Incorporation of Sulphanilic Acid in Antistatic Coatings for Electronics

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sulphanilic Acid in Antistatic Coatings: Background and Objectives

The incorporation of sulphanilic acid in antistatic coatings for electronics represents a significant advancement in the field of protective materials for electronic devices. This technology has evolved over the past few decades, driven by the increasing demand for effective static charge dissipation in sensitive electronic components. The primary objective of this research is to enhance the antistatic properties of coatings while maintaining or improving other essential characteristics such as durability, transparency, and ease of application.

Sulphanilic acid, an aromatic compound with both amino and sulfonic acid groups, has emerged as a promising additive for antistatic coatings due to its unique chemical structure. Its ability to form stable salts and its potential for ionic conductivity make it an attractive option for improving the electrostatic discharge (ESD) properties of coatings. The development of this technology can be traced back to the early 2000s when researchers began exploring alternatives to traditional antistatic agents.

The evolution of sulphanilic acid-based antistatic coatings has been closely tied to the rapid growth of the electronics industry. As devices became smaller, more complex, and more sensitive to electrostatic discharge, the need for advanced protective coatings became increasingly critical. This technological progression has been marked by several key milestones, including the optimization of sulphanilic acid concentrations, the development of compatible polymer matrices, and the fine-tuning of coating application methods.

Current research in this field aims to address several key challenges. These include improving the long-term stability of sulphanilic acid within the coating matrix, enhancing its compatibility with a wider range of substrate materials, and developing formulations that can withstand harsh environmental conditions without compromising antistatic performance. Additionally, there is a growing focus on creating environmentally friendly and sustainable coating solutions that align with global efforts to reduce the environmental impact of electronic manufacturing processes.

The incorporation of sulphanilic acid in antistatic coatings intersects with several other emerging technologies in the electronics industry. These include the development of flexible and wearable electronics, which require highly adaptable protective coatings, and the advancement of nanotechnology, which offers new possibilities for creating ultra-thin, highly effective antistatic layers. As the electronics industry continues to evolve, the role of sulphanilic acid in antistatic coatings is expected to expand, potentially leading to new applications in areas such as aerospace, automotive electronics, and medical devices.

Sulphanilic acid, an aromatic compound with both amino and sulfonic acid groups, has emerged as a promising additive for antistatic coatings due to its unique chemical structure. Its ability to form stable salts and its potential for ionic conductivity make it an attractive option for improving the electrostatic discharge (ESD) properties of coatings. The development of this technology can be traced back to the early 2000s when researchers began exploring alternatives to traditional antistatic agents.

The evolution of sulphanilic acid-based antistatic coatings has been closely tied to the rapid growth of the electronics industry. As devices became smaller, more complex, and more sensitive to electrostatic discharge, the need for advanced protective coatings became increasingly critical. This technological progression has been marked by several key milestones, including the optimization of sulphanilic acid concentrations, the development of compatible polymer matrices, and the fine-tuning of coating application methods.

Current research in this field aims to address several key challenges. These include improving the long-term stability of sulphanilic acid within the coating matrix, enhancing its compatibility with a wider range of substrate materials, and developing formulations that can withstand harsh environmental conditions without compromising antistatic performance. Additionally, there is a growing focus on creating environmentally friendly and sustainable coating solutions that align with global efforts to reduce the environmental impact of electronic manufacturing processes.

The incorporation of sulphanilic acid in antistatic coatings intersects with several other emerging technologies in the electronics industry. These include the development of flexible and wearable electronics, which require highly adaptable protective coatings, and the advancement of nanotechnology, which offers new possibilities for creating ultra-thin, highly effective antistatic layers. As the electronics industry continues to evolve, the role of sulphanilic acid in antistatic coatings is expected to expand, potentially leading to new applications in areas such as aerospace, automotive electronics, and medical devices.

Market Analysis for Antistatic Coatings in Electronics

The global market for antistatic coatings in electronics has experienced significant growth in recent years, driven by the increasing demand for electronic devices and components that require protection against electrostatic discharge (ESD). The incorporation of sulphanilic acid in these coatings has emerged as a promising solution to enhance their antistatic properties, leading to a surge in research and development activities in this field.

The electronics industry, particularly in sectors such as consumer electronics, automotive electronics, and aerospace, has been the primary driver of demand for antistatic coatings. With the proliferation of sensitive electronic components in various devices, the need for effective ESD protection has become paramount. This has created a substantial market opportunity for advanced antistatic coating solutions, including those incorporating sulphanilic acid.

Market analysts project a steady growth trajectory for the antistatic coatings market in the electronics sector over the next five years. The Asia-Pacific region, led by countries like China, Japan, and South Korea, is expected to dominate the market due to their strong presence in electronics manufacturing. North America and Europe are also significant markets, driven by high-tech industries and stringent ESD protection standards.

The integration of sulphanilic acid in antistatic coatings has opened up new avenues for product differentiation and performance enhancement. Manufacturers are increasingly focusing on developing coatings that not only provide superior ESD protection but also offer additional benefits such as improved durability, transparency, and environmental friendliness. This trend is likely to fuel further innovation and market expansion in the coming years.

However, the market faces certain challenges, including the high cost of advanced antistatic coatings and the complexity of integrating these coatings into existing manufacturing processes. Additionally, environmental regulations regarding the use of certain chemicals in coatings may impact market dynamics and drive the development of more sustainable alternatives.

Despite these challenges, the overall market outlook remains positive. The growing adoption of IoT devices, the development of 5G technology, and the increasing miniaturization of electronic components are expected to create sustained demand for high-performance antistatic coatings. As a result, companies investing in research and development of sulphanilic acid-based antistatic coatings are likely to find significant opportunities for growth and market penetration in the electronics industry.

The electronics industry, particularly in sectors such as consumer electronics, automotive electronics, and aerospace, has been the primary driver of demand for antistatic coatings. With the proliferation of sensitive electronic components in various devices, the need for effective ESD protection has become paramount. This has created a substantial market opportunity for advanced antistatic coating solutions, including those incorporating sulphanilic acid.

Market analysts project a steady growth trajectory for the antistatic coatings market in the electronics sector over the next five years. The Asia-Pacific region, led by countries like China, Japan, and South Korea, is expected to dominate the market due to their strong presence in electronics manufacturing. North America and Europe are also significant markets, driven by high-tech industries and stringent ESD protection standards.

The integration of sulphanilic acid in antistatic coatings has opened up new avenues for product differentiation and performance enhancement. Manufacturers are increasingly focusing on developing coatings that not only provide superior ESD protection but also offer additional benefits such as improved durability, transparency, and environmental friendliness. This trend is likely to fuel further innovation and market expansion in the coming years.

However, the market faces certain challenges, including the high cost of advanced antistatic coatings and the complexity of integrating these coatings into existing manufacturing processes. Additionally, environmental regulations regarding the use of certain chemicals in coatings may impact market dynamics and drive the development of more sustainable alternatives.

Despite these challenges, the overall market outlook remains positive. The growing adoption of IoT devices, the development of 5G technology, and the increasing miniaturization of electronic components are expected to create sustained demand for high-performance antistatic coatings. As a result, companies investing in research and development of sulphanilic acid-based antistatic coatings are likely to find significant opportunities for growth and market penetration in the electronics industry.

Current Challenges in Antistatic Coating Technology

The field of antistatic coatings for electronics faces several significant challenges that hinder the widespread adoption and effectiveness of current technologies. One of the primary issues is the durability and longevity of antistatic coatings. Many existing solutions struggle to maintain their antistatic properties over extended periods, especially when exposed to harsh environmental conditions or frequent physical contact. This limitation often results in the need for frequent reapplication or replacement, increasing maintenance costs and reducing overall efficiency.

Another critical challenge lies in achieving a balance between antistatic performance and optical transparency. Many electronic devices, particularly those with displays, require coatings that do not interfere with visual clarity. However, some of the most effective antistatic materials can impart a slight tint or haze to the surface, compromising the aesthetic and functional qualities of the device. This trade-off between performance and appearance continues to be a significant hurdle for manufacturers and researchers alike.

The environmental impact of antistatic coatings is also becoming an increasingly important concern. Many traditional antistatic materials contain chemicals that may be harmful to the environment or pose health risks during production and disposal. As global regulations become more stringent, there is a growing need for eco-friendly alternatives that maintain high performance standards while minimizing environmental impact.

Compatibility with various substrate materials presents another challenge in antistatic coating technology. Different electronic components may require coatings that adhere well to a wide range of materials, including plastics, metals, and composites. Developing a universal solution that performs consistently across diverse substrates without compromising the underlying material properties remains a complex task for researchers and manufacturers.

Cost-effectiveness is a persistent challenge in the antistatic coating industry. While high-performance solutions exist, they often come at a premium price point that can be prohibitive for mass-market applications. Striking a balance between cost and performance is crucial for widespread adoption, particularly in consumer electronics where profit margins are often tight.

Lastly, the integration of antistatic properties with other functional characteristics, such as scratch resistance, UV protection, or antimicrobial properties, presents a multifaceted challenge. Creating multi-functional coatings that address various needs simultaneously without compromising on any single aspect requires advanced material science and engineering approaches. This challenge is particularly relevant as electronic devices become more sophisticated and demand increasingly complex protective solutions.

Another critical challenge lies in achieving a balance between antistatic performance and optical transparency. Many electronic devices, particularly those with displays, require coatings that do not interfere with visual clarity. However, some of the most effective antistatic materials can impart a slight tint or haze to the surface, compromising the aesthetic and functional qualities of the device. This trade-off between performance and appearance continues to be a significant hurdle for manufacturers and researchers alike.

The environmental impact of antistatic coatings is also becoming an increasingly important concern. Many traditional antistatic materials contain chemicals that may be harmful to the environment or pose health risks during production and disposal. As global regulations become more stringent, there is a growing need for eco-friendly alternatives that maintain high performance standards while minimizing environmental impact.

Compatibility with various substrate materials presents another challenge in antistatic coating technology. Different electronic components may require coatings that adhere well to a wide range of materials, including plastics, metals, and composites. Developing a universal solution that performs consistently across diverse substrates without compromising the underlying material properties remains a complex task for researchers and manufacturers.

Cost-effectiveness is a persistent challenge in the antistatic coating industry. While high-performance solutions exist, they often come at a premium price point that can be prohibitive for mass-market applications. Striking a balance between cost and performance is crucial for widespread adoption, particularly in consumer electronics where profit margins are often tight.

Lastly, the integration of antistatic properties with other functional characteristics, such as scratch resistance, UV protection, or antimicrobial properties, presents a multifaceted challenge. Creating multi-functional coatings that address various needs simultaneously without compromising on any single aspect requires advanced material science and engineering approaches. This challenge is particularly relevant as electronic devices become more sophisticated and demand increasingly complex protective solutions.

Existing Sulphanilic Acid Incorporation Methods

01 Use of sulphanilic acid in antistatic coatings

Sulphanilic acid can be incorporated into antistatic coatings to enhance their antistatic properties. This compound helps to reduce the accumulation of static electricity on surfaces, making it useful in various applications where static discharge needs to be controlled.- Use of sulphanilic acid in antistatic coatings: Sulphanilic acid can be incorporated into antistatic coatings to enhance their antistatic properties. This compound helps to reduce the accumulation of static electricity on surfaces, making it useful in various applications where static control is crucial.

- Combination with conductive polymers: Sulphanilic acid can be combined with conductive polymers to create more effective antistatic coatings. This combination improves the overall conductivity of the coating, leading to better dissipation of static charges and enhanced antistatic properties.

- Application in textile treatments: Sulphanilic acid-based antistatic coatings can be applied to textiles to impart antistatic properties. These treatments help reduce static cling and improve the overall performance of fabrics in various applications, including clothing and industrial textiles.

- Incorporation in polymer composites: Sulphanilic acid can be incorporated into polymer composites to enhance their antistatic properties. This approach allows for the creation of antistatic materials with improved mechanical properties, suitable for use in various industries such as electronics and automotive.

- Synergistic effects with other antistatic agents: Combining sulphanilic acid with other antistatic agents can lead to synergistic effects, resulting in enhanced antistatic properties. This approach allows for the development of more efficient and versatile antistatic coatings suitable for a wide range of applications.

02 Combination with conductive polymers

Sulphanilic acid can be combined with conductive polymers to create more effective antistatic coatings. This combination enhances the overall conductivity of the coating, improving its ability to dissipate static charges and maintain antistatic properties over time.Expand Specific Solutions03 Application in textile treatments

Sulphanilic acid-based antistatic coatings can be applied to textiles to impart antistatic properties. These treatments help reduce static cling and improve the overall performance of fabrics in various applications, including clothing and industrial textiles.Expand Specific Solutions04 Incorporation in polymer composites

Sulphanilic acid can be incorporated into polymer composites to create materials with enhanced antistatic properties. This approach allows for the development of antistatic plastics and other composite materials suitable for use in electronics, packaging, and other industries where static control is crucial.Expand Specific Solutions05 Use in surface coatings for electronic components

Antistatic coatings containing sulphanilic acid can be applied to electronic components and devices to protect them from static discharge. These coatings help prevent damage to sensitive electronic parts and improve the overall reliability and longevity of electronic equipment.Expand Specific Solutions

Key Players in Antistatic Coating Industry

The incorporation of sulphanilic acid in antistatic coatings for electronics is an emerging field in the advanced materials sector. The market is in its early growth stage, with increasing demand driven by the expanding electronics industry. While the market size is still relatively small, it is expected to grow significantly in the coming years. The technology is progressing towards maturity, with key players like Nitto Denko Corp., 3M Innovative Properties Co., and Henkel AG & Co. KGaA leading research and development efforts. These companies are investing in innovative solutions to improve the performance and durability of antistatic coatings, leveraging their expertise in materials science and electronics manufacturing.

Nitto Denko Corp.

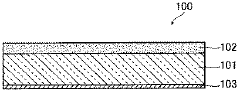

Technical Solution: Nitto Denko has innovated in the field of antistatic coatings by developing a novel approach incorporating sulphanilic acid. Their technology involves creating a multi-layered coating structure, with sulphanilic acid-based compounds forming the primary antistatic layer. This layer is sandwiched between protective polymer layers, enhancing durability and environmental resistance[2]. The company's process allows for precise control of sulphanilic acid concentration, optimizing antistatic performance while maintaining optical clarity. Nitto Denko's coating can be applied to various substrates, including flexible films and rigid surfaces, making it suitable for a wide range of electronic applications[4]. The coating also exhibits self-healing properties, with the ability to reorganize its molecular structure to maintain antistatic performance even after surface abrasion[6].

Strengths: Versatile application methods, self-healing properties, and excellent durability. Weaknesses: Potentially complex manufacturing process and higher production costs.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced antistatic coatings incorporating sulphanilic acid for electronics applications. Their proprietary technology utilizes a blend of sulphanilic acid derivatives and conductive polymers to create a durable, transparent coating with excellent antistatic properties. The coating is applied using a roll-to-roll process, allowing for high-volume production of antistatic films for various electronic devices[1]. The sulphanilic acid components in the coating form a network of charge-carrying pathways, effectively dissipating static electricity and preventing damage to sensitive electronic components[3]. 3M's coating also incorporates nanoparticles to enhance adhesion and scratch resistance, resulting in a long-lasting protective layer for electronic displays and housings[5].

Strengths: High-volume production capability, excellent antistatic performance, and enhanced durability. Weaknesses: Potential for higher cost compared to traditional coatings, and possible environmental concerns related to nanoparticle use.

Innovative Approaches in Sulphanilic Acid Integration

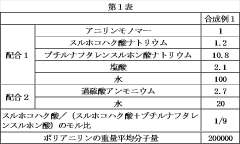

Antistatic coating and antistatic material using the same

PatentInactiveJP2012051959A

Innovation

- An antistatic paint formulation combining a conductive polymer, a binder resin, a phosphoric acid ester compound with a specific structure, a silicone-based or fluorine-based surfactant, and fine particles, optimized in terms of content ratios and particle sizes, to enhance conductivity and antifouling properties.

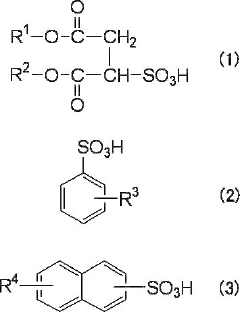

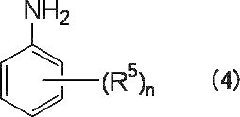

Compositions for forming antistatic coatings and articles coated with the compositions

PatentPendingUS20250115780A1

Innovation

- A coating composition comprising an ionomer with a polymer backbone and side chains containing sulfonic acid and sulfonate groups, where 50-95% of the ionic groups are in the sulfonate form with counter ions like lithium, sodium, magnesium, or calcium, providing a balanced combination of high surface conductivity, low charge build-up, and resistance to cleaning fluids.

Environmental Impact of Sulphanilic Acid-based Coatings

The incorporation of sulphanilic acid in antistatic coatings for electronics raises important environmental considerations. These coatings, while essential for protecting sensitive electronic components from electrostatic discharge, may have significant impacts on the environment throughout their lifecycle.

During the production phase, the synthesis of sulphanilic acid involves potentially hazardous chemicals and processes. The manufacturing of these coatings may result in the release of volatile organic compounds (VOCs) and other pollutants into the air and water. Proper handling and disposal of waste materials from the production process are crucial to minimize environmental contamination.

The application of sulphanilic acid-based coatings on electronic devices presents another set of environmental challenges. The coating process often requires solvents that can contribute to air pollution and pose risks to worker health if not properly managed. Additionally, overspray and waste from the application process must be carefully controlled to prevent soil and water contamination.

Throughout the use phase of electronic products, the environmental impact of these coatings is generally minimal. However, the durability and longevity of the coating can affect the overall lifespan of the electronic device. A more durable coating may extend the product's life, reducing electronic waste generation.

End-of-life considerations for electronics with sulphanilic acid-based coatings are particularly important. The presence of these coatings can complicate recycling processes, potentially requiring additional steps to separate and properly dispose of the coating material. If not handled correctly, the chemicals in the coating could leach into the environment when electronic waste is improperly disposed of or processed.

The potential for bioaccumulation and persistence of sulphanilic acid and its derivatives in the environment is a concern that requires further study. While sulphanilic acid itself is generally considered to have low toxicity, its long-term effects on ecosystems and potential for accumulation in food chains are not fully understood.

Efforts to mitigate the environmental impact of sulphanilic acid-based coatings are ongoing. Research into more environmentally friendly alternatives, such as water-based formulations or bio-derived components, shows promise for reducing the ecological footprint of antistatic coatings. Additionally, improvements in application techniques and recycling technologies are being developed to minimize waste and enhance the recyclability of coated electronics.

Regulatory frameworks play a crucial role in managing the environmental impact of these coatings. Compliance with regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) in the European Union, and similar regulations worldwide, is essential for manufacturers using sulphanilic acid-based coatings.

During the production phase, the synthesis of sulphanilic acid involves potentially hazardous chemicals and processes. The manufacturing of these coatings may result in the release of volatile organic compounds (VOCs) and other pollutants into the air and water. Proper handling and disposal of waste materials from the production process are crucial to minimize environmental contamination.

The application of sulphanilic acid-based coatings on electronic devices presents another set of environmental challenges. The coating process often requires solvents that can contribute to air pollution and pose risks to worker health if not properly managed. Additionally, overspray and waste from the application process must be carefully controlled to prevent soil and water contamination.

Throughout the use phase of electronic products, the environmental impact of these coatings is generally minimal. However, the durability and longevity of the coating can affect the overall lifespan of the electronic device. A more durable coating may extend the product's life, reducing electronic waste generation.

End-of-life considerations for electronics with sulphanilic acid-based coatings are particularly important. The presence of these coatings can complicate recycling processes, potentially requiring additional steps to separate and properly dispose of the coating material. If not handled correctly, the chemicals in the coating could leach into the environment when electronic waste is improperly disposed of or processed.

The potential for bioaccumulation and persistence of sulphanilic acid and its derivatives in the environment is a concern that requires further study. While sulphanilic acid itself is generally considered to have low toxicity, its long-term effects on ecosystems and potential for accumulation in food chains are not fully understood.

Efforts to mitigate the environmental impact of sulphanilic acid-based coatings are ongoing. Research into more environmentally friendly alternatives, such as water-based formulations or bio-derived components, shows promise for reducing the ecological footprint of antistatic coatings. Additionally, improvements in application techniques and recycling technologies are being developed to minimize waste and enhance the recyclability of coated electronics.

Regulatory frameworks play a crucial role in managing the environmental impact of these coatings. Compliance with regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) in the European Union, and similar regulations worldwide, is essential for manufacturers using sulphanilic acid-based coatings.

Regulatory Compliance for Electronic Coating Materials

The incorporation of sulphanilic acid in antistatic coatings for electronics necessitates careful consideration of regulatory compliance. Electronic coating materials are subject to stringent regulations to ensure safety, environmental protection, and product performance.

In the United States, the Environmental Protection Agency (EPA) regulates the use of chemical substances in electronic coatings under the Toxic Substances Control Act (TSCA). Manufacturers must ensure that sulphanilic acid and other components are listed on the TSCA inventory or exempt from listing. Additionally, they must comply with any Significant New Use Rules (SNURs) that may apply to these substances.

The European Union's Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation is another crucial consideration. Sulphanilic acid and other coating components must be registered with the European Chemicals Agency (ECHA) if manufactured or imported in quantities exceeding one tonne per year. Manufacturers must also provide safety data sheets and ensure compliance with any restrictions or authorisation requirements.

Specific to electronics, the Restriction of Hazardous Substances (RoHS) Directive limits the use of certain hazardous substances in electrical and electronic equipment. While sulphanilic acid is not explicitly restricted under RoHS, manufacturers must ensure that its use does not introduce any restricted substances above permitted levels in the final product.

The International Electrotechnical Commission (IEC) provides standards for electronic components and materials, including coatings. Compliance with relevant IEC standards, such as IEC 60664 for insulation coordination, may be necessary to ensure the coating's performance and safety in electronic applications.

Occupational safety regulations, such as those set by the Occupational Safety and Health Administration (OSHA) in the US, must be considered during the manufacturing process. This includes proper handling, storage, and disposal of sulphanilic acid and other coating materials, as well as ensuring worker safety through appropriate personal protective equipment and ventilation systems.

Environmental regulations, including those governing air emissions and waste disposal, may apply to the manufacturing process of antistatic coatings. Compliance with local, state, and federal environmental regulations is essential to prevent pollution and ensure sustainable production practices.

Manufacturers must also consider industry-specific standards and certifications, such as those set by the Institute of Printed Circuits (IPC) for printed circuit board materials. These standards may include requirements for coating performance, durability, and compatibility with other electronic components.

To ensure ongoing compliance, manufacturers should implement robust quality management systems and maintain thorough documentation of their compliance efforts. Regular audits and updates to compliance strategies are necessary to adapt to evolving regulations and maintain market access for electronic products incorporating sulphanilic acid-based antistatic coatings.

In the United States, the Environmental Protection Agency (EPA) regulates the use of chemical substances in electronic coatings under the Toxic Substances Control Act (TSCA). Manufacturers must ensure that sulphanilic acid and other components are listed on the TSCA inventory or exempt from listing. Additionally, they must comply with any Significant New Use Rules (SNURs) that may apply to these substances.

The European Union's Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation is another crucial consideration. Sulphanilic acid and other coating components must be registered with the European Chemicals Agency (ECHA) if manufactured or imported in quantities exceeding one tonne per year. Manufacturers must also provide safety data sheets and ensure compliance with any restrictions or authorisation requirements.

Specific to electronics, the Restriction of Hazardous Substances (RoHS) Directive limits the use of certain hazardous substances in electrical and electronic equipment. While sulphanilic acid is not explicitly restricted under RoHS, manufacturers must ensure that its use does not introduce any restricted substances above permitted levels in the final product.

The International Electrotechnical Commission (IEC) provides standards for electronic components and materials, including coatings. Compliance with relevant IEC standards, such as IEC 60664 for insulation coordination, may be necessary to ensure the coating's performance and safety in electronic applications.

Occupational safety regulations, such as those set by the Occupational Safety and Health Administration (OSHA) in the US, must be considered during the manufacturing process. This includes proper handling, storage, and disposal of sulphanilic acid and other coating materials, as well as ensuring worker safety through appropriate personal protective equipment and ventilation systems.

Environmental regulations, including those governing air emissions and waste disposal, may apply to the manufacturing process of antistatic coatings. Compliance with local, state, and federal environmental regulations is essential to prevent pollution and ensure sustainable production practices.

Manufacturers must also consider industry-specific standards and certifications, such as those set by the Institute of Printed Circuits (IPC) for printed circuit board materials. These standards may include requirements for coating performance, durability, and compatibility with other electronic components.

To ensure ongoing compliance, manufacturers should implement robust quality management systems and maintain thorough documentation of their compliance efforts. Regular audits and updates to compliance strategies are necessary to adapt to evolving regulations and maintain market access for electronic products incorporating sulphanilic acid-based antistatic coatings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!