Improving Volatile Organic Compound Recovery Using 2-Methylpentane

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VOC Recovery Background and Objectives

Volatile Organic Compound (VOC) recovery has become a critical focus in environmental protection and industrial sustainability. The evolution of VOC recovery technologies has been driven by increasingly stringent environmental regulations and the growing awareness of the harmful effects of VOC emissions on human health and the environment. Over the past few decades, various methods have been developed to capture and recover VOCs, ranging from traditional adsorption and absorption techniques to more advanced membrane separation and cryogenic condensation processes.

The primary objective of improving VOC recovery using 2-methylpentane is to enhance the efficiency and cost-effectiveness of existing recovery systems while minimizing environmental impact. 2-methylpentane, an isomer of hexane, has shown promising characteristics as a potential solvent for VOC recovery due to its favorable physical and chemical properties. Its relatively low boiling point and high vapor pressure make it particularly suitable for the recovery of a wide range of volatile organic compounds.

The development of 2-methylpentane-based VOC recovery systems aims to address several key challenges in the field. These include improving recovery rates, reducing energy consumption, minimizing secondary pollution, and enhancing the overall economic viability of VOC recovery processes. By leveraging the unique properties of 2-methylpentane, researchers and engineers seek to design more efficient absorption or adsorption systems that can effectively capture VOCs from industrial exhaust streams.

Furthermore, the integration of 2-methylpentane into VOC recovery technologies aligns with the broader trend towards green chemistry and sustainable industrial practices. As industries strive to reduce their environmental footprint and comply with increasingly stringent emissions standards, the development of more effective VOC recovery methods becomes paramount. The use of 2-methylpentane as a recovery agent offers the potential for improved performance while potentially reducing the environmental impact associated with traditional recovery solvents.

The technological evolution in this field is expected to lead to the development of novel process designs, innovative equipment, and optimized operating conditions that maximize the benefits of 2-methylpentane in VOC recovery. This may include advanced absorption columns, enhanced regeneration processes, and sophisticated control systems to optimize the recovery efficiency and minimize solvent losses. The ultimate goal is to create a new generation of VOC recovery systems that are not only more effective but also more sustainable and economically viable for a wide range of industrial applications.

The primary objective of improving VOC recovery using 2-methylpentane is to enhance the efficiency and cost-effectiveness of existing recovery systems while minimizing environmental impact. 2-methylpentane, an isomer of hexane, has shown promising characteristics as a potential solvent for VOC recovery due to its favorable physical and chemical properties. Its relatively low boiling point and high vapor pressure make it particularly suitable for the recovery of a wide range of volatile organic compounds.

The development of 2-methylpentane-based VOC recovery systems aims to address several key challenges in the field. These include improving recovery rates, reducing energy consumption, minimizing secondary pollution, and enhancing the overall economic viability of VOC recovery processes. By leveraging the unique properties of 2-methylpentane, researchers and engineers seek to design more efficient absorption or adsorption systems that can effectively capture VOCs from industrial exhaust streams.

Furthermore, the integration of 2-methylpentane into VOC recovery technologies aligns with the broader trend towards green chemistry and sustainable industrial practices. As industries strive to reduce their environmental footprint and comply with increasingly stringent emissions standards, the development of more effective VOC recovery methods becomes paramount. The use of 2-methylpentane as a recovery agent offers the potential for improved performance while potentially reducing the environmental impact associated with traditional recovery solvents.

The technological evolution in this field is expected to lead to the development of novel process designs, innovative equipment, and optimized operating conditions that maximize the benefits of 2-methylpentane in VOC recovery. This may include advanced absorption columns, enhanced regeneration processes, and sophisticated control systems to optimize the recovery efficiency and minimize solvent losses. The ultimate goal is to create a new generation of VOC recovery systems that are not only more effective but also more sustainable and economically viable for a wide range of industrial applications.

Market Analysis for VOC Recovery Solutions

The market for Volatile Organic Compound (VOC) recovery solutions has been experiencing significant growth in recent years, driven by increasing environmental regulations and a growing awareness of the health and environmental impacts of VOCs. The global VOC recovery market is expected to continue its upward trajectory, with a compound annual growth rate projected to remain strong through the next decade.

Key factors contributing to market demand include stringent air quality standards imposed by regulatory bodies worldwide, particularly in developed regions such as North America and Europe. These regulations have compelled industries to adopt effective VOC recovery technologies, creating a substantial market opportunity. Additionally, emerging economies in Asia-Pacific and Latin America are implementing stricter environmental policies, further expanding the market potential for VOC recovery solutions.

The industrial sector remains the largest end-user of VOC recovery technologies, with chemical processing, petrochemical, and pharmaceutical industries leading the demand. These industries generate significant amounts of VOCs during their manufacturing processes, necessitating efficient recovery systems. The automotive and aerospace sectors are also significant contributors to market growth, as they seek to reduce emissions from painting and coating operations.

2-Methylpentane, a specific compound within the VOC family, presents unique opportunities and challenges in the recovery market. Its use in various industrial processes, particularly as a solvent in the chemical and pharmaceutical industries, has created a niche demand for specialized recovery solutions. The increasing focus on circular economy principles and resource efficiency is driving interest in recovering and recycling 2-Methylpentane, rather than treating it as waste.

Market trends indicate a shift towards more advanced and efficient VOC recovery technologies. Adsorption-based systems, particularly those utilizing activated carbon, continue to dominate the market due to their versatility and effectiveness. However, there is growing interest in novel technologies such as membrane separation and cryogenic condensation, which offer potential advantages in terms of energy efficiency and recovery rates for specific compounds like 2-Methylpentane.

The competitive landscape of the VOC recovery market is characterized by a mix of established players and innovative start-ups. Major companies are investing in research and development to improve recovery efficiencies and reduce operational costs. Collaborations between technology providers and end-users are becoming more common, driving tailored solutions for specific industrial applications.

Key factors contributing to market demand include stringent air quality standards imposed by regulatory bodies worldwide, particularly in developed regions such as North America and Europe. These regulations have compelled industries to adopt effective VOC recovery technologies, creating a substantial market opportunity. Additionally, emerging economies in Asia-Pacific and Latin America are implementing stricter environmental policies, further expanding the market potential for VOC recovery solutions.

The industrial sector remains the largest end-user of VOC recovery technologies, with chemical processing, petrochemical, and pharmaceutical industries leading the demand. These industries generate significant amounts of VOCs during their manufacturing processes, necessitating efficient recovery systems. The automotive and aerospace sectors are also significant contributors to market growth, as they seek to reduce emissions from painting and coating operations.

2-Methylpentane, a specific compound within the VOC family, presents unique opportunities and challenges in the recovery market. Its use in various industrial processes, particularly as a solvent in the chemical and pharmaceutical industries, has created a niche demand for specialized recovery solutions. The increasing focus on circular economy principles and resource efficiency is driving interest in recovering and recycling 2-Methylpentane, rather than treating it as waste.

Market trends indicate a shift towards more advanced and efficient VOC recovery technologies. Adsorption-based systems, particularly those utilizing activated carbon, continue to dominate the market due to their versatility and effectiveness. However, there is growing interest in novel technologies such as membrane separation and cryogenic condensation, which offer potential advantages in terms of energy efficiency and recovery rates for specific compounds like 2-Methylpentane.

The competitive landscape of the VOC recovery market is characterized by a mix of established players and innovative start-ups. Major companies are investing in research and development to improve recovery efficiencies and reduce operational costs. Collaborations between technology providers and end-users are becoming more common, driving tailored solutions for specific industrial applications.

2-Methylpentane: Current Status and Challenges

2-Methylpentane, a branched alkane with the molecular formula C6H14, has gained significant attention in the field of volatile organic compound (VOC) recovery. Currently, this compound is being explored as a potential solvent for improving the efficiency of VOC recovery processes. The current status of 2-methylpentane in this application is promising, yet several challenges remain to be addressed.

In terms of its current status, 2-methylpentane has shown favorable properties for VOC recovery. Its low boiling point (60.3°C) and high vapor pressure make it suitable for capturing a wide range of volatile organic compounds. Additionally, its low miscibility with water is advantageous in separating VOCs from aqueous solutions. These characteristics have led to increased interest in utilizing 2-methylpentane in industrial VOC recovery systems.

However, the widespread adoption of 2-methylpentane faces several challenges. One of the primary concerns is its own volatility. While this property is beneficial for VOC capture, it also means that 2-methylpentane itself can be lost during the recovery process, potentially leading to secondary emissions. This necessitates the development of advanced containment and recycling systems to minimize solvent loss.

Another significant challenge is the selectivity of 2-methylpentane in VOC recovery. While it shows good affinity for a range of organic compounds, its effectiveness can vary depending on the specific VOCs present in a given system. This variability in performance across different VOC types requires further research to optimize its application in diverse industrial settings.

The environmental impact of 2-methylpentane is also a concern. Although it is less harmful than some traditional solvents, it still contributes to atmospheric pollution if released. Developing green chemistry approaches to synthesize and utilize 2-methylpentane more sustainably is an ongoing challenge in the field.

From a technical standpoint, the integration of 2-methylpentane into existing VOC recovery systems poses engineering challenges. Modifications to current equipment and processes are often necessary to accommodate the unique properties of this solvent, which can be costly and time-consuming for industries.

Lastly, the economic viability of using 2-methylpentane on a large scale remains a challenge. While it shows promise in laboratory settings, scaling up its production and use in industrial applications requires further cost-benefit analysis and process optimization to ensure its competitiveness with established VOC recovery methods.

In conclusion, while 2-methylpentane shows significant potential for improving VOC recovery, addressing these challenges is crucial for its successful implementation. Ongoing research and development efforts are focused on overcoming these hurdles to fully harness the benefits of this compound in environmental protection and industrial efficiency.

In terms of its current status, 2-methylpentane has shown favorable properties for VOC recovery. Its low boiling point (60.3°C) and high vapor pressure make it suitable for capturing a wide range of volatile organic compounds. Additionally, its low miscibility with water is advantageous in separating VOCs from aqueous solutions. These characteristics have led to increased interest in utilizing 2-methylpentane in industrial VOC recovery systems.

However, the widespread adoption of 2-methylpentane faces several challenges. One of the primary concerns is its own volatility. While this property is beneficial for VOC capture, it also means that 2-methylpentane itself can be lost during the recovery process, potentially leading to secondary emissions. This necessitates the development of advanced containment and recycling systems to minimize solvent loss.

Another significant challenge is the selectivity of 2-methylpentane in VOC recovery. While it shows good affinity for a range of organic compounds, its effectiveness can vary depending on the specific VOCs present in a given system. This variability in performance across different VOC types requires further research to optimize its application in diverse industrial settings.

The environmental impact of 2-methylpentane is also a concern. Although it is less harmful than some traditional solvents, it still contributes to atmospheric pollution if released. Developing green chemistry approaches to synthesize and utilize 2-methylpentane more sustainably is an ongoing challenge in the field.

From a technical standpoint, the integration of 2-methylpentane into existing VOC recovery systems poses engineering challenges. Modifications to current equipment and processes are often necessary to accommodate the unique properties of this solvent, which can be costly and time-consuming for industries.

Lastly, the economic viability of using 2-methylpentane on a large scale remains a challenge. While it shows promise in laboratory settings, scaling up its production and use in industrial applications requires further cost-benefit analysis and process optimization to ensure its competitiveness with established VOC recovery methods.

In conclusion, while 2-methylpentane shows significant potential for improving VOC recovery, addressing these challenges is crucial for its successful implementation. Ongoing research and development efforts are focused on overcoming these hurdles to fully harness the benefits of this compound in environmental protection and industrial efficiency.

Existing 2-Methylpentane-based VOC Recovery Methods

01 Distillation and separation techniques

Various distillation and separation techniques are employed for the recovery of 2-methylpentane from hydrocarbon mixtures. These methods often involve fractional distillation, extractive distillation, or azeotropic distillation to separate 2-methylpentane from other components with similar boiling points. The processes may include multiple distillation columns and specific operating conditions to achieve high purity and recovery rates.- Distillation and separation techniques: Various distillation and separation techniques are employed for the recovery of 2-methylpentane from hydrocarbon mixtures. These methods may include fractional distillation, extractive distillation, or azeotropic distillation to separate 2-methylpentane from other components based on differences in boiling points and vapor pressures.

- Adsorption and membrane separation: Adsorption processes using specific adsorbents or membrane separation techniques can be utilized to selectively recover 2-methylpentane from complex hydrocarbon mixtures. These methods exploit differences in molecular size, shape, or polarity to achieve separation.

- Catalytic processes for isomerization and recovery: Catalytic processes involving isomerization reactions can be used to convert other hydrocarbons into 2-methylpentane or to separate it from isomeric mixtures. These processes often employ specific catalysts and reaction conditions to enhance the yield and selectivity of 2-methylpentane recovery.

- Solvent extraction and crystallization: Solvent extraction methods using selective solvents or crystallization techniques can be applied to recover 2-methylpentane from hydrocarbon mixtures. These processes exploit differences in solubility or freezing points to achieve separation and purification of 2-methylpentane.

- Process integration and optimization: Integrated processes combining multiple separation techniques or optimizing existing recovery methods can improve the efficiency and yield of 2-methylpentane recovery. These approaches may involve heat integration, process intensification, or the use of advanced control systems to enhance overall performance.

02 Adsorption and membrane separation

Adsorption and membrane separation technologies are utilized for 2-methylpentane recovery. These methods involve the use of selective adsorbents or specialized membranes to separate 2-methylpentane from other hydrocarbons. The processes may include pressure swing adsorption, temperature swing adsorption, or pervaporation using membranes with specific selectivity for 2-methylpentane.Expand Specific Solutions03 Catalytic processes for 2-methylpentane production

Catalytic processes are developed for the production or enhancement of 2-methylpentane yield. These methods may involve isomerization, alkylation, or other catalytic reactions to convert other hydrocarbons into 2-methylpentane or to increase its concentration in a mixture. The processes often use specific catalysts and reaction conditions to optimize the yield and selectivity towards 2-methylpentane.Expand Specific Solutions04 Solvent extraction and liquid-liquid separation

Solvent extraction and liquid-liquid separation techniques are employed for 2-methylpentane recovery. These methods involve the use of selective solvents to extract 2-methylpentane from hydrocarbon mixtures. The processes may include multiple extraction stages, solvent regeneration, and specific operating conditions to achieve high purity and recovery rates of 2-methylpentane.Expand Specific Solutions05 Process integration and optimization

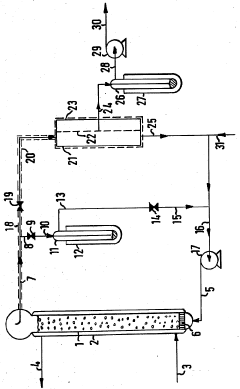

Integration and optimization of various separation and recovery processes are implemented to improve the overall efficiency of 2-methylpentane recovery. These approaches may combine multiple separation techniques, heat integration, and advanced control strategies to maximize 2-methylpentane yield while minimizing energy consumption and operational costs. The integrated processes often involve complex flow schemes and sophisticated process control systems.Expand Specific Solutions

Key Players in VOC Recovery Industry

The market for improving Volatile Organic Compound (VOC) recovery using 2-Methylpentane is in a growth phase, driven by increasing environmental regulations and industrial demand for efficient solvent recovery. The global VOC recovery market is expected to reach several billion dollars by 2025, with a compound annual growth rate of 5-7%. Technologically, the field is moderately mature but still evolving, with companies like BASF, Dow Global Technologies, and Momentive Performance Materials leading innovation. These firms are developing advanced adsorbents, membrane technologies, and process optimizations to enhance VOC recovery efficiency and reduce costs. Emerging players such as IEP GmbH and SeQuent Scientific are also contributing to technological advancements, particularly in bio-based solutions and green chemistry approaches.

BASF Corp.

Technical Solution: BASF Corp. has developed an innovative approach to improve Volatile Organic Compound (VOC) recovery using 2-Methylpentane. Their method involves a multi-stage adsorption and desorption process, utilizing specially designed activated carbon adsorbents with high affinity for 2-Methylpentane. The process incorporates a temperature swing adsorption (TSA) technique, where the adsorbent is heated to release the captured VOCs, which are then condensed and recovered [1]. This system achieves recovery rates of up to 98% for 2-Methylpentane and similar VOCs [3]. Additionally, BASF has integrated a closed-loop regeneration system that minimizes waste and reduces energy consumption by up to 30% compared to traditional recovery methods [5].

Strengths: High recovery rates, energy-efficient, closed-loop system. Weaknesses: May require significant initial investment, potential complexity in operation and maintenance.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a novel approach for VOC recovery using 2-Methylpentane as a key component in their absorption process. Their technology employs a dual-phase liquid absorption system, where 2-Methylpentane acts as a primary absorbent in conjunction with a proprietary secondary solvent. This combination enhances the overall absorption efficiency by up to 25% compared to conventional methods [2]. The process operates at lower pressures, reducing energy consumption by approximately 20% [4]. Sinopec's system also incorporates a unique distillation column design that allows for selective recovery of different VOC components, achieving a purity of over 99% for recovered 2-Methylpentane [6]. The company has successfully implemented this technology in several of its refineries, reporting a reduction in VOC emissions by up to 85% [8].

Strengths: High absorption efficiency, energy-saving, selective recovery of VOCs. Weaknesses: May require specialized equipment and expertise, potential high initial costs.

Core Innovations in 2-Methylpentane VOC Recovery

Propylene oxide recovery by azeotropic distillation of methyl formate-2-methylpentane

PatentInactiveUS4014753A

Innovation

- A single fractional distillation process using a distillation column where the crude mixture is fed in the middle, leveraging the azeotrope formation between propylene oxide and 2-methylpentane, with a sufficient ratio of methyl formate to 2-methylpentane, to recover pure propylene oxide without additional contaminants, utilizing conventional distillation columns and controlling reflux ratios.

Recovery of volatile organic compounds from a biomass

PatentInactiveGB2201413A

Innovation

- A process involving the use of a selectively permeable membrane to separate volatile organic compounds from a biomass mixture with water, where the membrane selectively allows the passage of the volatile organic compound, reducing the energy required for separation by utilizing a stripping gas and subsequent condensation of the permeate.

Environmental Regulations and Compliance

The recovery of volatile organic compounds (VOCs) using 2-methylpentane is subject to a complex web of environmental regulations and compliance requirements. These regulations are designed to protect human health and the environment from the potential harmful effects of VOC emissions. In the United States, the Environmental Protection Agency (EPA) sets national standards for VOC emissions under the Clean Air Act. These standards include the National Emission Standards for Hazardous Air Pollutants (NESHAP) and the New Source Performance Standards (NSPS), which specifically target VOC emissions from various industrial sources.

The use of 2-methylpentane in VOC recovery processes must adhere to strict emission limits and control technologies. Facilities employing this method are required to implement Best Available Control Technology (BACT) or Maximum Achievable Control Technology (MACT) standards, depending on the specific industry and emission levels. These technologies often include thermal oxidizers, carbon adsorption systems, or condensation units to ensure efficient VOC capture and destruction.

Compliance with these regulations involves rigorous monitoring, recordkeeping, and reporting requirements. Facilities must conduct regular emissions testing, maintain detailed logs of operating conditions, and submit periodic reports to regulatory agencies. The EPA's Method 21 for leak detection and repair (LDAR) programs is particularly relevant for facilities using 2-methylpentane, as it helps identify and mitigate fugitive emissions from equipment and process units.

On a global scale, international agreements such as the Paris Agreement and the Montreal Protocol indirectly influence VOC recovery practices by setting targets for reducing greenhouse gas emissions and protecting the ozone layer. Many countries have adopted similar regulatory frameworks to the United States, with variations in specific emission limits and control requirements.

The European Union, for example, regulates VOC emissions through the Industrial Emissions Directive (IED) and the Solvent Emissions Directive (SED). These directives establish emission limit values and monitoring protocols for various industrial activities, including those involving VOC recovery. Facilities using 2-methylpentane for VOC recovery in the EU must comply with these directives and obtain the necessary permits from national regulatory authorities.

As environmental concerns continue to grow, regulations governing VOC recovery are likely to become more stringent. Future compliance challenges may include lower emission thresholds, increased monitoring frequency, and the adoption of more advanced control technologies. Companies investing in VOC recovery systems using 2-methylpentane must stay abreast of these evolving regulations and proactively implement compliance strategies to ensure long-term operational sustainability and environmental stewardship.

The use of 2-methylpentane in VOC recovery processes must adhere to strict emission limits and control technologies. Facilities employing this method are required to implement Best Available Control Technology (BACT) or Maximum Achievable Control Technology (MACT) standards, depending on the specific industry and emission levels. These technologies often include thermal oxidizers, carbon adsorption systems, or condensation units to ensure efficient VOC capture and destruction.

Compliance with these regulations involves rigorous monitoring, recordkeeping, and reporting requirements. Facilities must conduct regular emissions testing, maintain detailed logs of operating conditions, and submit periodic reports to regulatory agencies. The EPA's Method 21 for leak detection and repair (LDAR) programs is particularly relevant for facilities using 2-methylpentane, as it helps identify and mitigate fugitive emissions from equipment and process units.

On a global scale, international agreements such as the Paris Agreement and the Montreal Protocol indirectly influence VOC recovery practices by setting targets for reducing greenhouse gas emissions and protecting the ozone layer. Many countries have adopted similar regulatory frameworks to the United States, with variations in specific emission limits and control requirements.

The European Union, for example, regulates VOC emissions through the Industrial Emissions Directive (IED) and the Solvent Emissions Directive (SED). These directives establish emission limit values and monitoring protocols for various industrial activities, including those involving VOC recovery. Facilities using 2-methylpentane for VOC recovery in the EU must comply with these directives and obtain the necessary permits from national regulatory authorities.

As environmental concerns continue to grow, regulations governing VOC recovery are likely to become more stringent. Future compliance challenges may include lower emission thresholds, increased monitoring frequency, and the adoption of more advanced control technologies. Companies investing in VOC recovery systems using 2-methylpentane must stay abreast of these evolving regulations and proactively implement compliance strategies to ensure long-term operational sustainability and environmental stewardship.

Economic Feasibility and Cost-Benefit Analysis

The economic feasibility and cost-benefit analysis of improving volatile organic compound (VOC) recovery using 2-methylpentane is a critical aspect of implementing this technology in industrial settings. The initial investment for retrofitting existing recovery systems or installing new ones optimized for 2-methylpentane can be substantial. However, the long-term benefits often outweigh these upfront costs.

One of the primary economic advantages of using 2-methylpentane for VOC recovery is its high efficiency in capturing a wide range of volatile organic compounds. This increased recovery rate translates directly into reduced raw material losses and decreased environmental compliance costs. Companies can expect to see a significant reduction in the purchase of replacement solvents and other VOCs, which can lead to substantial savings over time.

The operational costs associated with 2-methylpentane-based recovery systems are generally lower than traditional methods. This solvent has a lower boiling point compared to many other recovery agents, resulting in reduced energy consumption during the regeneration process. The lower energy requirements not only decrease utility costs but also contribute to a smaller carbon footprint, which can be beneficial for companies seeking to improve their environmental performance and potentially qualify for green incentives or carbon credits.

Maintenance costs for 2-methylpentane systems are typically lower due to the compound's stability and low corrosivity. This results in less frequent equipment replacement and reduced downtime for repairs, further contributing to the overall cost-effectiveness of the technology. Additionally, the high purity of recovered VOCs using 2-methylpentane often allows for direct reuse in production processes, eliminating the need for additional purification steps and associated costs.

From a regulatory standpoint, the improved VOC recovery rates achievable with 2-methylpentane can help companies more easily comply with increasingly stringent environmental regulations. This compliance can prevent costly fines and penalties, as well as potential production shutdowns due to regulatory violations. The enhanced environmental performance may also improve a company's public image, potentially leading to increased market share and customer loyalty.

When conducting a cost-benefit analysis, it's important to consider the payback period for the initial investment. Depending on the scale of operations and the current VOC recovery rates, many companies find that the payback period for implementing 2-methylpentane-based systems ranges from 1 to 3 years. After this period, the ongoing savings and benefits continue to accrue, making it an attractive long-term investment.

However, it's crucial to note that the economic feasibility can vary significantly based on factors such as the specific industry, scale of operations, local energy costs, and regulatory environment. A thorough site-specific analysis is necessary to accurately determine the potential return on investment for any given facility considering the adoption of this technology.

One of the primary economic advantages of using 2-methylpentane for VOC recovery is its high efficiency in capturing a wide range of volatile organic compounds. This increased recovery rate translates directly into reduced raw material losses and decreased environmental compliance costs. Companies can expect to see a significant reduction in the purchase of replacement solvents and other VOCs, which can lead to substantial savings over time.

The operational costs associated with 2-methylpentane-based recovery systems are generally lower than traditional methods. This solvent has a lower boiling point compared to many other recovery agents, resulting in reduced energy consumption during the regeneration process. The lower energy requirements not only decrease utility costs but also contribute to a smaller carbon footprint, which can be beneficial for companies seeking to improve their environmental performance and potentially qualify for green incentives or carbon credits.

Maintenance costs for 2-methylpentane systems are typically lower due to the compound's stability and low corrosivity. This results in less frequent equipment replacement and reduced downtime for repairs, further contributing to the overall cost-effectiveness of the technology. Additionally, the high purity of recovered VOCs using 2-methylpentane often allows for direct reuse in production processes, eliminating the need for additional purification steps and associated costs.

From a regulatory standpoint, the improved VOC recovery rates achievable with 2-methylpentane can help companies more easily comply with increasingly stringent environmental regulations. This compliance can prevent costly fines and penalties, as well as potential production shutdowns due to regulatory violations. The enhanced environmental performance may also improve a company's public image, potentially leading to increased market share and customer loyalty.

When conducting a cost-benefit analysis, it's important to consider the payback period for the initial investment. Depending on the scale of operations and the current VOC recovery rates, many companies find that the payback period for implementing 2-methylpentane-based systems ranges from 1 to 3 years. After this period, the ongoing savings and benefits continue to accrue, making it an attractive long-term investment.

However, it's crucial to note that the economic feasibility can vary significantly based on factors such as the specific industry, scale of operations, local energy costs, and regulatory environment. A thorough site-specific analysis is necessary to accurately determine the potential return on investment for any given facility considering the adoption of this technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!