Hypochlorous Acid: Transforming Water Treatment Solutions

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HOCL Tech Background

Hypochlorous acid (HOCl) has emerged as a revolutionary solution in water treatment, marking a significant milestone in the evolution of disinfection technologies. This naturally occurring compound, found in the human immune system, has been harnessed for its powerful antimicrobial properties, offering a safer and more effective alternative to traditional chemical disinfectants.

The journey of HOCl in water treatment began in the early 20th century when it was first identified as a key component in chlorine-based disinfection processes. However, it wasn't until recent decades that technological advancements allowed for the stable production and application of HOCl as a standalone solution. This breakthrough has paved the way for its widespread adoption in various industries, including municipal water treatment, healthcare, agriculture, and food processing.

The growing interest in HOCl stems from its unique characteristics that address many of the limitations associated with conventional disinfectants. Unlike chlorine-based products, HOCl is non-toxic, non-corrosive, and environmentally friendly, making it an ideal choice for sustainable water treatment practices. Its efficacy against a broad spectrum of pathogens, including bacteria, viruses, and fungi, coupled with its rapid action and lack of harmful byproducts, positions HOCl as a superior disinfection agent.

The technological evolution of HOCl production has been driven by the need for more efficient and cost-effective water treatment solutions. Early methods of generating HOCl were complex and unstable, limiting its practical applications. However, recent innovations in electrochemical activation (ECA) technology have revolutionized HOCl production, enabling on-site generation of the compound from simple salt and water. This development has significantly reduced costs and improved accessibility, making HOCl a viable option for a wide range of applications.

As the water treatment industry faces increasing challenges, including emerging contaminants, stricter regulations, and growing demand for sustainable solutions, HOCl technology continues to evolve. Current research focuses on optimizing production methods, enhancing stability, and expanding applications. The integration of HOCl with other advanced water treatment technologies, such as membrane filtration and UV disinfection, is also being explored to create more comprehensive and efficient water treatment systems.

The future trajectory of HOCl in water treatment is promising, with ongoing efforts to standardize its use and develop new applications. As awareness of its benefits grows, HOCl is expected to play an increasingly significant role in addressing global water quality challenges, contributing to improved public health and environmental sustainability.

The journey of HOCl in water treatment began in the early 20th century when it was first identified as a key component in chlorine-based disinfection processes. However, it wasn't until recent decades that technological advancements allowed for the stable production and application of HOCl as a standalone solution. This breakthrough has paved the way for its widespread adoption in various industries, including municipal water treatment, healthcare, agriculture, and food processing.

The growing interest in HOCl stems from its unique characteristics that address many of the limitations associated with conventional disinfectants. Unlike chlorine-based products, HOCl is non-toxic, non-corrosive, and environmentally friendly, making it an ideal choice for sustainable water treatment practices. Its efficacy against a broad spectrum of pathogens, including bacteria, viruses, and fungi, coupled with its rapid action and lack of harmful byproducts, positions HOCl as a superior disinfection agent.

The technological evolution of HOCl production has been driven by the need for more efficient and cost-effective water treatment solutions. Early methods of generating HOCl were complex and unstable, limiting its practical applications. However, recent innovations in electrochemical activation (ECA) technology have revolutionized HOCl production, enabling on-site generation of the compound from simple salt and water. This development has significantly reduced costs and improved accessibility, making HOCl a viable option for a wide range of applications.

As the water treatment industry faces increasing challenges, including emerging contaminants, stricter regulations, and growing demand for sustainable solutions, HOCl technology continues to evolve. Current research focuses on optimizing production methods, enhancing stability, and expanding applications. The integration of HOCl with other advanced water treatment technologies, such as membrane filtration and UV disinfection, is also being explored to create more comprehensive and efficient water treatment systems.

The future trajectory of HOCl in water treatment is promising, with ongoing efforts to standardize its use and develop new applications. As awareness of its benefits grows, HOCl is expected to play an increasingly significant role in addressing global water quality challenges, contributing to improved public health and environmental sustainability.

Market Demand Analysis

The market demand for hypochlorous acid (HOCl) in water treatment solutions has been experiencing significant growth in recent years. This surge is primarily driven by the increasing awareness of water quality issues and the need for more effective, environmentally friendly disinfection methods. HOCl offers a unique combination of high efficacy and low toxicity, making it an attractive option for various water treatment applications.

In the municipal water treatment sector, there is a growing demand for HOCl-based systems as an alternative to traditional chlorine-based treatments. This shift is motivated by concerns over the formation of harmful disinfection by-products associated with chlorine use. HOCl provides effective disinfection without these drawbacks, leading to increased adoption by water utilities seeking to improve water quality and safety for consumers.

The industrial sector represents another significant market for HOCl water treatment solutions. Industries such as food and beverage processing, pharmaceuticals, and electronics manufacturing require high-purity water for their operations. HOCl systems offer these industries a reliable method to achieve stringent water quality standards while minimizing chemical residues and environmental impact.

Healthcare facilities, including hospitals and clinics, are also driving demand for HOCl-based water treatment. The need for effective disinfection to prevent healthcare-associated infections has led to increased interest in HOCl solutions for water systems, surface disinfection, and wound care applications. The non-toxic nature of HOCl makes it particularly suitable for healthcare environments where patient safety is paramount.

The agriculture sector is emerging as a promising market for HOCl water treatment. Farmers are increasingly adopting HOCl systems for irrigation water treatment, livestock drinking water, and post-harvest produce washing. The ability of HOCl to effectively control pathogens without leaving harmful residues aligns well with the growing trend towards sustainable and organic farming practices.

In the consumer market, there is rising demand for HOCl-based products for home water treatment and personal care. Portable HOCl generators and ready-to-use solutions are gaining popularity among health-conscious consumers seeking safe and effective alternatives to traditional chemical disinfectants.

The global market for HOCl in water treatment is expected to continue its upward trajectory. Factors such as stringent water quality regulations, increasing industrialization in developing countries, and growing concerns over waterborne diseases are likely to fuel further demand. Additionally, the ongoing research into new applications and delivery methods for HOCl is expected to open up new market opportunities in the coming years.

In the municipal water treatment sector, there is a growing demand for HOCl-based systems as an alternative to traditional chlorine-based treatments. This shift is motivated by concerns over the formation of harmful disinfection by-products associated with chlorine use. HOCl provides effective disinfection without these drawbacks, leading to increased adoption by water utilities seeking to improve water quality and safety for consumers.

The industrial sector represents another significant market for HOCl water treatment solutions. Industries such as food and beverage processing, pharmaceuticals, and electronics manufacturing require high-purity water for their operations. HOCl systems offer these industries a reliable method to achieve stringent water quality standards while minimizing chemical residues and environmental impact.

Healthcare facilities, including hospitals and clinics, are also driving demand for HOCl-based water treatment. The need for effective disinfection to prevent healthcare-associated infections has led to increased interest in HOCl solutions for water systems, surface disinfection, and wound care applications. The non-toxic nature of HOCl makes it particularly suitable for healthcare environments where patient safety is paramount.

The agriculture sector is emerging as a promising market for HOCl water treatment. Farmers are increasingly adopting HOCl systems for irrigation water treatment, livestock drinking water, and post-harvest produce washing. The ability of HOCl to effectively control pathogens without leaving harmful residues aligns well with the growing trend towards sustainable and organic farming practices.

In the consumer market, there is rising demand for HOCl-based products for home water treatment and personal care. Portable HOCl generators and ready-to-use solutions are gaining popularity among health-conscious consumers seeking safe and effective alternatives to traditional chemical disinfectants.

The global market for HOCl in water treatment is expected to continue its upward trajectory. Factors such as stringent water quality regulations, increasing industrialization in developing countries, and growing concerns over waterborne diseases are likely to fuel further demand. Additionally, the ongoing research into new applications and delivery methods for HOCl is expected to open up new market opportunities in the coming years.

HOCL Challenges

Despite the numerous advantages of Hypochlorous Acid (HOCl) in water treatment solutions, several challenges hinder its widespread adoption and optimal utilization. One of the primary obstacles is the stability of HOCl solutions. The compound is inherently unstable and tends to degrade over time, particularly when exposed to light, heat, or organic matter. This instability necessitates careful storage and handling procedures, which can be challenging in various operational environments.

Another significant challenge is the production and maintenance of consistent HOCl concentrations. The effectiveness of HOCl as a disinfectant is highly dependent on its concentration, and maintaining the optimal level requires precise control mechanisms. Fluctuations in pH, temperature, and other environmental factors can affect the equilibrium between HOCl and its dissociated forms, potentially reducing its efficacy.

The pH-dependent nature of HOCl presents an additional hurdle. The compound is most effective as a disinfectant at a pH range of 5.5 to 7.5. Outside this range, it may convert to less effective forms or lose its antimicrobial properties altogether. Maintaining the ideal pH in diverse water treatment scenarios can be technically demanding and resource-intensive.

Scale-up and integration of HOCl generation systems into existing water treatment infrastructure pose significant engineering challenges. Many current HOCl production methods are designed for small-scale or point-of-use applications. Adapting these technologies for large-scale municipal water treatment plants requires substantial modifications and investments in equipment and processes.

The perception and regulatory landscape surrounding HOCl also present obstacles. Despite its effectiveness and safety profile, there is still limited awareness and acceptance of HOCl as a mainstream water treatment solution among policymakers, water treatment professionals, and the general public. Regulatory frameworks in many regions have not fully caught up with the potential of HOCl, leading to hesitation in its adoption.

Lastly, the economic aspects of implementing HOCl-based water treatment solutions can be challenging. While the operational costs of HOCl generation can be lower than traditional chlorine-based methods in the long run, the initial capital investment for equipment and training can be substantial. This economic barrier can be particularly significant for smaller municipalities or developing regions with limited resources.

Addressing these challenges requires a multifaceted approach involving continued research and development, public education, regulatory engagement, and innovative engineering solutions. Overcoming these hurdles will be crucial in realizing the full potential of HOCl in transforming water treatment solutions globally.

Another significant challenge is the production and maintenance of consistent HOCl concentrations. The effectiveness of HOCl as a disinfectant is highly dependent on its concentration, and maintaining the optimal level requires precise control mechanisms. Fluctuations in pH, temperature, and other environmental factors can affect the equilibrium between HOCl and its dissociated forms, potentially reducing its efficacy.

The pH-dependent nature of HOCl presents an additional hurdle. The compound is most effective as a disinfectant at a pH range of 5.5 to 7.5. Outside this range, it may convert to less effective forms or lose its antimicrobial properties altogether. Maintaining the ideal pH in diverse water treatment scenarios can be technically demanding and resource-intensive.

Scale-up and integration of HOCl generation systems into existing water treatment infrastructure pose significant engineering challenges. Many current HOCl production methods are designed for small-scale or point-of-use applications. Adapting these technologies for large-scale municipal water treatment plants requires substantial modifications and investments in equipment and processes.

The perception and regulatory landscape surrounding HOCl also present obstacles. Despite its effectiveness and safety profile, there is still limited awareness and acceptance of HOCl as a mainstream water treatment solution among policymakers, water treatment professionals, and the general public. Regulatory frameworks in many regions have not fully caught up with the potential of HOCl, leading to hesitation in its adoption.

Lastly, the economic aspects of implementing HOCl-based water treatment solutions can be challenging. While the operational costs of HOCl generation can be lower than traditional chlorine-based methods in the long run, the initial capital investment for equipment and training can be substantial. This economic barrier can be particularly significant for smaller municipalities or developing regions with limited resources.

Addressing these challenges requires a multifaceted approach involving continued research and development, public education, regulatory engagement, and innovative engineering solutions. Overcoming these hurdles will be crucial in realizing the full potential of HOCl in transforming water treatment solutions globally.

Current HOCL Solutions

01 Generation of hypochlorous acid for water treatment

Methods for producing hypochlorous acid solutions for water treatment applications. This involves electrolysis of salt water or other chloride-containing solutions to generate hypochlorous acid, which can be used as a disinfectant and sanitizer in water treatment processes.- Hypochlorous acid generation for water treatment: Methods and systems for generating hypochlorous acid for water treatment applications. This involves electrolysis of salt solutions or other chemical processes to produce hypochlorous acid, which is then used as a disinfectant in various water treatment scenarios.

- Hypochlorous acid-based disinfection systems: Development of specialized systems and equipment for applying hypochlorous acid in water disinfection processes. These systems may include storage tanks, dosing mechanisms, and monitoring devices to ensure effective and controlled application of hypochlorous acid in water treatment.

- Combination of hypochlorous acid with other treatment methods: Integration of hypochlorous acid treatment with other water purification techniques such as filtration, UV irradiation, or ozonation. This combined approach aims to enhance overall water treatment efficiency and address a broader range of contaminants.

- Stabilization and storage of hypochlorous acid solutions: Techniques for improving the stability and shelf life of hypochlorous acid solutions used in water treatment. This may involve pH adjustment, addition of stabilizing agents, or specialized packaging to maintain the efficacy of the hypochlorous acid over time.

- Environmental and safety considerations in hypochlorous acid water treatment: Addressing environmental concerns and safety aspects related to the use of hypochlorous acid in water treatment. This includes developing eco-friendly production methods, minimizing by-product formation, and ensuring safe handling and application procedures.

02 Hypochlorous acid-based water purification systems

Development of water purification systems that utilize hypochlorous acid as the primary disinfectant. These systems may include components for generating, storing, and dispensing hypochlorous acid solutions for various water treatment applications, such as drinking water purification or wastewater treatment.Expand Specific Solutions03 Stabilization of hypochlorous acid solutions

Techniques for stabilizing hypochlorous acid solutions to extend their shelf life and maintain their effectiveness in water treatment applications. This may involve the use of additives or specific storage conditions to prevent degradation of the hypochlorous acid.Expand Specific Solutions04 Combination of hypochlorous acid with other water treatment methods

Integration of hypochlorous acid treatment with other water purification techniques, such as filtration, UV disinfection, or ozonation. This combined approach aims to enhance overall water treatment efficiency and address a broader range of contaminants.Expand Specific Solutions05 Control and monitoring of hypochlorous acid in water treatment

Development of systems and methods for precise control and monitoring of hypochlorous acid concentrations in water treatment processes. This includes sensors, dosing equipment, and automated control systems to maintain optimal disinfection levels while minimizing chemical usage.Expand Specific Solutions

Key Industry Players

The hypochlorous acid water treatment market is in a growth phase, driven by increasing demand for safe and effective disinfection solutions. The global market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, the field is advancing, with companies like Kurita Water Industries, Halliburton Energy Services, and Toshiba Corp. leading innovation. These firms are developing more efficient production methods and application techniques for hypochlorous acid. Emerging players such as Innovative Water Care LLC and Vontron Technology Co., Ltd. are also contributing to market diversification and technological progress. The technology's maturity is moderate, with ongoing research focused on improving stability, efficacy, and cost-effectiveness of hypochlorous acid solutions for various water treatment applications.

Innovative Water Care LLC

Technical Solution: Innovative Water Care LLC has developed advanced hypochlorous acid generation systems for water treatment. Their technology utilizes electrolysis of salt water to produce a stable and effective hypochlorous acid solution on-site. The company's systems can generate hypochlorous acid at concentrations of 200-500 ppm, which is highly effective for disinfection while remaining safe for human contact[1]. They have also implemented smart dosing systems that automatically adjust hypochlorous acid production based on real-time water quality measurements, ensuring optimal treatment efficiency[2]. Additionally, Innovative Water Care has developed proprietary stabilization methods to extend the shelf life of their hypochlorous acid solutions, allowing for easier storage and transportation[3].

Strengths: On-site generation reduces transportation costs and environmental impact; smart dosing improves efficiency; stabilized solutions increase versatility. Weaknesses: Requires consistent salt and electricity supply; initial setup costs may be higher than traditional chlorine systems.

Kurita Water Industries Ltd.

Technical Solution: Kurita Water Industries has pioneered a novel approach to hypochlorous acid production and application in water treatment. Their patented technology combines electrochemical activation with membrane separation to produce highly pure and stable hypochlorous acid solutions[4]. This method allows for precise control of pH and oxidation-reduction potential, resulting in optimized disinfection efficacy. Kurita's system can generate hypochlorous acid at concentrations up to 1000 ppm, suitable for a wide range of applications from drinking water treatment to industrial processes[5]. The company has also developed specialized delivery systems that maintain the stability of hypochlorous acid during distribution, ensuring consistent performance across large-scale water treatment facilities[6].

Strengths: High purity and stability of produced hypochlorous acid; versatile application range; advanced delivery systems. Weaknesses: May require specialized training for operation; higher initial investment compared to conventional chlorination methods.

Core HOCL Innovations

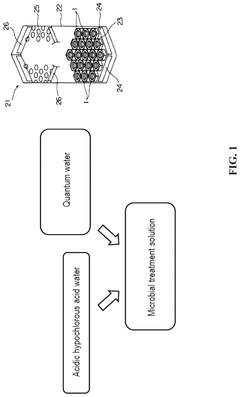

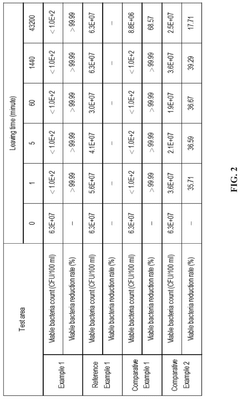

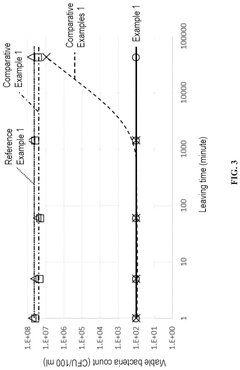

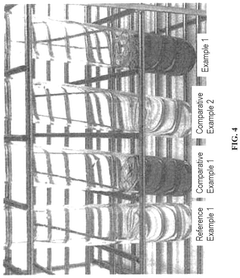

Microbial treatment solution and method of producing microbial treatment solution

PatentActiveUS12127561B2

Innovation

- A microbial treatment solution combining acidic hypochlorous acid water with quantum water, where the quantum water is passed through a converter with austenitic or martensitic stainless steel fragments arranged in a regular hexagonal prism shape, maintaining the sterilizing power by diluting the acidic hypochlorous acid water to concentrations between 0.5 wt % to 5.0 wt % and quantum water between 90.0 wt % to 99.5 wt %.

Water treatment processes utilizing sequential addition of a base and an oxidant

PatentWO2016093864A1

Innovation

- A sequential addition method where a base is added first to an acidic aqueous stream, followed by a delay and then the addition of an alkaline source of hypochlorous acid, allowing for a more reliable and higher pH increase, reducing chemical usage, and stabilizing the oxidant to enhance metal ion precipitation.

Environmental Impact

The environmental impact of hypochlorous acid (HOCl) in water treatment solutions is multifaceted and generally positive compared to traditional chlorine-based disinfectants. HOCl is a naturally occurring compound produced by the human immune system, making it inherently biocompatible and less harmful to ecosystems when released into the environment.

One of the primary environmental benefits of HOCl is its rapid decomposition into harmless byproducts. Unlike chlorine, which can form persistent and toxic chlorinated organic compounds, HOCl breaks down quickly into water, oxygen, and salt. This characteristic significantly reduces the risk of long-term environmental contamination and minimizes the potential for bioaccumulation in aquatic organisms.

The use of HOCl in water treatment also leads to a reduction in the formation of disinfection byproducts (DBPs), such as trihalomethanes and haloacetic acids, which are known to have adverse effects on human health and aquatic ecosystems. By minimizing DBP formation, HOCl helps maintain better water quality in treated effluents and receiving water bodies.

Furthermore, the production of HOCl through electrolysis of saltwater solutions is an environmentally friendly process that requires minimal chemical inputs. This method reduces the need for transportation and storage of hazardous chemicals, thereby lowering the carbon footprint associated with water treatment operations.

HOCl's effectiveness as a disinfectant at lower concentrations compared to traditional chlorine-based treatments also contributes to its positive environmental profile. Lower dosage requirements mean less chemical discharge into the environment and reduced potential for ecological disruption.

In aquaculture and agriculture, HOCl offers a safer alternative for water treatment and crop protection. Its use can help minimize the environmental impact of these industries by reducing the reliance on more persistent and potentially harmful chemical treatments.

However, it is important to note that while HOCl presents numerous environmental advantages, proper management and monitoring of its use are still necessary. Overuse or improper application could potentially lead to localized pH changes or temporary alterations in microbial communities in receiving waters. Therefore, responsible implementation and adherence to regulatory guidelines remain crucial for maximizing the environmental benefits of HOCl in water treatment solutions.

One of the primary environmental benefits of HOCl is its rapid decomposition into harmless byproducts. Unlike chlorine, which can form persistent and toxic chlorinated organic compounds, HOCl breaks down quickly into water, oxygen, and salt. This characteristic significantly reduces the risk of long-term environmental contamination and minimizes the potential for bioaccumulation in aquatic organisms.

The use of HOCl in water treatment also leads to a reduction in the formation of disinfection byproducts (DBPs), such as trihalomethanes and haloacetic acids, which are known to have adverse effects on human health and aquatic ecosystems. By minimizing DBP formation, HOCl helps maintain better water quality in treated effluents and receiving water bodies.

Furthermore, the production of HOCl through electrolysis of saltwater solutions is an environmentally friendly process that requires minimal chemical inputs. This method reduces the need for transportation and storage of hazardous chemicals, thereby lowering the carbon footprint associated with water treatment operations.

HOCl's effectiveness as a disinfectant at lower concentrations compared to traditional chlorine-based treatments also contributes to its positive environmental profile. Lower dosage requirements mean less chemical discharge into the environment and reduced potential for ecological disruption.

In aquaculture and agriculture, HOCl offers a safer alternative for water treatment and crop protection. Its use can help minimize the environmental impact of these industries by reducing the reliance on more persistent and potentially harmful chemical treatments.

However, it is important to note that while HOCl presents numerous environmental advantages, proper management and monitoring of its use are still necessary. Overuse or improper application could potentially lead to localized pH changes or temporary alterations in microbial communities in receiving waters. Therefore, responsible implementation and adherence to regulatory guidelines remain crucial for maximizing the environmental benefits of HOCl in water treatment solutions.

Regulatory Framework

The regulatory framework surrounding hypochlorous acid (HOCl) in water treatment solutions is complex and multifaceted, reflecting the importance of ensuring public health and environmental safety. In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating HOCl use under the Safe Drinking Water Act and the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA).

The EPA has established guidelines for the use of HOCl in drinking water treatment, setting maximum residual disinfectant levels (MRDLs) to balance effective disinfection with potential health risks. These regulations require water treatment facilities to monitor and report HOCl levels regularly, ensuring compliance with safety standards.

Internationally, the World Health Organization (WHO) provides guidelines for drinking water quality, which many countries adopt or adapt for their national standards. The WHO recognizes HOCl as an effective disinfectant and provides recommendations for its use in water treatment.

In the European Union, the European Chemicals Agency (ECHA) oversees the registration, evaluation, authorization, and restriction of chemicals, including HOCl. The EU's Drinking Water Directive sets quality standards for water intended for human consumption, influencing HOCl usage in member states.

Regulatory bodies also address the environmental impact of HOCl. Discharge limits and monitoring requirements are in place to protect aquatic ecosystems from potential adverse effects of chlorinated compounds. These regulations often require water treatment facilities to implement dechlorination processes before releasing treated water into the environment.

The food industry faces specific regulations regarding HOCl use. In the United States, the Food and Drug Administration (FDA) has approved HOCl as a food-contact substance and sanitizer for various applications. Similar approvals exist in other countries, with specific guidelines for concentration levels and application methods.

As research continues to unveil the benefits and potential risks of HOCl, regulatory frameworks are evolving. There is a growing trend towards promoting sustainable and environmentally friendly water treatment solutions, which may influence future regulations on HOCl use. Policymakers are increasingly considering the balance between effective disinfection and minimizing disinfection by-products.

Compliance with these regulations requires water treatment facilities and industries using HOCl to implement robust monitoring systems, maintain detailed records, and regularly report to regulatory authorities. This regulatory landscape shapes the development and adoption of HOCl-based water treatment technologies, driving innovation in measurement techniques, application methods, and safety protocols.

The EPA has established guidelines for the use of HOCl in drinking water treatment, setting maximum residual disinfectant levels (MRDLs) to balance effective disinfection with potential health risks. These regulations require water treatment facilities to monitor and report HOCl levels regularly, ensuring compliance with safety standards.

Internationally, the World Health Organization (WHO) provides guidelines for drinking water quality, which many countries adopt or adapt for their national standards. The WHO recognizes HOCl as an effective disinfectant and provides recommendations for its use in water treatment.

In the European Union, the European Chemicals Agency (ECHA) oversees the registration, evaluation, authorization, and restriction of chemicals, including HOCl. The EU's Drinking Water Directive sets quality standards for water intended for human consumption, influencing HOCl usage in member states.

Regulatory bodies also address the environmental impact of HOCl. Discharge limits and monitoring requirements are in place to protect aquatic ecosystems from potential adverse effects of chlorinated compounds. These regulations often require water treatment facilities to implement dechlorination processes before releasing treated water into the environment.

The food industry faces specific regulations regarding HOCl use. In the United States, the Food and Drug Administration (FDA) has approved HOCl as a food-contact substance and sanitizer for various applications. Similar approvals exist in other countries, with specific guidelines for concentration levels and application methods.

As research continues to unveil the benefits and potential risks of HOCl, regulatory frameworks are evolving. There is a growing trend towards promoting sustainable and environmentally friendly water treatment solutions, which may influence future regulations on HOCl use. Policymakers are increasingly considering the balance between effective disinfection and minimizing disinfection by-products.

Compliance with these regulations requires water treatment facilities and industries using HOCl to implement robust monitoring systems, maintain detailed records, and regularly report to regulatory authorities. This regulatory landscape shapes the development and adoption of HOCl-based water treatment technologies, driving innovation in measurement techniques, application methods, and safety protocols.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!