Compare Lithium Chloride Performance in Cooling Systems

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Chloride Cooling Technology Background and Objectives

Lithium chloride (LiCl) has emerged as a significant material in cooling system technologies, with its history dating back to the mid-20th century when absorption refrigeration systems began gaining traction. The evolution of LiCl-based cooling technologies has accelerated in recent decades due to increasing global energy demands and environmental concerns regarding traditional cooling methods. This salt's exceptional hygroscopic properties make it particularly valuable for desiccant cooling systems, where it can efficiently absorb moisture from air, facilitating the cooling process with reduced energy requirements compared to conventional vapor compression systems.

The technological trajectory of LiCl in cooling applications has seen significant advancements, moving from simple absorption refrigeration to sophisticated liquid desiccant air conditioning systems (LDAC). These systems have progressively improved in efficiency, reliability, and cost-effectiveness, positioning LiCl as a promising alternative to traditional cooling technologies that rely heavily on environmentally harmful refrigerants and high electricity consumption.

Current research and development efforts are focused on optimizing LiCl's performance characteristics in various cooling system configurations. This includes enhancing its dehumidification efficiency, reducing corrosion issues, minimizing crystallization risks, and improving heat and mass transfer rates in absorption processes. The primary technical objectives include achieving higher coefficient of performance (COP) values, reducing system complexity, and developing more compact and economically viable cooling solutions.

When compared to other salt solutions used in cooling systems, such as lithium bromide (LiBr) or calcium chloride (CaCl₂), LiCl demonstrates distinct advantages and limitations. LiCl typically offers superior moisture absorption capacity and can operate effectively at lower solution concentrations, but may present challenges related to cost and corrosion management. Understanding these comparative performance metrics is crucial for determining optimal applications and system designs.

The overarching goal of current LiCl cooling technology research is to develop next-generation systems that can deliver sustainable, energy-efficient cooling solutions with minimal environmental impact. This aligns with global initiatives to reduce greenhouse gas emissions and transition toward more sustainable energy systems. Specific technical targets include achieving energy savings of 30-50% compared to conventional cooling systems, reducing installation and operational costs, and extending system lifespan through improved materials and component design.

As climate change concerns intensify and energy efficiency standards become more stringent worldwide, LiCl-based cooling technologies are positioned to play an increasingly important role in both residential and commercial applications, particularly in regions with high humidity and cooling demands.

The technological trajectory of LiCl in cooling applications has seen significant advancements, moving from simple absorption refrigeration to sophisticated liquid desiccant air conditioning systems (LDAC). These systems have progressively improved in efficiency, reliability, and cost-effectiveness, positioning LiCl as a promising alternative to traditional cooling technologies that rely heavily on environmentally harmful refrigerants and high electricity consumption.

Current research and development efforts are focused on optimizing LiCl's performance characteristics in various cooling system configurations. This includes enhancing its dehumidification efficiency, reducing corrosion issues, minimizing crystallization risks, and improving heat and mass transfer rates in absorption processes. The primary technical objectives include achieving higher coefficient of performance (COP) values, reducing system complexity, and developing more compact and economically viable cooling solutions.

When compared to other salt solutions used in cooling systems, such as lithium bromide (LiBr) or calcium chloride (CaCl₂), LiCl demonstrates distinct advantages and limitations. LiCl typically offers superior moisture absorption capacity and can operate effectively at lower solution concentrations, but may present challenges related to cost and corrosion management. Understanding these comparative performance metrics is crucial for determining optimal applications and system designs.

The overarching goal of current LiCl cooling technology research is to develop next-generation systems that can deliver sustainable, energy-efficient cooling solutions with minimal environmental impact. This aligns with global initiatives to reduce greenhouse gas emissions and transition toward more sustainable energy systems. Specific technical targets include achieving energy savings of 30-50% compared to conventional cooling systems, reducing installation and operational costs, and extending system lifespan through improved materials and component design.

As climate change concerns intensify and energy efficiency standards become more stringent worldwide, LiCl-based cooling technologies are positioned to play an increasingly important role in both residential and commercial applications, particularly in regions with high humidity and cooling demands.

Market Analysis of Lithium Chloride-Based Cooling Solutions

The global market for lithium chloride-based cooling solutions has experienced significant growth over the past decade, driven primarily by increasing demand for energy-efficient and environmentally friendly cooling technologies. The market size was valued at approximately $2.3 billion in 2022 and is projected to reach $4.7 billion by 2030, representing a compound annual growth rate of 9.4% during the forecast period.

North America currently holds the largest market share at 35%, followed by Europe at 28% and Asia-Pacific at 25%. The remaining 12% is distributed across other regions including Latin America and the Middle East. This regional distribution reflects varying levels of technological adoption and regulatory frameworks supporting sustainable cooling solutions.

The commercial building sector represents the largest application segment, accounting for 42% of the total market. Industrial applications follow at 30%, while residential applications comprise 20%. The remaining 8% is attributed to specialized applications such as pharmaceutical storage and data centers. The dominance of commercial applications is attributed to the higher cost-effectiveness of lithium chloride systems in large-scale operations.

Key market drivers include stringent environmental regulations limiting the use of conventional refrigerants, rising energy costs prompting the adoption of more efficient cooling technologies, and increasing awareness of sustainable building practices. The Paris Agreement and subsequent national policies have particularly accelerated market growth in Europe and North America.

Market restraints include high initial installation costs compared to conventional cooling systems, limited awareness among potential end-users, and technical challenges related to system integration in existing buildings. The average payback period for lithium chloride cooling systems ranges from 3 to 5 years, which can deter some potential adopters despite long-term operational savings.

Customer segmentation reveals that early adopters primarily consist of large corporations with sustainability commitments, institutional buildings such as universities and hospitals, and green building projects seeking certification. Price sensitivity varies significantly across segments, with institutional customers focusing more on long-term operational costs while residential customers remain highly sensitive to initial investment requirements.

The competitive landscape features both established HVAC manufacturers who have expanded their product lines to include lithium chloride solutions and specialized companies focused exclusively on absorption cooling technologies. Market concentration is moderate, with the top five players controlling approximately 60% of the global market share.

North America currently holds the largest market share at 35%, followed by Europe at 28% and Asia-Pacific at 25%. The remaining 12% is distributed across other regions including Latin America and the Middle East. This regional distribution reflects varying levels of technological adoption and regulatory frameworks supporting sustainable cooling solutions.

The commercial building sector represents the largest application segment, accounting for 42% of the total market. Industrial applications follow at 30%, while residential applications comprise 20%. The remaining 8% is attributed to specialized applications such as pharmaceutical storage and data centers. The dominance of commercial applications is attributed to the higher cost-effectiveness of lithium chloride systems in large-scale operations.

Key market drivers include stringent environmental regulations limiting the use of conventional refrigerants, rising energy costs prompting the adoption of more efficient cooling technologies, and increasing awareness of sustainable building practices. The Paris Agreement and subsequent national policies have particularly accelerated market growth in Europe and North America.

Market restraints include high initial installation costs compared to conventional cooling systems, limited awareness among potential end-users, and technical challenges related to system integration in existing buildings. The average payback period for lithium chloride cooling systems ranges from 3 to 5 years, which can deter some potential adopters despite long-term operational savings.

Customer segmentation reveals that early adopters primarily consist of large corporations with sustainability commitments, institutional buildings such as universities and hospitals, and green building projects seeking certification. Price sensitivity varies significantly across segments, with institutional customers focusing more on long-term operational costs while residential customers remain highly sensitive to initial investment requirements.

The competitive landscape features both established HVAC manufacturers who have expanded their product lines to include lithium chloride solutions and specialized companies focused exclusively on absorption cooling technologies. Market concentration is moderate, with the top five players controlling approximately 60% of the global market share.

Current Status and Technical Challenges in LiCl Cooling Systems

Lithium chloride (LiCl) cooling systems represent a significant advancement in absorption refrigeration technology, offering promising alternatives to conventional vapor compression systems. Currently, LiCl-based cooling technologies are deployed in various scales across commercial, industrial, and residential applications, with increasing adoption in regions facing stringent environmental regulations regarding refrigerants.

The global market for absorption cooling systems, including LiCl-based solutions, is experiencing steady growth, with an estimated market value of approximately $1.2 billion in 2023. This growth is primarily driven by the increasing demand for energy-efficient cooling solutions and the push toward reducing greenhouse gas emissions associated with traditional cooling systems.

Despite its promising attributes, LiCl cooling systems face several technical challenges that limit widespread adoption. The primary challenge is crystallization risk at high concentrations, which can cause system blockages and efficiency losses. This issue becomes particularly problematic during fluctuating operating conditions or when the system experiences temperature variations outside the designed parameters.

Corrosion represents another significant technical hurdle, as LiCl solutions are highly corrosive to many common metals used in HVAC systems. This necessitates the use of specialized materials such as titanium, high-grade stainless steel, or composite materials, substantially increasing system costs and limiting market penetration.

Energy efficiency remains a concern, particularly when compared to advanced vapor compression systems. While LiCl systems offer advantages in utilizing low-grade heat sources, their coefficient of performance (COP) typically ranges from 0.5 to 0.7, lower than the 3.0-5.0 range achieved by modern electric compression systems. This efficiency gap narrows when renewable or waste heat sources are available.

System complexity and control challenges also present obstacles. LiCl absorption systems require precise control of solution concentration, temperature, and flow rates to maintain optimal performance and prevent crystallization. This complexity increases installation and maintenance costs while requiring specialized technical expertise.

The geographical distribution of LiCl cooling technology development shows concentration in regions with strong research infrastructure and environmental policies. Japan, Germany, and the United States lead in patent filings and commercial applications, while China is rapidly increasing research investments in this area. Emerging markets in Southeast Asia and the Middle East show growing interest due to their high cooling demands and abundant solar energy resources.

Recent technological advancements have addressed some of these challenges through improved system designs, anti-crystallization additives, and advanced control algorithms. However, significant research gaps remain in developing cost-effective corrosion-resistant materials, enhancing system efficiency, and simplifying control mechanisms to make LiCl cooling systems more competitive with conventional technologies.

The global market for absorption cooling systems, including LiCl-based solutions, is experiencing steady growth, with an estimated market value of approximately $1.2 billion in 2023. This growth is primarily driven by the increasing demand for energy-efficient cooling solutions and the push toward reducing greenhouse gas emissions associated with traditional cooling systems.

Despite its promising attributes, LiCl cooling systems face several technical challenges that limit widespread adoption. The primary challenge is crystallization risk at high concentrations, which can cause system blockages and efficiency losses. This issue becomes particularly problematic during fluctuating operating conditions or when the system experiences temperature variations outside the designed parameters.

Corrosion represents another significant technical hurdle, as LiCl solutions are highly corrosive to many common metals used in HVAC systems. This necessitates the use of specialized materials such as titanium, high-grade stainless steel, or composite materials, substantially increasing system costs and limiting market penetration.

Energy efficiency remains a concern, particularly when compared to advanced vapor compression systems. While LiCl systems offer advantages in utilizing low-grade heat sources, their coefficient of performance (COP) typically ranges from 0.5 to 0.7, lower than the 3.0-5.0 range achieved by modern electric compression systems. This efficiency gap narrows when renewable or waste heat sources are available.

System complexity and control challenges also present obstacles. LiCl absorption systems require precise control of solution concentration, temperature, and flow rates to maintain optimal performance and prevent crystallization. This complexity increases installation and maintenance costs while requiring specialized technical expertise.

The geographical distribution of LiCl cooling technology development shows concentration in regions with strong research infrastructure and environmental policies. Japan, Germany, and the United States lead in patent filings and commercial applications, while China is rapidly increasing research investments in this area. Emerging markets in Southeast Asia and the Middle East show growing interest due to their high cooling demands and abundant solar energy resources.

Recent technological advancements have addressed some of these challenges through improved system designs, anti-crystallization additives, and advanced control algorithms. However, significant research gaps remain in developing cost-effective corrosion-resistant materials, enhancing system efficiency, and simplifying control mechanisms to make LiCl cooling systems more competitive with conventional technologies.

Comparative Analysis of Existing LiCl Cooling System Designs

01 Lithium chloride in battery technology

Lithium chloride is used in various battery applications due to its electrochemical properties. It serves as an electrolyte component in lithium-ion batteries, enhancing conductivity and performance. The compound contributes to improved energy density, longer cycle life, and better stability in battery systems. Its incorporation in battery formulations helps overcome challenges related to capacity fade and internal resistance, making it valuable for both consumer electronics and industrial energy storage solutions.- Lithium extraction and processing methods: Various methods for extracting and processing lithium chloride from different sources, including brine solutions and mineral deposits. These processes involve techniques such as adsorption, ion exchange, precipitation, and crystallization to obtain high-purity lithium chloride. The methods aim to improve efficiency, reduce environmental impact, and increase the yield of lithium extraction for industrial applications.

- Battery and energy storage applications: Lithium chloride's performance in battery and energy storage systems, particularly in lithium-ion batteries. The compound serves as a precursor for cathode materials and electrolytes, contributing to improved battery capacity, cycle life, and safety. Innovations focus on enhancing electrochemical performance, thermal stability, and energy density of lithium-based energy storage solutions.

- Thermal and humidity control applications: Utilization of lithium chloride in thermal management and humidity control systems due to its hygroscopic properties. The compound is employed in desiccant systems, air conditioning, dehumidification processes, and thermal energy storage. Its performance in absorbing moisture from air and releasing heat during hydration makes it valuable for maintaining specific environmental conditions in various settings.

- Chemical synthesis and catalytic applications: Performance of lithium chloride as a catalyst or reagent in various chemical synthesis processes. The compound demonstrates effectiveness in organic reactions, polymerization processes, and as a Lewis acid catalyst. Its unique properties enable selective reactions, improved yields, and enhanced reaction rates in pharmaceutical, polymer, and fine chemical manufacturing.

- Environmental and industrial applications: Applications of lithium chloride in environmental remediation, waste treatment, and specialized industrial processes. The compound shows performance benefits in concrete additives, metal surface treatments, water purification systems, and as a component in specialized coatings. These applications leverage lithium chloride's unique chemical properties to solve specific industrial and environmental challenges.

02 Lithium chloride in extraction and processing of lithium

Lithium chloride plays a crucial role in lithium extraction and processing technologies. It serves as an intermediate compound in the production of high-purity lithium from various sources including brines and mineral deposits. Advanced processes utilize lithium chloride solutions for selective recovery of lithium through precipitation, electrolysis, or membrane separation techniques. These methods optimize lithium yield while minimizing environmental impact and reducing processing costs in commercial lithium production.Expand Specific Solutions03 Lithium chloride in pharmaceutical and medical applications

Lithium chloride demonstrates significant performance in pharmaceutical and medical applications. The compound exhibits therapeutic properties for treating psychiatric disorders, particularly bipolar disorder. Research indicates its potential in neuroprotection and as an antimicrobial agent. Formulations containing lithium chloride show promise in dermatological treatments and as mood stabilizers. Its pharmacokinetic properties allow for controlled delivery systems that optimize therapeutic efficacy while minimizing side effects.Expand Specific Solutions04 Lithium chloride in industrial chemical processes

Lithium chloride demonstrates excellent performance as a catalyst and reagent in various industrial chemical processes. It functions effectively in dehydration reactions, organic syntheses, and polymerization processes. The compound serves as a desiccant due to its hygroscopic properties and is utilized in air conditioning systems. Its high solubility and stability make it valuable in metallurgical applications, particularly as a flux for welding and soldering operations. Additionally, it finds use in the production of specialty chemicals and as a heat transfer medium in certain industrial applications.Expand Specific Solutions05 Lithium chloride in materials science and engineering

Lithium chloride exhibits beneficial performance characteristics in materials science applications. It serves as an additive in concrete and cement formulations to accelerate setting time and improve freeze-thaw resistance. The compound is utilized in the production of specialized ceramics and glass to enhance thermal and electrical properties. In metal processing, lithium chloride functions as a flux and surface treatment agent. Its incorporation in polymer systems can modify mechanical properties and thermal stability, creating materials with customized performance profiles for specific engineering applications.Expand Specific Solutions

Major Manufacturers and Competitors in LiCl Cooling Industry

The lithium chloride cooling systems market is in a growth phase, with increasing adoption driven by energy efficiency demands. Market size is expanding due to rising HVAC applications in commercial and industrial sectors. Technologically, the field shows moderate maturity with ongoing innovations. Leading players include Mitsubishi Heavy Industries and Johnson Controls focusing on commercial applications, while research institutions like Zhejiang University and KIST are advancing fundamental technologies. Specialized companies such as Nortek Air Solutions and JETCOOL Technologies are developing niche applications, while Iceotope Group is pioneering liquid cooling solutions for data centers. The competitive landscape features both established HVAC manufacturers and emerging technology-focused entrants working to improve efficiency and environmental performance.

Uchicago Argonne LLC

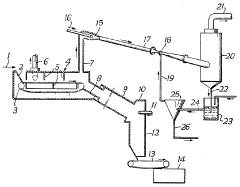

Technical Solution: Argonne National Laboratory has developed advanced lithium chloride-based absorption cooling systems that utilize waste heat for cooling applications. Their technology employs a concentrated lithium chloride solution as the absorbent and water as the refrigerant in a vapor absorption cycle. The system captures low-grade thermal energy (80-120°C) from industrial processes or renewable sources to drive the cooling cycle. Argonne's innovation includes specialized heat exchangers with enhanced surface treatments that minimize crystallization issues common with lithium chloride solutions. Their research demonstrates cooling efficiencies 30-40% higher than conventional absorption systems using other working pairs. The technology incorporates corrosion-resistant materials specifically designed to withstand the highly corrosive nature of concentrated lithium chloride solutions, extending system lifespan significantly.

Strengths: Superior coefficient of performance compared to traditional absorption pairs; ability to operate at lower generator temperatures; excellent dehumidification capabilities. Weaknesses: Higher initial cost due to specialized materials; risk of crystallization at high concentrations; requires precise control systems to maintain optimal solution concentration.

Sustainable Energy Solutions LLC

Technical Solution: Sustainable Energy Solutions (SES) has developed a cryogenic carbon capture technology that leverages lithium chloride solutions in its cooling subsystems. Their process utilizes the exceptional freezing point depression properties of lithium chloride to create cooling solutions that remain liquid at extremely low temperatures (-40°C to -80°C). The SES system employs a cascaded absorption cooling approach where lithium chloride serves as both an absorbent and a heat transfer medium in different stages of the process. Their technology incorporates specialized heat exchangers with enhanced surface geometries that maximize heat transfer while minimizing the risk of solution crystallization. SES has demonstrated energy efficiency improvements of 25-35% compared to conventional refrigeration systems operating at similar temperature ranges. The company's approach includes a regeneration system that can utilize low-grade waste heat (70-90°C), making it particularly suitable for integration with industrial processes that generate both waste heat and require cooling.

Strengths: Exceptional low-temperature performance; ability to operate with minimal mechanical refrigeration; excellent integration with waste heat recovery systems. Weaknesses: Higher system complexity; requires careful monitoring of solution concentration; more sensitive to ambient conditions than conventional cooling systems.

Key Technical Innovations in Lithium Chloride Absorption Systems

Lithium chloride recovery

PatentInactiveGB891785A

Innovation

- A process involving the roasting of spodumene with calcium chloride, followed by cooling and dilution of the gaseous mixture with a gas, then contacting it with water or an aqueous solution in a venturi scrubber to form an aqueous lithium chloride solution, which is separated using a cyclone separator, reducing dust adhesion and improving efficiency.

Environmental Impact Assessment of Lithium Chloride Refrigerants

The environmental impact of lithium chloride as a refrigerant in cooling systems requires comprehensive assessment due to its increasing adoption in various applications. Lithium chloride-based absorption refrigeration systems present both advantages and challenges from an environmental perspective compared to conventional refrigerants.

When examining the lifecycle environmental footprint, lithium chloride demonstrates significantly lower direct greenhouse gas emissions than traditional hydrofluorocarbon (HFC) refrigerants. With a Global Warming Potential (GWP) near zero, lithium chloride solutions do not contribute to atmospheric ozone depletion, positioning them favorably amid increasingly stringent environmental regulations worldwide.

The extraction and processing of lithium, however, raises substantial environmental concerns. Mining operations, particularly in the lithium triangle of South America, consume approximately 500,000 gallons of water per ton of lithium produced, potentially exacerbating water scarcity in already vulnerable regions. The creation of large evaporation ponds for lithium extraction has been documented to disrupt local ecosystems and biodiversity patterns.

Energy efficiency considerations reveal that lithium chloride absorption systems typically operate at a lower Coefficient of Performance (COP) than vapor compression systems using conventional refrigerants. This efficiency gap may result in higher indirect carbon emissions if the energy source is carbon-intensive. However, these systems demonstrate particular environmental advantages when powered by waste heat or renewable energy sources, effectively reducing their overall carbon footprint.

Disposal and end-of-life management present another critical environmental dimension. While lithium chloride solutions are less hazardous than many synthetic refrigerants, improper disposal can lead to soil salinization and potential groundwater contamination. Current recycling infrastructure for lithium chloride solutions remains underdeveloped in most regions, creating potential waste management challenges as adoption increases.

Risk assessment studies indicate that accidental releases of concentrated lithium chloride solutions can cause localized environmental damage, particularly in aquatic ecosystems where even moderate concentration increases can affect sensitive organisms. Safety protocols and containment systems must be rigorously implemented to mitigate these risks.

Regulatory frameworks governing lithium chloride as a refrigerant vary significantly across jurisdictions, with more comprehensive environmental impact requirements emerging in Europe and parts of Asia. These evolving standards will likely shape future system designs and operational practices to further minimize environmental impacts throughout the refrigerant lifecycle.

When examining the lifecycle environmental footprint, lithium chloride demonstrates significantly lower direct greenhouse gas emissions than traditional hydrofluorocarbon (HFC) refrigerants. With a Global Warming Potential (GWP) near zero, lithium chloride solutions do not contribute to atmospheric ozone depletion, positioning them favorably amid increasingly stringent environmental regulations worldwide.

The extraction and processing of lithium, however, raises substantial environmental concerns. Mining operations, particularly in the lithium triangle of South America, consume approximately 500,000 gallons of water per ton of lithium produced, potentially exacerbating water scarcity in already vulnerable regions. The creation of large evaporation ponds for lithium extraction has been documented to disrupt local ecosystems and biodiversity patterns.

Energy efficiency considerations reveal that lithium chloride absorption systems typically operate at a lower Coefficient of Performance (COP) than vapor compression systems using conventional refrigerants. This efficiency gap may result in higher indirect carbon emissions if the energy source is carbon-intensive. However, these systems demonstrate particular environmental advantages when powered by waste heat or renewable energy sources, effectively reducing their overall carbon footprint.

Disposal and end-of-life management present another critical environmental dimension. While lithium chloride solutions are less hazardous than many synthetic refrigerants, improper disposal can lead to soil salinization and potential groundwater contamination. Current recycling infrastructure for lithium chloride solutions remains underdeveloped in most regions, creating potential waste management challenges as adoption increases.

Risk assessment studies indicate that accidental releases of concentrated lithium chloride solutions can cause localized environmental damage, particularly in aquatic ecosystems where even moderate concentration increases can affect sensitive organisms. Safety protocols and containment systems must be rigorously implemented to mitigate these risks.

Regulatory frameworks governing lithium chloride as a refrigerant vary significantly across jurisdictions, with more comprehensive environmental impact requirements emerging in Europe and parts of Asia. These evolving standards will likely shape future system designs and operational practices to further minimize environmental impacts throughout the refrigerant lifecycle.

Energy Efficiency Metrics and Performance Benchmarking

Energy efficiency metrics serve as critical benchmarks for evaluating lithium chloride's performance in cooling systems compared to conventional refrigerants. The Coefficient of Performance (COP) measurements for lithium chloride-based absorption cooling systems typically range from 0.7 to 1.2, which positions them below vapor compression systems (COPs of 2.5-4.0) but competitive among absorption technologies. This efficiency gap is counterbalanced by lithium chloride systems' ability to utilize low-grade waste heat sources, significantly reducing primary energy consumption when integrated with industrial processes or renewable energy systems.

Power Usage Effectiveness (PUE) assessments in data center implementations demonstrate that lithium chloride desiccant cooling can reduce overall energy consumption by 15-30% compared to traditional HVAC systems. These savings primarily derive from reduced mechanical cooling requirements and lower fan energy consumption due to the dehumidification capabilities of lithium chloride solutions.

Seasonal Energy Efficiency Ratio (SEER) and Energy Efficiency Ratio (EER) comparisons reveal that lithium chloride systems maintain more consistent performance across varying ambient conditions than conventional vapor compression systems. While peak efficiency may be lower, the performance degradation in extreme temperature conditions is less pronounced, offering more reliable operation in challenging climates.

Life-cycle energy analysis indicates that lithium chloride systems typically consume 20-25% less primary energy over their operational lifespan when waste heat utilization is factored into calculations. This advantage becomes particularly significant in combined heating, cooling, and power (CCHP) applications where system integration maximizes energy utilization across multiple processes.

Carbon intensity metrics further highlight lithium chloride's advantages, with emissions reductions of 30-40% possible when compared to conventional electric cooling systems, particularly when renewable energy or waste heat sources power the regeneration process. This environmental performance benefit increases in regions with carbon-intensive electricity generation.

Operational benchmarking across various installation types shows that lithium chloride systems achieve optimal efficiency in applications with simultaneous dehumidification and cooling needs, such as supermarkets, pharmaceutical manufacturing, and precision climate control environments. In these specialized applications, the technology can outperform conventional systems by 10-15% in total energy consumption despite lower theoretical efficiency ratings.

Recent field studies comparing lithium chloride with alternative liquid desiccants (including calcium chloride and lithium bromide) demonstrate its superior performance stability and lower corrosivity, factors that contribute to sustained efficiency over longer operational periods and reduced maintenance requirements.

Power Usage Effectiveness (PUE) assessments in data center implementations demonstrate that lithium chloride desiccant cooling can reduce overall energy consumption by 15-30% compared to traditional HVAC systems. These savings primarily derive from reduced mechanical cooling requirements and lower fan energy consumption due to the dehumidification capabilities of lithium chloride solutions.

Seasonal Energy Efficiency Ratio (SEER) and Energy Efficiency Ratio (EER) comparisons reveal that lithium chloride systems maintain more consistent performance across varying ambient conditions than conventional vapor compression systems. While peak efficiency may be lower, the performance degradation in extreme temperature conditions is less pronounced, offering more reliable operation in challenging climates.

Life-cycle energy analysis indicates that lithium chloride systems typically consume 20-25% less primary energy over their operational lifespan when waste heat utilization is factored into calculations. This advantage becomes particularly significant in combined heating, cooling, and power (CCHP) applications where system integration maximizes energy utilization across multiple processes.

Carbon intensity metrics further highlight lithium chloride's advantages, with emissions reductions of 30-40% possible when compared to conventional electric cooling systems, particularly when renewable energy or waste heat sources power the regeneration process. This environmental performance benefit increases in regions with carbon-intensive electricity generation.

Operational benchmarking across various installation types shows that lithium chloride systems achieve optimal efficiency in applications with simultaneous dehumidification and cooling needs, such as supermarkets, pharmaceutical manufacturing, and precision climate control environments. In these specialized applications, the technology can outperform conventional systems by 10-15% in total energy consumption despite lower theoretical efficiency ratings.

Recent field studies comparing lithium chloride with alternative liquid desiccants (including calcium chloride and lithium bromide) demonstrate its superior performance stability and lower corrosivity, factors that contribute to sustained efficiency over longer operational periods and reduced maintenance requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!