Laminar Flow in Marine Applications: Techniques and Benefits

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Marine Laminar Flow Background and Objectives

Laminar flow, a fundamental concept in fluid dynamics, has gained significant attention in marine applications due to its potential to enhance vessel efficiency and reduce environmental impact. The study of laminar flow in marine contexts dates back to the mid-20th century, with pioneering research conducted by naval architects and hydrodynamicists seeking to optimize hull designs for improved performance.

The evolution of laminar flow technology in marine applications has been driven by the increasing demand for fuel-efficient and environmentally friendly vessels. As global maritime regulations become more stringent, particularly concerning emissions and energy efficiency, the importance of laminar flow techniques has grown exponentially. This has led to a surge in research and development efforts aimed at harnessing the benefits of laminar flow in various marine applications.

The primary objective of implementing laminar flow techniques in marine applications is to reduce drag and improve overall vessel efficiency. By maintaining a smooth, streamlined flow of water around the hull, laminar flow can significantly decrease the energy required to propel a vessel through water. This, in turn, leads to reduced fuel consumption, lower operating costs, and decreased environmental impact through reduced emissions.

Another key goal is to extend the range of laminar flow along the hull surface. Traditionally, laminar flow has been challenging to maintain over large areas due to factors such as surface roughness, pressure gradients, and flow instabilities. Overcoming these limitations through innovative design and materials is a central focus of current research efforts.

The marine industry is also exploring the potential of laminar flow techniques to enhance the performance of underwater vehicles, propellers, and other submerged structures. By optimizing flow characteristics, researchers aim to improve maneuverability, reduce noise generation, and increase the operational efficiency of various marine systems.

As technology advances, the integration of smart materials and active flow control systems presents new opportunities for achieving and maintaining laminar flow in marine environments. These developments aim to create adaptive hull surfaces that can respond to changing flow conditions, further expanding the potential benefits of laminar flow techniques.

In conclusion, the background and objectives of laminar flow in marine applications reflect a growing emphasis on efficiency, sustainability, and innovation in the maritime sector. As research continues to progress, the potential for laminar flow techniques to revolutionize marine vessel design and operation remains a compelling area of study with far-reaching implications for the future of maritime transportation and technology.

The evolution of laminar flow technology in marine applications has been driven by the increasing demand for fuel-efficient and environmentally friendly vessels. As global maritime regulations become more stringent, particularly concerning emissions and energy efficiency, the importance of laminar flow techniques has grown exponentially. This has led to a surge in research and development efforts aimed at harnessing the benefits of laminar flow in various marine applications.

The primary objective of implementing laminar flow techniques in marine applications is to reduce drag and improve overall vessel efficiency. By maintaining a smooth, streamlined flow of water around the hull, laminar flow can significantly decrease the energy required to propel a vessel through water. This, in turn, leads to reduced fuel consumption, lower operating costs, and decreased environmental impact through reduced emissions.

Another key goal is to extend the range of laminar flow along the hull surface. Traditionally, laminar flow has been challenging to maintain over large areas due to factors such as surface roughness, pressure gradients, and flow instabilities. Overcoming these limitations through innovative design and materials is a central focus of current research efforts.

The marine industry is also exploring the potential of laminar flow techniques to enhance the performance of underwater vehicles, propellers, and other submerged structures. By optimizing flow characteristics, researchers aim to improve maneuverability, reduce noise generation, and increase the operational efficiency of various marine systems.

As technology advances, the integration of smart materials and active flow control systems presents new opportunities for achieving and maintaining laminar flow in marine environments. These developments aim to create adaptive hull surfaces that can respond to changing flow conditions, further expanding the potential benefits of laminar flow techniques.

In conclusion, the background and objectives of laminar flow in marine applications reflect a growing emphasis on efficiency, sustainability, and innovation in the maritime sector. As research continues to progress, the potential for laminar flow techniques to revolutionize marine vessel design and operation remains a compelling area of study with far-reaching implications for the future of maritime transportation and technology.

Market Analysis for Marine Laminar Flow Technologies

The market for marine laminar flow technologies has been experiencing significant growth in recent years, driven by the increasing demand for fuel-efficient and environmentally friendly marine vessels. As global shipping continues to expand and environmental regulations become more stringent, the adoption of laminar flow technologies in marine applications is expected to accelerate.

The primary market segments for marine laminar flow technologies include commercial shipping, naval vessels, and high-performance recreational boats. The commercial shipping sector, which includes container ships, tankers, and bulk carriers, represents the largest potential market due to the sheer volume of vessels and the industry's focus on reducing operational costs and emissions. Naval applications are also a significant market, as military organizations seek to enhance vessel performance and reduce fuel consumption for extended missions.

Market analysis indicates that the Asia-Pacific region, particularly China, South Korea, and Japan, dominates the marine laminar flow technology market due to their strong shipbuilding industries. Europe and North America follow closely, with a growing emphasis on retrofitting existing vessels with laminar flow solutions.

The market is characterized by a mix of established marine technology companies and innovative startups. Key players include major shipbuilders, marine engineering firms, and specialized fluid dynamics companies. These organizations are investing heavily in research and development to improve laminar flow techniques and expand their application across various vessel types.

One of the primary drivers of market growth is the potential for significant fuel savings. Studies have shown that effective laminar flow technologies can reduce fuel consumption by up to 15% in certain vessel types. This translates to substantial cost savings for ship operators and a reduction in greenhouse gas emissions, aligning with global sustainability goals.

The market is also influenced by regulatory factors, such as the International Maritime Organization's (IMO) emissions regulations. These standards are pushing ship owners and operators to adopt more efficient technologies, including laminar flow solutions, to meet compliance requirements.

Despite the promising outlook, the market faces challenges such as high initial implementation costs and the complexity of integrating laminar flow technologies into existing vessel designs. Additionally, the effectiveness of laminar flow techniques can vary depending on operational conditions, which may impact widespread adoption.

Looking ahead, the marine laminar flow technology market is projected to continue its growth trajectory. Advancements in computational fluid dynamics, materials science, and manufacturing techniques are expected to enhance the performance and cost-effectiveness of laminar flow solutions, further driving market expansion across various marine sectors.

The primary market segments for marine laminar flow technologies include commercial shipping, naval vessels, and high-performance recreational boats. The commercial shipping sector, which includes container ships, tankers, and bulk carriers, represents the largest potential market due to the sheer volume of vessels and the industry's focus on reducing operational costs and emissions. Naval applications are also a significant market, as military organizations seek to enhance vessel performance and reduce fuel consumption for extended missions.

Market analysis indicates that the Asia-Pacific region, particularly China, South Korea, and Japan, dominates the marine laminar flow technology market due to their strong shipbuilding industries. Europe and North America follow closely, with a growing emphasis on retrofitting existing vessels with laminar flow solutions.

The market is characterized by a mix of established marine technology companies and innovative startups. Key players include major shipbuilders, marine engineering firms, and specialized fluid dynamics companies. These organizations are investing heavily in research and development to improve laminar flow techniques and expand their application across various vessel types.

One of the primary drivers of market growth is the potential for significant fuel savings. Studies have shown that effective laminar flow technologies can reduce fuel consumption by up to 15% in certain vessel types. This translates to substantial cost savings for ship operators and a reduction in greenhouse gas emissions, aligning with global sustainability goals.

The market is also influenced by regulatory factors, such as the International Maritime Organization's (IMO) emissions regulations. These standards are pushing ship owners and operators to adopt more efficient technologies, including laminar flow solutions, to meet compliance requirements.

Despite the promising outlook, the market faces challenges such as high initial implementation costs and the complexity of integrating laminar flow technologies into existing vessel designs. Additionally, the effectiveness of laminar flow techniques can vary depending on operational conditions, which may impact widespread adoption.

Looking ahead, the marine laminar flow technology market is projected to continue its growth trajectory. Advancements in computational fluid dynamics, materials science, and manufacturing techniques are expected to enhance the performance and cost-effectiveness of laminar flow solutions, further driving market expansion across various marine sectors.

Current Challenges in Marine Laminar Flow Implementation

Despite the promising potential of laminar flow in marine applications, several significant challenges hinder its widespread implementation. One of the primary obstacles is the difficulty in maintaining laminar flow over large surface areas in real-world marine environments. The complex and dynamic nature of ocean conditions, including waves, currents, and varying water temperatures, can disrupt the delicate balance required for laminar flow.

Surface roughness presents another major challenge. Even minor imperfections or biofouling on a ship's hull can trigger turbulence, negating the benefits of laminar flow. Developing and maintaining ultra-smooth surfaces that can withstand harsh marine conditions remains a significant technical hurdle.

The integration of laminar flow control systems into existing ship designs poses substantial engineering challenges. Retrofitting older vessels with laminar flow technology is often impractical or cost-prohibitive, limiting its application primarily to new builds. Additionally, the added complexity of these systems can increase maintenance requirements and the potential for mechanical failures.

Energy consumption is another concern. While laminar flow can reduce overall drag, the power required to operate active flow control systems may offset some of these gains. Optimizing the energy efficiency of these systems without compromising their effectiveness is an ongoing challenge for engineers and researchers.

Scale-up issues also present significant obstacles. Technologies that demonstrate success in controlled laboratory environments or small-scale prototypes often face unforeseen difficulties when applied to full-size vessels. The behavior of laminar flow at larger scales and under diverse operating conditions is not yet fully understood, making it challenging to predict and optimize performance.

Economic factors further complicate the adoption of laminar flow technologies. The high initial costs associated with research, development, and implementation can be prohibitive for many shipping companies, especially given the uncertain return on investment in real-world operations. This economic barrier slows down both innovation and adoption rates within the industry.

Regulatory and safety considerations also pose challenges. New technologies must meet stringent maritime safety standards and environmental regulations. The lack of long-term performance data and established industry standards for laminar flow systems can make it difficult to obtain necessary approvals and certifications.

Lastly, there is a knowledge gap within the maritime industry. The successful implementation of laminar flow technologies requires specialized expertise that is not yet widespread among naval architects, marine engineers, and ship operators. Bridging this knowledge gap through education and training programs is essential for the broader adoption of these advanced technologies in marine applications.

Surface roughness presents another major challenge. Even minor imperfections or biofouling on a ship's hull can trigger turbulence, negating the benefits of laminar flow. Developing and maintaining ultra-smooth surfaces that can withstand harsh marine conditions remains a significant technical hurdle.

The integration of laminar flow control systems into existing ship designs poses substantial engineering challenges. Retrofitting older vessels with laminar flow technology is often impractical or cost-prohibitive, limiting its application primarily to new builds. Additionally, the added complexity of these systems can increase maintenance requirements and the potential for mechanical failures.

Energy consumption is another concern. While laminar flow can reduce overall drag, the power required to operate active flow control systems may offset some of these gains. Optimizing the energy efficiency of these systems without compromising their effectiveness is an ongoing challenge for engineers and researchers.

Scale-up issues also present significant obstacles. Technologies that demonstrate success in controlled laboratory environments or small-scale prototypes often face unforeseen difficulties when applied to full-size vessels. The behavior of laminar flow at larger scales and under diverse operating conditions is not yet fully understood, making it challenging to predict and optimize performance.

Economic factors further complicate the adoption of laminar flow technologies. The high initial costs associated with research, development, and implementation can be prohibitive for many shipping companies, especially given the uncertain return on investment in real-world operations. This economic barrier slows down both innovation and adoption rates within the industry.

Regulatory and safety considerations also pose challenges. New technologies must meet stringent maritime safety standards and environmental regulations. The lack of long-term performance data and established industry standards for laminar flow systems can make it difficult to obtain necessary approvals and certifications.

Lastly, there is a knowledge gap within the maritime industry. The successful implementation of laminar flow technologies requires specialized expertise that is not yet widespread among naval architects, marine engineers, and ship operators. Bridging this knowledge gap through education and training programs is essential for the broader adoption of these advanced technologies in marine applications.

Existing Laminar Flow Solutions for Marine Applications

01 Laminar flow measurement and control

Various methods and devices are used to measure and control laminar flow in different applications. These include optical systems, flow sensors, and specialized valves that help maintain and regulate laminar flow conditions. Such technologies are crucial in industries requiring precise fluid control and analysis.- Laminar flow measurement and control: Various methods and devices are used to measure and control laminar flow in different applications. These include optical systems, flow sensors, and specialized valves that help maintain and regulate laminar flow conditions. Such technologies are crucial in industries requiring precise fluid control.

- Laminar flow in fluid delivery systems: Laminar flow principles are applied in fluid delivery systems to ensure smooth and controlled distribution of liquids or gases. This includes designs for nozzles, pipes, and channels that promote laminar flow, reducing turbulence and improving efficiency in various industrial and medical applications.

- Laminar flow in air handling and ventilation: Laminar flow is utilized in air handling and ventilation systems to create controlled environments with minimal air turbulence. This is particularly important in clean rooms, laboratories, and medical facilities where maintaining a sterile environment is crucial.

- Laminar flow in manufacturing processes: Laminar flow principles are applied in various manufacturing processes to improve product quality and process efficiency. This includes applications in coating, printing, and material deposition where controlled, uniform flow is essential for achieving desired results.

- Laminar flow in microfluidic devices: Microfluidic devices utilize laminar flow characteristics for precise control of small fluid volumes. These devices are used in various fields including biomedical research, chemical analysis, and drug delivery systems, where the manipulation of fluids at microscale levels is required.

02 Laminar flow in fluid delivery systems

Laminar flow principles are applied in fluid delivery systems to ensure smooth and controlled distribution of liquids or gases. This includes designs for nozzles, pipes, and channels that promote laminar flow, reducing turbulence and improving efficiency in various industrial and medical applications.Expand Specific Solutions03 Laminar flow in air handling and ventilation

Laminar flow is crucial in air handling and ventilation systems, particularly in clean rooms and controlled environments. Specialized equipment and designs are used to create and maintain laminar airflow, ensuring particle-free environments for sensitive processes in industries such as electronics and pharmaceuticals.Expand Specific Solutions04 Laminar flow in microfluidic devices

Microfluidic devices utilize laminar flow properties for various applications in biotechnology and chemical analysis. These devices often incorporate specialized channel designs and flow control mechanisms to manipulate small volumes of fluids with high precision, enabling advanced research and diagnostic capabilities.Expand Specific Solutions05 Laminar flow in industrial processes

Laminar flow principles are applied in various industrial processes to improve efficiency and product quality. This includes applications in coating technologies, material processing, and chemical reactions where controlled, uniform flow is essential for achieving desired outcomes and maintaining process stability.Expand Specific Solutions

Key Players in Marine Laminar Flow Technology

The marine laminar flow technology market is in a growth phase, with increasing applications in naval architecture and marine engineering. The market size is expanding due to rising demand for fuel-efficient vessels and improved hydrodynamic performance. Technological maturity varies across different applications, with ongoing research and development efforts. Key players like Naval Research Laboratory, Zhejiang University, and Harbin Engineering University are advancing the field through academic research. Companies such as Pentair Water Pool & Spa and Hayward Industries are applying laminar flow principles in marine-related products. The collaboration between academic institutions and industry partners is driving innovation and practical implementation of laminar flow technologies in marine applications.

Naval Research Laboratory

Technical Solution: The Naval Research Laboratory (NRL) has developed advanced techniques for laminar flow control in marine applications. Their approach involves the use of micro-textured surfaces and active flow control systems to reduce drag on ship hulls. NRL's research has shown that these techniques can reduce skin friction drag by up to 30% in certain conditions [1]. They have also explored the use of polymer additives in the boundary layer to maintain laminar flow over larger areas of the hull. Additionally, NRL has conducted extensive computational fluid dynamics (CFD) simulations to optimize hull designs for laminar flow, incorporating factors such as pressure gradients and surface roughness [2]. Their work extends to the development of smart coatings that can adapt to changing flow conditions, further enhancing laminar flow benefits.

Strengths: Cutting-edge research in laminar flow control, potential for significant fuel savings in naval vessels. Weaknesses: High implementation costs, potential maintenance challenges in real-world marine environments.

Parker Maritime Technologies LLC

Technical Solution: Parker Maritime Technologies LLC has focused on developing laminar flow control systems for marine propulsion and maneuvering devices. Their approach involves the use of biomimetic designs inspired by marine animals that naturally maintain laminar flow, such as dolphins and penguins. Parker has developed specialized coatings and surface treatments that mimic the micro-structure of these animals' skin, promoting laminar flow and reducing drag. Their research indicates potential drag reductions of up to 12% for propeller blades and rudders [8]. Additionally, Parker has explored the use of flexible hull materials that can dynamically adjust to maintain optimal laminar flow conditions. They are also working on integrating smart sensors and actuators into hull surfaces to actively control boundary layer behavior in real-time.

Strengths: Innovative biomimetic approach, focus on critical propulsion components. Weaknesses: Limited application to specific parts of the vessel, may require significant changes to existing ship designs.

Core Innovations in Marine Laminar Flow Research

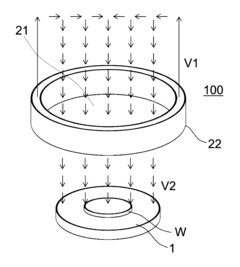

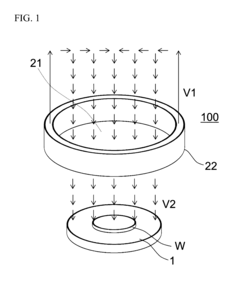

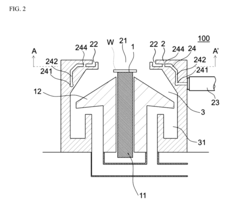

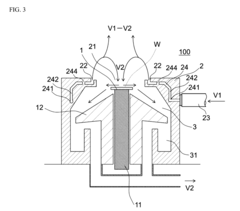

Columnar laminar flow generation device and method for generating columnar laminar flows

PatentActiveUS20170072438A1

Innovation

- A columnar laminar flow generation device that focuses gas blow-out and suction within a localized columnar area, allowing for adjustable flow velocity and reduced gas usage by positioning a gas blow-out port vertically within an opening and a corresponding suction path, thereby generating laminar flows only where needed, with a feed pipe filter for purification.

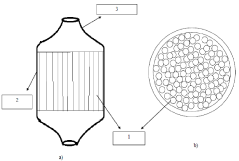

A novel nozzle to produce laminar flow

PatentInactiveIN202011051350A

Innovation

- A nozzle design featuring plastic tubes as the core and a stainless steel outer shell with rubber openings, which converts turbulent flow into laminar flow without significant pressure loss, utilizing the plastic tubes to straighten the flow and the stainless steel to maintain structural integrity while minimizing obstruction.

Environmental Impact of Laminar Flow in Marine Applications

The implementation of laminar flow techniques in marine applications has significant environmental implications, both positive and negative. One of the primary benefits is the reduction in fuel consumption for marine vessels. By minimizing turbulence and drag, laminar flow designs allow ships to move through water more efficiently, resulting in lower fuel requirements. This directly translates to reduced greenhouse gas emissions, particularly carbon dioxide, which is a major contributor to global warming and ocean acidification.

The decreased fuel consumption also means less risk of oil spills during transportation and refueling processes. Oil spills can have devastating effects on marine ecosystems, affecting wildlife, water quality, and coastal habitats. By reducing the frequency and volume of fuel transfers, laminar flow technology indirectly contributes to the preservation of marine biodiversity and ecosystem health.

However, the environmental impact of laminar flow technology is not entirely positive. The manufacturing and application of specialized hull coatings or materials required for maintaining laminar flow conditions may involve the use of chemicals or processes that could be potentially harmful to the environment. The long-term effects of these materials on marine life and water quality need to be carefully studied and monitored.

Additionally, the increased efficiency of ships utilizing laminar flow technology could lead to more frequent maritime traffic. While individual vessels may have a reduced environmental footprint, the cumulative effect of increased shipping activity could potentially offset some of the gains. This could result in greater noise pollution, which is known to adversely affect marine mammals and other sea life.

The implementation of laminar flow technology may also require more frequent maintenance and cleaning of ship hulls to maintain optimal performance. This could lead to increased use of antifouling agents and cleaning chemicals, which may have negative impacts on local marine environments if not properly managed.

On a broader scale, the adoption of laminar flow technology in marine applications could contribute to the overall sustainability of the shipping industry. By improving fuel efficiency, it aligns with global efforts to reduce carbon emissions and combat climate change. This could have far-reaching positive impacts on marine ecosystems, as climate change is a significant threat to ocean health, causing issues such as coral bleaching, sea-level rise, and changes in ocean currents and temperatures.

In conclusion, while laminar flow technology in marine applications offers substantial environmental benefits, particularly in terms of reduced emissions and fuel consumption, it is crucial to consider and mitigate potential negative impacts. Ongoing research and careful implementation strategies are necessary to ensure that the overall environmental impact remains positive as this technology becomes more widespread in the maritime industry.

The decreased fuel consumption also means less risk of oil spills during transportation and refueling processes. Oil spills can have devastating effects on marine ecosystems, affecting wildlife, water quality, and coastal habitats. By reducing the frequency and volume of fuel transfers, laminar flow technology indirectly contributes to the preservation of marine biodiversity and ecosystem health.

However, the environmental impact of laminar flow technology is not entirely positive. The manufacturing and application of specialized hull coatings or materials required for maintaining laminar flow conditions may involve the use of chemicals or processes that could be potentially harmful to the environment. The long-term effects of these materials on marine life and water quality need to be carefully studied and monitored.

Additionally, the increased efficiency of ships utilizing laminar flow technology could lead to more frequent maritime traffic. While individual vessels may have a reduced environmental footprint, the cumulative effect of increased shipping activity could potentially offset some of the gains. This could result in greater noise pollution, which is known to adversely affect marine mammals and other sea life.

The implementation of laminar flow technology may also require more frequent maintenance and cleaning of ship hulls to maintain optimal performance. This could lead to increased use of antifouling agents and cleaning chemicals, which may have negative impacts on local marine environments if not properly managed.

On a broader scale, the adoption of laminar flow technology in marine applications could contribute to the overall sustainability of the shipping industry. By improving fuel efficiency, it aligns with global efforts to reduce carbon emissions and combat climate change. This could have far-reaching positive impacts on marine ecosystems, as climate change is a significant threat to ocean health, causing issues such as coral bleaching, sea-level rise, and changes in ocean currents and temperatures.

In conclusion, while laminar flow technology in marine applications offers substantial environmental benefits, particularly in terms of reduced emissions and fuel consumption, it is crucial to consider and mitigate potential negative impacts. Ongoing research and careful implementation strategies are necessary to ensure that the overall environmental impact remains positive as this technology becomes more widespread in the maritime industry.

Regulatory Framework for Marine Laminar Flow Technologies

The regulatory framework for marine laminar flow technologies is a complex and evolving landscape that encompasses various international, regional, and national regulations. The International Maritime Organization (IMO) plays a crucial role in setting global standards for ship design and operation, including aspects related to energy efficiency and environmental protection. The Energy Efficiency Design Index (EEDI) and the Ship Energy Efficiency Management Plan (SEEMP) are two key IMO instruments that indirectly impact the adoption of laminar flow technologies.

At the regional level, the European Union has implemented stringent regulations through its Monitoring, Reporting, and Verification (MRV) system, which requires ships to report their CO2 emissions. This regulatory pressure incentivizes the adoption of energy-efficient technologies, including laminar flow solutions. Similarly, the United States Environmental Protection Agency (EPA) has established the Vessel General Permit (VGP) program, which sets standards for discharges from commercial vessels, potentially influencing the design and application of laminar flow technologies.

National maritime authorities also play a significant role in shaping the regulatory landscape. Countries like Norway, Japan, and South Korea have implemented their own energy efficiency standards and incentive programs for ships, which can impact the development and deployment of laminar flow technologies. These national regulations often focus on specific aspects such as hull coatings, propeller design, and overall vessel hydrodynamics.

Classification societies, such as Lloyd's Register, DNV GL, and the American Bureau of Shipping, contribute to the regulatory framework by developing technical standards and guidelines for the implementation of energy-efficient technologies. These organizations work closely with shipowners, shipyards, and technology providers to ensure that laminar flow solutions meet safety and performance requirements.

The regulatory landscape also includes environmental regulations that indirectly affect laminar flow technologies. For instance, the IMO's regulations on ballast water management and hull biofouling can influence the design and maintenance of hull surfaces, which are critical for achieving laminar flow. Additionally, emerging regulations on underwater noise pollution may further drive the adoption of laminar flow technologies, as they can contribute to reducing vessel noise.

As the maritime industry continues to face pressure to reduce its environmental impact, the regulatory framework for laminar flow technologies is likely to evolve. Future regulations may include more specific requirements for hull design, surface treatments, and operational practices that promote laminar flow. This evolving regulatory landscape presents both challenges and opportunities for technology developers, shipowners, and regulatory bodies in the pursuit of more efficient and sustainable marine transportation.

At the regional level, the European Union has implemented stringent regulations through its Monitoring, Reporting, and Verification (MRV) system, which requires ships to report their CO2 emissions. This regulatory pressure incentivizes the adoption of energy-efficient technologies, including laminar flow solutions. Similarly, the United States Environmental Protection Agency (EPA) has established the Vessel General Permit (VGP) program, which sets standards for discharges from commercial vessels, potentially influencing the design and application of laminar flow technologies.

National maritime authorities also play a significant role in shaping the regulatory landscape. Countries like Norway, Japan, and South Korea have implemented their own energy efficiency standards and incentive programs for ships, which can impact the development and deployment of laminar flow technologies. These national regulations often focus on specific aspects such as hull coatings, propeller design, and overall vessel hydrodynamics.

Classification societies, such as Lloyd's Register, DNV GL, and the American Bureau of Shipping, contribute to the regulatory framework by developing technical standards and guidelines for the implementation of energy-efficient technologies. These organizations work closely with shipowners, shipyards, and technology providers to ensure that laminar flow solutions meet safety and performance requirements.

The regulatory landscape also includes environmental regulations that indirectly affect laminar flow technologies. For instance, the IMO's regulations on ballast water management and hull biofouling can influence the design and maintenance of hull surfaces, which are critical for achieving laminar flow. Additionally, emerging regulations on underwater noise pollution may further drive the adoption of laminar flow technologies, as they can contribute to reducing vessel noise.

As the maritime industry continues to face pressure to reduce its environmental impact, the regulatory framework for laminar flow technologies is likely to evolve. Future regulations may include more specific requirements for hull design, surface treatments, and operational practices that promote laminar flow. This evolving regulatory landscape presents both challenges and opportunities for technology developers, shipowners, and regulatory bodies in the pursuit of more efficient and sustainable marine transportation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!