Integrating Laminar Flow with Digital Twin Technologies

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laminar Flow and Digital Twin Integration Overview

The integration of laminar flow principles with digital twin technologies represents a significant advancement in fluid dynamics modeling and simulation. Laminar flow, characterized by smooth and predictable fluid motion, is a critical concept in various engineering applications, from microfluidics to aerodynamics. Digital twins, on the other hand, are virtual representations of physical systems that can simulate, predict, and optimize performance in real-time.

The convergence of these two domains offers unprecedented opportunities for enhancing the design, operation, and maintenance of fluid-based systems. By incorporating laminar flow models into digital twin frameworks, engineers can create highly accurate virtual replicas of fluid systems that behave identically to their physical counterparts under laminar flow conditions. This integration enables real-time monitoring, analysis, and optimization of fluid dynamics in a wide range of applications.

One of the primary benefits of this integration is the ability to predict and control fluid behavior with exceptional precision. In industries such as pharmaceuticals and chemical processing, where maintaining laminar flow is crucial for product quality and process efficiency, digital twins can provide invaluable insights into system performance. They allow for the simulation of various scenarios and operating conditions, helping to identify potential issues before they occur in the physical system.

Moreover, the combination of laminar flow principles and digital twin technologies facilitates the development of more sophisticated control systems. By continuously updating the digital model with real-time data from sensors in the physical system, engineers can implement adaptive control strategies that maintain optimal laminar flow conditions even in the face of changing environmental factors or system parameters.

The integration also holds significant promise for advancing research and development in fluid dynamics. Scientists and engineers can use these enhanced digital models to explore new designs and concepts without the need for costly physical prototypes. This capability accelerates innovation and reduces the time-to-market for new products and technologies that rely on laminar flow principles.

In the context of Industry 4.0 and smart manufacturing, the integration of laminar flow with digital twin technologies aligns perfectly with the trend towards more intelligent and interconnected industrial systems. It enables predictive maintenance strategies by allowing operators to detect deviations from ideal laminar flow conditions that may indicate equipment wear or impending failures.

As this integration continues to evolve, we can expect to see more sophisticated applications across various sectors, including aerospace, automotive, and biomedical engineering. The ability to create highly accurate, real-time simulations of laminar flow systems will drive improvements in efficiency, reliability, and performance across these industries, ultimately leading to more innovative and sustainable solutions.

The convergence of these two domains offers unprecedented opportunities for enhancing the design, operation, and maintenance of fluid-based systems. By incorporating laminar flow models into digital twin frameworks, engineers can create highly accurate virtual replicas of fluid systems that behave identically to their physical counterparts under laminar flow conditions. This integration enables real-time monitoring, analysis, and optimization of fluid dynamics in a wide range of applications.

One of the primary benefits of this integration is the ability to predict and control fluid behavior with exceptional precision. In industries such as pharmaceuticals and chemical processing, where maintaining laminar flow is crucial for product quality and process efficiency, digital twins can provide invaluable insights into system performance. They allow for the simulation of various scenarios and operating conditions, helping to identify potential issues before they occur in the physical system.

Moreover, the combination of laminar flow principles and digital twin technologies facilitates the development of more sophisticated control systems. By continuously updating the digital model with real-time data from sensors in the physical system, engineers can implement adaptive control strategies that maintain optimal laminar flow conditions even in the face of changing environmental factors or system parameters.

The integration also holds significant promise for advancing research and development in fluid dynamics. Scientists and engineers can use these enhanced digital models to explore new designs and concepts without the need for costly physical prototypes. This capability accelerates innovation and reduces the time-to-market for new products and technologies that rely on laminar flow principles.

In the context of Industry 4.0 and smart manufacturing, the integration of laminar flow with digital twin technologies aligns perfectly with the trend towards more intelligent and interconnected industrial systems. It enables predictive maintenance strategies by allowing operators to detect deviations from ideal laminar flow conditions that may indicate equipment wear or impending failures.

As this integration continues to evolve, we can expect to see more sophisticated applications across various sectors, including aerospace, automotive, and biomedical engineering. The ability to create highly accurate, real-time simulations of laminar flow systems will drive improvements in efficiency, reliability, and performance across these industries, ultimately leading to more innovative and sustainable solutions.

Market Demand for Smart Fluid Dynamics Solutions

The integration of laminar flow with digital twin technologies has sparked significant interest in the smart fluid dynamics solutions market. This convergence addresses a growing demand for more sophisticated and efficient fluid management systems across various industries. The market for these advanced solutions is primarily driven by the need for improved process optimization, reduced operational costs, and enhanced safety measures in fluid-intensive operations.

In the manufacturing sector, there is a strong demand for smart fluid dynamics solutions that can optimize production processes and reduce waste. Companies are increasingly looking for ways to monitor and control fluid behavior in real-time, leading to improved product quality and consistency. The automotive industry, in particular, has shown keen interest in these technologies for enhancing engine cooling systems and improving overall vehicle performance.

The oil and gas industry represents another significant market for smart fluid dynamics solutions. With the increasing complexity of extraction and refining processes, there is a growing need for advanced fluid modeling and simulation capabilities. These solutions enable better prediction of fluid behavior in pipelines, reservoirs, and processing facilities, leading to more efficient operations and reduced environmental risks.

In the healthcare sector, the demand for smart fluid dynamics solutions is driven by the need for more precise drug delivery systems and improved medical devices. The ability to accurately model and control fluid behavior at microscale levels is crucial for developing innovative treatments and diagnostic tools.

The aerospace industry is also a key driver of market demand for smart fluid dynamics solutions. As aircraft designs become more complex and fuel efficiency requirements more stringent, there is an increasing need for advanced fluid modeling and simulation tools. These solutions help in optimizing aerodynamics, reducing fuel consumption, and improving overall aircraft performance.

The water management sector presents another significant market opportunity. With growing concerns over water scarcity and the need for more efficient water distribution systems, smart fluid dynamics solutions are in high demand for optimizing water flow in urban infrastructure and irrigation systems.

As environmental regulations become more stringent, industries across the board are seeking smart fluid dynamics solutions to help reduce their environmental footprint. These technologies enable more precise control over fluid-related processes, leading to reduced emissions and improved resource utilization.

The market demand for smart fluid dynamics solutions is further bolstered by the increasing adoption of Industry 4.0 technologies. As more companies embrace digital transformation, the integration of laminar flow modeling with digital twin technologies becomes a natural progression in their quest for operational excellence and competitive advantage.

In the manufacturing sector, there is a strong demand for smart fluid dynamics solutions that can optimize production processes and reduce waste. Companies are increasingly looking for ways to monitor and control fluid behavior in real-time, leading to improved product quality and consistency. The automotive industry, in particular, has shown keen interest in these technologies for enhancing engine cooling systems and improving overall vehicle performance.

The oil and gas industry represents another significant market for smart fluid dynamics solutions. With the increasing complexity of extraction and refining processes, there is a growing need for advanced fluid modeling and simulation capabilities. These solutions enable better prediction of fluid behavior in pipelines, reservoirs, and processing facilities, leading to more efficient operations and reduced environmental risks.

In the healthcare sector, the demand for smart fluid dynamics solutions is driven by the need for more precise drug delivery systems and improved medical devices. The ability to accurately model and control fluid behavior at microscale levels is crucial for developing innovative treatments and diagnostic tools.

The aerospace industry is also a key driver of market demand for smart fluid dynamics solutions. As aircraft designs become more complex and fuel efficiency requirements more stringent, there is an increasing need for advanced fluid modeling and simulation tools. These solutions help in optimizing aerodynamics, reducing fuel consumption, and improving overall aircraft performance.

The water management sector presents another significant market opportunity. With growing concerns over water scarcity and the need for more efficient water distribution systems, smart fluid dynamics solutions are in high demand for optimizing water flow in urban infrastructure and irrigation systems.

As environmental regulations become more stringent, industries across the board are seeking smart fluid dynamics solutions to help reduce their environmental footprint. These technologies enable more precise control over fluid-related processes, leading to reduced emissions and improved resource utilization.

The market demand for smart fluid dynamics solutions is further bolstered by the increasing adoption of Industry 4.0 technologies. As more companies embrace digital transformation, the integration of laminar flow modeling with digital twin technologies becomes a natural progression in their quest for operational excellence and competitive advantage.

Current Challenges in Laminar Flow Simulation

Laminar flow simulation faces several significant challenges when integrating with digital twin technologies. One of the primary obstacles is the computational complexity required for accurate modeling of laminar flow behavior. As digital twins demand real-time or near-real-time data processing, the intensive calculations associated with laminar flow simulations can create bottlenecks in system performance.

The multi-scale nature of laminar flow phenomena presents another hurdle. Digital twins need to capture both microscopic fluid interactions and macroscopic system behavior simultaneously. Bridging these scales while maintaining computational efficiency remains a formidable task, often requiring sophisticated multi-scale modeling techniques that are still in development.

Data integration and synchronization between physical systems and their digital counterparts pose additional challenges. Laminar flow simulations rely on precise boundary conditions and initial states, which must be continuously updated from sensor data in a digital twin environment. Ensuring seamless data flow and maintaining consistency between the physical and digital realms is crucial but technically demanding.

The accuracy of laminar flow models in complex geometries is another area of concern. Digital twins often represent intricate real-world systems, and simulating laminar flow in such environments can lead to accumulation of errors or instabilities in the numerical methods employed. This necessitates the development of more robust and adaptive simulation algorithms capable of handling diverse and dynamic scenarios.

Uncertainty quantification and error propagation present further complications. Laminar flow simulations inherently contain uncertainties due to modeling assumptions, numerical approximations, and input data variability. Propagating these uncertainties through the digital twin framework while maintaining meaningful predictions is a significant challenge that requires advanced statistical and probabilistic methods.

The need for model reduction techniques is also paramount. Full-scale laminar flow simulations are often too computationally expensive for real-time digital twin applications. Developing reduced-order models that capture essential flow characteristics while dramatically reducing computational overhead is an active area of research, but striking the right balance between accuracy and efficiency remains challenging.

Lastly, the integration of laminar flow simulations with other physical phenomena in a digital twin context presents interoperability challenges. Coupling flow simulations with heat transfer, structural mechanics, or chemical reactions requires sophisticated multi-physics frameworks that can handle the diverse time and length scales involved in these interactions.

The multi-scale nature of laminar flow phenomena presents another hurdle. Digital twins need to capture both microscopic fluid interactions and macroscopic system behavior simultaneously. Bridging these scales while maintaining computational efficiency remains a formidable task, often requiring sophisticated multi-scale modeling techniques that are still in development.

Data integration and synchronization between physical systems and their digital counterparts pose additional challenges. Laminar flow simulations rely on precise boundary conditions and initial states, which must be continuously updated from sensor data in a digital twin environment. Ensuring seamless data flow and maintaining consistency between the physical and digital realms is crucial but technically demanding.

The accuracy of laminar flow models in complex geometries is another area of concern. Digital twins often represent intricate real-world systems, and simulating laminar flow in such environments can lead to accumulation of errors or instabilities in the numerical methods employed. This necessitates the development of more robust and adaptive simulation algorithms capable of handling diverse and dynamic scenarios.

Uncertainty quantification and error propagation present further complications. Laminar flow simulations inherently contain uncertainties due to modeling assumptions, numerical approximations, and input data variability. Propagating these uncertainties through the digital twin framework while maintaining meaningful predictions is a significant challenge that requires advanced statistical and probabilistic methods.

The need for model reduction techniques is also paramount. Full-scale laminar flow simulations are often too computationally expensive for real-time digital twin applications. Developing reduced-order models that capture essential flow characteristics while dramatically reducing computational overhead is an active area of research, but striking the right balance between accuracy and efficiency remains challenging.

Lastly, the integration of laminar flow simulations with other physical phenomena in a digital twin context presents interoperability challenges. Coupling flow simulations with heat transfer, structural mechanics, or chemical reactions requires sophisticated multi-physics frameworks that can handle the diverse time and length scales involved in these interactions.

Existing Laminar Flow Digital Twin Solutions

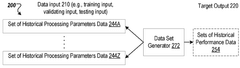

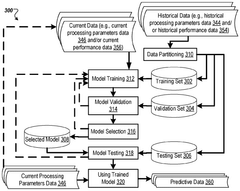

01 Digital twin modeling for laminar flow systems

Digital twin technology is applied to model and simulate laminar flow systems, providing real-time insights and predictive capabilities. This approach enables accurate representation of fluid dynamics in various applications, enhancing system performance and efficiency.- Digital twin technology for fluid flow simulation: Digital twin technology is used to create virtual models of fluid flow systems, allowing for real-time simulation and analysis of laminar flow conditions. This enables engineers to optimize system designs, predict performance, and identify potential issues before physical implementation.

- Laminar flow control in microfluidic devices: Advanced techniques are developed to control and maintain laminar flow in microfluidic devices. These methods involve precise channel geometries, surface treatments, and flow rate control to ensure stable laminar flow conditions for various applications in biotechnology and chemical analysis.

- Integration of sensors for laminar flow monitoring: Innovative sensor technologies are integrated into fluid systems to monitor and maintain laminar flow conditions. These sensors provide real-time data on flow characteristics, enabling automated adjustments and ensuring optimal performance in applications such as heat exchangers and precision manufacturing processes.

- Machine learning algorithms for laminar flow prediction: Advanced machine learning algorithms are developed to predict and optimize laminar flow conditions in complex fluid systems. These algorithms analyze historical data and real-time inputs to provide accurate predictions of flow behavior, enabling proactive system adjustments and improved efficiency.

- Virtual reality interfaces for laminar flow visualization: Virtual reality (VR) interfaces are created to visualize and interact with laminar flow simulations. These immersive environments allow engineers and researchers to explore fluid dynamics in three-dimensional space, enhancing understanding and facilitating collaborative design processes.

02 Laminar flow control in manufacturing processes

Advanced techniques for controlling laminar flow in manufacturing environments are developed, integrating digital twin technologies for process optimization. These methods improve product quality, reduce waste, and enhance overall production efficiency in industries such as semiconductor and pharmaceutical manufacturing.Expand Specific Solutions03 Sensor integration for real-time laminar flow monitoring

Innovative sensor systems are incorporated into laminar flow setups, providing real-time data for digital twin models. This integration allows for continuous monitoring and adjustment of flow conditions, ensuring optimal performance in applications such as cleanrooms and precision engineering.Expand Specific Solutions04 AI-enhanced laminar flow prediction and optimization

Artificial intelligence algorithms are employed to enhance digital twin models of laminar flow systems. These AI-driven approaches improve prediction accuracy, enable adaptive control strategies, and optimize system parameters for various industrial and scientific applications.Expand Specific Solutions05 Virtual testing and validation of laminar flow designs

Digital twin technologies are utilized to create virtual environments for testing and validating laminar flow designs. This approach reduces physical prototyping costs, accelerates development cycles, and improves the reliability of flow systems in aerospace, automotive, and other high-precision industries.Expand Specific Solutions

Key Players in Digital Twin and Fluid Simulation Industries

The integration of Laminar Flow with Digital Twin Technologies is an emerging field in the early stages of development, with a growing market potential as industries seek more efficient and precise fluid dynamics modeling. The technology's maturity is still evolving, with key players like Applied Materials, Siemens Healthcare Diagnostics, and Lam Research Corporation leading the way in research and development. These companies are leveraging their expertise in semiconductor manufacturing, healthcare diagnostics, and wafer fabrication equipment to advance the integration of laminar flow principles with digital twin technologies. As the market expands, we can expect increased competition and innovation from both established tech giants and specialized startups, driving further advancements in this promising field.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed an integrated Digital Twin solution that combines laminar flow analysis with advanced process control for semiconductor and display manufacturing. Their approach utilizes a network of sensors and advanced modeling techniques to create accurate digital representations of complex manufacturing processes. For laminar flow integration, Applied Materials employs sophisticated CFD simulations that account for multi-phase flows and particle transport in ultra-clean environments[9]. The platform includes real-time monitoring and control capabilities, allowing for immediate adjustments to maintain optimal laminar flow conditions. Applied Materials' solution also incorporates machine learning algorithms to predict equipment performance and optimize maintenance schedules based on flow analysis data[10].

Strengths: Deep expertise in semiconductor manufacturing processes, advanced multi-physics simulation capabilities, and strong integration with existing fab systems. Weaknesses: Primarily focused on semiconductor and display industries, potentially limiting broader application.

Lam Research Corp.

Technical Solution: Lam Research has developed a specialized Digital Twin solution for semiconductor manufacturing that incorporates laminar flow analysis. Their approach focuses on optimizing clean room environments and wafer processing equipment where laminar flow is critical. The system uses high-precision sensors and advanced CFD models to simulate and monitor airflow patterns within semiconductor fabrication facilities[7]. Lam's Digital Twin platform integrates real-time data from manufacturing equipment with historical process data to predict and optimize laminar flow conditions. The solution includes AI-driven anomaly detection to identify potential contamination risks and maintain ultra-clean manufacturing environments[8].

Strengths: Highly specialized for semiconductor industry, excellent integration with existing fab equipment, and advanced contamination control. Weaknesses: Limited applicability outside of semiconductor manufacturing.

Core Innovations in Fluid-Digital Integration

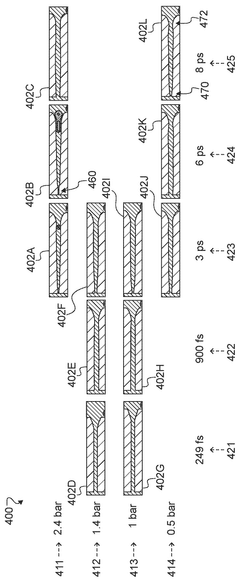

Digital twin for laser material processing

PatentWO2025038131A1

Innovation

- The implementation of a digital twin for laser material processing, which includes a trained machine learning model, allows for real-time simulation and optimization of processing parameters, predicting performance data and enabling precise material processing.

Digital twin with physics and learning blocks

PatentWO2025119643A1

Innovation

- A computer-implemented method using a digital twin comprising at least one learning block and one physics block, where sensor data is processed through both blocks to generate an output, and the digital twin is trained using supervised learning with backpropagation, constrained by the physics block, to ensure compliance with known rules and improve accuracy.

Data Security in Digital Twin Fluid Simulations

Data security in digital twin fluid simulations is a critical concern as the integration of laminar flow with digital twin technologies advances. The sensitive nature of fluid dynamics data, often involving proprietary designs and processes, necessitates robust security measures to protect intellectual property and maintain competitive advantage.

One of the primary challenges in securing digital twin fluid simulations is the vast amount of data generated and processed in real-time. This data includes not only the fluid dynamics parameters but also sensor readings, environmental conditions, and system configurations. Implementing end-to-end encryption for data in transit and at rest is essential to prevent unauthorized access and data breaches.

Access control mechanisms play a crucial role in maintaining data security. Multi-factor authentication, role-based access control, and least privilege principles should be implemented to ensure that only authorized personnel can access and manipulate simulation data. Additionally, comprehensive audit trails and logging systems are necessary to track user activities and detect any suspicious behavior or potential security breaches.

Data integrity is another vital aspect of security in digital twin fluid simulations. Ensuring the accuracy and consistency of simulation data is paramount for reliable results. Blockchain technology has emerged as a potential solution for maintaining data integrity in digital twins. By creating an immutable ledger of data transactions and changes, blockchain can provide a tamper-proof record of simulation history and results.

Cloud security considerations are also significant, as many digital twin implementations leverage cloud computing for scalability and accessibility. Secure cloud configurations, regular vulnerability assessments, and compliance with industry standards such as ISO 27001 and NIST are essential for protecting simulation data stored and processed in cloud environments.

As digital twins often involve collaboration between multiple stakeholders, secure data sharing mechanisms are crucial. Implementing secure APIs, data anonymization techniques, and granular permission systems can facilitate collaboration while maintaining data confidentiality. Furthermore, establishing clear data governance policies and procedures is essential to define data ownership, usage rights, and retention periods.

Artificial intelligence and machine learning techniques can be employed to enhance security in digital twin fluid simulations. These technologies can be used for anomaly detection, identifying potential security threats, and automating incident response processes. However, it is important to note that AI models themselves can be targets for attacks, necessitating secure AI development practices and model protection measures.

One of the primary challenges in securing digital twin fluid simulations is the vast amount of data generated and processed in real-time. This data includes not only the fluid dynamics parameters but also sensor readings, environmental conditions, and system configurations. Implementing end-to-end encryption for data in transit and at rest is essential to prevent unauthorized access and data breaches.

Access control mechanisms play a crucial role in maintaining data security. Multi-factor authentication, role-based access control, and least privilege principles should be implemented to ensure that only authorized personnel can access and manipulate simulation data. Additionally, comprehensive audit trails and logging systems are necessary to track user activities and detect any suspicious behavior or potential security breaches.

Data integrity is another vital aspect of security in digital twin fluid simulations. Ensuring the accuracy and consistency of simulation data is paramount for reliable results. Blockchain technology has emerged as a potential solution for maintaining data integrity in digital twins. By creating an immutable ledger of data transactions and changes, blockchain can provide a tamper-proof record of simulation history and results.

Cloud security considerations are also significant, as many digital twin implementations leverage cloud computing for scalability and accessibility. Secure cloud configurations, regular vulnerability assessments, and compliance with industry standards such as ISO 27001 and NIST are essential for protecting simulation data stored and processed in cloud environments.

As digital twins often involve collaboration between multiple stakeholders, secure data sharing mechanisms are crucial. Implementing secure APIs, data anonymization techniques, and granular permission systems can facilitate collaboration while maintaining data confidentiality. Furthermore, establishing clear data governance policies and procedures is essential to define data ownership, usage rights, and retention periods.

Artificial intelligence and machine learning techniques can be employed to enhance security in digital twin fluid simulations. These technologies can be used for anomaly detection, identifying potential security threats, and automating incident response processes. However, it is important to note that AI models themselves can be targets for attacks, necessitating secure AI development practices and model protection measures.

Standardization Efforts for Digital Fluid Dynamics

Standardization efforts for digital fluid dynamics in the context of integrating laminar flow with digital twin technologies have become increasingly crucial as the field advances. These efforts aim to establish common protocols, data formats, and methodologies to ensure interoperability and consistency across different platforms and applications.

One of the primary focuses of standardization is the development of unified data models for representing fluid dynamics simulations within digital twin environments. This includes standardizing the representation of laminar flow characteristics, boundary conditions, and material properties. By creating a common language for describing these elements, researchers and engineers can more easily share and compare results across different simulation tools and platforms.

Efforts are also underway to standardize the integration of experimental data with digital twin models. This involves developing protocols for data acquisition, processing, and incorporation into digital representations of fluid systems. Standardized methods for calibrating and validating digital twin models against real-world measurements are being established to ensure the accuracy and reliability of simulations.

Interoperability standards are being developed to facilitate seamless communication between different software tools used in digital fluid dynamics. These standards aim to enable the exchange of data and models between simulation software, visualization tools, and digital twin platforms. By promoting interoperability, these efforts seek to create a more cohesive ecosystem for digital fluid dynamics research and applications.

Another key area of standardization is the development of benchmarks and reference cases for laminar flow simulations in digital twin environments. These standardized test cases provide a common basis for evaluating the performance and accuracy of different simulation tools and methodologies. By establishing agreed-upon benchmarks, the community can more effectively compare and validate new approaches to integrating laminar flow with digital twin technologies.

Efforts are also being made to standardize the reporting and documentation of digital fluid dynamics simulations. This includes developing guidelines for describing simulation setups, reporting results, and documenting the assumptions and limitations of digital twin models. Standardized reporting practices enhance reproducibility and facilitate the peer review process in scientific publications.

As the field of digital fluid dynamics continues to evolve, ongoing standardization efforts will play a crucial role in fostering collaboration, accelerating innovation, and ensuring the reliability and consistency of simulations across different applications and industries.

One of the primary focuses of standardization is the development of unified data models for representing fluid dynamics simulations within digital twin environments. This includes standardizing the representation of laminar flow characteristics, boundary conditions, and material properties. By creating a common language for describing these elements, researchers and engineers can more easily share and compare results across different simulation tools and platforms.

Efforts are also underway to standardize the integration of experimental data with digital twin models. This involves developing protocols for data acquisition, processing, and incorporation into digital representations of fluid systems. Standardized methods for calibrating and validating digital twin models against real-world measurements are being established to ensure the accuracy and reliability of simulations.

Interoperability standards are being developed to facilitate seamless communication between different software tools used in digital fluid dynamics. These standards aim to enable the exchange of data and models between simulation software, visualization tools, and digital twin platforms. By promoting interoperability, these efforts seek to create a more cohesive ecosystem for digital fluid dynamics research and applications.

Another key area of standardization is the development of benchmarks and reference cases for laminar flow simulations in digital twin environments. These standardized test cases provide a common basis for evaluating the performance and accuracy of different simulation tools and methodologies. By establishing agreed-upon benchmarks, the community can more effectively compare and validate new approaches to integrating laminar flow with digital twin technologies.

Efforts are also being made to standardize the reporting and documentation of digital fluid dynamics simulations. This includes developing guidelines for describing simulation setups, reporting results, and documenting the assumptions and limitations of digital twin models. Standardized reporting practices enhance reproducibility and facilitate the peer review process in scientific publications.

As the field of digital fluid dynamics continues to evolve, ongoing standardization efforts will play a crucial role in fostering collaboration, accelerating innovation, and ensuring the reliability and consistency of simulations across different applications and industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!