.

Thermal management has emerged as another critical area for sustainability improvements. Advanced cooling systems, including variable-speed water pumps and intelligent thermostat control, help maintain optimal engine temperatures. This results in improved efficiency, reduced friction losses, and lower emissions, particularly during cold starts and warm-up periods.

Exhaust gas recirculation (EGR) systems have been refined to further reduce emissions. By recirculating a portion of exhaust gases back into the combustion chamber, EGR systems lower combustion temperatures, reducing the formation of nitrogen oxides (NOx). Advanced EGR systems incorporate precise control mechanisms and cooling technologies to maximize their effectiveness across various operating conditions.

Cylinder deactivation technology has gained prominence in V8 engine sustainability initiatives. This system allows the engine to selectively shut down cylinders during low-load conditions, effectively operating as a smaller, more efficient engine. By reducing pumping losses and improving thermal efficiency, cylinder deactivation significantly enhances fuel economy without compromising performance when full power is needed.

Looking ahead, V8 engine manufacturers are exploring hybrid and mild-hybrid technologies to further improve sustainability. These systems integrate electric motors and battery packs with traditional V8 engines, enabling features such as regenerative braking, electric boost, and start-stop functionality. By leveraging the strengths of both internal combustion and electric propulsion, these hybrid V8 powertrains offer a promising path towards reduced emissions and improved efficiency.

One key area of focus is the development of advanced fuel injection systems. Direct injection technology, for instance, has been widely adopted to improve fuel efficiency and reduce emissions. By precisely controlling the amount and timing of fuel delivery, these systems optimize combustion processes, resulting in lower fuel consumption and reduced pollutant formation.

Engine management systems have also undergone significant improvements. Modern V8 engines utilize sophisticated electronic control units (ECUs) that continuously monitor and adjust various engine parameters in real-time. These systems optimize air-fuel ratios, ignition timing, and valve timing to maximize efficiency and minimize emissions across different operating conditions.

Lightweight materials and advanced manufacturing techniques play a crucial role in V8 engine sustainability efforts. The use of aluminum alloys, composite materials, and high-strength steels has led to significant weight reductions in engine components. This not only improves fuel efficiency but also reduces the overall environmental impact of vehicle production and operation.

Thermal management has emerged as another critical area for sustainability improvements. Advanced cooling systems, including variable-speed water pumps and intelligent thermostat control, help maintain optimal engine temperatures. This results in improved efficiency, reduced friction losses, and lower emissions, particularly during cold starts and warm-up periods.

Exhaust gas recirculation (EGR) systems have been refined to further reduce emissions. By recirculating a portion of exhaust gases back into the combustion chamber, EGR systems lower combustion temperatures, reducing the formation of nitrogen oxides (NOx). Advanced EGR systems incorporate precise control mechanisms and cooling technologies to maximize their effectiveness across various operating conditions.

Cylinder deactivation technology has gained prominence in V8 engine sustainability initiatives. This system allows the engine to selectively shut down cylinders during low-load conditions, effectively operating as a smaller, more efficient engine. By reducing pumping losses and improving thermal efficiency, cylinder deactivation significantly enhances fuel economy without compromising performance when full power is needed.

Looking ahead, V8 engine manufacturers are exploring hybrid and mild-hybrid technologies to further improve sustainability. These systems integrate electric motors and battery packs with traditional V8 engines, enabling features such as regenerative braking, electric boost, and start-stop functionality. By leveraging the strengths of both internal combustion and electric propulsion, these hybrid V8 powertrains offer a promising path towards reduced emissions and improved efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!