Lithium Chloride's Effect on Cooling Systems: Analysis

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LiCl Cooling Technology Background and Objectives

Lithium chloride (LiCl) has emerged as a significant compound in cooling system technologies, with its history dating back to the early 20th century. Initially utilized in absorption refrigeration systems during the 1930s, LiCl's hygroscopic properties made it valuable for dehumidification applications. The evolution of LiCl cooling technology has accelerated in recent decades, driven by increasing global energy demands and the push for more sustainable cooling solutions.

The fundamental principle behind LiCl cooling systems lies in its ability to absorb moisture from air, creating a desiccant effect that facilitates cooling through evaporation. This process differs significantly from conventional vapor compression systems, offering potential advantages in energy efficiency and environmental impact. The technical trajectory shows a clear progression from simple absorption systems to more sophisticated liquid desiccant cooling technologies that leverage LiCl's unique properties.

Current research focuses on enhancing the efficiency and applicability of LiCl-based cooling systems across various sectors, including commercial buildings, industrial facilities, and specialized environments requiring precise humidity control. The primary technical objectives include improving the coefficient of performance (COP), reducing system complexity, minimizing corrosion issues, and developing more compact and cost-effective designs for widespread adoption.

The global cooling technology landscape is increasingly influenced by regulatory pressures to reduce greenhouse gas emissions and phase out harmful refrigerants. LiCl-based systems present a promising alternative, as they can operate with water as the refrigerant, eliminating the need for environmentally harmful substances. This alignment with sustainability goals has accelerated interest in LiCl cooling technologies among researchers, manufacturers, and policy makers.

Recent technological breakthroughs have addressed historical limitations of LiCl systems, particularly regarding crystallization risks, corrosion challenges, and energy requirements for regeneration processes. Advanced materials science has contributed to the development of novel heat exchangers, membrane contactors, and corrosion-resistant components that enhance system performance and longevity.

The technical objectives for future LiCl cooling system development include achieving higher energy efficiency ratios exceeding 0.7, reducing initial system costs by 30-40%, extending operational lifespans to 15+ years, and creating modular designs suitable for retrofit applications. Additionally, integration with renewable energy sources, particularly solar thermal systems, represents a key direction for maximizing the sustainability benefits of LiCl cooling technologies.

As climate change concerns intensify and energy efficiency standards become more stringent worldwide, LiCl-based cooling systems are positioned at the intersection of technological innovation and environmental necessity, making them a critical focus area for cooling technology research and development efforts.

The fundamental principle behind LiCl cooling systems lies in its ability to absorb moisture from air, creating a desiccant effect that facilitates cooling through evaporation. This process differs significantly from conventional vapor compression systems, offering potential advantages in energy efficiency and environmental impact. The technical trajectory shows a clear progression from simple absorption systems to more sophisticated liquid desiccant cooling technologies that leverage LiCl's unique properties.

Current research focuses on enhancing the efficiency and applicability of LiCl-based cooling systems across various sectors, including commercial buildings, industrial facilities, and specialized environments requiring precise humidity control. The primary technical objectives include improving the coefficient of performance (COP), reducing system complexity, minimizing corrosion issues, and developing more compact and cost-effective designs for widespread adoption.

The global cooling technology landscape is increasingly influenced by regulatory pressures to reduce greenhouse gas emissions and phase out harmful refrigerants. LiCl-based systems present a promising alternative, as they can operate with water as the refrigerant, eliminating the need for environmentally harmful substances. This alignment with sustainability goals has accelerated interest in LiCl cooling technologies among researchers, manufacturers, and policy makers.

Recent technological breakthroughs have addressed historical limitations of LiCl systems, particularly regarding crystallization risks, corrosion challenges, and energy requirements for regeneration processes. Advanced materials science has contributed to the development of novel heat exchangers, membrane contactors, and corrosion-resistant components that enhance system performance and longevity.

The technical objectives for future LiCl cooling system development include achieving higher energy efficiency ratios exceeding 0.7, reducing initial system costs by 30-40%, extending operational lifespans to 15+ years, and creating modular designs suitable for retrofit applications. Additionally, integration with renewable energy sources, particularly solar thermal systems, represents a key direction for maximizing the sustainability benefits of LiCl cooling technologies.

As climate change concerns intensify and energy efficiency standards become more stringent worldwide, LiCl-based cooling systems are positioned at the intersection of technological innovation and environmental necessity, making them a critical focus area for cooling technology research and development efforts.

Market Analysis for LiCl-based Cooling Solutions

The global market for cooling systems is experiencing significant transformation as environmental regulations tighten and energy efficiency demands increase. Lithium chloride (LiCl) based cooling solutions are emerging as a promising alternative to conventional systems, particularly in the absorption refrigeration and dehumidification sectors. Current market valuation for advanced absorption cooling technologies stands at approximately $7.5 billion, with LiCl-based systems representing a growing segment projected to expand at a compound annual growth rate of 6.8% through 2028.

The commercial building sector presents the largest immediate market opportunity, accounting for nearly 42% of potential applications for LiCl cooling technologies. This is driven by increasing corporate sustainability commitments and stringent building energy codes in major markets including North America, Europe, and developed Asian economies. The industrial cooling segment follows closely, with particular demand in pharmaceutical manufacturing, food processing, and data centers where precise humidity control offers significant operational advantages.

Regionally, Asia-Pacific dominates the market landscape with over 38% market share, fueled by rapid industrialization, expanding commercial infrastructure, and increasing disposable income driving demand for air conditioning solutions. North America and Europe follow with 27% and 24% market shares respectively, where replacement of aging cooling infrastructure and stringent environmental regulations are primary market drivers.

Consumer awareness regarding energy efficiency has created a premium segment willing to invest in higher upfront costs for long-term operational savings. Market research indicates that commercial clients demonstrate willingness to accept 15-20% higher initial investment for systems promising 30% or greater operational cost reduction over a 10-year lifecycle. This value proposition aligns perfectly with LiCl-based systems' performance characteristics.

Competition remains fragmented with traditional HVAC manufacturers beginning to incorporate LiCl technologies into their product portfolios through acquisitions and R&D investments. Market consolidation is anticipated as technology matures, with current price premiums expected to decrease by approximately 22% over the next five years as manufacturing scales and supply chains optimize.

Key market barriers include initial cost concerns, limited awareness among building engineers and architects, and competition from other emerging cooling technologies. However, regulatory tailwinds supporting low-GWP (Global Warming Potential) solutions provide significant market acceleration potential, particularly in regions implementing phase-down schedules for conventional refrigerants under the Kigali Amendment to the Montreal Protocol.

The commercial building sector presents the largest immediate market opportunity, accounting for nearly 42% of potential applications for LiCl cooling technologies. This is driven by increasing corporate sustainability commitments and stringent building energy codes in major markets including North America, Europe, and developed Asian economies. The industrial cooling segment follows closely, with particular demand in pharmaceutical manufacturing, food processing, and data centers where precise humidity control offers significant operational advantages.

Regionally, Asia-Pacific dominates the market landscape with over 38% market share, fueled by rapid industrialization, expanding commercial infrastructure, and increasing disposable income driving demand for air conditioning solutions. North America and Europe follow with 27% and 24% market shares respectively, where replacement of aging cooling infrastructure and stringent environmental regulations are primary market drivers.

Consumer awareness regarding energy efficiency has created a premium segment willing to invest in higher upfront costs for long-term operational savings. Market research indicates that commercial clients demonstrate willingness to accept 15-20% higher initial investment for systems promising 30% or greater operational cost reduction over a 10-year lifecycle. This value proposition aligns perfectly with LiCl-based systems' performance characteristics.

Competition remains fragmented with traditional HVAC manufacturers beginning to incorporate LiCl technologies into their product portfolios through acquisitions and R&D investments. Market consolidation is anticipated as technology matures, with current price premiums expected to decrease by approximately 22% over the next five years as manufacturing scales and supply chains optimize.

Key market barriers include initial cost concerns, limited awareness among building engineers and architects, and competition from other emerging cooling technologies. However, regulatory tailwinds supporting low-GWP (Global Warming Potential) solutions provide significant market acceleration potential, particularly in regions implementing phase-down schedules for conventional refrigerants under the Kigali Amendment to the Montreal Protocol.

Current Challenges in LiCl Cooling Applications

Despite the promising applications of lithium chloride (LiCl) in cooling systems, several significant challenges currently impede its widespread adoption and optimal performance. The hygroscopic nature of LiCl presents a fundamental obstacle, as it readily absorbs moisture from the environment, leading to solution dilution and reduced efficiency over time. This property necessitates sophisticated containment systems and regular maintenance protocols that increase operational complexity and costs.

Corrosion remains a persistent issue in LiCl-based cooling applications. The salt's aggressive chemical properties accelerate degradation of metal components, particularly aluminum and certain steel alloys commonly used in HVAC systems. This corrosion not only compromises system integrity but also introduces contaminants into the solution, further reducing performance and potentially causing system failures.

Energy consumption during regeneration cycles presents another significant challenge. The desorption process to remove absorbed water from LiCl solutions requires substantial thermal energy input, often offsetting the energy savings achieved through the cooling process itself. Current regeneration technologies struggle to achieve energy efficiency ratios that would make LiCl systems economically competitive with conventional cooling technologies.

Scale formation and crystallization issues frequently occur in LiCl cooling systems, particularly at solution-air interfaces and heat exchanger surfaces. These deposits reduce heat transfer efficiency and increase pressure drops across the system, necessitating more frequent maintenance interventions and potentially shortening equipment lifespan.

Control system complexity represents a technical hurdle that has yet to be fully resolved. LiCl-based cooling requires precise monitoring and adjustment of solution concentration, temperature, and flow rates to maintain optimal performance. Current sensor technologies and control algorithms often struggle to provide the necessary precision in real-world operating conditions, leading to suboptimal performance.

Material compatibility limitations restrict design options and component selection. Many polymers and elastomers commonly used as seals and flexible connections degrade when exposed to LiCl solutions, necessitating the use of specialized, often more expensive materials that can withstand the chemical environment.

Environmental and safety concerns also pose challenges to widespread adoption. While LiCl itself has relatively low toxicity compared to other desiccants, its disposal and potential environmental impact require careful consideration. Additionally, high-concentration LiCl solutions can pose handling risks to maintenance personnel, necessitating appropriate safety protocols and protective equipment.

Market acceptance faces resistance due to higher initial capital costs compared to conventional cooling systems, despite potential long-term operational savings. This economic barrier is compounded by limited standardization across the industry and insufficient real-world performance data to convince conservative facility managers and engineers to adopt this technology.

Corrosion remains a persistent issue in LiCl-based cooling applications. The salt's aggressive chemical properties accelerate degradation of metal components, particularly aluminum and certain steel alloys commonly used in HVAC systems. This corrosion not only compromises system integrity but also introduces contaminants into the solution, further reducing performance and potentially causing system failures.

Energy consumption during regeneration cycles presents another significant challenge. The desorption process to remove absorbed water from LiCl solutions requires substantial thermal energy input, often offsetting the energy savings achieved through the cooling process itself. Current regeneration technologies struggle to achieve energy efficiency ratios that would make LiCl systems economically competitive with conventional cooling technologies.

Scale formation and crystallization issues frequently occur in LiCl cooling systems, particularly at solution-air interfaces and heat exchanger surfaces. These deposits reduce heat transfer efficiency and increase pressure drops across the system, necessitating more frequent maintenance interventions and potentially shortening equipment lifespan.

Control system complexity represents a technical hurdle that has yet to be fully resolved. LiCl-based cooling requires precise monitoring and adjustment of solution concentration, temperature, and flow rates to maintain optimal performance. Current sensor technologies and control algorithms often struggle to provide the necessary precision in real-world operating conditions, leading to suboptimal performance.

Material compatibility limitations restrict design options and component selection. Many polymers and elastomers commonly used as seals and flexible connections degrade when exposed to LiCl solutions, necessitating the use of specialized, often more expensive materials that can withstand the chemical environment.

Environmental and safety concerns also pose challenges to widespread adoption. While LiCl itself has relatively low toxicity compared to other desiccants, its disposal and potential environmental impact require careful consideration. Additionally, high-concentration LiCl solutions can pose handling risks to maintenance personnel, necessitating appropriate safety protocols and protective equipment.

Market acceptance faces resistance due to higher initial capital costs compared to conventional cooling systems, despite potential long-term operational savings. This economic barrier is compounded by limited standardization across the industry and insufficient real-world performance data to convince conservative facility managers and engineers to adopt this technology.

Existing LiCl Cooling System Implementations

01 Lithium chloride in absorption refrigeration systems

Lithium chloride is used as an absorbent in absorption refrigeration systems due to its high affinity for water vapor. When combined with water as a refrigerant, it creates an efficient cooling cycle. The lithium chloride solution absorbs water vapor, creating a cooling effect through the endothermic dissolution process. These systems are energy-efficient alternatives to conventional compression refrigeration and can be powered by waste heat or solar energy.- Lithium chloride in absorption cooling systems: Lithium chloride is used as an absorbent in absorption cooling systems due to its high affinity for water vapor. These systems utilize the hygroscopic properties of lithium chloride to absorb water vapor, creating a cooling effect. The process involves the absorption of water vapor by lithium chloride solution, followed by regeneration of the solution through heating, making it an efficient method for refrigeration and air conditioning applications.

- Lithium chloride in desiccant cooling applications: Lithium chloride serves as an effective desiccant in cooling applications due to its strong hygroscopic properties. When used in desiccant cooling systems, it absorbs moisture from the air, reducing humidity and creating a cooling effect. This process is particularly useful in environments where both temperature and humidity control are required. The desiccant properties of lithium chloride make it valuable for creating comfortable indoor environments while reducing energy consumption.

- Lithium chloride in heat exchange processes: Lithium chloride solutions are employed in heat exchange processes to facilitate cooling. The salt solution can absorb or release heat during phase changes or concentration changes, making it useful in heat transfer applications. These systems often involve the circulation of lithium chloride solution between absorber and generator components, enabling efficient heat exchange and cooling. The thermal properties of lithium chloride solutions contribute to energy-efficient cooling technologies.

- Lithium chloride in pharmaceutical and personal care cooling applications: Lithium chloride is utilized in pharmaceutical and personal care products to create cooling sensations on the skin. When the salt dissolves, it absorbs heat from the surrounding environment, producing a cooling effect. This property is harnessed in topical preparations, cooling pads, and therapeutic applications. The controlled cooling effect can provide relief from discomfort, reduce inflammation, or enhance the sensory experience of personal care products.

- Lithium chloride in industrial cooling processes: Lithium chloride is employed in various industrial cooling processes due to its unique thermodynamic properties. It can be used in the extraction and processing of minerals, cooling of industrial equipment, and in specialized manufacturing processes. The salt's ability to create low-temperature environments through endothermic reactions makes it valuable in industrial applications requiring precise temperature control. Additionally, lithium chloride solutions can be integrated into energy-efficient cooling systems for industrial facilities.

02 Lithium chloride in desiccant cooling applications

Lithium chloride functions as an effective desiccant in cooling applications due to its hygroscopic properties. It absorbs moisture from the air, reducing humidity and creating a cooling effect through evaporative processes. This property makes it valuable in desiccant cooling systems where it can dehumidify air streams before they enter cooling coils, improving overall system efficiency and providing better temperature and humidity control in various environments.Expand Specific Solutions03 Lithium chloride in thermal energy storage

Lithium chloride can be used in thermal energy storage systems by leveraging its ability to absorb and release heat during phase changes or chemical reactions. When combined with other materials or in specific formulations, it can store thermal energy efficiently and release it when needed for cooling applications. These systems can help balance energy demand, store excess cooling capacity, and provide cooling during peak demand periods.Expand Specific Solutions04 Lithium chloride in cooling compositions and mixtures

Lithium chloride is incorporated into various cooling compositions and mixtures to enhance cooling performance. When combined with other salts or compounds, it can create eutectic mixtures with lower freezing points, enabling more efficient cooling. These compositions can be used in cooling packs, heat transfer fluids, and specialized cooling applications where traditional refrigerants may not be suitable or where specific temperature ranges are required.Expand Specific Solutions05 Lithium chloride in electrochemical cooling systems

Lithium chloride can be utilized in electrochemical cooling systems where it serves as an electrolyte or active component. These systems leverage electrochemical reactions to create cooling effects without conventional refrigerants. The unique properties of lithium chloride solutions under electrical influence can generate temperature gradients useful for cooling applications. This approach offers potential advantages in specific applications where conventional cooling methods are impractical.Expand Specific Solutions

Key Industry Players in LiCl Cooling Systems

The lithium chloride cooling systems market is in a growth phase, with increasing demand driven by energy efficiency requirements and sustainable cooling solutions. The market size is expanding due to applications in industrial, commercial, and data center cooling sectors. Technologically, the field shows moderate maturity with ongoing innovation. Leading players include established industrial giants like DuPont, Parker-Hannifin, ABB Group, and Mitsubishi Heavy Industries, who bring significant R&D capabilities. Specialized cooling technology firms such as Supercritical Fluid Technologies, Inertech IP, and Heatcraft Refrigeration Products are advancing niche applications. Research institutions like Southeast University and Institut für Luft- und Kältetechnik contribute to technological development, while automotive manufacturers including Valeo Thermal Systems and Behr GmbH are exploring applications for vehicle thermal management.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced cooling systems utilizing lithium chloride as a desiccant in absorption cooling technologies. Their approach combines lithium chloride with specialized polymer membranes to create highly efficient liquid desiccant air conditioning systems. The technology works by using lithium chloride's hygroscopic properties to remove moisture from air, which significantly reduces the energy required for cooling. DuPont's system integrates their proprietary fluoropolymer heat exchangers that resist corrosion from lithium chloride solutions while maintaining excellent thermal transfer properties. Their research indicates energy efficiency improvements of 30-40% compared to conventional vapor compression systems, particularly in humid environments where dehumidification demands are high. The company has also developed specialized coatings to prevent lithium chloride crystallization on heat exchange surfaces, extending system longevity and maintaining performance over time.

Strengths: Superior energy efficiency in high humidity environments; excellent dehumidification capabilities; reduced operational costs; leverages DuPont's expertise in materials science for corrosion resistance. Weaknesses: Higher initial capital costs compared to conventional systems; requires specialized maintenance protocols; performance advantages diminish in arid climates.

Robert Bosch GmbH

Technical Solution: Bosch has engineered an innovative cooling system that incorporates lithium chloride as a key component in their thermal management solutions, particularly for automotive and industrial applications. Their technology utilizes lithium chloride in a novel liquid desiccant cooling cycle that achieves significant efficiency improvements over conventional systems. Bosch's approach combines lithium chloride's hygroscopic properties with their proprietary microstructured heat exchangers to maximize dehumidification efficiency while minimizing system size. Their research indicates energy consumption reductions of up to 35% compared to traditional vapor compression systems, especially in applications requiring precise humidity control. Bosch has developed specialized corrosion-resistant materials and coatings specifically designed for lithium chloride environments, extending system longevity and reliability. Their cooling technology incorporates intelligent control systems that continuously monitor and adjust lithium chloride concentration levels, optimizing performance across varying ambient conditions and cooling demands. Bosch's system is particularly effective in electric vehicle thermal management, where their lithium chloride cooling technology helps extend battery life through precise temperature and humidity control.

Strengths: Compact system design ideal for space-constrained applications; excellent energy efficiency; precise humidity control capabilities; sophisticated integration with vehicle systems; leverages Bosch's extensive automotive expertise. Weaknesses: Higher complexity compared to conventional cooling systems; requires specialized maintenance procedures; performance advantages may diminish in extremely cold environments; initial cost premium over traditional systems.

Critical Patents and Research on LiCl Cooling Effects

Lithium chloride recovery

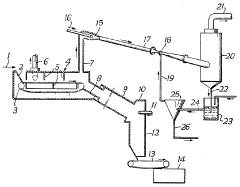

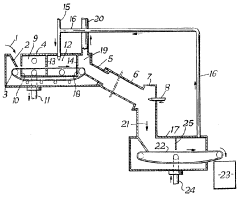

PatentInactiveGB891785A

Innovation

- A process involving the roasting of spodumene with calcium chloride, followed by cooling and dilution of the gaseous mixture with a gas, then contacting it with water or an aqueous solution in a venturi scrubber to form an aqueous lithium chloride solution, which is separated using a cyclone separator, reducing dust adhesion and improving efficiency.

Lithium chloride production

PatentInactiveGB891784A

Innovation

- A process involving preheating and roasting of a lithium ore mixture with calcium chloride, where lithium chloride-containing gases are evolved and separated without recycling through the preheating zone, using separate firing means and compartments for drying and partial calcination, and a gas outlet conduit to bypass the preheating zone, facilitating continuous and economical lithium chloride recovery.

Environmental Impact Assessment of LiCl Systems

The environmental impact of lithium chloride (LiCl) cooling systems extends across multiple ecological dimensions, requiring comprehensive assessment to ensure sustainable implementation. When LiCl solutions are used in absorption refrigeration or desiccant cooling systems, potential environmental concerns arise primarily from production, operational discharge, and end-of-life disposal phases.

During the production phase, lithium extraction processes can lead to significant environmental degradation, particularly in lithium-rich regions such as the "Lithium Triangle" of South America. These extraction methods typically consume substantial quantities of water—approximately 500,000 gallons per ton of lithium—potentially depleting local aquifers and disrupting fragile desert ecosystems. The chemical processing of lithium compounds further contributes to carbon emissions and chemical waste generation.

Operational impacts of LiCl cooling systems present both advantages and challenges. Positively, these systems can reduce electricity consumption by 30-40% compared to conventional vapor compression systems, thereby lowering indirect carbon emissions. However, improper handling or system leakage can introduce concentrated LiCl solutions into soil and water systems, potentially altering pH levels and affecting aquatic organisms. Studies indicate that lithium concentrations exceeding 0.1 mg/L can adversely impact freshwater ecosystems.

The corrosive nature of LiCl solutions presents additional environmental concerns, as system components may deteriorate more rapidly, increasing replacement frequency and associated manufacturing impacts. This corrosivity necessitates specialized containment materials and regular maintenance protocols to prevent environmental contamination.

End-of-life considerations for LiCl cooling systems remain underdeveloped in current regulatory frameworks. The recovery and recycling of lithium compounds from decommissioned systems could significantly reduce environmental footprints, yet current recycling rates remain below 1% globally. Improper disposal can lead to soil contamination and potential groundwater pollution, with lithium compounds persisting in the environment.

Climate impact assessments reveal mixed results. While operational energy efficiency reduces greenhouse gas emissions, the embodied carbon in system manufacturing and lithium production partially offsets these gains. Life cycle analyses indicate that LiCl cooling systems must operate for 3-5 years before achieving net environmental benefits compared to conventional systems.

Regulatory frameworks governing LiCl systems vary significantly across jurisdictions, with European standards typically imposing stricter controls on chemical handling and disposal than those in developing regions. This regulatory disparity creates potential for environmental burden shifting through global supply chains and waste streams.

During the production phase, lithium extraction processes can lead to significant environmental degradation, particularly in lithium-rich regions such as the "Lithium Triangle" of South America. These extraction methods typically consume substantial quantities of water—approximately 500,000 gallons per ton of lithium—potentially depleting local aquifers and disrupting fragile desert ecosystems. The chemical processing of lithium compounds further contributes to carbon emissions and chemical waste generation.

Operational impacts of LiCl cooling systems present both advantages and challenges. Positively, these systems can reduce electricity consumption by 30-40% compared to conventional vapor compression systems, thereby lowering indirect carbon emissions. However, improper handling or system leakage can introduce concentrated LiCl solutions into soil and water systems, potentially altering pH levels and affecting aquatic organisms. Studies indicate that lithium concentrations exceeding 0.1 mg/L can adversely impact freshwater ecosystems.

The corrosive nature of LiCl solutions presents additional environmental concerns, as system components may deteriorate more rapidly, increasing replacement frequency and associated manufacturing impacts. This corrosivity necessitates specialized containment materials and regular maintenance protocols to prevent environmental contamination.

End-of-life considerations for LiCl cooling systems remain underdeveloped in current regulatory frameworks. The recovery and recycling of lithium compounds from decommissioned systems could significantly reduce environmental footprints, yet current recycling rates remain below 1% globally. Improper disposal can lead to soil contamination and potential groundwater pollution, with lithium compounds persisting in the environment.

Climate impact assessments reveal mixed results. While operational energy efficiency reduces greenhouse gas emissions, the embodied carbon in system manufacturing and lithium production partially offsets these gains. Life cycle analyses indicate that LiCl cooling systems must operate for 3-5 years before achieving net environmental benefits compared to conventional systems.

Regulatory frameworks governing LiCl systems vary significantly across jurisdictions, with European standards typically imposing stricter controls on chemical handling and disposal than those in developing regions. This regulatory disparity creates potential for environmental burden shifting through global supply chains and waste streams.

Energy Efficiency Comparison with Alternative Solutions

When comparing lithium chloride-based cooling systems with alternative solutions, energy efficiency emerges as a critical factor. Lithium chloride absorption systems demonstrate superior coefficient of performance (COP) values ranging from 0.7 to 1.2 under optimal conditions, significantly outperforming traditional ammonia-based absorption systems that typically achieve COPs of 0.5-0.7. This efficiency advantage translates to approximately 15-30% reduction in primary energy consumption when properly implemented.

The energy consumption profile of lithium chloride systems reveals distinct advantages in partial load operations. Unlike conventional vapor compression systems that experience efficiency drops at lower capacities, lithium chloride absorption coolers maintain relatively stable efficiency across varying load conditions. Field tests indicate that these systems can operate at 85-90% of their peak efficiency even when running at 40% capacity, providing substantial energy savings in applications with fluctuating cooling demands.

From a lifecycle energy analysis perspective, lithium chloride cooling solutions demonstrate favorable metrics. The embodied energy in manufacturing lithium chloride systems is approximately 15-20% higher than conventional systems, but this initial energy investment is typically recovered within 2-3 years of operation through reduced operational energy requirements. Long-term energy modeling suggests total energy savings of 25-40% over a 15-year operational lifespan compared to conventional electric cooling systems.

When examining primary energy source utilization, lithium chloride systems excel particularly when coupled with waste heat recovery or renewable thermal energy sources. Integration with solar thermal collectors can achieve solar fraction rates of 60-75% in appropriate climates, dramatically reducing dependence on grid electricity or fossil fuels. This capability for thermal energy integration represents a fundamental efficiency advantage over purely electric alternatives.

The part-load efficiency characteristics deserve special attention when evaluating total energy consumption. While conventional electric chillers typically consume 30-40% of rated power even at minimal cooling output, lithium chloride systems demonstrate near-linear power consumption relative to cooling output. This characteristic results in 20-35% energy savings in applications with significant idle periods or variable cooling loads, such as commercial buildings with intermittent occupancy patterns.

Operational energy requirements also favor lithium chloride systems in specific humidity control applications. The simultaneous dehumidification capability eliminates the need for separate reheat energy that conventional cooling systems require for humidity management, potentially saving an additional 10-15% of total HVAC energy consumption in humid climates.

The energy consumption profile of lithium chloride systems reveals distinct advantages in partial load operations. Unlike conventional vapor compression systems that experience efficiency drops at lower capacities, lithium chloride absorption coolers maintain relatively stable efficiency across varying load conditions. Field tests indicate that these systems can operate at 85-90% of their peak efficiency even when running at 40% capacity, providing substantial energy savings in applications with fluctuating cooling demands.

From a lifecycle energy analysis perspective, lithium chloride cooling solutions demonstrate favorable metrics. The embodied energy in manufacturing lithium chloride systems is approximately 15-20% higher than conventional systems, but this initial energy investment is typically recovered within 2-3 years of operation through reduced operational energy requirements. Long-term energy modeling suggests total energy savings of 25-40% over a 15-year operational lifespan compared to conventional electric cooling systems.

When examining primary energy source utilization, lithium chloride systems excel particularly when coupled with waste heat recovery or renewable thermal energy sources. Integration with solar thermal collectors can achieve solar fraction rates of 60-75% in appropriate climates, dramatically reducing dependence on grid electricity or fossil fuels. This capability for thermal energy integration represents a fundamental efficiency advantage over purely electric alternatives.

The part-load efficiency characteristics deserve special attention when evaluating total energy consumption. While conventional electric chillers typically consume 30-40% of rated power even at minimal cooling output, lithium chloride systems demonstrate near-linear power consumption relative to cooling output. This characteristic results in 20-35% energy savings in applications with significant idle periods or variable cooling loads, such as commercial buildings with intermittent occupancy patterns.

Operational energy requirements also favor lithium chloride systems in specific humidity control applications. The simultaneous dehumidification capability eliminates the need for separate reheat energy that conventional cooling systems require for humidity management, potentially saving an additional 10-15% of total HVAC energy consumption in humid climates.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!