Benchmarking Lithium Chloride’s Hygroscopic Efficiency

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Chloride Hygroscopic Properties Background and Objectives

Lithium chloride (LiCl) has emerged as a significant compound in hygroscopic applications due to its exceptional moisture absorption capabilities. The history of LiCl usage dates back to the early 20th century when its hygroscopic properties were first systematically studied. Since then, the technological applications of LiCl have expanded considerably, particularly in dehumidification systems, desiccant air conditioning, and more recently in energy storage solutions.

The evolution of LiCl technology has been marked by several key developments. Initially utilized primarily as a laboratory desiccant, its application expanded to industrial dehumidification in the 1940s. The 1970s and 1980s saw significant advancements in liquid desiccant air conditioning systems using LiCl solutions. Recent decades have witnessed integration of LiCl-based systems with renewable energy technologies, particularly solar thermal systems, representing a convergence of traditional hygroscopic applications with sustainable energy solutions.

Current technological trends indicate growing interest in enhancing the efficiency of LiCl as a hygroscopic material. Research is increasingly focused on nano-engineering LiCl composites to improve moisture absorption rates and capacity. Additionally, there is substantial work being conducted on optimizing LiCl regeneration processes to reduce energy consumption in cyclic dehumidification applications.

The primary objective of benchmarking lithium chloride's hygroscopic efficiency is to establish standardized performance metrics that enable accurate comparison with alternative hygroscopic materials. This includes quantifying absorption rates under varying temperature and humidity conditions, determining maximum moisture capacity per unit mass, and evaluating energy requirements for regeneration cycles.

Secondary objectives include identifying the optimal concentration ranges for LiCl solutions in different applications, determining long-term stability and corrosion effects, and assessing environmental impacts throughout the lifecycle of LiCl-based systems. These benchmarks will serve as critical reference points for future technological developments in this field.

The technological goals extend beyond mere performance metrics to include practical implementation considerations. This encompasses developing more efficient heat and mass transfer designs for LiCl-based systems, creating corrosion-resistant materials compatible with LiCl solutions, and formulating hybrid systems that leverage LiCl's hygroscopic properties alongside other technologies for enhanced overall efficiency.

As global concerns regarding energy efficiency and indoor air quality continue to grow, establishing comprehensive benchmarks for LiCl's hygroscopic efficiency becomes increasingly important for advancing technological solutions in humidity control, air conditioning, and related fields.

The evolution of LiCl technology has been marked by several key developments. Initially utilized primarily as a laboratory desiccant, its application expanded to industrial dehumidification in the 1940s. The 1970s and 1980s saw significant advancements in liquid desiccant air conditioning systems using LiCl solutions. Recent decades have witnessed integration of LiCl-based systems with renewable energy technologies, particularly solar thermal systems, representing a convergence of traditional hygroscopic applications with sustainable energy solutions.

Current technological trends indicate growing interest in enhancing the efficiency of LiCl as a hygroscopic material. Research is increasingly focused on nano-engineering LiCl composites to improve moisture absorption rates and capacity. Additionally, there is substantial work being conducted on optimizing LiCl regeneration processes to reduce energy consumption in cyclic dehumidification applications.

The primary objective of benchmarking lithium chloride's hygroscopic efficiency is to establish standardized performance metrics that enable accurate comparison with alternative hygroscopic materials. This includes quantifying absorption rates under varying temperature and humidity conditions, determining maximum moisture capacity per unit mass, and evaluating energy requirements for regeneration cycles.

Secondary objectives include identifying the optimal concentration ranges for LiCl solutions in different applications, determining long-term stability and corrosion effects, and assessing environmental impacts throughout the lifecycle of LiCl-based systems. These benchmarks will serve as critical reference points for future technological developments in this field.

The technological goals extend beyond mere performance metrics to include practical implementation considerations. This encompasses developing more efficient heat and mass transfer designs for LiCl-based systems, creating corrosion-resistant materials compatible with LiCl solutions, and formulating hybrid systems that leverage LiCl's hygroscopic properties alongside other technologies for enhanced overall efficiency.

As global concerns regarding energy efficiency and indoor air quality continue to grow, establishing comprehensive benchmarks for LiCl's hygroscopic efficiency becomes increasingly important for advancing technological solutions in humidity control, air conditioning, and related fields.

Market Analysis for Hygroscopic Materials

The global hygroscopic materials market has witnessed substantial growth in recent years, driven primarily by increasing applications across diverse industries including pharmaceuticals, food preservation, electronics, and building materials. The market size for industrial hygroscopic materials reached approximately $3.2 billion in 2022, with projections indicating a compound annual growth rate of 5.7% through 2028.

Lithium chloride represents a significant segment within this market, valued at roughly $420 million globally. Its exceptional moisture absorption capabilities position it as a premium solution for specialized applications requiring precise humidity control. The pharmaceutical sector constitutes the largest end-user segment for lithium chloride, accounting for 37% of total consumption, followed by air conditioning systems at 28%.

Regional analysis reveals Asia-Pacific as the dominant market for hygroscopic materials, commanding 42% of global market share, with China being the largest consumer and producer. North America and Europe follow with 27% and 23% market shares respectively. Emerging economies in Southeast Asia and Latin America are experiencing the fastest growth rates, driven by expanding industrial bases and increasing awareness of moisture control benefits.

Competitive landscape assessment identifies key players including Dow Chemical Company, BASF SE, Clariant AG, and Solvay S.A. dominating the broader hygroscopic materials market. In the lithium chloride segment, Albemarle Corporation, SQM, and Tianqi Lithium hold significant market positions, collectively controlling approximately 65% of global production capacity.

Customer demand analysis reveals growing preference for environmentally sustainable hygroscopic solutions with minimal ecological footprint. This trend is particularly pronounced in European markets where regulatory frameworks increasingly favor green alternatives. Additionally, there is rising demand for multi-functional hygroscopic materials that combine moisture absorption with antimicrobial or fire-retardant properties.

Price sensitivity varies significantly across application segments. While pharmaceutical and electronics industries prioritize performance over cost, construction and general industrial applications demonstrate higher price elasticity. Lithium chloride commands premium pricing compared to alternatives like calcium chloride or silica gel, with current market prices ranging between $1,800-$2,200 per metric ton depending on purity levels.

Future market growth for lithium chloride as a hygroscopic agent faces potential constraints from increasing lithium demand in battery production, which may impact availability and pricing structures. This market dynamic creates opportunities for alternative hygroscopic materials development while simultaneously driving innovation in more efficient lithium chloride application methods to maximize performance with reduced material requirements.

Lithium chloride represents a significant segment within this market, valued at roughly $420 million globally. Its exceptional moisture absorption capabilities position it as a premium solution for specialized applications requiring precise humidity control. The pharmaceutical sector constitutes the largest end-user segment for lithium chloride, accounting for 37% of total consumption, followed by air conditioning systems at 28%.

Regional analysis reveals Asia-Pacific as the dominant market for hygroscopic materials, commanding 42% of global market share, with China being the largest consumer and producer. North America and Europe follow with 27% and 23% market shares respectively. Emerging economies in Southeast Asia and Latin America are experiencing the fastest growth rates, driven by expanding industrial bases and increasing awareness of moisture control benefits.

Competitive landscape assessment identifies key players including Dow Chemical Company, BASF SE, Clariant AG, and Solvay S.A. dominating the broader hygroscopic materials market. In the lithium chloride segment, Albemarle Corporation, SQM, and Tianqi Lithium hold significant market positions, collectively controlling approximately 65% of global production capacity.

Customer demand analysis reveals growing preference for environmentally sustainable hygroscopic solutions with minimal ecological footprint. This trend is particularly pronounced in European markets where regulatory frameworks increasingly favor green alternatives. Additionally, there is rising demand for multi-functional hygroscopic materials that combine moisture absorption with antimicrobial or fire-retardant properties.

Price sensitivity varies significantly across application segments. While pharmaceutical and electronics industries prioritize performance over cost, construction and general industrial applications demonstrate higher price elasticity. Lithium chloride commands premium pricing compared to alternatives like calcium chloride or silica gel, with current market prices ranging between $1,800-$2,200 per metric ton depending on purity levels.

Future market growth for lithium chloride as a hygroscopic agent faces potential constraints from increasing lithium demand in battery production, which may impact availability and pricing structures. This market dynamic creates opportunities for alternative hygroscopic materials development while simultaneously driving innovation in more efficient lithium chloride application methods to maximize performance with reduced material requirements.

Current Status and Challenges in Hygroscopic Efficiency Measurement

The measurement of hygroscopic efficiency for lithium chloride (LiCl) currently faces significant methodological inconsistencies across the industry and research sectors. While LiCl is widely recognized for its exceptional moisture absorption capabilities, standardized benchmarking protocols remain underdeveloped, creating challenges for comparative analysis and performance validation.

Current measurement approaches typically employ gravimetric analysis, dynamic vapor sorption (DVS), and environmental chamber testing. Gravimetric methods track mass changes as LiCl absorbs moisture under controlled conditions, offering simplicity but lacking real-time monitoring capabilities. DVS provides more precise data on sorption kinetics and equilibrium points but requires sophisticated instrumentation that limits widespread adoption. Environmental chamber testing attempts to simulate real-world conditions but suffers from reproducibility issues due to variable testing parameters.

A significant challenge in the field is the absence of universally accepted reference standards for hygroscopic efficiency. This deficiency hampers cross-study comparisons and technology validation, particularly when evaluating LiCl against alternative desiccants or when incorporated into composite materials. The performance metrics themselves lack standardization, with some researchers reporting absolute moisture uptake while others focus on relative humidity control capabilities or absorption rates.

Temperature dependency presents another major measurement challenge. LiCl's hygroscopic behavior varies significantly across temperature ranges, yet many current protocols fail to adequately account for these variations. This limitation becomes particularly problematic when benchmarking applications intended for environments with fluctuating temperatures, such as building dehumidification systems or seasonal storage solutions.

Concentration effects further complicate measurement efforts. The hygroscopic efficiency of LiCl solutions exhibits non-linear relationships with concentration levels, creating difficulties in establishing standardized measurement protocols that remain valid across concentration ranges. This non-linearity challenges the development of predictive models for real-world applications.

Cycling stability assessment represents perhaps the most critical gap in current measurement methodologies. While initial hygroscopic performance is well-documented, protocols for evaluating long-term efficiency after multiple absorption-desorption cycles remain inconsistent. This limitation is particularly problematic for applications requiring sustained performance over numerous operational cycles.

Internationally, research groups have begun collaborative efforts to address these challenges, with initiatives from NIST in the United States and similar organizations in Europe and Asia working toward standardized testing protocols. However, consensus remains elusive, with competing methodologies still prevalent across different research communities and industrial sectors.

Current measurement approaches typically employ gravimetric analysis, dynamic vapor sorption (DVS), and environmental chamber testing. Gravimetric methods track mass changes as LiCl absorbs moisture under controlled conditions, offering simplicity but lacking real-time monitoring capabilities. DVS provides more precise data on sorption kinetics and equilibrium points but requires sophisticated instrumentation that limits widespread adoption. Environmental chamber testing attempts to simulate real-world conditions but suffers from reproducibility issues due to variable testing parameters.

A significant challenge in the field is the absence of universally accepted reference standards for hygroscopic efficiency. This deficiency hampers cross-study comparisons and technology validation, particularly when evaluating LiCl against alternative desiccants or when incorporated into composite materials. The performance metrics themselves lack standardization, with some researchers reporting absolute moisture uptake while others focus on relative humidity control capabilities or absorption rates.

Temperature dependency presents another major measurement challenge. LiCl's hygroscopic behavior varies significantly across temperature ranges, yet many current protocols fail to adequately account for these variations. This limitation becomes particularly problematic when benchmarking applications intended for environments with fluctuating temperatures, such as building dehumidification systems or seasonal storage solutions.

Concentration effects further complicate measurement efforts. The hygroscopic efficiency of LiCl solutions exhibits non-linear relationships with concentration levels, creating difficulties in establishing standardized measurement protocols that remain valid across concentration ranges. This non-linearity challenges the development of predictive models for real-world applications.

Cycling stability assessment represents perhaps the most critical gap in current measurement methodologies. While initial hygroscopic performance is well-documented, protocols for evaluating long-term efficiency after multiple absorption-desorption cycles remain inconsistent. This limitation is particularly problematic for applications requiring sustained performance over numerous operational cycles.

Internationally, research groups have begun collaborative efforts to address these challenges, with initiatives from NIST in the United States and similar organizations in Europe and Asia working toward standardized testing protocols. However, consensus remains elusive, with competing methodologies still prevalent across different research communities and industrial sectors.

Current Methodologies for Measuring Hygroscopic Efficiency

01 Lithium chloride as a hygroscopic agent in energy storage systems

Lithium chloride is utilized as a hygroscopic agent in energy storage systems due to its high moisture absorption capacity. It can effectively control humidity levels in battery systems, extending their lifespan and improving performance. The hygroscopic properties of lithium chloride make it particularly valuable in lithium-ion batteries and other energy storage applications where moisture control is critical for maintaining efficiency and preventing degradation.- Lithium chloride as a hygroscopic agent in energy storage systems: Lithium chloride is utilized as a hygroscopic agent in energy storage systems due to its high efficiency in absorbing moisture from the air. This property makes it valuable in battery technologies, particularly in lithium-ion batteries, where moisture control is critical for performance and safety. The hygroscopic nature of lithium chloride helps maintain dry conditions within battery cells, preventing degradation and extending battery life.

- Lithium chloride in dehumidification and moisture control applications: Lithium chloride demonstrates superior hygroscopic efficiency in dehumidification systems and moisture control applications. It can absorb significant amounts of water vapor from the surrounding environment, making it effective for maintaining specific humidity levels in enclosed spaces. This property is utilized in industrial dehumidifiers, air conditioning systems, and moisture control devices where efficient water absorption is required.

- Comparative hygroscopic efficiency of lithium chloride versus other salts: Studies show that lithium chloride exhibits superior hygroscopic efficiency compared to many other hygroscopic salts. Its ability to absorb moisture from the atmosphere even at low relative humidity makes it more effective than alternatives such as calcium chloride, magnesium chloride, or sodium chloride. This comparative advantage is particularly valuable in applications requiring consistent moisture absorption across varying environmental conditions.

- Lithium chloride in heat storage and thermal energy applications: The hygroscopic properties of lithium chloride are leveraged in thermal energy storage systems. When lithium chloride absorbs moisture, it releases heat (exothermic reaction), which can be harnessed for heating applications. Conversely, when dried, it absorbs heat (endothermic reaction). This characteristic makes it valuable in heat pumps, thermal storage systems, and climate control applications where energy efficiency is paramount.

- Enhancement of lithium chloride hygroscopic efficiency through formulation techniques: Various formulation techniques can enhance the hygroscopic efficiency of lithium chloride. These include combining it with other materials to create composite absorbents, modifying its physical form (such as creating porous structures), or incorporating it into polymer matrices. Such modifications can increase the surface area available for moisture absorption, improve absorption kinetics, and enhance the overall moisture absorption capacity of lithium chloride-based systems.

02 Lithium chloride in dehumidification and moisture control systems

Lithium chloride demonstrates superior hygroscopic efficiency in dehumidification applications. It can absorb moisture from the air at various humidity levels, making it ideal for use in industrial dehumidifiers, HVAC systems, and moisture control devices. The compound's ability to maintain low humidity environments makes it valuable for preserving sensitive materials and creating controlled atmospheric conditions in various settings.Expand Specific Solutions03 Lithium chloride in desiccant mixtures and compositions

Lithium chloride is frequently incorporated into desiccant mixtures and compositions to enhance their overall hygroscopic efficiency. When combined with other desiccants or supporting materials, lithium chloride can provide improved moisture absorption capacity and controlled absorption rates. These mixtures are used in various applications including packaging, preservation of goods, and industrial processes where moisture control is essential.Expand Specific Solutions04 Lithium chloride in heat exchange and thermal energy storage

The hygroscopic properties of lithium chloride are utilized in heat exchange and thermal energy storage systems. When lithium chloride absorbs moisture, it releases heat, making it useful in heat pump applications and thermal storage solutions. This property allows for efficient energy transfer and storage in systems that leverage the absorption and desorption cycles of the compound with water vapor.Expand Specific Solutions05 Lithium chloride in chemical processing and manufacturing

Lithium chloride's hygroscopic efficiency is valuable in various chemical processing and manufacturing applications. It can be used as a catalyst, drying agent, or process additive in chemical synthesis. The compound's ability to control moisture levels precisely makes it useful in pharmaceutical manufacturing, chemical reactions sensitive to water content, and industrial processes requiring anhydrous conditions.Expand Specific Solutions

Key Industry Players in Hygroscopic Materials

The lithium chloride hygroscopic efficiency benchmarking market is in its growth phase, with increasing applications in energy storage, pharmaceuticals, and industrial dehumidification systems. The market is projected to expand significantly due to rising demand for efficient moisture control solutions across multiple industries. Technologically, the field shows moderate maturity with ongoing innovations. Key players demonstrate varying levels of expertise: LG Energy Solution and LG Chem lead in battery applications; Beckman Coulter and Waters Technology contribute analytical measurement capabilities; while Qinghai Salt Lake Industry and General Lithium provide raw material expertise. Academic institutions like Kyoto University and Nanyang Technological University are advancing fundamental research, creating a competitive landscape where industrial-academic partnerships drive innovation in hygroscopic efficiency measurement and application.

Qinghai Salt Lake Industry Co., Ltd.

Technical Solution: Qinghai Salt Lake Industry has developed a comprehensive benchmarking system for lithium chloride's hygroscopic efficiency that utilizes controlled environmental chambers with precise humidity regulation (10-95% RH) and temperature control (0-60°C). Their approach employs gravimetric analysis with high-precision microbalances (0.01mg accuracy) to measure moisture absorption rates across varying conditions. The company has pioneered a standardized testing protocol that evaluates LiCl's performance against reference desiccants, establishing absorption isotherms and kinetic profiles. Their methodology includes cyclic testing to determine long-term stability and regeneration efficiency, with automated data acquisition systems providing real-time monitoring of weight changes, temperature, and relative humidity. This benchmarking system has been validated through interlaboratory comparisons and has become an industry reference for hygroscopic material evaluation.

Strengths: Direct access to high-purity lithium chloride from their salt lake operations provides exceptional material consistency for benchmarking. Their extensive experience in lithium processing enables precise control of material properties. Weaknesses: Their benchmarking methodology may be optimized for industrial applications rather than academic research, potentially limiting applicability in fundamental studies.

Institute of Process Engineering, Chinese Academy of Sciences

Technical Solution: The Institute of Process Engineering at the Chinese Academy of Sciences has developed a sophisticated multi-parameter benchmarking framework for evaluating lithium chloride's hygroscopic efficiency. Their approach combines dynamic vapor sorption (DVS) analysis with environmental scanning electron microscopy (ESEM) to simultaneously quantify moisture absorption capacity and visualize the microscopic changes during hydration processes. The institute has created standardized testing protocols that measure absorption rates across temperature ranges of -10°C to 80°C and relative humidity levels from 5% to 95%, with precision control of ±0.5°C and ±1% RH. Their methodology incorporates thermogravimetric analysis coupled with differential scanning calorimetry (TG-DSC) to determine the energetics of water absorption and release, providing comprehensive data on both equilibrium and kinetic parameters. The institute has also pioneered the use of in-situ FTIR spectroscopy to monitor molecular interactions between water and lithium chloride during absorption cycles.

Strengths: Exceptional scientific rigor with advanced analytical instrumentation provides highly accurate and reproducible benchmarking data. Their comprehensive approach addresses both fundamental mechanisms and practical applications. Weaknesses: Their highly academic approach may be overly complex for industrial applications requiring simplified metrics for quality control purposes.

Critical Patents and Research on Lithium Chloride Applications

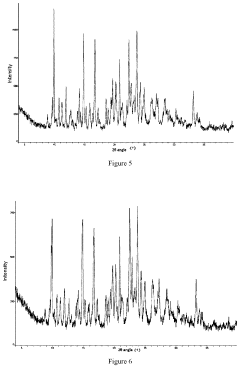

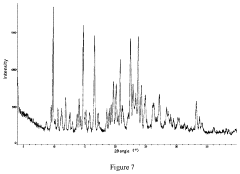

Crystal form of estrogen receptor inhibitor and preparation method therefor

PatentActiveUS20200247748A1

Innovation

- A crystal form A of a compound with specific X-ray powder diffraction peaks and a preparation method involving solvent selection and drying conditions to produce a stable, non-hygroscopic form suitable for oral administration, potentially overcoming bioavailability and resistance challenges.

Environmental Impact and Sustainability Considerations

The environmental impact of lithium chloride (LiCl) as a hygroscopic agent presents significant considerations for sustainable implementation. LiCl production primarily relies on lithium mining operations, which have documented environmental consequences including habitat disruption, water table alterations, and soil contamination. The extraction process typically requires substantial water resources—approximately 500,000 gallons per ton of lithium—creating particular sustainability challenges in arid regions where lithium deposits are commonly found.

Energy consumption represents another critical environmental factor, as the processing and purification of lithium chloride demands considerable energy inputs. Current industry estimates suggest that producing pharmaceutical-grade LiCl requires between 5,000-7,000 kWh per ton, contributing to carbon emissions when non-renewable energy sources are utilized. The carbon footprint of LiCl production varies significantly based on the energy mix employed, ranging from 2.3 to 6.8 tons of CO2 equivalent per ton of processed material.

Waste management concerns emerge throughout the LiCl lifecycle. The hygroscopic efficiency benchmarking process itself generates waste solutions containing lithium chloride that require proper treatment before discharge. Conventional disposal methods may lead to soil salinization and potential groundwater contamination if improperly managed. Recent research indicates that lithium concentrations exceeding 0.05 mg/L can adversely affect aquatic ecosystems and potentially enter the food chain.

Encouragingly, several sustainability initiatives are emerging within the industry. Closed-loop systems for LiCl recovery and reuse have demonstrated 85-92% reclamation efficiency in laboratory settings, substantially reducing waste generation. Advanced membrane filtration technologies show promise for minimizing water consumption during production processes, with pilot programs reporting water usage reductions of up to 30%.

Renewable energy integration represents another promising avenue for improving the sustainability profile of LiCl production. Solar-powered processing facilities in Australia and Chile have reduced carbon emissions by approximately 40% compared to conventional operations. Additionally, innovative extraction methodologies utilizing direct lithium extraction (DLE) technologies demonstrate potential for reducing both environmental impact and resource consumption, though these approaches remain in early commercial deployment stages.

Regulatory frameworks increasingly address these environmental considerations, with several jurisdictions implementing specific guidelines for lithium compound production and disposal. The EU's recent classification of lithium as a critical raw material has accelerated sustainability requirements, mandating life cycle assessments and environmental impact studies for new production facilities.

Energy consumption represents another critical environmental factor, as the processing and purification of lithium chloride demands considerable energy inputs. Current industry estimates suggest that producing pharmaceutical-grade LiCl requires between 5,000-7,000 kWh per ton, contributing to carbon emissions when non-renewable energy sources are utilized. The carbon footprint of LiCl production varies significantly based on the energy mix employed, ranging from 2.3 to 6.8 tons of CO2 equivalent per ton of processed material.

Waste management concerns emerge throughout the LiCl lifecycle. The hygroscopic efficiency benchmarking process itself generates waste solutions containing lithium chloride that require proper treatment before discharge. Conventional disposal methods may lead to soil salinization and potential groundwater contamination if improperly managed. Recent research indicates that lithium concentrations exceeding 0.05 mg/L can adversely affect aquatic ecosystems and potentially enter the food chain.

Encouragingly, several sustainability initiatives are emerging within the industry. Closed-loop systems for LiCl recovery and reuse have demonstrated 85-92% reclamation efficiency in laboratory settings, substantially reducing waste generation. Advanced membrane filtration technologies show promise for minimizing water consumption during production processes, with pilot programs reporting water usage reductions of up to 30%.

Renewable energy integration represents another promising avenue for improving the sustainability profile of LiCl production. Solar-powered processing facilities in Australia and Chile have reduced carbon emissions by approximately 40% compared to conventional operations. Additionally, innovative extraction methodologies utilizing direct lithium extraction (DLE) technologies demonstrate potential for reducing both environmental impact and resource consumption, though these approaches remain in early commercial deployment stages.

Regulatory frameworks increasingly address these environmental considerations, with several jurisdictions implementing specific guidelines for lithium compound production and disposal. The EU's recent classification of lithium as a critical raw material has accelerated sustainability requirements, mandating life cycle assessments and environmental impact studies for new production facilities.

Standardization and Quality Control Protocols

To ensure consistent and reliable evaluation of lithium chloride's hygroscopic efficiency across different research settings and industrial applications, standardized protocols and rigorous quality control measures are essential. The establishment of these protocols requires a multi-faceted approach that addresses sample preparation, testing conditions, measurement techniques, and data analysis methodologies.

The primary standardization protocol should include precise specifications for lithium chloride sample preparation, including purity requirements (minimum 99.5%), particle size distribution parameters, and pre-conditioning procedures to ensure consistent initial moisture content. These specifications must be documented with traceability to recognized standards such as those established by ASTM International or ISO.

Environmental testing conditions represent another critical aspect of standardization. Protocols should mandate controlled temperature ranges (typically 20-25°C), relative humidity levels (with incremental testing points from 10% to 90%), and air flow rates (0.5-2.0 m/s) to ensure reproducibility across different testing facilities. Calibration requirements for environmental chambers should be specified with maximum allowable deviations.

Measurement methodologies must be standardized to include gravimetric analysis techniques with precision requirements of ±0.1mg, spectroscopic methods with defined wavelength ranges, and time-resolved measurements with standardized intervals. The protocol should specify equipment calibration frequencies and reference materials to be used as controls during testing procedures.

Quality control measures should incorporate statistical process control techniques with defined acceptance criteria for batch-to-batch consistency. This includes establishing control charts with upper and lower control limits for key performance indicators such as moisture absorption capacity, absorption rate, and desorption characteristics under standardized conditions.

Interlaboratory comparison programs represent an essential component of the quality assurance framework. These programs should be conducted semi-annually with participation from both academic and industrial laboratories to validate measurement consistency and identify potential methodological biases or instrumentation discrepancies.

Documentation requirements constitute the final element of the standardization protocol, specifying data recording formats, uncertainty calculation methodologies, and reporting templates that facilitate comparison across different studies. This documentation should include mandatory reporting of experimental conditions, material specifications, and statistical analysis of results with confidence intervals.

Implementation of these standardization and quality control protocols will significantly enhance the reliability of hygroscopic efficiency benchmarking for lithium chloride, enabling more meaningful comparisons between different formulations and applications across the industry.

The primary standardization protocol should include precise specifications for lithium chloride sample preparation, including purity requirements (minimum 99.5%), particle size distribution parameters, and pre-conditioning procedures to ensure consistent initial moisture content. These specifications must be documented with traceability to recognized standards such as those established by ASTM International or ISO.

Environmental testing conditions represent another critical aspect of standardization. Protocols should mandate controlled temperature ranges (typically 20-25°C), relative humidity levels (with incremental testing points from 10% to 90%), and air flow rates (0.5-2.0 m/s) to ensure reproducibility across different testing facilities. Calibration requirements for environmental chambers should be specified with maximum allowable deviations.

Measurement methodologies must be standardized to include gravimetric analysis techniques with precision requirements of ±0.1mg, spectroscopic methods with defined wavelength ranges, and time-resolved measurements with standardized intervals. The protocol should specify equipment calibration frequencies and reference materials to be used as controls during testing procedures.

Quality control measures should incorporate statistical process control techniques with defined acceptance criteria for batch-to-batch consistency. This includes establishing control charts with upper and lower control limits for key performance indicators such as moisture absorption capacity, absorption rate, and desorption characteristics under standardized conditions.

Interlaboratory comparison programs represent an essential component of the quality assurance framework. These programs should be conducted semi-annually with participation from both academic and industrial laboratories to validate measurement consistency and identify potential methodological biases or instrumentation discrepancies.

Documentation requirements constitute the final element of the standardization protocol, specifying data recording formats, uncertainty calculation methodologies, and reporting templates that facilitate comparison across different studies. This documentation should include mandatory reporting of experimental conditions, material specifications, and statistical analysis of results with confidence intervals.

Implementation of these standardization and quality control protocols will significantly enhance the reliability of hygroscopic efficiency benchmarking for lithium chloride, enabling more meaningful comparisons between different formulations and applications across the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!