Impact of Variable Valve Timing on LS Engine Performance

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VVT LS Engine Evolution

The evolution of Variable Valve Timing (VVT) in LS engines represents a significant advancement in automotive engineering, particularly in the realm of performance optimization. The journey began in the early 2000s when General Motors recognized the potential of VVT to enhance engine efficiency and power output across a broader range of operating conditions.

Initially, VVT technology was introduced in the LS2 engine, which debuted in 2005. This early implementation focused primarily on the exhaust camshaft, allowing for improved exhaust scavenging and reduced pumping losses. The system utilized a hydraulic cam phaser to adjust the timing of the exhaust valves, providing modest gains in both low-end torque and high-end horsepower.

As the technology matured, GM engineers expanded VVT capabilities to include both intake and exhaust camshafts. This dual-independent VVT system first appeared in the LS3 engine in 2008. By allowing independent control of both intake and exhaust valve timing, engineers could fine-tune engine breathing characteristics across the entire RPM range, resulting in significant improvements in power delivery, fuel efficiency, and emissions control.

The next major milestone came with the introduction of the LT1 engine in 2014, which featured an advanced VVT system integrated with direct fuel injection and Active Fuel Management. This combination allowed for unprecedented control over the combustion process, enabling the engine to seamlessly transition between high-performance and fuel-efficient operating modes.

Throughout this evolution, GM continually refined the VVT control algorithms and mechanical components. Early systems relied on simple lookup tables for cam phasing, while later iterations incorporated real-time adaptive strategies that could optimize valve timing based on a multitude of sensor inputs, including engine load, temperature, and even altitude.

The impact of VVT on LS engine performance has been profound. Compared to their fixed-timing counterparts, VVT-equipped LS engines typically demonstrate improvements of 5-10% in peak horsepower and torque, with even greater gains in low and mid-range performance. Moreover, VVT has enabled LS engines to meet increasingly stringent emissions standards while maintaining their reputation for robust performance.

Looking forward, the evolution of VVT in LS engines continues. Current research focuses on expanding the range of cam phasing, implementing more sophisticated control strategies, and integrating VVT with other advanced technologies such as variable valve lift and cylinder deactivation. These ongoing developments promise to further enhance the legendary performance and efficiency of the LS engine family.

Initially, VVT technology was introduced in the LS2 engine, which debuted in 2005. This early implementation focused primarily on the exhaust camshaft, allowing for improved exhaust scavenging and reduced pumping losses. The system utilized a hydraulic cam phaser to adjust the timing of the exhaust valves, providing modest gains in both low-end torque and high-end horsepower.

As the technology matured, GM engineers expanded VVT capabilities to include both intake and exhaust camshafts. This dual-independent VVT system first appeared in the LS3 engine in 2008. By allowing independent control of both intake and exhaust valve timing, engineers could fine-tune engine breathing characteristics across the entire RPM range, resulting in significant improvements in power delivery, fuel efficiency, and emissions control.

The next major milestone came with the introduction of the LT1 engine in 2014, which featured an advanced VVT system integrated with direct fuel injection and Active Fuel Management. This combination allowed for unprecedented control over the combustion process, enabling the engine to seamlessly transition between high-performance and fuel-efficient operating modes.

Throughout this evolution, GM continually refined the VVT control algorithms and mechanical components. Early systems relied on simple lookup tables for cam phasing, while later iterations incorporated real-time adaptive strategies that could optimize valve timing based on a multitude of sensor inputs, including engine load, temperature, and even altitude.

The impact of VVT on LS engine performance has been profound. Compared to their fixed-timing counterparts, VVT-equipped LS engines typically demonstrate improvements of 5-10% in peak horsepower and torque, with even greater gains in low and mid-range performance. Moreover, VVT has enabled LS engines to meet increasingly stringent emissions standards while maintaining their reputation for robust performance.

Looking forward, the evolution of VVT in LS engines continues. Current research focuses on expanding the range of cam phasing, implementing more sophisticated control strategies, and integrating VVT with other advanced technologies such as variable valve lift and cylinder deactivation. These ongoing developments promise to further enhance the legendary performance and efficiency of the LS engine family.

Market Demand Analysis

The market demand for variable valve timing (VVT) technology in LS engines has been steadily increasing over the past decade. This growth is primarily driven by the automotive industry's push for improved engine performance, fuel efficiency, and reduced emissions. As environmental regulations become more stringent worldwide, manufacturers are increasingly turning to advanced technologies like VVT to meet these challenges.

In the performance vehicle segment, where LS engines are particularly popular, there is a growing demand for engines that can deliver both high power output and improved fuel economy. VVT technology allows for precise control of valve timing, which can be optimized for different engine speeds and load conditions. This adaptability is highly valued by consumers who seek vehicles that can provide exhilarating performance without sacrificing efficiency in everyday driving scenarios.

The aftermarket sector has also shown significant interest in VVT systems for LS engines. Performance enthusiasts and tuners are constantly seeking ways to extract more power and efficiency from their engines. The ability to retrofit VVT systems to older LS engines has created a new market segment, with numerous companies offering aftermarket VVT kits and related components.

From an industry perspective, major automotive manufacturers have been investing heavily in VVT technology for their LS engine lineups. This investment is a clear indicator of the market's direction and the perceived value of VVT in meeting consumer demands and regulatory requirements. The integration of VVT into LS engines has become a key selling point for many high-performance vehicles, demonstrating its importance in the competitive automotive market.

The commercial vehicle sector, including light trucks and SUVs that often utilize LS engines, has also shown increased demand for VVT technology. Fleet operators and businesses are looking for ways to reduce fuel consumption and operating costs while maintaining the power and reliability associated with LS engines. VVT offers a solution that addresses these needs without compromising on performance.

Looking at market trends, the adoption rate of VVT in LS engines is expected to continue its upward trajectory. As the technology matures and becomes more cost-effective to implement, it is likely to become a standard feature across a wider range of vehicles powered by LS engines. This trend is further supported by the ongoing shift towards electrification, where VVT can play a crucial role in optimizing the performance of hybrid powertrains that combine LS engines with electric motors.

In the performance vehicle segment, where LS engines are particularly popular, there is a growing demand for engines that can deliver both high power output and improved fuel economy. VVT technology allows for precise control of valve timing, which can be optimized for different engine speeds and load conditions. This adaptability is highly valued by consumers who seek vehicles that can provide exhilarating performance without sacrificing efficiency in everyday driving scenarios.

The aftermarket sector has also shown significant interest in VVT systems for LS engines. Performance enthusiasts and tuners are constantly seeking ways to extract more power and efficiency from their engines. The ability to retrofit VVT systems to older LS engines has created a new market segment, with numerous companies offering aftermarket VVT kits and related components.

From an industry perspective, major automotive manufacturers have been investing heavily in VVT technology for their LS engine lineups. This investment is a clear indicator of the market's direction and the perceived value of VVT in meeting consumer demands and regulatory requirements. The integration of VVT into LS engines has become a key selling point for many high-performance vehicles, demonstrating its importance in the competitive automotive market.

The commercial vehicle sector, including light trucks and SUVs that often utilize LS engines, has also shown increased demand for VVT technology. Fleet operators and businesses are looking for ways to reduce fuel consumption and operating costs while maintaining the power and reliability associated with LS engines. VVT offers a solution that addresses these needs without compromising on performance.

Looking at market trends, the adoption rate of VVT in LS engines is expected to continue its upward trajectory. As the technology matures and becomes more cost-effective to implement, it is likely to become a standard feature across a wider range of vehicles powered by LS engines. This trend is further supported by the ongoing shift towards electrification, where VVT can play a crucial role in optimizing the performance of hybrid powertrains that combine LS engines with electric motors.

VVT LS Tech Challenges

Variable Valve Timing (VVT) technology has presented several significant challenges in its implementation on LS engines. One of the primary obstacles is the integration of VVT mechanisms into the existing LS engine architecture without compromising its renowned compact design and lightweight characteristics. Engineers have had to develop innovative solutions to incorporate VVT components within the limited space available in the cylinder heads and valvetrain.

Another major challenge lies in the development of robust control systems capable of precisely managing valve timing across a wide range of operating conditions. The LS engine's high-performance nature demands a VVT system that can respond rapidly to changes in engine speed and load while maintaining optimal efficiency and power output. This requires sophisticated electronic control units and advanced algorithms to predict and adjust valve timing in real-time.

Durability and reliability have also posed significant hurdles in VVT implementation for LS engines. The high-stress environment of performance applications necessitates VVT components that can withstand extreme temperatures, pressures, and mechanical forces over extended periods. Engineers have had to carefully select materials and design components that can maintain consistent performance under these demanding conditions.

The cost-effectiveness of VVT systems for LS engines has been another challenge. While VVT technology offers substantial performance benefits, it also adds complexity and cost to the engine. Balancing the performance gains against the increased production expenses has required careful consideration and innovative engineering solutions to make VVT economically viable for a broader range of LS engine applications.

Compatibility with aftermarket modifications and tuning has presented additional challenges. The LS engine's popularity in the performance aftermarket means that any VVT system must be adaptable to various upgrades and modifications. Developing VVT systems that can be easily integrated with aftermarket engine management systems and performance parts has been crucial for widespread adoption.

Emissions compliance has been a significant consideration in VVT development for LS engines. Engineers have had to design systems that not only enhance performance but also contribute to reduced emissions across various operating conditions. This has involved complex calibration processes to optimize valve timing for both power output and emissions reduction.

Lastly, the challenge of maintaining the characteristic LS engine sound and feel while implementing VVT has required careful engineering. Enthusiasts and manufacturers alike have sought to preserve the distinctive auditory and performance characteristics that have made LS engines so popular, necessitating a delicate balance between technological advancement and traditional engine attributes.

Another major challenge lies in the development of robust control systems capable of precisely managing valve timing across a wide range of operating conditions. The LS engine's high-performance nature demands a VVT system that can respond rapidly to changes in engine speed and load while maintaining optimal efficiency and power output. This requires sophisticated electronic control units and advanced algorithms to predict and adjust valve timing in real-time.

Durability and reliability have also posed significant hurdles in VVT implementation for LS engines. The high-stress environment of performance applications necessitates VVT components that can withstand extreme temperatures, pressures, and mechanical forces over extended periods. Engineers have had to carefully select materials and design components that can maintain consistent performance under these demanding conditions.

The cost-effectiveness of VVT systems for LS engines has been another challenge. While VVT technology offers substantial performance benefits, it also adds complexity and cost to the engine. Balancing the performance gains against the increased production expenses has required careful consideration and innovative engineering solutions to make VVT economically viable for a broader range of LS engine applications.

Compatibility with aftermarket modifications and tuning has presented additional challenges. The LS engine's popularity in the performance aftermarket means that any VVT system must be adaptable to various upgrades and modifications. Developing VVT systems that can be easily integrated with aftermarket engine management systems and performance parts has been crucial for widespread adoption.

Emissions compliance has been a significant consideration in VVT development for LS engines. Engineers have had to design systems that not only enhance performance but also contribute to reduced emissions across various operating conditions. This has involved complex calibration processes to optimize valve timing for both power output and emissions reduction.

Lastly, the challenge of maintaining the characteristic LS engine sound and feel while implementing VVT has required careful engineering. Enthusiasts and manufacturers alike have sought to preserve the distinctive auditory and performance characteristics that have made LS engines so popular, necessitating a delicate balance between technological advancement and traditional engine attributes.

Current VVT Solutions

01 Cam phasing mechanisms for variable valve timing

Cam phasing mechanisms are used to adjust the timing of valve opening and closing relative to crankshaft position. These systems typically employ hydraulic or electric actuators to rotate the camshaft relative to its drive, allowing for improved engine performance, fuel efficiency, and emissions control across different operating conditions.- Optimization of valve timing control: Variable valve timing systems are optimized to improve engine performance and efficiency. This involves precise control of valve opening and closing timings based on various engine operating conditions. Advanced control algorithms and sensors are used to adjust valve timing for optimal combustion, reduced emissions, and improved fuel economy.

- Hydraulic actuation mechanisms: Hydraulic systems are commonly used in variable valve timing mechanisms. These systems utilize oil pressure to adjust the phase angle between the camshaft and crankshaft, allowing for dynamic control of valve timing. Hydraulic actuators provide quick response times and precise control, enhancing overall engine performance.

- Electronic control units for VVT: Electronic control units (ECUs) play a crucial role in managing variable valve timing systems. These units process data from various engine sensors and determine the optimal valve timing based on predefined maps and algorithms. ECUs enable real-time adjustments to valve timing, improving engine responsiveness and adaptability to different driving conditions.

- Cam phasing mechanisms: Cam phasing mechanisms are essential components of variable valve timing systems. These mechanisms allow for the rotation of the camshaft relative to its drive sprocket, effectively altering the valve timing. Various designs, including vane-type and helical spline actuators, are used to achieve smooth and precise cam phasing for improved engine performance.

- Integration with other engine technologies: Variable valve timing systems are often integrated with other advanced engine technologies to maximize performance benefits. This includes combining VVT with direct fuel injection, turbocharging, and cylinder deactivation systems. The synergy between these technologies allows for further improvements in power output, fuel efficiency, and emissions reduction across various engine operating conditions.

02 Electronic control systems for variable valve timing

Advanced electronic control systems are implemented to optimize variable valve timing performance. These systems use sensors to monitor engine conditions and adjust valve timing in real-time. They can integrate with other engine management systems to provide precise control over valve events, enhancing overall engine efficiency and power output.Expand Specific Solutions03 Continuous variable valve lift mechanisms

Continuous variable valve lift mechanisms allow for stepless adjustment of valve lift in addition to timing. These systems can optimize valve lift for different engine speeds and loads, further improving engine breathing, combustion efficiency, and performance across a wide operating range.Expand Specific Solutions04 Integration of variable valve timing with cylinder deactivation

Advanced variable valve timing systems are integrated with cylinder deactivation technology. This combination allows for selective deactivation of cylinders under light load conditions while optimizing valve timing for active cylinders, resulting in improved fuel efficiency without compromising performance when needed.Expand Specific Solutions05 Hydraulic lash adjusters for variable valve timing

Hydraulic lash adjusters are incorporated into variable valve timing systems to maintain proper valve clearance across different operating conditions. These components help ensure consistent valve operation and timing accuracy, contributing to improved engine performance and reduced maintenance requirements.Expand Specific Solutions

Key VVT LS Players

The variable valve timing (VVT) technology for LS engines is in a mature stage of development, with a substantial market size driven by the automotive industry's focus on improving engine performance and efficiency. The competitive landscape is characterized by established automotive manufacturers and specialized powertrain companies. Key players like Toyota Motor Corp., Hyundai Motor Co., and BorgWarner, Inc. have made significant advancements in VVT systems, leveraging their extensive R&D capabilities and industry experience. The technology's maturity is evident in its widespread adoption across various vehicle segments, with companies like Ford Global Technologies LLC and Mitsubishi Motors Corp. continuously refining their VVT implementations to meet evolving emissions standards and performance demands.

Toyota Motor Corp.

Technical Solution: Toyota has developed a sophisticated Variable Valve Timing with intelligence (VVT-i) system for their LS engines. This technology allows for continuous adjustment of both intake and exhaust valve timing, optimizing engine performance across various operating conditions[1]. Toyota's VVT-i system utilizes an oil-pressure-activated cam phaser that can adjust valve timing by up to 60 degrees[3]. The system incorporates advanced electronic control units that continuously monitor engine parameters and adjust valve timing accordingly[5]. Toyota has also integrated their VVT-i technology with their D-4S direct and port fuel injection system, creating a synergistic effect that enhances both power output and fuel efficiency[7]. Additionally, Toyota has developed a Valvematic system, which not only adjusts valve timing but also valve lift, further improving engine performance and efficiency[9].

Strengths: Seamless integration with other engine technologies, improved fuel efficiency, and enhanced engine performance. Weaknesses: Increased system complexity and potential for higher production costs.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed an innovative Continuously Variable Valve Duration (CVVD) system for their LS engines, which goes beyond traditional Variable Valve Timing by also adjusting the duration of valve opening[1]. This technology allows for unprecedented control over the engine's breathing, optimizing performance across all operating conditions[3]. Hyundai's CVVD system utilizes a unique camshaft with a rotating cam that can adjust both the timing and duration of valve events[5]. The system can vary the valve opening duration between 128 and 231 degrees, significantly improving engine efficiency and performance[7]. Hyundai has integrated this technology with their existing Continuously Variable Valve Timing (CVVT) system, creating a comprehensive valve control strategy that maximizes power output while minimizing fuel consumption and emissions[9]. Additionally, the CVVD system incorporates advanced sensors and control algorithms that continuously optimize valve events based on real-time engine parameters and driving conditions[11].

Strengths: Unparalleled control over engine breathing, significant improvements in both performance and efficiency, and reduced emissions. Weaknesses: Increased mechanical complexity and potential for higher production costs.

VVT LS Core Patents

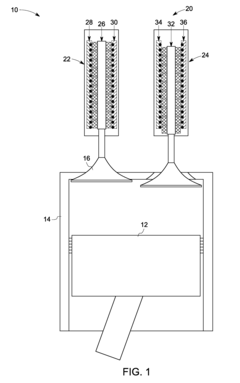

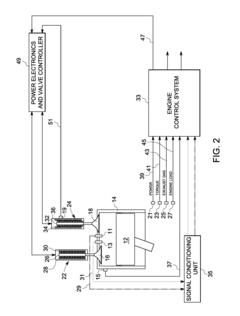

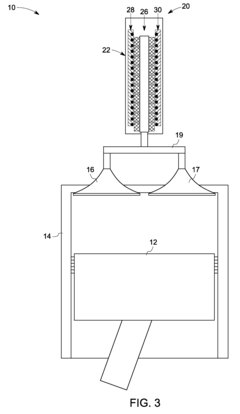

Electric valve actuation system

PatentActiveUS8047166B2

Innovation

- A magnetically-geared valve actuation system that includes sensors and a control system to dynamically control valve timing, providing flexible operation and reduced valve losses by using magnetic gearing to actuate intake and exhaust valves in engines and suction and discharge valves in compressors.

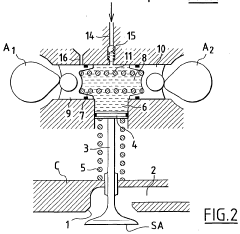

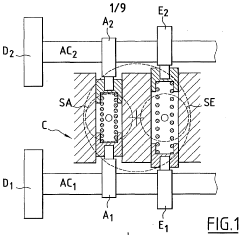

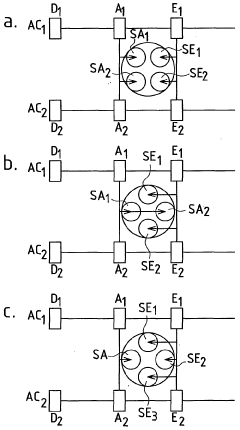

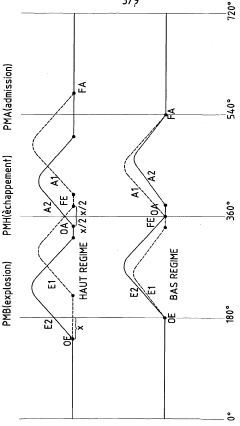

Variable timing device for reciprocating engines, engines comprising same and distribution and turbocharging method

PatentWO2002048510A2

Innovation

- A variable valve timing device utilizing hydraulic transmission means to actuate valves with movements from separate camshafts, allowing for flexible adjustment of valve opening and closing moments, angular durations, and lift, while automatically canceling operating clearance to reduce noise and wear, using phase shifters sensitive to engine parameters like speed and load.

Emissions Regulations

Emissions regulations have played a significant role in shaping the development and implementation of variable valve timing (VVT) technology in LS engines. As environmental concerns have grown, governments worldwide have imposed increasingly stringent emissions standards on automotive manufacturers. These regulations have driven the need for more efficient and cleaner engine technologies, with VVT emerging as a key solution to meet these requirements.

The introduction of VVT in LS engines has been largely influenced by the need to reduce harmful emissions, particularly nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons (HC). By allowing for precise control of valve timing, VVT enables engines to optimize combustion processes across different operating conditions, resulting in improved fuel efficiency and reduced emissions.

In the United States, the Environmental Protection Agency (EPA) has progressively tightened emissions standards for passenger vehicles and light-duty trucks. The implementation of Tier 2 and Tier 3 standards has pushed automakers to adopt advanced technologies like VVT to meet these requirements. Similarly, the European Union's Euro 6 standards and China's China 6 regulations have further accelerated the adoption of VVT in LS engines globally.

The impact of emissions regulations on VVT development for LS engines can be observed in several key areas. Firstly, it has led to the refinement of VVT systems to provide greater flexibility in valve timing adjustment. This allows engines to operate more efficiently across a wider range of speeds and loads, reducing overall emissions. Secondly, the integration of VVT with other emissions control technologies, such as exhaust gas recirculation (EGR) and catalytic converters, has become more sophisticated to meet stricter standards.

Furthermore, emissions regulations have driven research into more advanced VVT systems, such as continuously variable valve timing (CVVT) and cam-phasing technologies. These innovations offer even greater control over valve events, allowing for further optimization of engine performance and emissions reduction. The push for lower emissions has also led to the development of VVT systems that can quickly adapt to changing driving conditions, ensuring optimal performance and minimal emissions in real-world scenarios.

As emissions standards continue to evolve, the role of VVT in LS engines is expected to become even more critical. Future regulations may require even greater reductions in greenhouse gas emissions, potentially leading to the development of more sophisticated VVT systems that can work in conjunction with hybrid and electric powertrains. This ongoing regulatory pressure ensures that VVT technology will remain a key focus area for engine designers and automotive manufacturers in their efforts to produce cleaner, more efficient vehicles.

The introduction of VVT in LS engines has been largely influenced by the need to reduce harmful emissions, particularly nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons (HC). By allowing for precise control of valve timing, VVT enables engines to optimize combustion processes across different operating conditions, resulting in improved fuel efficiency and reduced emissions.

In the United States, the Environmental Protection Agency (EPA) has progressively tightened emissions standards for passenger vehicles and light-duty trucks. The implementation of Tier 2 and Tier 3 standards has pushed automakers to adopt advanced technologies like VVT to meet these requirements. Similarly, the European Union's Euro 6 standards and China's China 6 regulations have further accelerated the adoption of VVT in LS engines globally.

The impact of emissions regulations on VVT development for LS engines can be observed in several key areas. Firstly, it has led to the refinement of VVT systems to provide greater flexibility in valve timing adjustment. This allows engines to operate more efficiently across a wider range of speeds and loads, reducing overall emissions. Secondly, the integration of VVT with other emissions control technologies, such as exhaust gas recirculation (EGR) and catalytic converters, has become more sophisticated to meet stricter standards.

Furthermore, emissions regulations have driven research into more advanced VVT systems, such as continuously variable valve timing (CVVT) and cam-phasing technologies. These innovations offer even greater control over valve events, allowing for further optimization of engine performance and emissions reduction. The push for lower emissions has also led to the development of VVT systems that can quickly adapt to changing driving conditions, ensuring optimal performance and minimal emissions in real-world scenarios.

As emissions standards continue to evolve, the role of VVT in LS engines is expected to become even more critical. Future regulations may require even greater reductions in greenhouse gas emissions, potentially leading to the development of more sophisticated VVT systems that can work in conjunction with hybrid and electric powertrains. This ongoing regulatory pressure ensures that VVT technology will remain a key focus area for engine designers and automotive manufacturers in their efforts to produce cleaner, more efficient vehicles.

VVT Fuel Efficiency

Variable Valve Timing (VVT) technology has significantly impacted fuel efficiency in LS engines, offering substantial improvements in both performance and economy. By allowing for precise control of valve timing across different engine speeds and load conditions, VVT systems optimize air-fuel mixture and combustion efficiency, leading to reduced fuel consumption.

One of the primary ways VVT enhances fuel efficiency is through improved volumetric efficiency. By adjusting valve overlap, VVT systems can increase the amount of air drawn into the cylinders at lower engine speeds, effectively improving low-end torque and reducing the need for downshifting. This results in better fuel economy during everyday driving conditions.

At higher engine speeds, VVT can reduce pumping losses by optimizing valve timing to minimize the work required to draw air into the cylinders. This reduction in pumping losses translates directly to improved fuel efficiency, particularly during highway cruising conditions.

VVT also enables more precise control over the combustion process. By adjusting valve timing, engineers can fine-tune the compression ratio and combustion chamber turbulence, leading to more complete fuel burning and reduced emissions. This optimization not only improves fuel efficiency but also helps meet increasingly stringent emissions regulations.

Another significant advantage of VVT in LS engines is its ability to effectively implement cylinder deactivation. By selectively shutting off cylinders during light load conditions, fuel consumption can be dramatically reduced without sacrificing the ability to deliver full power when needed.

The integration of VVT with other advanced technologies, such as direct fuel injection and turbocharging, has further amplified its impact on fuel efficiency. These combined technologies allow for even greater control over the combustion process, enabling lean-burn strategies and more aggressive engine downsizing without compromising performance.

Quantitative studies have shown that VVT can improve fuel efficiency by up to 5-10% in LS engines, depending on the specific implementation and driving conditions. This improvement is particularly notable in urban driving cycles, where frequent changes in engine load and speed occur.

As automotive manufacturers continue to face pressure to improve fuel economy and reduce emissions, VVT technology in LS engines remains a crucial tool in achieving these goals. Ongoing research and development in this area promise even greater efficiency gains in the future, potentially pushing the boundaries of internal combustion engine performance and sustainability.

One of the primary ways VVT enhances fuel efficiency is through improved volumetric efficiency. By adjusting valve overlap, VVT systems can increase the amount of air drawn into the cylinders at lower engine speeds, effectively improving low-end torque and reducing the need for downshifting. This results in better fuel economy during everyday driving conditions.

At higher engine speeds, VVT can reduce pumping losses by optimizing valve timing to minimize the work required to draw air into the cylinders. This reduction in pumping losses translates directly to improved fuel efficiency, particularly during highway cruising conditions.

VVT also enables more precise control over the combustion process. By adjusting valve timing, engineers can fine-tune the compression ratio and combustion chamber turbulence, leading to more complete fuel burning and reduced emissions. This optimization not only improves fuel efficiency but also helps meet increasingly stringent emissions regulations.

Another significant advantage of VVT in LS engines is its ability to effectively implement cylinder deactivation. By selectively shutting off cylinders during light load conditions, fuel consumption can be dramatically reduced without sacrificing the ability to deliver full power when needed.

The integration of VVT with other advanced technologies, such as direct fuel injection and turbocharging, has further amplified its impact on fuel efficiency. These combined technologies allow for even greater control over the combustion process, enabling lean-burn strategies and more aggressive engine downsizing without compromising performance.

Quantitative studies have shown that VVT can improve fuel efficiency by up to 5-10% in LS engines, depending on the specific implementation and driving conditions. This improvement is particularly notable in urban driving cycles, where frequent changes in engine load and speed occur.

As automotive manufacturers continue to face pressure to improve fuel economy and reduce emissions, VVT technology in LS engines remains a crucial tool in achieving these goals. Ongoing research and development in this area promise even greater efficiency gains in the future, potentially pushing the boundaries of internal combustion engine performance and sustainability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!