How to Evaluate Lithium Chloride for Humidification Systems

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Chloride Humidification Technology Background and Objectives

Lithium chloride (LiCl) has emerged as a significant material in humidification technology over the past several decades. The evolution of this technology can be traced back to the early 20th century when the hygroscopic properties of lithium chloride were first recognized and applied in industrial dehumidification systems. Since then, the application scope has expanded considerably, encompassing not only industrial settings but also commercial and residential environments.

The fundamental principle behind lithium chloride humidification systems lies in its exceptional hygroscopic nature. This salt solution can absorb moisture from the air when the ambient humidity is high and release it when the humidity drops below a certain threshold. This property makes lithium chloride an ideal candidate for maintaining stable humidity levels in various environments, particularly in applications requiring precise humidity control.

Recent technological advancements have significantly improved the efficiency and reliability of lithium chloride-based humidification systems. The integration of digital controls, IoT capabilities, and advanced materials science has transformed these systems from simple mechanical devices to sophisticated environmental management solutions. The trend is moving towards more energy-efficient, environmentally friendly, and cost-effective systems that can operate with minimal maintenance requirements.

The global focus on sustainable technologies has further accelerated research in this field. As energy consumption and environmental impact become increasingly important considerations, lithium chloride systems are being redesigned to minimize resource usage while maximizing performance. This includes developing regenerative systems that can recover and reuse lithium chloride, reducing waste and operational costs.

The primary technical objective in evaluating lithium chloride for humidification systems is to determine its efficacy, efficiency, and sustainability compared to alternative technologies. This involves assessing parameters such as moisture absorption capacity, energy consumption, system longevity, maintenance requirements, and environmental impact. Additionally, the evaluation aims to identify optimal concentration levels, solution stability under various operating conditions, and potential material compatibility issues.

Another critical objective is to explore innovative applications and integration possibilities. As smart building technologies continue to evolve, there is growing interest in how lithium chloride humidification systems can be incorporated into comprehensive building management systems, contributing to overall energy efficiency and indoor air quality improvements.

Looking forward, the technology roadmap for lithium chloride humidification systems points towards miniaturization, increased automation, and enhanced performance metrics. Research is also focusing on addressing current limitations, such as corrosion issues, crystallization challenges, and optimizing the regeneration process to extend the operational life of these systems.

The fundamental principle behind lithium chloride humidification systems lies in its exceptional hygroscopic nature. This salt solution can absorb moisture from the air when the ambient humidity is high and release it when the humidity drops below a certain threshold. This property makes lithium chloride an ideal candidate for maintaining stable humidity levels in various environments, particularly in applications requiring precise humidity control.

Recent technological advancements have significantly improved the efficiency and reliability of lithium chloride-based humidification systems. The integration of digital controls, IoT capabilities, and advanced materials science has transformed these systems from simple mechanical devices to sophisticated environmental management solutions. The trend is moving towards more energy-efficient, environmentally friendly, and cost-effective systems that can operate with minimal maintenance requirements.

The global focus on sustainable technologies has further accelerated research in this field. As energy consumption and environmental impact become increasingly important considerations, lithium chloride systems are being redesigned to minimize resource usage while maximizing performance. This includes developing regenerative systems that can recover and reuse lithium chloride, reducing waste and operational costs.

The primary technical objective in evaluating lithium chloride for humidification systems is to determine its efficacy, efficiency, and sustainability compared to alternative technologies. This involves assessing parameters such as moisture absorption capacity, energy consumption, system longevity, maintenance requirements, and environmental impact. Additionally, the evaluation aims to identify optimal concentration levels, solution stability under various operating conditions, and potential material compatibility issues.

Another critical objective is to explore innovative applications and integration possibilities. As smart building technologies continue to evolve, there is growing interest in how lithium chloride humidification systems can be incorporated into comprehensive building management systems, contributing to overall energy efficiency and indoor air quality improvements.

Looking forward, the technology roadmap for lithium chloride humidification systems points towards miniaturization, increased automation, and enhanced performance metrics. Research is also focusing on addressing current limitations, such as corrosion issues, crystallization challenges, and optimizing the regeneration process to extend the operational life of these systems.

Market Analysis for Lithium Chloride-Based Humidification Systems

The global market for humidification systems has been experiencing steady growth, driven by increasing awareness of indoor air quality and its impact on health, productivity, and equipment performance. Lithium chloride-based humidification systems represent a specialized segment within this market, offering unique advantages over conventional technologies such as steam, ultrasonic, or evaporative humidifiers.

The current market size for industrial and commercial humidification systems is estimated at $3.5 billion globally, with a compound annual growth rate of 5.7%. Within this broader market, desiccant-based systems, including lithium chloride solutions, account for approximately $890 million, showing faster growth at 7.2% annually due to their energy efficiency advantages and precise humidity control capabilities.

Key market segments driving demand for lithium chloride humidification systems include pharmaceutical manufacturing, where strict humidity control is essential for product quality; data centers, where proper humidity levels prevent static electricity and equipment damage; food processing facilities requiring precise environmental control; and high-end commercial buildings seeking energy-efficient HVAC solutions.

Geographically, North America and Europe currently dominate the market for advanced humidification technologies, collectively accounting for 62% of global demand. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India showing particular interest in energy-efficient building technologies as they implement stricter indoor air quality regulations.

Customer demand patterns indicate a growing preference for systems that offer precise humidity control while minimizing energy consumption. Lithium chloride systems address this need effectively, as they can maintain relative humidity levels within ±2% while consuming 30-40% less energy than conventional steam humidifiers under comparable conditions.

Price sensitivity varies significantly by market segment. While initial installation costs for lithium chloride systems are typically 25-35% higher than conventional alternatives, the total cost of ownership analysis reveals competitive advantages due to lower operational costs, reduced maintenance requirements, and longer service life.

Market research indicates that sustainability considerations are increasingly influencing purchasing decisions, with 73% of commercial building operators citing energy efficiency as a "very important" factor when selecting humidification systems. This trend favors lithium chloride technology, which offers superior performance in this regard compared to conventional steam-based systems.

Competition in this space includes established HVAC manufacturers expanding their product lines to include advanced desiccant-based systems, as well as specialized companies focused exclusively on liquid desiccant technology. Recent market consolidation through mergers and acquisitions suggests growing recognition of the technology's commercial potential.

The current market size for industrial and commercial humidification systems is estimated at $3.5 billion globally, with a compound annual growth rate of 5.7%. Within this broader market, desiccant-based systems, including lithium chloride solutions, account for approximately $890 million, showing faster growth at 7.2% annually due to their energy efficiency advantages and precise humidity control capabilities.

Key market segments driving demand for lithium chloride humidification systems include pharmaceutical manufacturing, where strict humidity control is essential for product quality; data centers, where proper humidity levels prevent static electricity and equipment damage; food processing facilities requiring precise environmental control; and high-end commercial buildings seeking energy-efficient HVAC solutions.

Geographically, North America and Europe currently dominate the market for advanced humidification technologies, collectively accounting for 62% of global demand. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India showing particular interest in energy-efficient building technologies as they implement stricter indoor air quality regulations.

Customer demand patterns indicate a growing preference for systems that offer precise humidity control while minimizing energy consumption. Lithium chloride systems address this need effectively, as they can maintain relative humidity levels within ±2% while consuming 30-40% less energy than conventional steam humidifiers under comparable conditions.

Price sensitivity varies significantly by market segment. While initial installation costs for lithium chloride systems are typically 25-35% higher than conventional alternatives, the total cost of ownership analysis reveals competitive advantages due to lower operational costs, reduced maintenance requirements, and longer service life.

Market research indicates that sustainability considerations are increasingly influencing purchasing decisions, with 73% of commercial building operators citing energy efficiency as a "very important" factor when selecting humidification systems. This trend favors lithium chloride technology, which offers superior performance in this regard compared to conventional steam-based systems.

Competition in this space includes established HVAC manufacturers expanding their product lines to include advanced desiccant-based systems, as well as specialized companies focused exclusively on liquid desiccant technology. Recent market consolidation through mergers and acquisitions suggests growing recognition of the technology's commercial potential.

Current State and Technical Challenges in LiCl Humidification

Lithium chloride (LiCl) has emerged as a significant material in humidification systems due to its exceptional hygroscopic properties. Currently, LiCl-based humidification technologies are deployed across various sectors including HVAC systems, industrial processes, and specialized environments requiring precise humidity control. The global market for advanced humidification solutions has seen substantial growth, with LiCl systems gaining traction particularly in regions with extreme climate conditions.

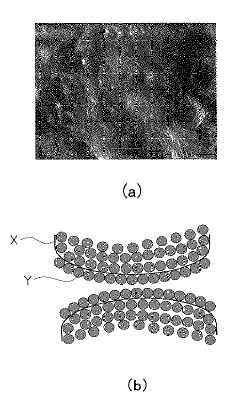

The technical landscape of LiCl humidification systems reveals several established approaches. Liquid desiccant systems utilize LiCl solutions to absorb moisture from air streams, while solid desiccant wheels impregnated with LiCl offer an alternative configuration. More recently, membrane-based systems incorporating LiCl have demonstrated promising performance characteristics. These systems typically achieve humidity control with precision levels of ±2-5% relative humidity, representing the current industry standard.

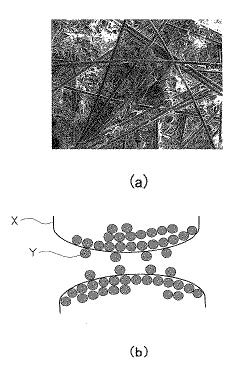

Despite these advancements, significant technical challenges persist in LiCl humidification technology. Crystallization and precipitation of LiCl during operation cycles remains a critical issue, leading to reduced efficiency and increased maintenance requirements. This phenomenon is particularly problematic in systems experiencing wide temperature fluctuations or operating near saturation points. Material compatibility presents another substantial challenge, as LiCl's corrosive nature necessitates careful selection of system components and containment materials.

Energy efficiency represents a persistent constraint in current LiCl systems. The regeneration process, which restores the desiccant properties after moisture absorption, typically demands considerable thermal energy inputs, reducing the overall system efficiency. This limitation becomes particularly pronounced in applications requiring continuous operation or rapid cycling between absorption and regeneration phases.

Control system integration poses additional challenges, as the non-linear absorption characteristics of LiCl solutions complicate the development of precise control algorithms. Current systems often struggle to maintain optimal performance across varying environmental conditions, particularly during transient operations or when facing fluctuating humidity loads.

From a geographical perspective, LiCl humidification technology development shows concentration in North America, Western Europe, and East Asia, particularly Japan and South Korea. These regions have established research centers and industrial facilities focused on advancing desiccant technologies. However, adoption rates vary significantly across regions, influenced by factors including climate conditions, energy costs, and regulatory frameworks governing indoor air quality and energy efficiency.

The environmental impact of LiCl systems presents both advantages and challenges. While these systems can reduce energy consumption compared to conventional humidification methods, concerns regarding lithium resource sustainability and potential environmental contamination from system leakage require careful consideration in future development efforts.

The technical landscape of LiCl humidification systems reveals several established approaches. Liquid desiccant systems utilize LiCl solutions to absorb moisture from air streams, while solid desiccant wheels impregnated with LiCl offer an alternative configuration. More recently, membrane-based systems incorporating LiCl have demonstrated promising performance characteristics. These systems typically achieve humidity control with precision levels of ±2-5% relative humidity, representing the current industry standard.

Despite these advancements, significant technical challenges persist in LiCl humidification technology. Crystallization and precipitation of LiCl during operation cycles remains a critical issue, leading to reduced efficiency and increased maintenance requirements. This phenomenon is particularly problematic in systems experiencing wide temperature fluctuations or operating near saturation points. Material compatibility presents another substantial challenge, as LiCl's corrosive nature necessitates careful selection of system components and containment materials.

Energy efficiency represents a persistent constraint in current LiCl systems. The regeneration process, which restores the desiccant properties after moisture absorption, typically demands considerable thermal energy inputs, reducing the overall system efficiency. This limitation becomes particularly pronounced in applications requiring continuous operation or rapid cycling between absorption and regeneration phases.

Control system integration poses additional challenges, as the non-linear absorption characteristics of LiCl solutions complicate the development of precise control algorithms. Current systems often struggle to maintain optimal performance across varying environmental conditions, particularly during transient operations or when facing fluctuating humidity loads.

From a geographical perspective, LiCl humidification technology development shows concentration in North America, Western Europe, and East Asia, particularly Japan and South Korea. These regions have established research centers and industrial facilities focused on advancing desiccant technologies. However, adoption rates vary significantly across regions, influenced by factors including climate conditions, energy costs, and regulatory frameworks governing indoor air quality and energy efficiency.

The environmental impact of LiCl systems presents both advantages and challenges. While these systems can reduce energy consumption compared to conventional humidification methods, concerns regarding lithium resource sustainability and potential environmental contamination from system leakage require careful consideration in future development efforts.

Current Evaluation Methods for LiCl Humidification Performance

01 Lithium chloride extraction and production methods

Various methods for extracting and producing lithium chloride from natural sources such as brines and minerals. These processes typically involve concentration, purification, and crystallization steps to obtain high-purity lithium chloride. Advanced techniques may include selective precipitation, ion exchange, and membrane separation to improve yield and purity while reducing environmental impact.- Lithium chloride extraction and production methods: Various methods for extracting and producing lithium chloride from natural sources or through chemical processes. These methods include techniques for obtaining lithium chloride from brines, minerals, or through conversion of other lithium compounds. The processes often involve steps such as concentration, purification, crystallization, and drying to obtain high-purity lithium chloride suitable for industrial applications.

- Applications in battery technology: Lithium chloride is utilized in various aspects of battery technology, particularly in lithium-ion batteries. It serves as a precursor for cathode materials, electrolyte components, or as an additive to improve battery performance. The compound contributes to enhanced electrochemical properties, improved stability, and extended battery life in energy storage applications.

- Pharmaceutical and medical applications: Lithium chloride has applications in pharmaceutical formulations and medical treatments. It is used in the treatment of psychiatric disorders, particularly bipolar disorder, and has potential applications in other medical conditions. Research indicates its potential therapeutic effects in various neurological and psychiatric conditions, with specific formulations designed to optimize efficacy while minimizing side effects.

- Industrial chemical processes and catalysis: Lithium chloride serves as a catalyst or reagent in various industrial chemical processes. It is used in organic synthesis reactions, polymerization processes, and as a drying agent. The compound's properties make it valuable in specific chemical transformations, enabling more efficient production of various industrial chemicals and materials.

- Environmental and specialized applications: Lithium chloride finds applications in environmental technologies and specialized fields. These include use in dehumidification systems, heat storage applications, and as a component in specialized materials. The hygroscopic properties of lithium chloride make it particularly useful in moisture control applications, while its thermal properties are valuable in heat exchange systems.

02 Lithium chloride applications in battery technology

Lithium chloride serves as a precursor or component in the manufacturing of lithium-ion batteries and other energy storage systems. It can be used in electrolyte formulations, electrode materials, and as an intermediate in the production of other lithium compounds essential for battery production. These applications leverage lithium chloride's ionic properties to enhance battery performance, stability, and longevity.Expand Specific Solutions03 Lithium chloride in pharmaceutical and medical applications

Lithium chloride has various pharmaceutical and medical applications, including use as a therapeutic agent for mental health conditions such as bipolar disorder. It can also be incorporated into formulations for topical treatments and other medical preparations. Research continues to explore its potential in new therapeutic areas and drug delivery systems.Expand Specific Solutions04 Industrial applications of lithium chloride

Lithium chloride finds use in various industrial processes including as a desiccant in air conditioning systems, a flux in welding and soldering operations, and a component in heat transfer fluids. It's also utilized in the production of specialty chemicals, ceramics, and as a catalyst in certain chemical reactions. Its hygroscopic properties make it valuable for humidity control in industrial settings.Expand Specific Solutions05 Environmental and recycling processes for lithium chloride

Methods for recycling and recovering lithium chloride from spent materials and industrial waste streams. These processes aim to reduce environmental impact while reclaiming valuable lithium resources. Techniques include hydrometallurgical processes, selective precipitation, and advanced separation methods that enable the sustainable management of lithium resources and minimize waste generation.Expand Specific Solutions

Key Industry Players in Chemical Humidification Solutions

The lithium chloride humidification systems market is in a growth phase, with increasing applications in industrial and commercial sectors. The market size is expanding due to rising demand for efficient humidity control solutions in various industries. Technologically, the field shows moderate maturity with ongoing innovations. Leading players include SANYO Electric and Toshiba from Japan, demonstrating strong technological capabilities in consumer and commercial applications. BYD and General Lithium are leveraging their expertise in lithium processing to develop advanced humidification solutions. Research institutions like Central South University and KIST are contributing significant advancements through academic-industrial collaborations. Korean companies such as Korea Hydro & Nuclear Power are exploring specialized applications in energy sectors, while chemical manufacturers like Nobian Chemicals and Sumitomo Metal Mining provide essential raw materials for system development.

Halliburton Energy Services, Inc.

Technical Solution: Halliburton has developed specialized evaluation methodologies for lithium chloride in industrial humidification systems used in oil and gas processing facilities. Their approach focuses on performance under extreme conditions, including high-pressure environments, wide temperature fluctuations (-20°C to 80°C), and exposure to hydrocarbon contaminants. Halliburton's evaluation protocol includes comprehensive thermodynamic modeling of LiCl solutions at varying concentrations (25-45%) to predict moisture absorption capacity and regeneration energy requirements across operational conditions. Their testing incorporates specialized high-pressure chambers that simulate downhole conditions, evaluating solution stability and performance under elevated pressures up to 200 bar. Halliburton has pioneered advanced materials compatibility testing for LiCl solutions in contact with specialized alloys and elastomers used in energy sector applications, developing a comprehensive database of compatibility ratings. Their evaluation methodology includes field validation in actual processing facilities, with real-time monitoring systems that track performance metrics including moisture removal efficiency, solution degradation rates, and energy consumption over extended operational periods.

Strengths: Exceptional performance in harsh industrial environments; robust design withstands contamination better than alternative systems; capable of precise humidity control even under fluctuating process conditions. Weaknesses: Higher implementation costs compared to conventional systems; requires specialized maintenance protocols; potential for crystallization issues in extremely cold environments without proper thermal management.

Corona Corp.

Technical Solution: Corona Corporation has developed advanced lithium chloride-based desiccant dehumidification systems that utilize the hygroscopic properties of LiCl for precise humidity control. Their evaluation methodology includes comprehensive performance testing under varying temperature and humidity conditions (10-40°C, 30-90% RH), measuring moisture absorption capacity, regeneration efficiency, and system stability over extended operational periods. Corona's proprietary LiCl solution formulation undergoes rigorous quality control testing for concentration stability (typically maintained at 30-40% by weight) and contamination resistance. Their evaluation process incorporates accelerated aging tests to simulate years of operational wear, corrosion resistance assessment using standardized ASTM protocols, and energy efficiency measurements comparing power consumption against moisture removal rates. The company has also developed specialized instrumentation for real-time monitoring of solution properties during operation.

Strengths: Superior moisture absorption capacity compared to other desiccants; highly stable performance across wide temperature ranges; precise humidity control capabilities. Weaknesses: Higher initial cost compared to alternative desiccants; requires specialized handling due to LiCl's corrosive properties; system complexity increases maintenance requirements.

Critical Technical Parameters and Testing Protocols for LiCl

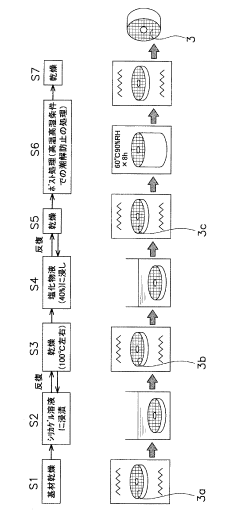

Desiccant device having metal halide salt and method for producing the same

PatentInactiveJPWO2007119416A1

Innovation

- A method involving a metal halide salt dipping step followed by a forced deliquescence step to optimize the content of metal halide salt, ensuring it does not easily deliquesce, combined with additional drying steps to remove excess liquid, resulting in a composite desiccant device with enhanced moisture adsorption and desorption performance.

Process for obtaining lithium chloride from solutions and a device for carrying out the same

PatentWO1994019280A1

Innovation

- A method involving a stepwise-protivotchnom mode for lithium sorption and desorption using a granulated sorbent, with double contact operation in sorption and desorption zones, followed by electrodialysis for concentration, achieving maximum lithium chloride extraction and minimizing impurities.

Environmental Impact and Sustainability Assessment

The environmental impact of lithium chloride in humidification systems requires comprehensive assessment across multiple dimensions. Lithium chloride, while effective as a desiccant material, presents several environmental concerns throughout its lifecycle. The extraction of lithium from natural sources, primarily brine pools and mineral ores, involves significant land use, water consumption, and potential habitat disruption in ecologically sensitive areas such as the lithium triangle in South America.

During operational use in humidification systems, lithium chloride solutions require careful handling and containment protocols to prevent environmental release. Accidental spills or improper disposal can lead to soil contamination and potentially affect groundwater quality, as lithium compounds remain highly soluble and mobile in aquatic environments. The toxicity profile of lithium chloride to aquatic organisms necessitates stringent waste management practices.

Energy consumption represents another critical environmental factor. Regeneration of lithium chloride solutions typically requires substantial thermal energy, contributing to the carbon footprint of humidification systems unless renewable energy sources are employed. Life cycle assessment (LCA) studies indicate that the environmental burden of lithium chloride systems varies significantly based on energy source selection and system efficiency parameters.

From a sustainability perspective, lithium chloride presents both challenges and opportunities. The growing demand for lithium in battery technologies creates potential resource competition, raising concerns about long-term availability for humidification applications. However, closed-loop systems that effectively recover and reuse lithium chloride can substantially mitigate resource depletion concerns and improve sustainability metrics.

Regulatory compliance frameworks increasingly emphasize environmental performance. Evaluations must consider regional variations in environmental regulations governing chemical use, disposal requirements, and emissions standards. Forward-looking assessments should anticipate regulatory trends toward stricter environmental controls and incorporate compliance planning into system design and operational protocols.

Alternative desiccant materials with potentially lower environmental impacts, such as calcium chloride or certain bio-based solutions, warrant comparative assessment against lithium chloride. Such comparisons should employ standardized environmental impact categories including global warming potential, acidification potential, eutrophication potential, and resource depletion metrics to ensure comprehensive evaluation of sustainability performance across different technological options.

During operational use in humidification systems, lithium chloride solutions require careful handling and containment protocols to prevent environmental release. Accidental spills or improper disposal can lead to soil contamination and potentially affect groundwater quality, as lithium compounds remain highly soluble and mobile in aquatic environments. The toxicity profile of lithium chloride to aquatic organisms necessitates stringent waste management practices.

Energy consumption represents another critical environmental factor. Regeneration of lithium chloride solutions typically requires substantial thermal energy, contributing to the carbon footprint of humidification systems unless renewable energy sources are employed. Life cycle assessment (LCA) studies indicate that the environmental burden of lithium chloride systems varies significantly based on energy source selection and system efficiency parameters.

From a sustainability perspective, lithium chloride presents both challenges and opportunities. The growing demand for lithium in battery technologies creates potential resource competition, raising concerns about long-term availability for humidification applications. However, closed-loop systems that effectively recover and reuse lithium chloride can substantially mitigate resource depletion concerns and improve sustainability metrics.

Regulatory compliance frameworks increasingly emphasize environmental performance. Evaluations must consider regional variations in environmental regulations governing chemical use, disposal requirements, and emissions standards. Forward-looking assessments should anticipate regulatory trends toward stricter environmental controls and incorporate compliance planning into system design and operational protocols.

Alternative desiccant materials with potentially lower environmental impacts, such as calcium chloride or certain bio-based solutions, warrant comparative assessment against lithium chloride. Such comparisons should employ standardized environmental impact categories including global warming potential, acidification potential, eutrophication potential, and resource depletion metrics to ensure comprehensive evaluation of sustainability performance across different technological options.

Safety Standards and Regulatory Compliance Requirements

The evaluation of lithium chloride for humidification systems must adhere to stringent safety standards and regulatory compliance requirements across multiple jurisdictions. In the United States, OSHA regulations establish permissible exposure limits (PELs) for lithium compounds, requiring workplace monitoring and appropriate engineering controls when handling lithium chloride. The EPA regulates lithium compounds under the Toxic Substances Control Act (TSCA), mandating proper disposal procedures and environmental impact assessments for systems utilizing this hygroscopic salt.

The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) provides specific guidelines for liquid desiccant systems in Standard 62.1, which addresses ventilation requirements and indoor air quality considerations when lithium chloride solutions are employed in HVAC applications. These standards establish minimum performance criteria and safety parameters that must be incorporated into system design and operation protocols.

European regulations, particularly REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), classify lithium chloride as a substance requiring comprehensive safety data sheets and risk assessments. The EU's Classification, Labeling and Packaging (CLP) Regulation mandates specific hazard communication requirements for lithium chloride solutions, including appropriate warning labels and safety information for end-users and maintenance personnel.

International standards such as ISO 16000 series for indoor air quality assessment provide methodologies for evaluating potential contaminants that might result from lithium chloride-based humidification systems. These standards establish testing protocols to ensure that indoor air quality remains within acceptable parameters when such systems are deployed in occupied spaces.

Material compatibility standards must also be considered, as lithium chloride's corrosive properties necessitate compliance with materials standards such as ASTM B117 for salt spray testing and NACE standards for corrosion prevention. Equipment utilizing lithium chloride solutions must demonstrate compliance with these standards to ensure long-term system integrity and safety.

Water quality regulations present another critical compliance area, as discharge of lithium chloride solutions may be subject to local wastewater treatment requirements. The Clean Water Act in the US and similar regulations internationally may impose limitations on lithium concentration in discharged water, necessitating appropriate treatment or recovery systems as part of the humidification installation.

Certification requirements from organizations such as UL (Underwriters Laboratories) or CE marking in Europe establish additional compliance pathways for lithium chloride-based systems, verifying that equipment meets established safety standards before market introduction. These certifications often require extensive testing and documentation of safety features, emergency protocols, and maintenance procedures.

The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) provides specific guidelines for liquid desiccant systems in Standard 62.1, which addresses ventilation requirements and indoor air quality considerations when lithium chloride solutions are employed in HVAC applications. These standards establish minimum performance criteria and safety parameters that must be incorporated into system design and operation protocols.

European regulations, particularly REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), classify lithium chloride as a substance requiring comprehensive safety data sheets and risk assessments. The EU's Classification, Labeling and Packaging (CLP) Regulation mandates specific hazard communication requirements for lithium chloride solutions, including appropriate warning labels and safety information for end-users and maintenance personnel.

International standards such as ISO 16000 series for indoor air quality assessment provide methodologies for evaluating potential contaminants that might result from lithium chloride-based humidification systems. These standards establish testing protocols to ensure that indoor air quality remains within acceptable parameters when such systems are deployed in occupied spaces.

Material compatibility standards must also be considered, as lithium chloride's corrosive properties necessitate compliance with materials standards such as ASTM B117 for salt spray testing and NACE standards for corrosion prevention. Equipment utilizing lithium chloride solutions must demonstrate compliance with these standards to ensure long-term system integrity and safety.

Water quality regulations present another critical compliance area, as discharge of lithium chloride solutions may be subject to local wastewater treatment requirements. The Clean Water Act in the US and similar regulations internationally may impose limitations on lithium concentration in discharged water, necessitating appropriate treatment or recovery systems as part of the humidification installation.

Certification requirements from organizations such as UL (Underwriters Laboratories) or CE marking in Europe establish additional compliance pathways for lithium chloride-based systems, verifying that equipment meets established safety standards before market introduction. These certifications often require extensive testing and documentation of safety features, emergency protocols, and maintenance procedures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!