Innovative Uses of Thermite in High‑Tech Industries

JUN 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermite Tech Evolution

Thermite, a pyrotechnic composition of metal powder fuel and metal oxide, has undergone significant technological evolution since its discovery in the late 19th century. Initially used primarily for welding and incendiary devices, thermite has found innovative applications in high-tech industries over the past few decades.

The early stages of thermite technology focused on refining the composition and improving ignition methods. In the 1950s and 1960s, researchers explored various metal combinations to enhance reaction temperatures and energy output. This led to the development of specialized thermite mixtures for specific industrial applications, such as rail welding and metal purification.

The 1970s and 1980s saw a shift towards miniaturization and precision control of thermite reactions. This period marked the beginning of thermite's integration into microelectronics manufacturing, where it was used for hermetic sealing of sensitive components. Concurrently, advancements in particle size control and mixing techniques allowed for more consistent and predictable reactions.

The 1990s brought about a revolution in thermite technology with the introduction of nano-thermites. These materials, composed of nanoscale particles, exhibited significantly higher reaction rates and energy densities compared to traditional thermite mixtures. This breakthrough opened up new possibilities in areas such as propulsion systems and energetic materials for aerospace applications.

In the early 2000s, researchers began exploring thermite's potential in advanced materials synthesis. The extreme temperatures and rapid cooling rates achievable with thermite reactions were harnessed to create novel materials with unique properties, including high-performance ceramics and metal matrix composites.

The past decade has seen a focus on environmentally friendly and sustainable thermite technologies. Green thermite formulations, using less toxic components and producing fewer harmful byproducts, have been developed for applications in waste treatment and environmental remediation.

Most recently, the integration of thermite technology with additive manufacturing processes has emerged as a promising frontier. 3D-printed thermite structures offer unprecedented control over reaction kinetics and energy release, enabling tailored solutions for advanced manufacturing and energy storage applications.

Looking ahead, the evolution of thermite technology is likely to continue in directions that leverage its unique properties for solving complex challenges in emerging high-tech fields, such as space exploration, advanced energy systems, and next-generation electronics manufacturing.

The early stages of thermite technology focused on refining the composition and improving ignition methods. In the 1950s and 1960s, researchers explored various metal combinations to enhance reaction temperatures and energy output. This led to the development of specialized thermite mixtures for specific industrial applications, such as rail welding and metal purification.

The 1970s and 1980s saw a shift towards miniaturization and precision control of thermite reactions. This period marked the beginning of thermite's integration into microelectronics manufacturing, where it was used for hermetic sealing of sensitive components. Concurrently, advancements in particle size control and mixing techniques allowed for more consistent and predictable reactions.

The 1990s brought about a revolution in thermite technology with the introduction of nano-thermites. These materials, composed of nanoscale particles, exhibited significantly higher reaction rates and energy densities compared to traditional thermite mixtures. This breakthrough opened up new possibilities in areas such as propulsion systems and energetic materials for aerospace applications.

In the early 2000s, researchers began exploring thermite's potential in advanced materials synthesis. The extreme temperatures and rapid cooling rates achievable with thermite reactions were harnessed to create novel materials with unique properties, including high-performance ceramics and metal matrix composites.

The past decade has seen a focus on environmentally friendly and sustainable thermite technologies. Green thermite formulations, using less toxic components and producing fewer harmful byproducts, have been developed for applications in waste treatment and environmental remediation.

Most recently, the integration of thermite technology with additive manufacturing processes has emerged as a promising frontier. 3D-printed thermite structures offer unprecedented control over reaction kinetics and energy release, enabling tailored solutions for advanced manufacturing and energy storage applications.

Looking ahead, the evolution of thermite technology is likely to continue in directions that leverage its unique properties for solving complex challenges in emerging high-tech fields, such as space exploration, advanced energy systems, and next-generation electronics manufacturing.

High-Tech Industry Demand

The demand for innovative uses of thermite in high-tech industries has been steadily growing, driven by the unique properties of this exothermic mixture. Thermite's ability to generate intense heat and molten metal has found applications across various sectors, particularly in advanced manufacturing and materials processing.

In the semiconductor industry, thermite reactions are being explored for precise chip packaging and advanced interconnect technologies. The controlled, localized heat generated by thermite reactions allows for targeted melting and bonding of materials, potentially revolutionizing chip assembly processes. This application addresses the industry's need for more efficient and reliable packaging methods as chip designs become increasingly complex.

Aerospace and defense sectors have shown significant interest in thermite-based technologies for specialized welding and metal joining applications. The ability to create strong, seamless joints in challenging environments makes thermite an attractive option for manufacturing and repairing critical components in aircraft and military equipment. This demand is fueled by the ongoing push for lighter, stronger materials in aerospace applications.

The renewable energy sector, particularly in solar panel manufacturing, has identified potential uses for thermite in the production of high-purity silicon. Thermite reactions could offer a more energy-efficient method for reducing silicon dioxide to pure silicon, addressing the industry's need for more sustainable manufacturing processes.

In the field of additive manufacturing, researchers are exploring thermite-based 3D printing techniques for metal components. This innovative approach could enable the production of complex metal parts with unique properties, meeting the growing demand for advanced manufacturing capabilities in industries such as automotive and medical devices.

The mining and resource extraction industries are investigating thermite for specialized cutting and perforation tasks. The intense heat and focused energy of thermite reactions could provide more efficient methods for accessing hard-to-reach mineral deposits or for emergency rescue operations in mining accidents.

As nanotechnology advances, there is increasing interest in nano-thermite materials for various high-tech applications. These materials offer the potential for highly controlled, microscale energy release, which could find uses in microelectromechanical systems (MEMS) and advanced sensor technologies.

The demand for thermite in high-tech industries is also driven by its potential in energy storage and conversion technologies. Research is ongoing into thermite-based thermal batteries and energy harvesting systems, which could provide novel solutions for portable power sources and waste heat recovery in industrial processes.

In the semiconductor industry, thermite reactions are being explored for precise chip packaging and advanced interconnect technologies. The controlled, localized heat generated by thermite reactions allows for targeted melting and bonding of materials, potentially revolutionizing chip assembly processes. This application addresses the industry's need for more efficient and reliable packaging methods as chip designs become increasingly complex.

Aerospace and defense sectors have shown significant interest in thermite-based technologies for specialized welding and metal joining applications. The ability to create strong, seamless joints in challenging environments makes thermite an attractive option for manufacturing and repairing critical components in aircraft and military equipment. This demand is fueled by the ongoing push for lighter, stronger materials in aerospace applications.

The renewable energy sector, particularly in solar panel manufacturing, has identified potential uses for thermite in the production of high-purity silicon. Thermite reactions could offer a more energy-efficient method for reducing silicon dioxide to pure silicon, addressing the industry's need for more sustainable manufacturing processes.

In the field of additive manufacturing, researchers are exploring thermite-based 3D printing techniques for metal components. This innovative approach could enable the production of complex metal parts with unique properties, meeting the growing demand for advanced manufacturing capabilities in industries such as automotive and medical devices.

The mining and resource extraction industries are investigating thermite for specialized cutting and perforation tasks. The intense heat and focused energy of thermite reactions could provide more efficient methods for accessing hard-to-reach mineral deposits or for emergency rescue operations in mining accidents.

As nanotechnology advances, there is increasing interest in nano-thermite materials for various high-tech applications. These materials offer the potential for highly controlled, microscale energy release, which could find uses in microelectromechanical systems (MEMS) and advanced sensor technologies.

The demand for thermite in high-tech industries is also driven by its potential in energy storage and conversion technologies. Research is ongoing into thermite-based thermal batteries and energy harvesting systems, which could provide novel solutions for portable power sources and waste heat recovery in industrial processes.

Thermite Challenges

Despite its long history and well-established applications, thermite technology faces several significant challenges in high-tech industries. These challenges primarily stem from the inherent properties of thermite reactions and the demanding requirements of advanced technological applications.

One of the foremost challenges is controlling the reaction rate and temperature of thermite. In high-tech applications, precise control over these parameters is crucial for achieving desired outcomes. The exothermic nature of thermite reactions makes them difficult to modulate, potentially leading to unintended consequences or damage to sensitive components in advanced manufacturing processes.

Safety concerns present another major hurdle in the widespread adoption of thermite in high-tech industries. The high temperatures and intense light produced during thermite reactions pose significant risks in controlled environments typical of high-tech manufacturing facilities. Developing robust safety protocols and containment systems that can withstand these extreme conditions without compromising the integrity of the surrounding equipment remains a complex challenge.

The issue of scalability also presents difficulties when integrating thermite into high-tech production processes. While thermite reactions are well-suited for certain small-scale applications, scaling up for industrial use introduces complexities in terms of reaction control, heat management, and product consistency. Achieving uniform results across larger batches or continuous production lines requires sophisticated engineering solutions.

Another challenge lies in the precision and repeatability of thermite-based processes. High-tech industries often demand extremely tight tolerances and consistent results. The variability inherent in thermite reactions, influenced by factors such as particle size, mixing ratios, and environmental conditions, can make it difficult to achieve the level of precision required for cutting-edge applications.

Material compatibility is a further concern when incorporating thermite into high-tech manufacturing. The high temperatures and reactive nature of thermite can potentially interact with or damage sensitive materials commonly used in advanced technologies. Finding ways to harness the benefits of thermite reactions while protecting delicate components or substrates is an ongoing challenge for researchers and engineers.

Lastly, the environmental impact of thermite use in industrial settings poses challenges. As sustainability becomes increasingly important in high-tech industries, addressing the emissions and waste products associated with thermite reactions is crucial. Developing cleaner, more environmentally friendly thermite formulations or implementing effective containment and filtration systems are areas that require continued research and innovation.

One of the foremost challenges is controlling the reaction rate and temperature of thermite. In high-tech applications, precise control over these parameters is crucial for achieving desired outcomes. The exothermic nature of thermite reactions makes them difficult to modulate, potentially leading to unintended consequences or damage to sensitive components in advanced manufacturing processes.

Safety concerns present another major hurdle in the widespread adoption of thermite in high-tech industries. The high temperatures and intense light produced during thermite reactions pose significant risks in controlled environments typical of high-tech manufacturing facilities. Developing robust safety protocols and containment systems that can withstand these extreme conditions without compromising the integrity of the surrounding equipment remains a complex challenge.

The issue of scalability also presents difficulties when integrating thermite into high-tech production processes. While thermite reactions are well-suited for certain small-scale applications, scaling up for industrial use introduces complexities in terms of reaction control, heat management, and product consistency. Achieving uniform results across larger batches or continuous production lines requires sophisticated engineering solutions.

Another challenge lies in the precision and repeatability of thermite-based processes. High-tech industries often demand extremely tight tolerances and consistent results. The variability inherent in thermite reactions, influenced by factors such as particle size, mixing ratios, and environmental conditions, can make it difficult to achieve the level of precision required for cutting-edge applications.

Material compatibility is a further concern when incorporating thermite into high-tech manufacturing. The high temperatures and reactive nature of thermite can potentially interact with or damage sensitive materials commonly used in advanced technologies. Finding ways to harness the benefits of thermite reactions while protecting delicate components or substrates is an ongoing challenge for researchers and engineers.

Lastly, the environmental impact of thermite use in industrial settings poses challenges. As sustainability becomes increasingly important in high-tech industries, addressing the emissions and waste products associated with thermite reactions is crucial. Developing cleaner, more environmentally friendly thermite formulations or implementing effective containment and filtration systems are areas that require continued research and innovation.

Current Thermite Apps

01 Thermite composition and ignition methods

Thermite compositions typically consist of metal oxides and aluminum powder. Various ignition methods are used, including electrical, chemical, and mechanical means. The reaction produces intense heat and molten metal, making it useful for welding, incendiary devices, and metal purification.- Thermite composition and applications: Thermite is a pyrotechnic composition of metal powder fuel and metal oxide. It's used in various applications including welding, incendiary devices, and metal purification. The reaction produces intense heat and molten metal, making it suitable for specialized industrial and military uses.

- Thermite-based cutting and perforation tools: Thermite reactions are utilized in cutting and perforation tools, particularly in the oil and gas industry. These tools use the high-temperature thermite reaction to cut through or perforate metal casings and surrounding rock formations, enhancing well productivity and enabling various downhole operations.

- Enhanced thermite formulations: Advanced thermite formulations incorporate additives or modified compositions to improve performance characteristics. These enhancements may include increased reaction speed, higher temperature output, or better control over the reaction. Such formulations find use in specialized applications requiring precise and powerful thermal reactions.

- Thermite in additive manufacturing: Thermite reactions are being explored in additive manufacturing processes. This innovative approach uses the heat generated by thermite reactions to fuse metal powders, potentially enabling rapid, on-site manufacturing of metal components or repairs, particularly in remote or challenging environments.

- Safety and control mechanisms for thermite reactions: Given the intense nature of thermite reactions, various safety and control mechanisms have been developed. These include specialized ignition systems, containment vessels, and methods for controlling the reaction rate and direction. Such innovations enhance the safe use of thermite in both industrial and research settings.

02 Applications in oil and gas well operations

Thermite reactions are utilized in oil and gas well operations for tasks such as cutting pipes, sealing wells, and initiating other downhole tools. The high temperature generated by the reaction can effectively melt and cut through metal barriers in well bores.Expand Specific Solutions03 Thermite welding for railway tracks

Thermite welding is widely used for joining railway tracks. The process involves pouring molten metal produced by a thermite reaction into a mold surrounding the rail ends. This creates a strong, continuous weld that can withstand the stresses of train traffic.Expand Specific Solutions04 Enhanced thermite formulations

Research focuses on improving thermite formulations for increased efficiency and specific applications. This includes incorporating nanomaterials, adjusting particle sizes, and adding catalysts or other reactive components to enhance performance or tailor the reaction for specific uses.Expand Specific Solutions05 Safety and control mechanisms

Given the high reactivity of thermite, safety measures and control mechanisms are crucial. This includes developing safer ignition systems, containment methods, and reaction moderators. Additionally, research is conducted on extinguishing methods and protective equipment for handling thermite materials.Expand Specific Solutions

Key Thermite Players

The innovative uses of thermite in high-tech industries are at a nascent stage, with the market showing significant growth potential. The technology's maturity varies across applications, ranging from experimental to early commercial stages. Key players like Naval Research Laboratory, Lockheed Martin Corp., and Northrop Grumman Systems Corp. are driving advancements in defense and aerospace sectors. Universities such as Nanjing University of Science & Technology and Central South University are contributing to fundamental research. Companies like BiSN Oil Tools Ltd. and ConocoPhillips Co. are exploring thermite applications in the energy sector. The diverse range of players, including Hewlett Packard Enterprise Development LP and Intel Corp., suggests potential cross-industry applications, indicating a dynamic and evolving competitive landscape.

Lockheed Martin Corp.

Technical Solution: Lockheed Martin has developed advanced thermite-based systems for aerospace and defense applications. Their innovative approach involves using precisely engineered thermite compositions to create controlled, high-temperature reactions for welding, cutting, and ignition purposes in extreme environments. The company has also explored the use of thermite in satellite deployment mechanisms and spacecraft separation systems, leveraging its ability to produce reliable, instantaneous, and high-energy reactions in space conditions.

Strengths: Expertise in aerospace applications, advanced engineering capabilities, and proven track record in defense technologies. Weaknesses: High costs associated with specialized aerospace applications and potential environmental concerns.

BiSN Oil Tools Ltd.

Technical Solution: BiSN Oil Tools has pioneered the use of thermite reactions in downhole well sealing and plugging operations. Their Wel-lok M2M technology utilizes a modified thermite reaction to melt and form a metal-to-metal seal in oil and gas wells. This innovative approach allows for the creation of gas-tight seals at various depths and temperatures, providing a more effective and long-lasting solution compared to traditional cement-based methods. The company has further developed this technology to address complex well integrity issues and decommissioning challenges in the oil and gas industry.

Strengths: Unique application in oil and gas industry, effective well sealing solution, and potential for cost savings in well operations. Weaknesses: Limited to specific industry applications and potential safety concerns in handling reactive materials.

Thermite Patent Analysis

Thermite with tailored properties

PatentUndeterminedRO129221A2

Innovation

- Modifying the proportions of iron oxides (FeO, Fe2O3, Fe3O4) in the termite mixture by heating them in controlled atmospheres within specific temperature ranges to adjust the molding temperature of the steel, allowing for tailored thermite recipes with optimized properties for various applications.

Fuzzy Interface Layer For Thermite And Primer Made From Thermite With Fuzzy Layer

PatentPendingUS20240361113A1

Innovation

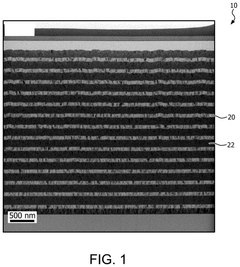

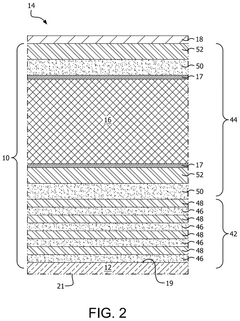

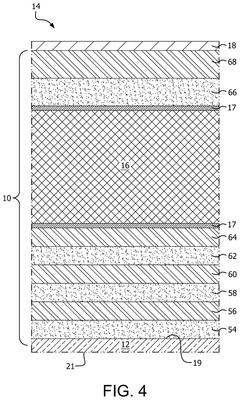

- A layered thermite composite with a fuzzy interface layer is developed, comprising alternating metal oxide and reducing metal layers deposited on a substrate, where the fuzzy interface layer contains a mixture of reducing metal, reducing metal oxide, and metal oxide, enhancing ignition rates while protecting against oxidization and facilitating automated manufacturing.

Safety Regulations

The use of thermite in high-tech industries necessitates stringent safety regulations due to its highly exothermic nature and potential hazards. Regulatory bodies worldwide have established comprehensive guidelines to ensure the safe handling, storage, and application of thermite in industrial settings. These regulations typically cover various aspects, including personnel training, protective equipment, storage facilities, and emergency response protocols.

One of the primary safety concerns addressed by regulations is the proper storage of thermite materials. Strict guidelines mandate the use of specialized containers that are resistant to heat and impact. These containers must be stored in designated areas with controlled temperature and humidity levels to prevent accidental ignition. Additionally, regulations often require the implementation of fire suppression systems and regular inspections of storage facilities to maintain compliance.

Personnel safety is another critical aspect of thermite-related regulations. Workers involved in handling thermite must undergo extensive training programs that cover proper handling techniques, risk assessment, and emergency procedures. Personal protective equipment (PPE) requirements are typically stringent, including fire-resistant clothing, face shields, and respiratory protection. Regular safety drills and refresher courses are often mandated to ensure that workers maintain their knowledge and skills in handling thermite safely.

Environmental considerations also play a significant role in safety regulations for thermite use. Guidelines often address the proper disposal of thermite residues and byproducts to prevent contamination of soil and water sources. Air quality monitoring may be required in facilities where thermite is frequently used to ensure that emissions are within acceptable limits and do not pose health risks to workers or surrounding communities.

The transportation of thermite materials is subject to strict regulations as well. Specialized packaging and labeling requirements are in place to ensure safe transport and handling during shipment. Vehicles used for transporting thermite must meet specific safety standards and may require special permits or certifications.

As innovative uses of thermite in high-tech industries continue to emerge, regulatory bodies are adapting their guidelines to address new applications and potential risks. This ongoing process involves collaboration between industry experts, researchers, and regulatory agencies to develop and refine safety standards that keep pace with technological advancements. Companies engaged in thermite-related research and development must stay informed about evolving regulations and proactively implement safety measures to ensure compliance and protect their workforce and the environment.

One of the primary safety concerns addressed by regulations is the proper storage of thermite materials. Strict guidelines mandate the use of specialized containers that are resistant to heat and impact. These containers must be stored in designated areas with controlled temperature and humidity levels to prevent accidental ignition. Additionally, regulations often require the implementation of fire suppression systems and regular inspections of storage facilities to maintain compliance.

Personnel safety is another critical aspect of thermite-related regulations. Workers involved in handling thermite must undergo extensive training programs that cover proper handling techniques, risk assessment, and emergency procedures. Personal protective equipment (PPE) requirements are typically stringent, including fire-resistant clothing, face shields, and respiratory protection. Regular safety drills and refresher courses are often mandated to ensure that workers maintain their knowledge and skills in handling thermite safely.

Environmental considerations also play a significant role in safety regulations for thermite use. Guidelines often address the proper disposal of thermite residues and byproducts to prevent contamination of soil and water sources. Air quality monitoring may be required in facilities where thermite is frequently used to ensure that emissions are within acceptable limits and do not pose health risks to workers or surrounding communities.

The transportation of thermite materials is subject to strict regulations as well. Specialized packaging and labeling requirements are in place to ensure safe transport and handling during shipment. Vehicles used for transporting thermite must meet specific safety standards and may require special permits or certifications.

As innovative uses of thermite in high-tech industries continue to emerge, regulatory bodies are adapting their guidelines to address new applications and potential risks. This ongoing process involves collaboration between industry experts, researchers, and regulatory agencies to develop and refine safety standards that keep pace with technological advancements. Companies engaged in thermite-related research and development must stay informed about evolving regulations and proactively implement safety measures to ensure compliance and protect their workforce and the environment.

Environmental Impact

The innovative use of thermite in high-tech industries has raised significant environmental concerns that warrant careful consideration. Thermite reactions, known for their high temperatures and rapid oxidation, can potentially release harmful byproducts into the atmosphere. These emissions may include metal oxides, particulate matter, and in some cases, toxic fumes, depending on the specific composition of the thermite mixture and the materials involved in the reaction.

One of the primary environmental impacts is air pollution. The intense heat generated during thermite reactions can vaporize various compounds, leading to the release of fine particulates and gaseous emissions. These airborne pollutants can contribute to smog formation, affect local air quality, and potentially harm both human health and ecosystems. Long-term exposure to such emissions may lead to respiratory issues and other health problems in nearby communities.

Water pollution is another critical concern. In industrial applications where thermite is used near water sources, there is a risk of contamination through runoff or direct contact. The high-temperature reaction products, including molten metals and slag, can introduce harmful substances into aquatic environments, potentially disrupting ecosystems and affecting water quality for both wildlife and human consumption.

Soil contamination is also a potential consequence of thermite use in high-tech industries. The residues from thermite reactions, including metal oxides and other byproducts, can accumulate in the soil over time. This accumulation may alter soil chemistry, affect plant growth, and potentially enter the food chain through bioaccumulation in plants and animals.

The energy-intensive nature of thermite reactions also raises concerns about carbon footprint and energy efficiency. While the reactions themselves are exothermic, the production and transportation of thermite materials, as well as the energy required for containment and safety measures, contribute to the overall environmental impact of this technology.

To mitigate these environmental risks, industries employing thermite technology must implement stringent control measures. These may include advanced filtration systems to capture emissions, proper containment and disposal protocols for reaction byproducts, and the development of more environmentally friendly thermite compositions. Additionally, regulatory bodies need to establish and enforce strict environmental standards for the use of thermite in industrial applications.

Research into green alternatives and process optimizations is crucial for reducing the environmental footprint of thermite use. This may involve exploring less reactive or more controllable exothermic reactions, developing closed-loop systems to capture and recycle byproducts, or investigating entirely new technologies that can achieve similar results with minimal environmental impact.

One of the primary environmental impacts is air pollution. The intense heat generated during thermite reactions can vaporize various compounds, leading to the release of fine particulates and gaseous emissions. These airborne pollutants can contribute to smog formation, affect local air quality, and potentially harm both human health and ecosystems. Long-term exposure to such emissions may lead to respiratory issues and other health problems in nearby communities.

Water pollution is another critical concern. In industrial applications where thermite is used near water sources, there is a risk of contamination through runoff or direct contact. The high-temperature reaction products, including molten metals and slag, can introduce harmful substances into aquatic environments, potentially disrupting ecosystems and affecting water quality for both wildlife and human consumption.

Soil contamination is also a potential consequence of thermite use in high-tech industries. The residues from thermite reactions, including metal oxides and other byproducts, can accumulate in the soil over time. This accumulation may alter soil chemistry, affect plant growth, and potentially enter the food chain through bioaccumulation in plants and animals.

The energy-intensive nature of thermite reactions also raises concerns about carbon footprint and energy efficiency. While the reactions themselves are exothermic, the production and transportation of thermite materials, as well as the energy required for containment and safety measures, contribute to the overall environmental impact of this technology.

To mitigate these environmental risks, industries employing thermite technology must implement stringent control measures. These may include advanced filtration systems to capture emissions, proper containment and disposal protocols for reaction byproducts, and the development of more environmentally friendly thermite compositions. Additionally, regulatory bodies need to establish and enforce strict environmental standards for the use of thermite in industrial applications.

Research into green alternatives and process optimizations is crucial for reducing the environmental footprint of thermite use. This may involve exploring less reactive or more controllable exothermic reactions, developing closed-loop systems to capture and recycle byproducts, or investigating entirely new technologies that can achieve similar results with minimal environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!